Method of Detecting Three-axis Vibration of Spindle Bearing Using High-frequency Single-axis Acceleration Gauge

A technology of spindle bearing and accelerometer, applied in the field of bearing spindle working condition detection, can solve the problems of deviation of accelerometer detection data, loose fixed position, etc., to achieve the effect of stable position and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings.

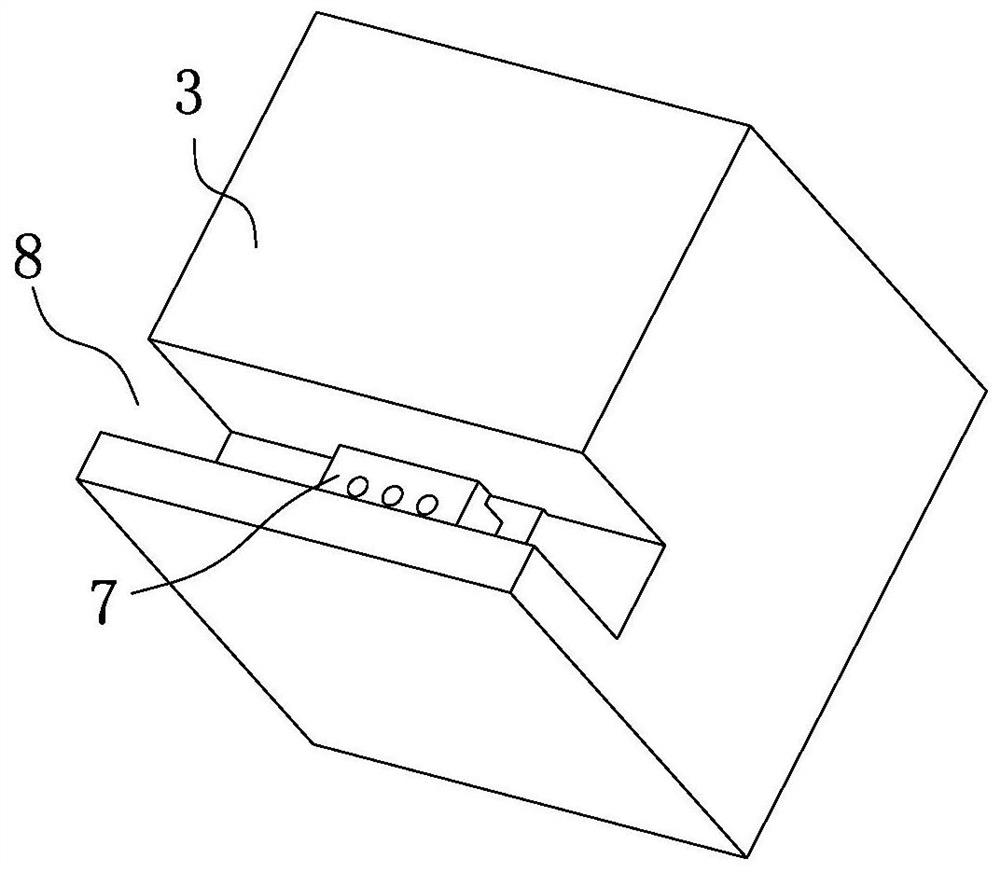

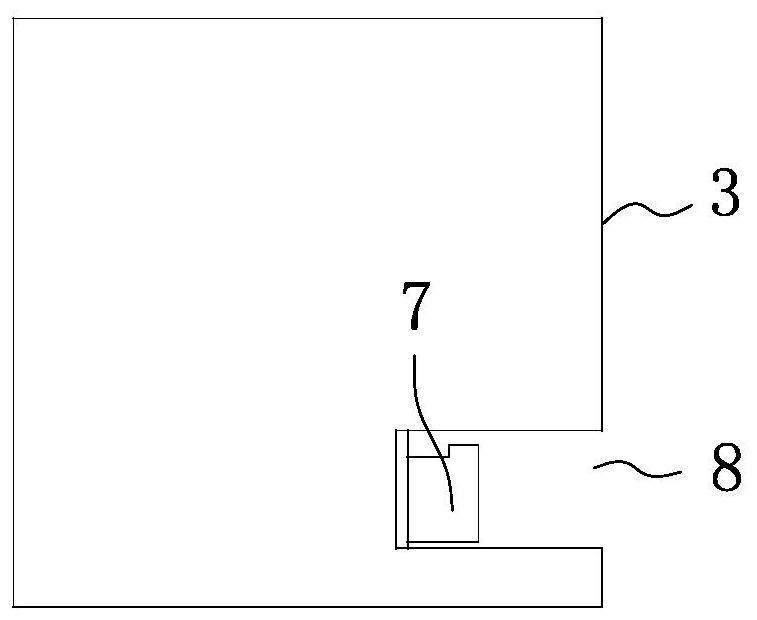

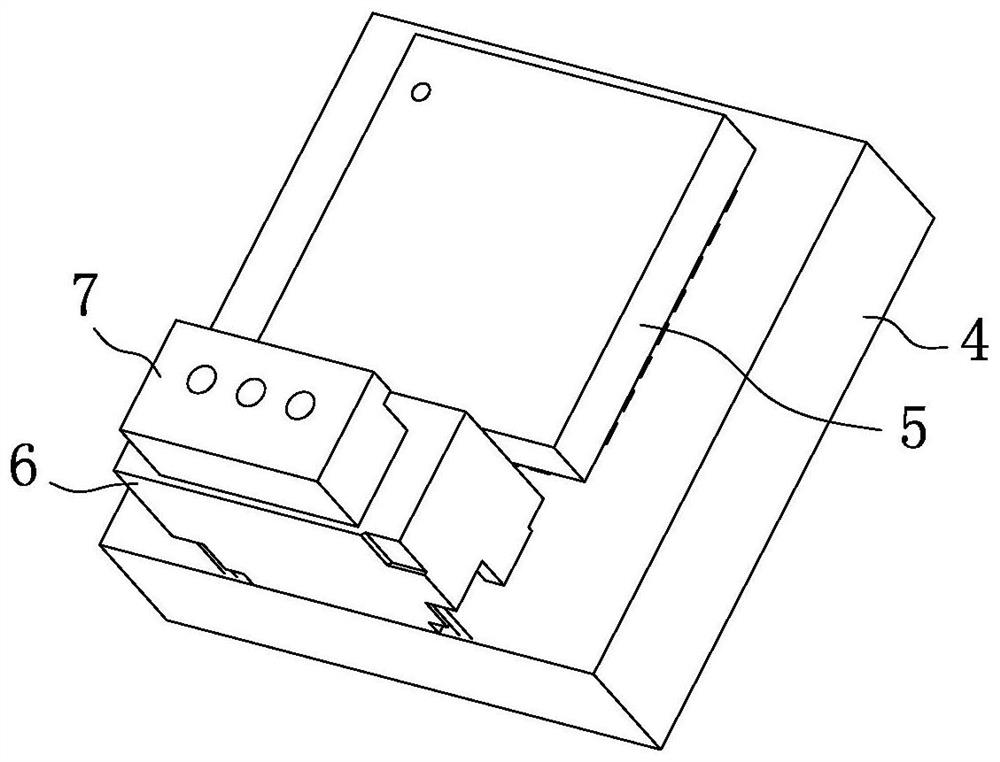

[0034] like Figure 6-7 As shown in Fig. 1, a method for detecting three-axis vibration of a spindle bearing with a high-frequency uniaxial accelerometer, the spindle connector 1 is set on the spindle to be tested, and three high-frequency uniaxial accelerometer components are arranged on the spindle connector 1 2. The detection surfaces of the three high-frequency uniaxial accelerometer assemblies 2 correspond to the X, Y, and Z-axis directions of the main shaft respectively, and the frequency detection limit of the high-frequency uniaxial accelerometer assembly 2 is at least 10,000 Hz.

[0035] The main shaft connector 1 here may be a front end cover, a rear end cover or a shaft sleeve, etc., which is not limited here. The high-frequency uniaxial accelerometer assembly 2 is connected with a data line for conducting vibration detection data.

[0036] The X, Y and Z-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com