Preparation of graphene UV curing adhesive and application of composite burning glass

A technology of graphene and curing glue, applied in the direction of adhesive additives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve time-consuming and labor-intensive, high-rise building cleaning safety hazards, and the lives of members of the car and pedestrians Threat and other problems, to achieve the effect of rapid heating, increase compatibility and leveling, and reduce secondary damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

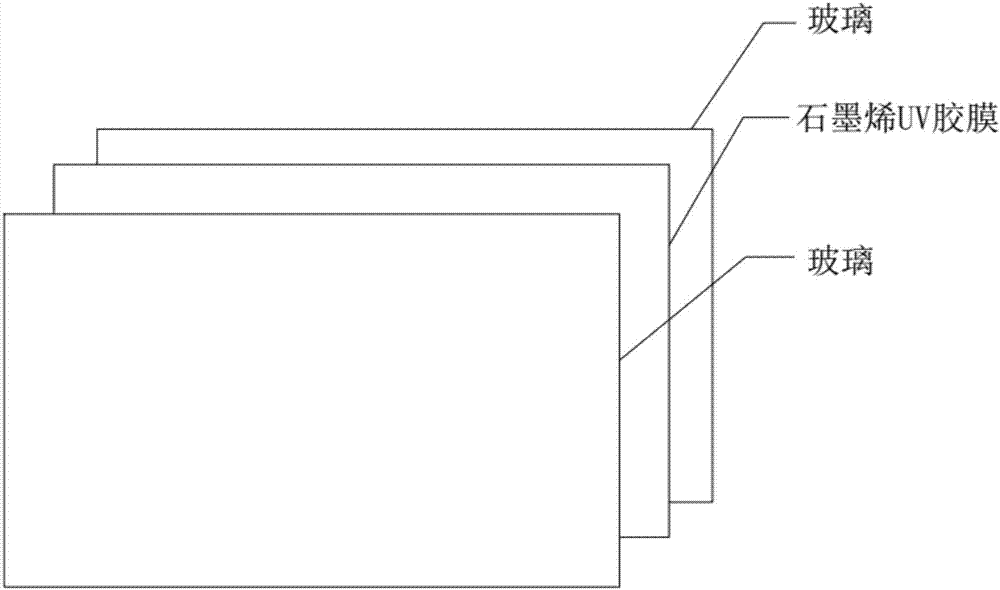

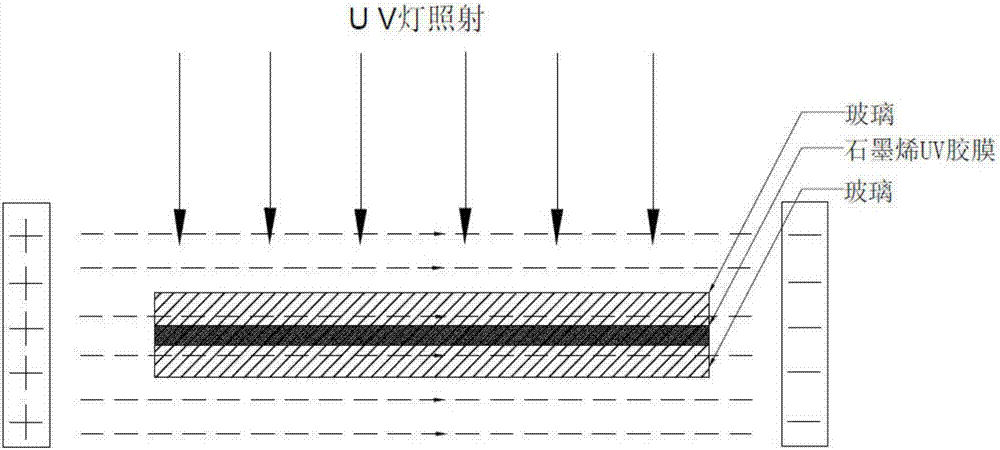

Image

Examples

Embodiment 1

[0036] (1) Prepare modified graphene color paste first: the amount of each raw material is UV resin B: graphene: surfactant: the mass ratio of leveling agent is 1:5:0.5:5, and UV resin B is aliphatic polyurethane EB230 Resin, surfactant is sodium dodecylbenzene sulfonate, leveling agent is silicone acrylate;

[0037] (2) After mixing UV resin B and graphene, stir and ultrasonically disperse at 40°C for 1 hour;

[0038] (3) Mix the surfactant and leveling agent evenly at 20°C, then quickly pour the ultrasonically dispersed mixture at 40°C obtained in step (2), and stir at 600r / min for 5 minutes at 20°C, Cool to 10°C; then stir at 20°C at a speed of 1100r / min for 10 minutes, and finally at 10°C at a speed of 100r / min for 1 hour to obtain the modified graphene paste.

[0039] (4) Graphene UV curing glue is prepared according to the proportioning ratio of the following mass ratios:

[0040]

[0041] UV resin A is aliphatic polyurethane EB230 resin, the photoinitiator is 1173,...

Embodiment 2

[0047] (1) prepare modified graphene color paste earlier: each raw material consumption is UV resin B: graphene: surfactant: the mass ratio of leveling agent is 1:1:0.1:1, and UV resin B is acrylate CN8004, The surfactant is sodium dodecylsulfonate, and the leveling agent is polymethylphenylsiloxane;

[0048] (2) After mixing UV resin B and graphene, stir and ultrasonically disperse at 50°C for 3 hours;

[0049] (3) Mix the surfactant and leveling agent evenly at 30°C, then quickly pour the ultrasonically dispersed mixture at 50°C obtained in step (2), and stir at 1000r / min for 15 minutes at 30°C, Cool to 20°C; then stir at 30°C at a speed of 1500r / min for 30 minutes, and finally stir at 20°C at a speed of 400r / min for 3 hours to obtain the modified graphene paste.

[0050] (4) Graphene UV curing glue is prepared according to the proportioning ratio of the following mass ratios:

[0051]

[0052] UV resin A is a mixture of acrylate CN8004 and polyester acrylate CN790 (mas...

Embodiment 3

[0058] (1) Prepare modified graphene color paste first: the amount of each raw material is UV resin B: graphene: surfactant: the mass ratio of leveling agent is 1:2:0.2:2, and UV resin B is epoxy acrylate CN104, acrylate CN8004 (mass ratio 1:1), surfactants are sodium dodecylbenzenesulfonate, sodium dodecylsulfonate (mass ratio 1:1), leveling agent is silicone acrylic acid Ester, polydimethylsiloxane (mass ratio 1:1);

[0059] (2) After mixing UV resin B and graphene, stir and ultrasonically disperse at 42°C for 1.5 hours;

[0060] (3) Mix the surfactant and leveling agent evenly at 22°C, then quickly pour the ultrasonically dispersed mixture at 42°C obtained in step (2), and stir at 700r / min for 8 minutes at 23°C, Cool to 13°C; then stir at 23°C at a speed of 1300r / min for 15 minutes, and finally at 14°C at a speed of 200r / min for 1.5 hours to obtain the modified graphene paste.

[0061] (4) Graphene UV curing glue is prepared according to the proportioning ratio of the fol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com