Wheel mounting base

A technology of mounting seat and mounting surface, which is applied in the direction of fixed grinding wheel device, grinding/polishing safety device, manufacturing tools, etc., which can solve the problem of not easy to spread the grinding surface, increased consumption of grinding abrasives, and difficult grinding chips and sufficient removal of processing heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

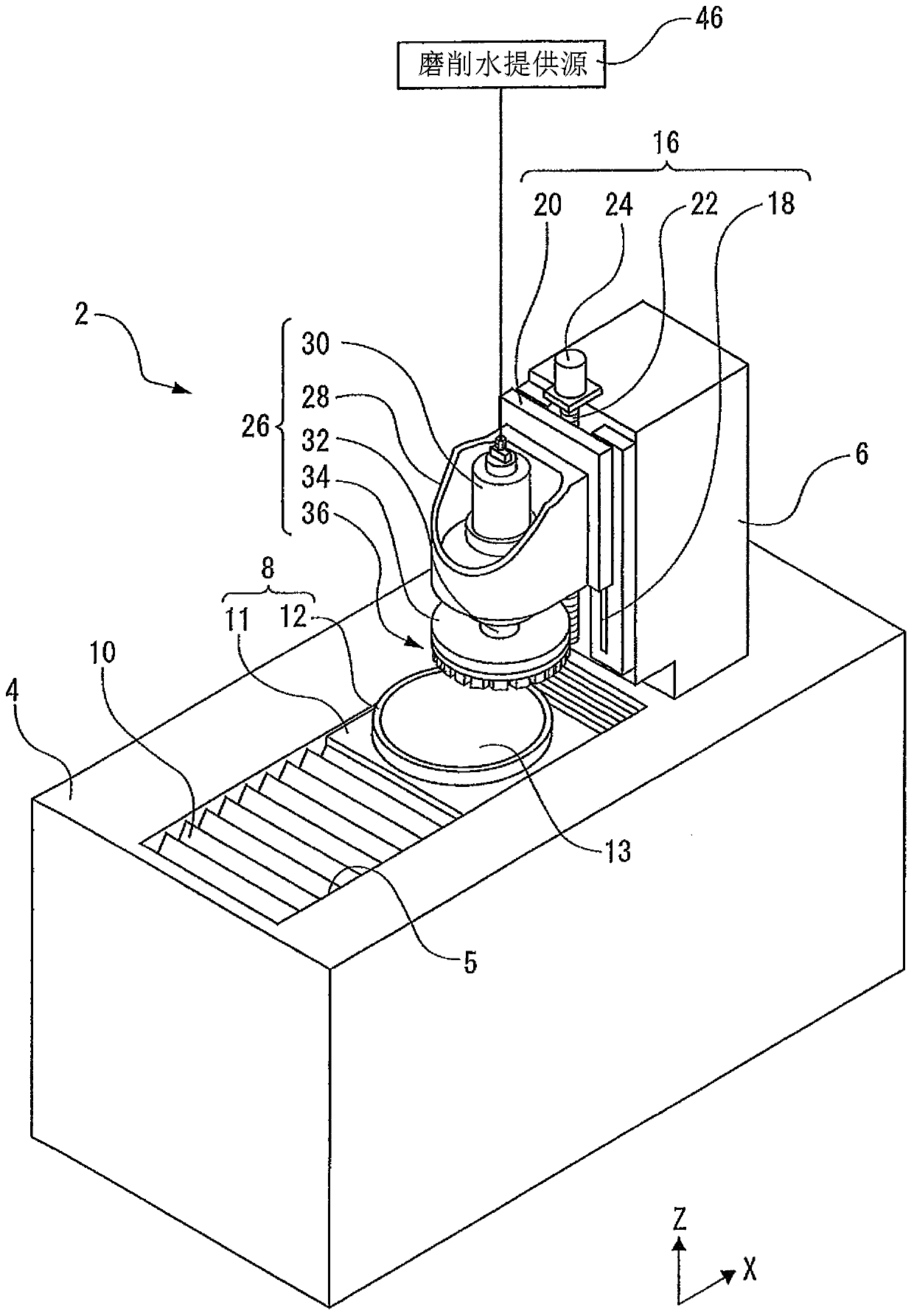

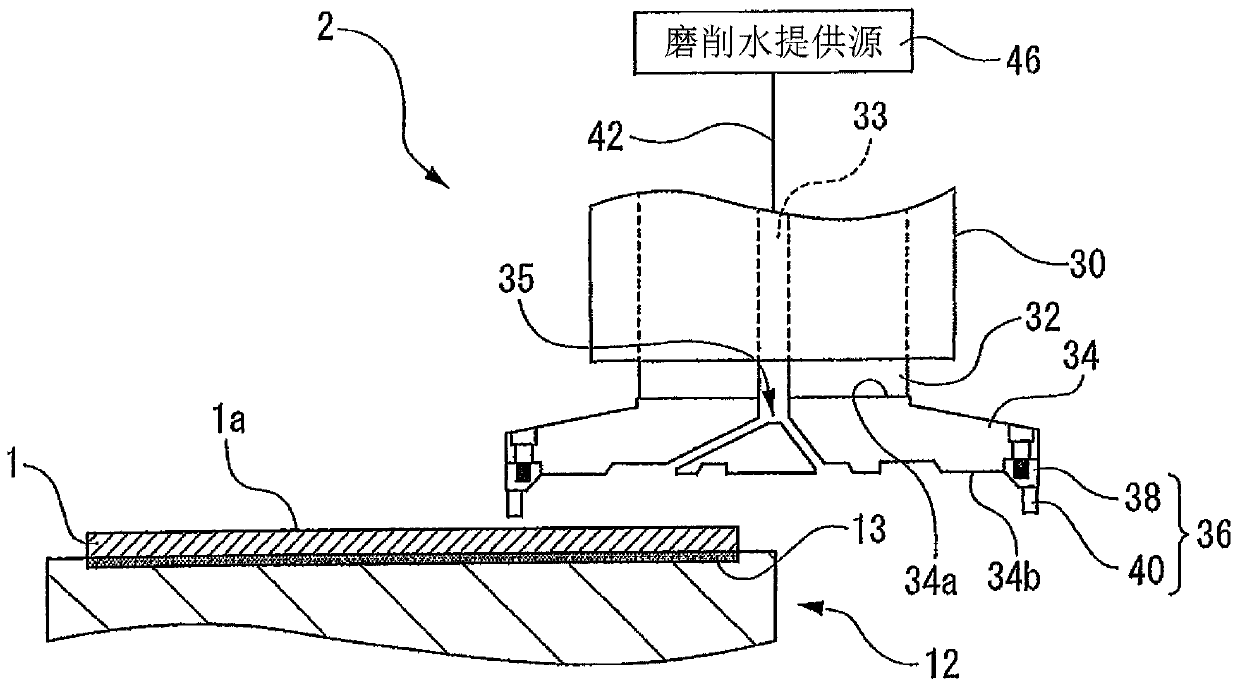

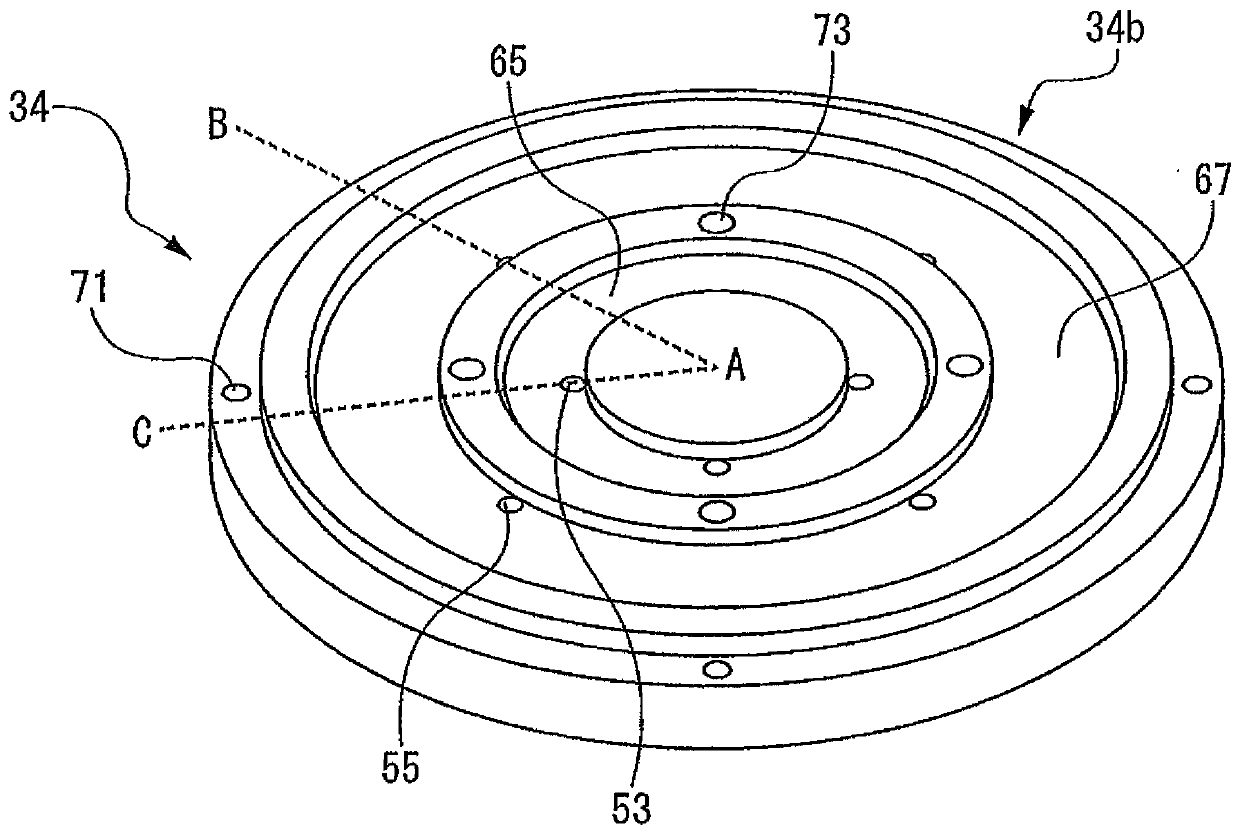

[0028] Such as figure 1 As shown, the grinding device 2 of this embodiment has: a cuboid base 4; a support column 6 extending upward; and a grinding water supply source 46 for supplying grinding water.

[0029] The front side of the upper surface of the base 4 is configured with: a chuck table portion 8 comprising a chuck table 12; an X-axis moving mechanism (not shown) that moves the chuck table portion 8 in the X-axis direction; And a waterproof cover 10 covering the X-axis moving mechanism.

[0030] The X-axis moving mechanism is provided in a rectangular opening 5 extending in the X-axis direction (front-rear direction). The X-axis moving mechanism has: a pair of X-axis guide rails parallel to the X-axis direction; an X-axis ball screw parallel to the X-axis guide rails; and a nut part connected to the X-axis ball screw and an X-axis pulse motor (not shown in the figure). Show).

[0031] An X-axis moving table 11 of the chuck table section 8 is slidably provided on the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap