A high-flux anti-pollution polyamide composite reverse osmosis membrane and its preparation method

A reverse osmosis membrane and anti-pollution technology, applied in the direction of reverse osmosis, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of difficult control of reactivity, high cost of modified reverse osmosis membrane, increased operating cost, etc., to achieve The effect of easy control of reactivity, easy control of reactivity, and low price of monomer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

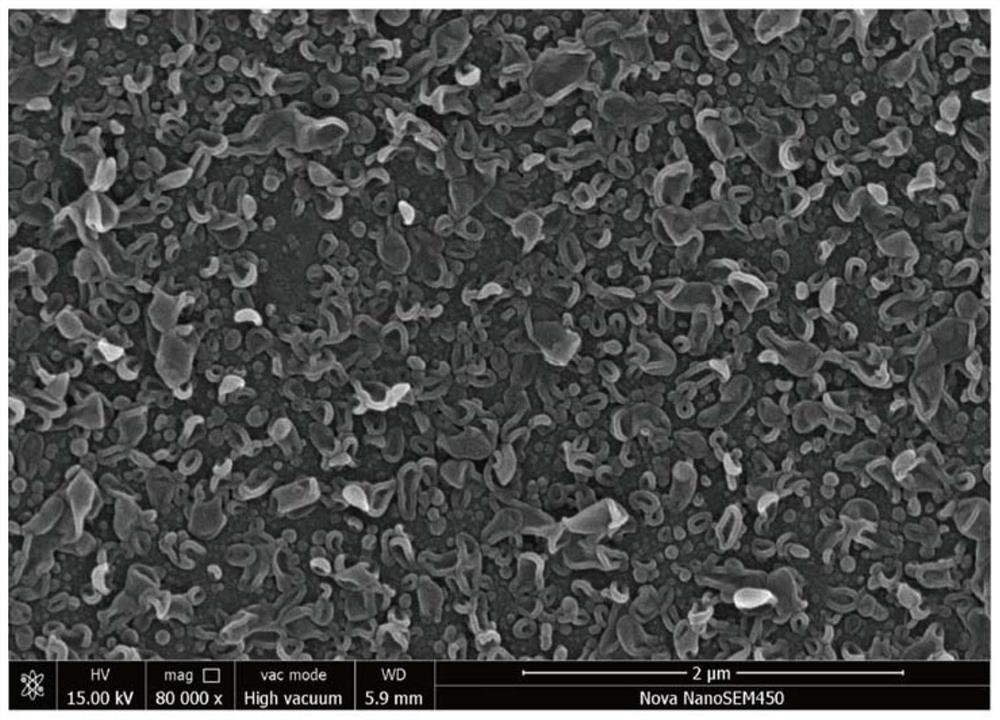

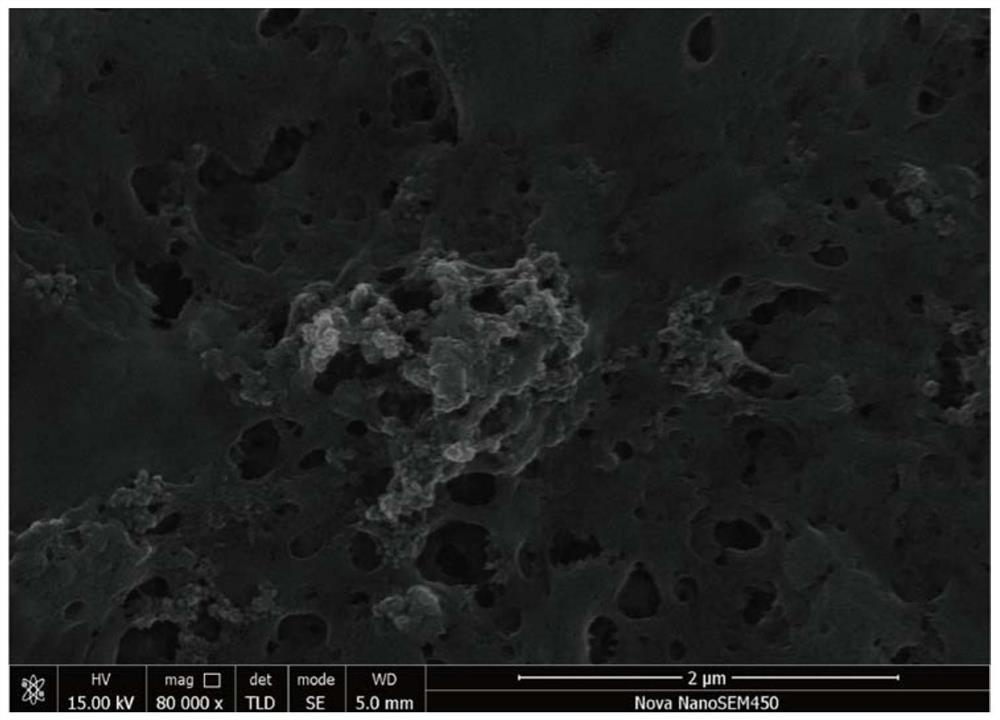

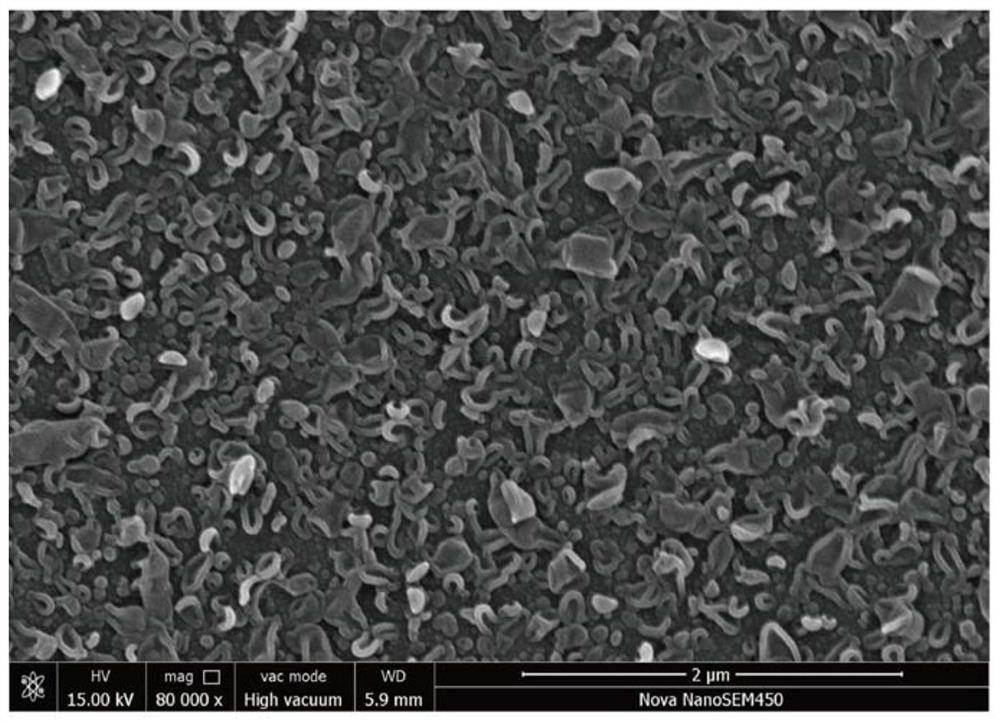

Image

Examples

Embodiment 1

[0047] A rectangular polysulfone ultrafiltration membrane with a size of 17cm × 10cm is fixed in a polytetrafluoroethylene frame, so that only the upper surface of the membrane (polysulfone layer) is in contact with the reactant during the reaction; use deionized water Rinse the polysulfone ultrafiltration membrane surface for 5min; 1g m-phenylenediamine (2wt%), 1.15g camphorsulfonic acid (2.3wt%), 0.55g triethylamine (1.1wt%) were added to 50ml deionized water, and The mixed aqueous solution was poured on the surface of the membrane, soaked for 120S, and the membrane was dried until there was no residual aqueous solution on the surface, and 0.035g of trimesoyl chloride (0.15wt%) was dissolved in 50ml of n-hexane solution. The solution was poured on the membrane surface, reacted for 15S, and the membrane surface was washed with de-n-hexane until there was no reaction residue, and the initial aromatic polyamide composite reverse osmosis membrane was prepared. Dissolve 0.5g tris...

Embodiment 2

[0050] The original aromatic polyamide composite reverse osmosis membrane was prepared according to the steps and conditions given in Example 1. Dissolve 1 g of tris in 50 ml of water (2.0 wt%), pour the tris aqueous solution on the surface of the initial aromatic polyamide composite reverse osmosis membrane, and react at 20° C. for 5 min. After the reaction is completed, the surface of the membrane is washed with deionized water until there is no reaction residue to prepare a composite reverse osmosis membrane grafted with trishydroxymethylaminomethane modified aromatic polyamide.

[0051] The initial water flux of the aromatic polyamide composite reverse osmosis membrane grafted with trishydroxymethylaminomethane is 44.1LMH (liter per square meter per hour), and the salt rejection rate is 98.78%; The recovery rate of water flux after ammonium bromide pollution was 71.4%; the recovery rate of water flux after rinsing the membrane surface with deionized water was 90.3%.

Embodiment 3

[0053] The original aromatic polyamide composite reverse osmosis membrane was prepared according to the steps and conditions given in Example 1. Dissolve 1.5g of Tris in 50ml of water (3wt%), pour the tris aqueous solution on the surface of the initial aromatic polyamide composite reverse osmosis membrane, and react at 25°C for 7min. After the reaction is completed, the surface of the membrane is washed with deionized water until there is no reaction residue to prepare a composite reverse osmosis membrane grafted with trishydroxymethylaminomethane modified aromatic polyamide.

[0054] The initial water flux of the aromatic polyamide composite reverse osmosis membrane modified by trishydroxymethylaminomethane grafting is 47.32LMH (liter per square meter per hour), and the salt rejection rate is 98.97%; The recovery rate of water flux after ammonium bromide pollution was 73.5%; the recovery rate of water flux after washing the membrane surface with deionized water was 91.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com