Method for reducing TSNAs in tobacco leaves of cigar by utilizing strains

A technology of cigars and tobacco leaves, which is applied in the field of tobacco industry, can solve the problems that the overall effect is not very obvious, and achieve the effects of improving survival rate and activity, convenient operation, and low cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] S100: Harvest the upper leaves, middle leaves and lower leaves of tobacco plants with suitable maturity in Gengma County, Lincang City, Yunnan Province, wherein:

[0039] The lower leaves are light green or slightly yellow in green, the main vein is white, the branch veins are tender white, the leaf surface is smooth and shiny with greenish yellow, part of the glandular hairs has fallen off, and the tip of the leaf is slightly withered and yellow.

[0040] The middle leaves are collected in light green or yellowish green, with bright white main veins and light white branch veins. The leaf surface is slightly wrinkled and shiny greenish yellow, with mature spots, leaf tips and margins drooping, glandular hairs basically fall off, and the angle of stems and leaves increases. Large tobacco leaves.

[0041] The upper leaves are yellow-green or greenish-yellow, the main veins are white and bright, the branches are white, the leaf surface is wrinkled and shiny yellow-green, m...

Embodiment 2

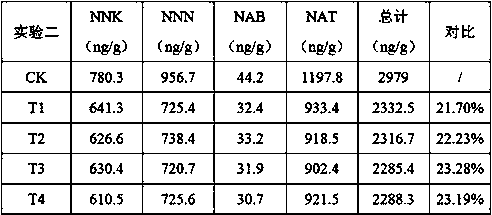

[0052] On the basis of Example 1, 05-101, J45, J54 and mixed strains were inoculated during the drying process of cigars, and their effects on the degradation of nitrosamines (TSNAs) in cigars were determined.

[0053] Experiment 1 process:

[0054] Cultivate the 05-101, J45, and J54 strains obtained through the separation, screening and purification processes at 25-30°C for 60 hours to obtain a fermentation agent, and then mix the fermentation agent with sterilized water to obtain OD 600 Bacteria with a value of 1. In the air-curing process of cigars, 4% bacterial liquid by weight of tobacco leaves is sprayed evenly on the tobacco leaves in turn at the beginning of the air-curing yellowing period and the beginning of the color-fixing period for inoculation.

[0055] This experiment set up 4 treatments (TI, T2, T3, T4, CK), among which: the non-inoculated strain in Example 1 was used as the control (CK); the T1 bacterial solution was prepared with 05-101 strain; the T2 bacter...

Embodiment 3

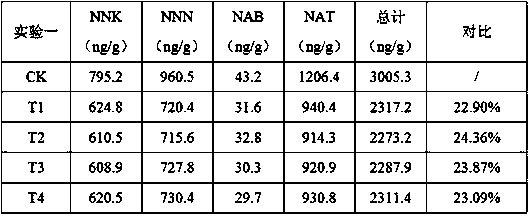

[0059] On the basis of Example 1, 05-101, J45, J54 and mixed strains were inoculated during the fermentation of cigars, and their effects on the degradation of nitrosamines (TSNAs) in cigars were determined.

[0060] Experiment 2 process:

[0061] Cultivate the 05-101, J45, and J54 strains obtained through the separation, screening and purification processes at 25-30°C for 60 hours to obtain a fermentation agent, and then mix the fermentation agent with sterilized water to obtain OD 600 Bacteria with a value of 1. During the fermentation process of cigars, 4% bacterial liquid by weight of tobacco leaves was evenly sprayed on the tobacco leaves for inoculation at the beginning of fermentation and 21 days of fermentation respectively.

[0062] This experiment set up 4 treatments (TI, T2, T3, T4, CK), among which: the non-inoculated strain in Example 1 was used as the control (CK); the T1 bacterial solution was prepared with 05-101 strain; the T2 bacterial solution was prepared ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com