Partial pressure oxygen sensor with ceramic heater structure and preparation method thereof

A ceramic heater and oxygen sensor technology, applied in ohmic resistance heating, heating element materials, ohmic resistance heating parts and other directions, can solve the problems of low heat transfer efficiency, poor endurance shock and vibration ability, and large heater volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

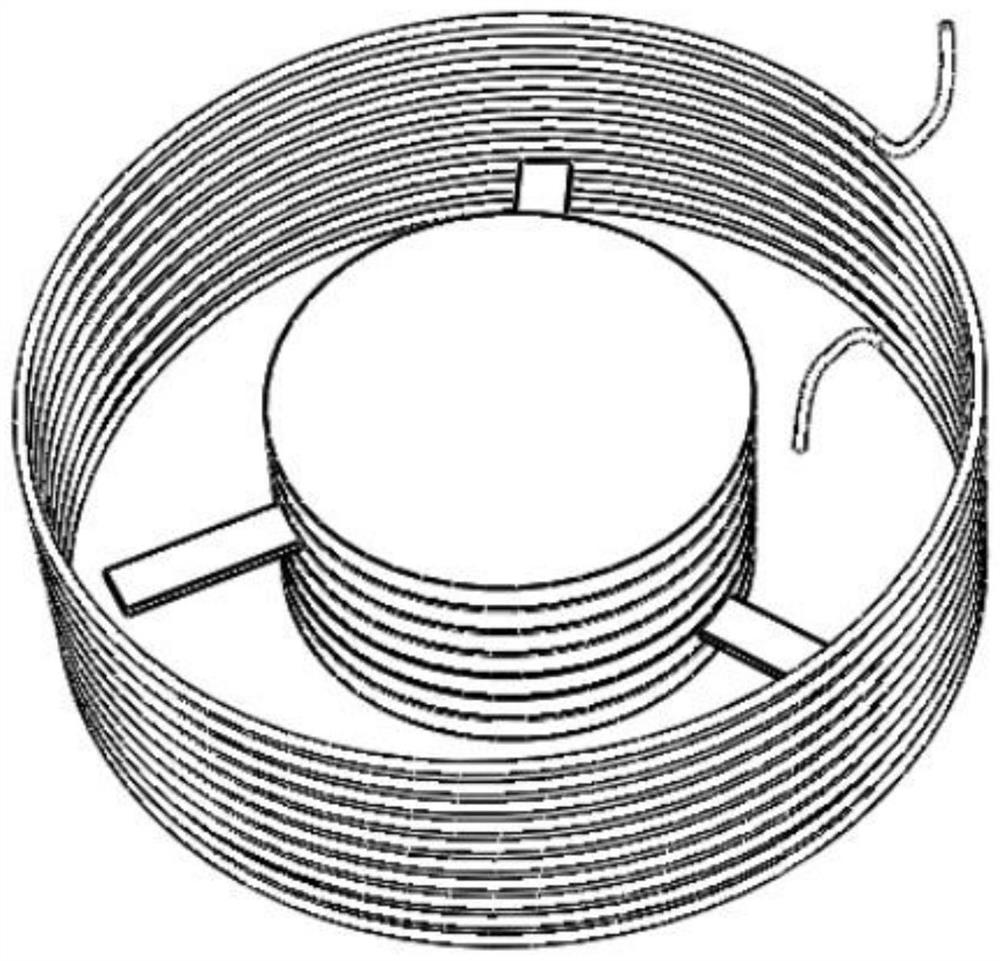

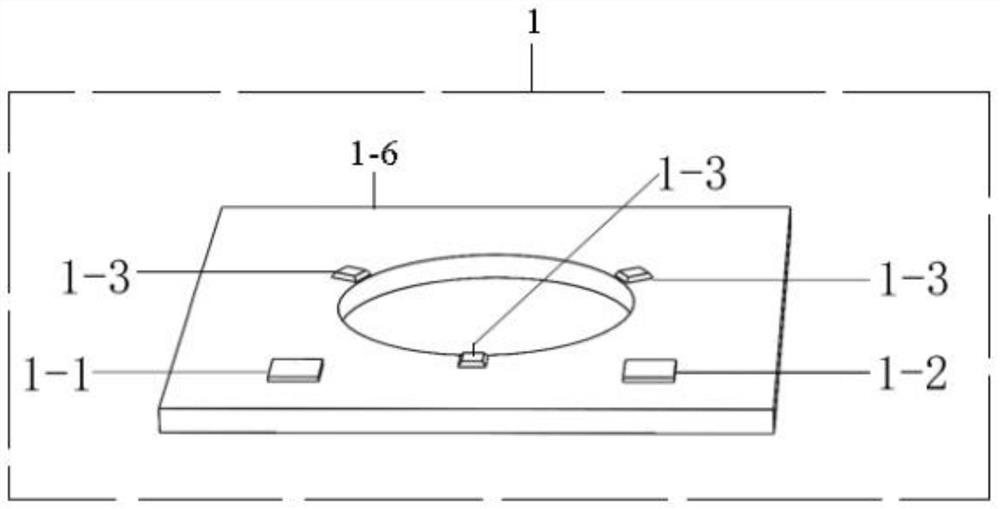

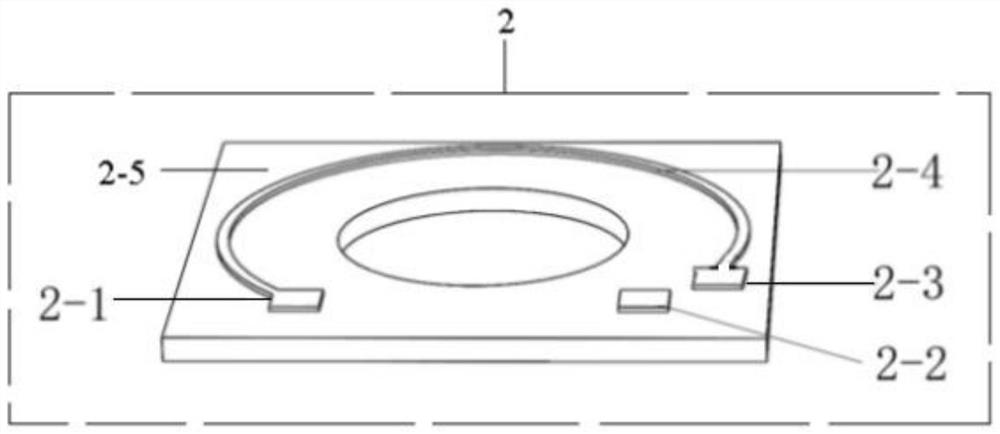

[0049] Specific implementation mode 1: This implementation mode is a partial pressure oxygen sensor with a ceramic heater structure, such as Figure 2-Figure 12 As shown, it is specifically composed of a core body 6 and a ceramic heater 5;

[0050] Such as Figure 11 As shown, the core body 6 is composed of two alumina filter discs 6-1, two zirconia solid electrolyte ceramic discs 6-2 and three platinum electrodes 6-3; the alumina filter disc 6 -1 and the zirconia solid electrolyte ceramic sheet 6-2 are both circular, and the diameters of the alumina filter sheet 6-1 and the zirconia solid electrolyte ceramic sheet 6-2 are equal;

[0051] Such as Figure 12 As shown, the platinum electrode 6-3 is composed of a platinum ring 6-3-2 and a platinum pin 6-3-1; one end of the platinum pin 6-3-1 is connected to the platinum ring 6-3 -2 fixed to form a lollipop structure; the platinum electrode 6-3 has an integrated structure;

[0052] The core body 6 is based on the alumina filte...

specific Embodiment approach 2

[0060] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the first arc-shaped heating wire 2-4, the second arc-shaped heating wire 3-4 and the third arc-shaped heating wire 4 The central angles of -1 are all 270°-330°. Others are the same as the first embodiment.

specific Embodiment approach 3

[0061] Specific embodiment three: the difference between this embodiment and specific embodiment one is: the first ceramic substrate 1-6, the second ceramic substrate 2-5, the third ceramic substrate 3-5 and the fourth ceramic substrate 4- 4 are aluminum oxide substrates, and the thickness is 0.35 mm to 1 mm. Others are the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com