Fabric arranging machine making bag and suitcase fabric convenient to spread

A bag fabric and material machine technology, applied in the field of the whole material machine, can solve the problems of poor flatness and unsatisfactory material spreading efficiency, and achieve the effect of smooth surface, improved efficiency and improved quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

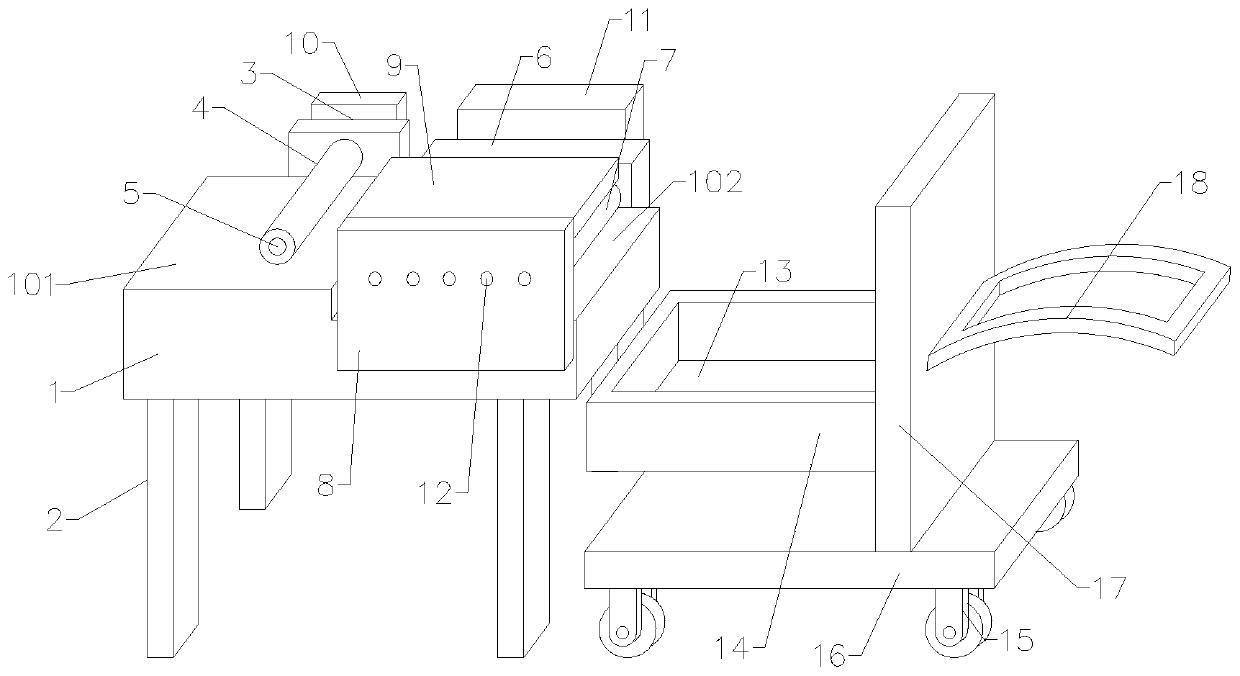

[0033] A whole material machine that facilitates the spreading of luggage fabrics, such as figure 1 As shown, including support 2 and processing platform 1 installed on the support 2, processing platform 1 is provided with spreading surface 101 and material guide surface 102, and one side of spreading surface 101 is equipped with the first mounting plate 3, the first The first motor 10 is installed on the mounting plate 3, the first rotating shaft 5 is installed on the first motor 10, the sleeve 4 is sleeved on the outer periphery of the first rotating shaft 5, and the third mounting plate 6 is installed on one side of the material guide surface 102, A second motor 11 is installed on the third mounting plate 6, and a second rotating shaft 12 is installed on the second motor 11. The outer circumference of the second rotating shaft 12 is sleeved with the first guide roller 7, and one side of the material guide surface 102 is installed with the second rotating shaft 12. Four moun...

Embodiment 2

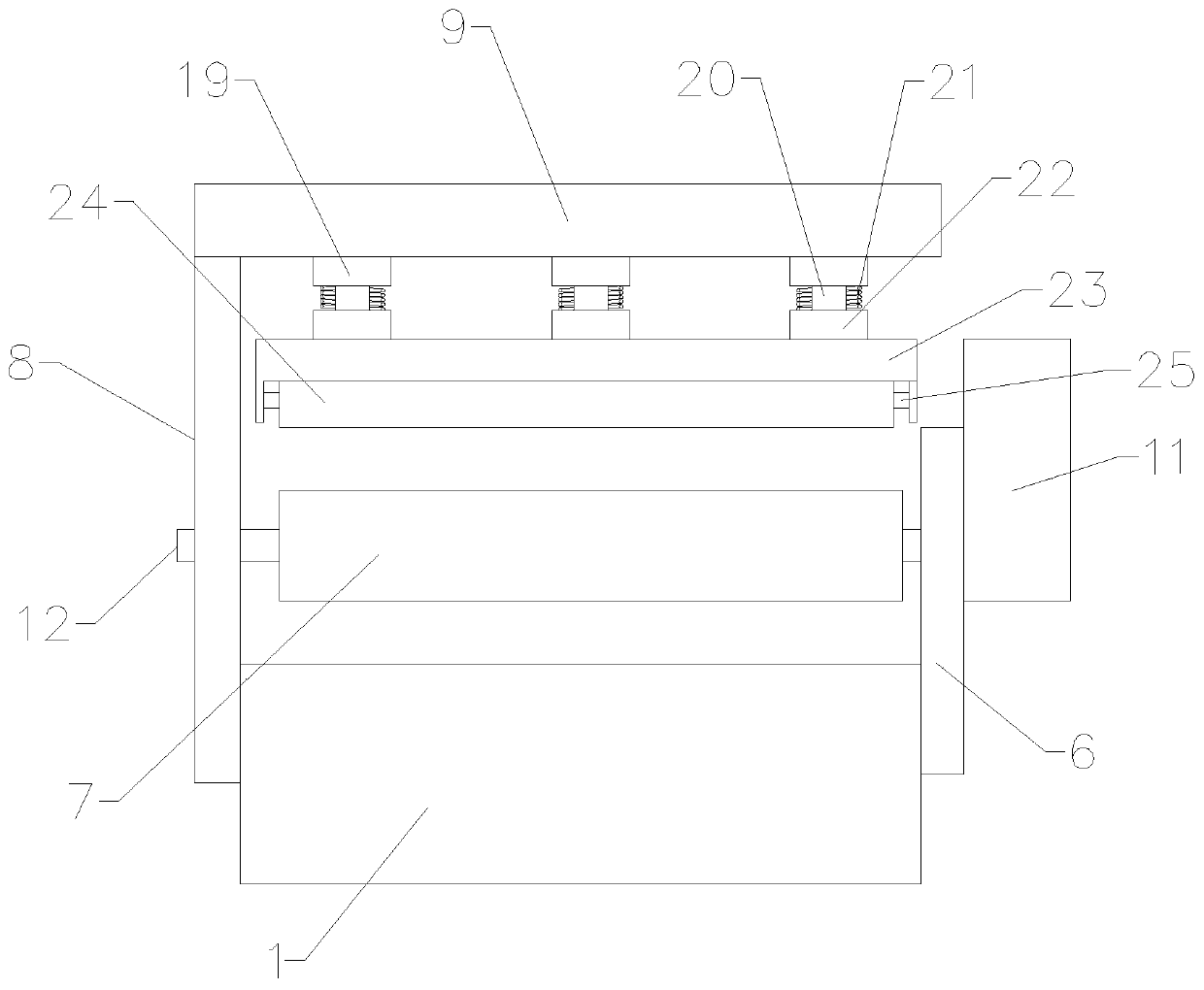

[0036] A whole material machine that facilitates the spreading of luggage fabrics, such as figure 2 As shown, in order to solve the problem of uneven surface of the fabric when spreading materials; this embodiment makes the following improvements on the basis of embodiment 1: the side of the second mounting plate 9 close to the first guide roller 7 is equipped with a second guide roller installation Seat 23 , the second guide roller mounting seat 23 is equipped with a third shaft 25 , the outer periphery of the third shaft 25 is sleeved with a second guide roller 24 , and the second guide roller 24 is located above the first guide roller 7 . The rotation of the second guide roller 24 not only accelerates the transmission of the fabric, but also realizes the flattening of the fabric to ensure a smoother surface when the fabric is spread out.

[0037] In order to meet the demand for guided flattening of fabrics of different thicknesses; figure 2 As shown, the first piston 19 ...

Embodiment 3

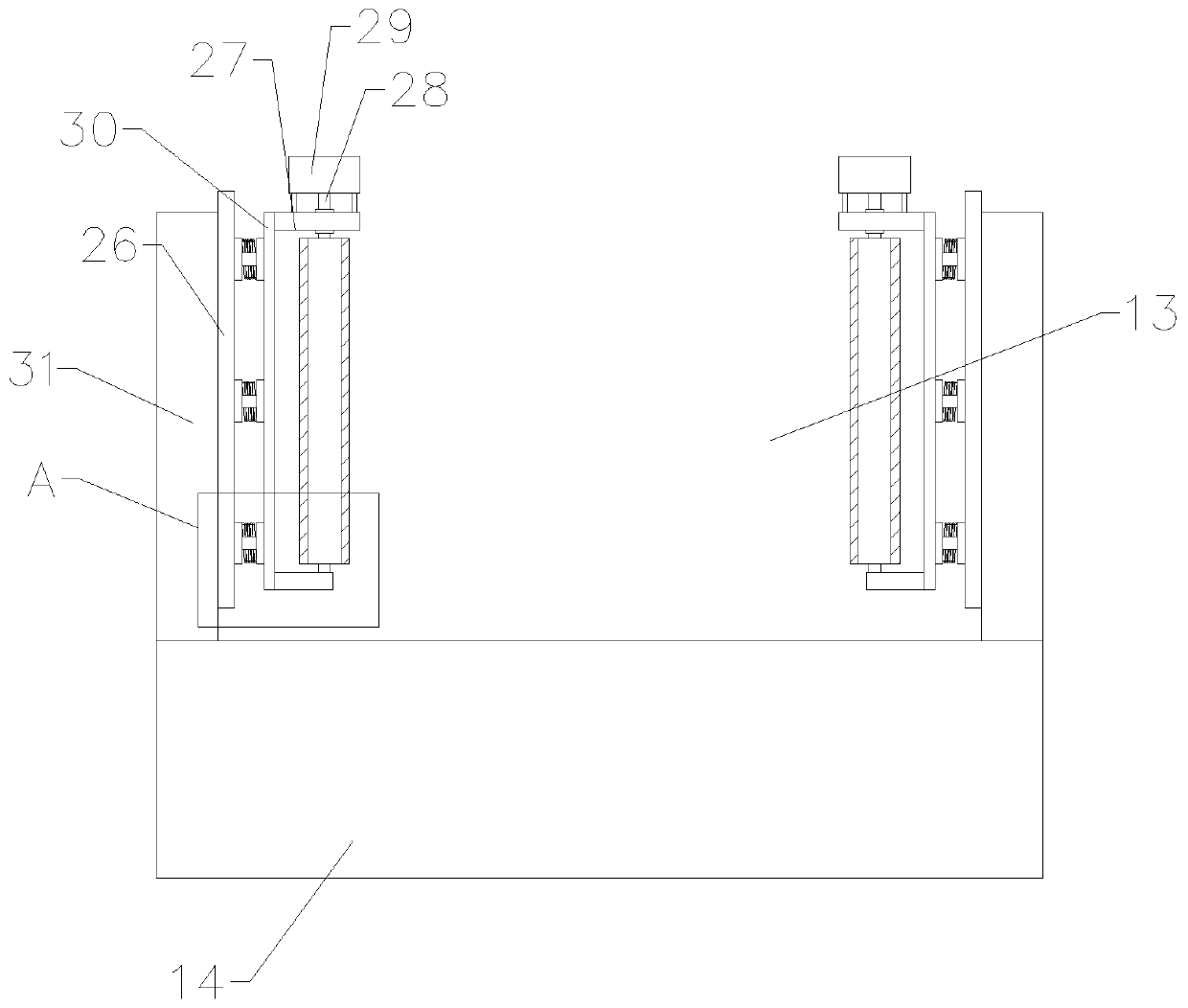

[0040] A whole material machine that facilitates the spreading of luggage fabrics, such as Figure 3-4 As shown, in order to improve the accuracy and flatness of the bag fabric falling into the material cavity 13 after discharge; this embodiment makes the following improvements on the basis of embodiment 1: both sides of the upper end of the material box 14 are equipped with sixth The mounting plate 31, the seventh mounting plate 26 is installed on the opposite side of the sixth mounting plate 31, the eighth mounting plate 27 is installed on the opposite side of the seventh mounting plate 26, and the eighth mounting plate 27 is installed on one end of the eighth mounting plate 27. Nine mounting plates 27, the other end is equipped with the 10th mounting plate 36, the 3rd motor 29 is installed on the 9th mounting plate 27, the 3rd motor 29 is equipped with the 4th rotating shaft 28 near the side of putting material box 14, the 4th rotating shaft A third guide roller 37 is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com