Rotary cutting insert and tool having declined axial support surfaces

A cutting insert, supporting surface technology, used in cutting inserts, manufacturing tools, drill accessories, etc., can solve problems such as stress concentration, cracked shank, fatigue, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

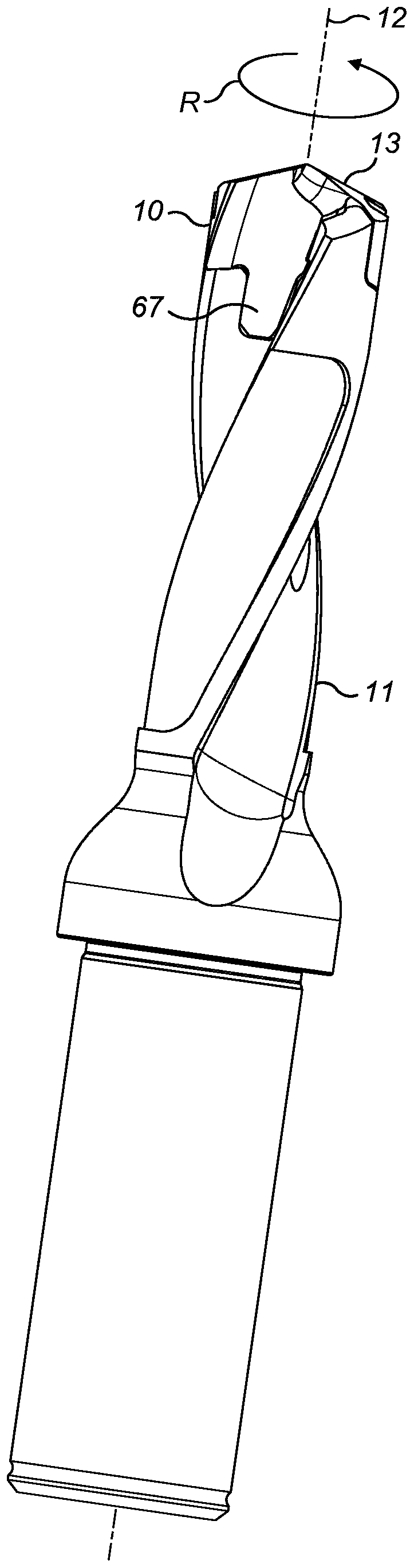

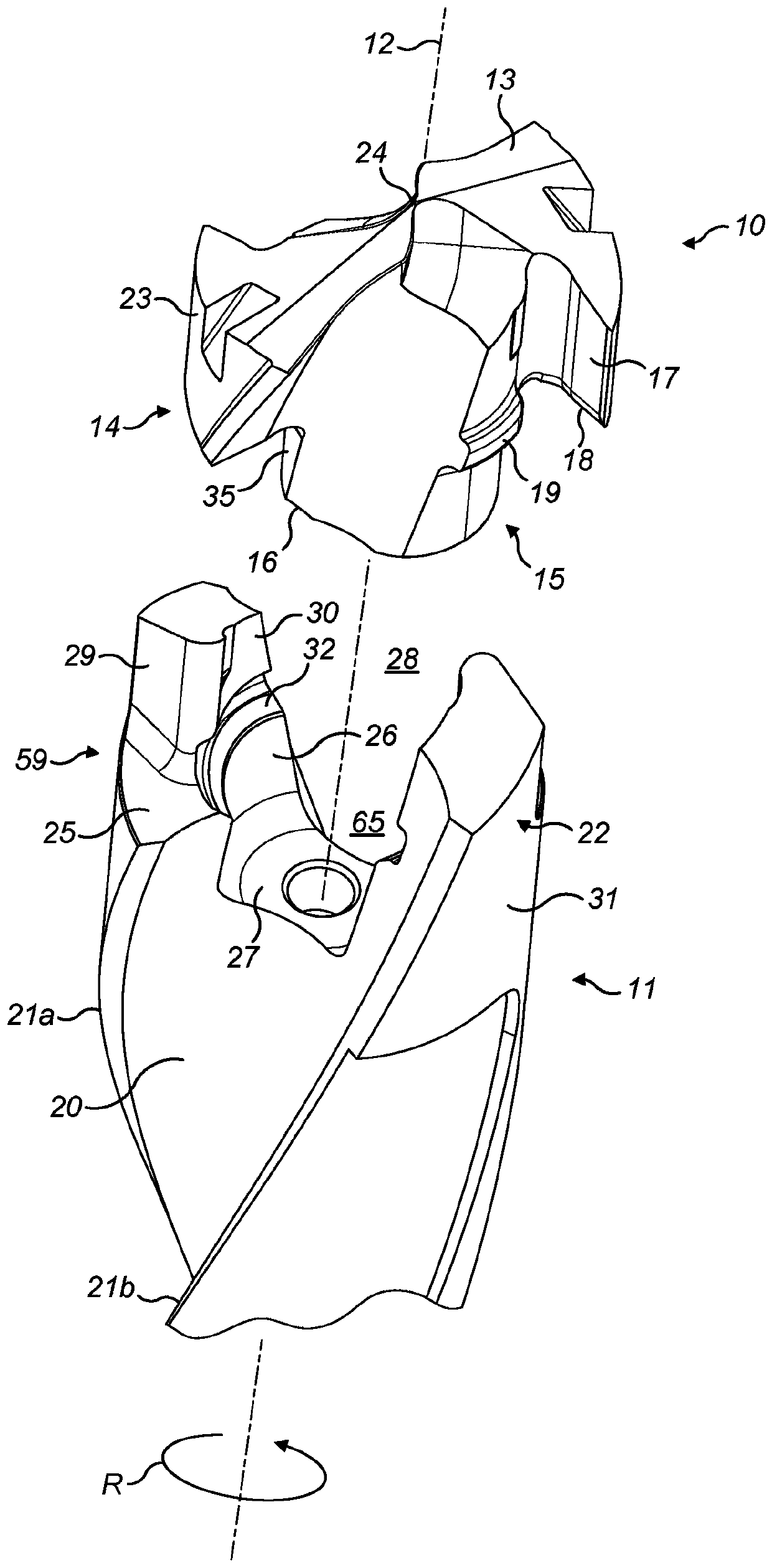

[0036] refer to figure 1 , the cutting tool embodied as a drilling tool comprises an elongated support body 11 . The cutting insert 10 is releasably mounted at the axial front end of the support body 11 . The insert 10 includes an axially forwardmost axially forward-facing cutting region 13 and an axially rearmost mounting region 67 . The mounting area 67 and the axial front end of the support body 11 are shaped to complement each other axially and radially as described in detail below in order to provide control over the transfer of load forces between the blade 10 and the support body 11 during use and management. Such load forces include axial and radial forces in addition to the torque generated by the cutting tool rotating in direction R about a central longitudinal axis 12 extending through the insert 10 and support body 11 .

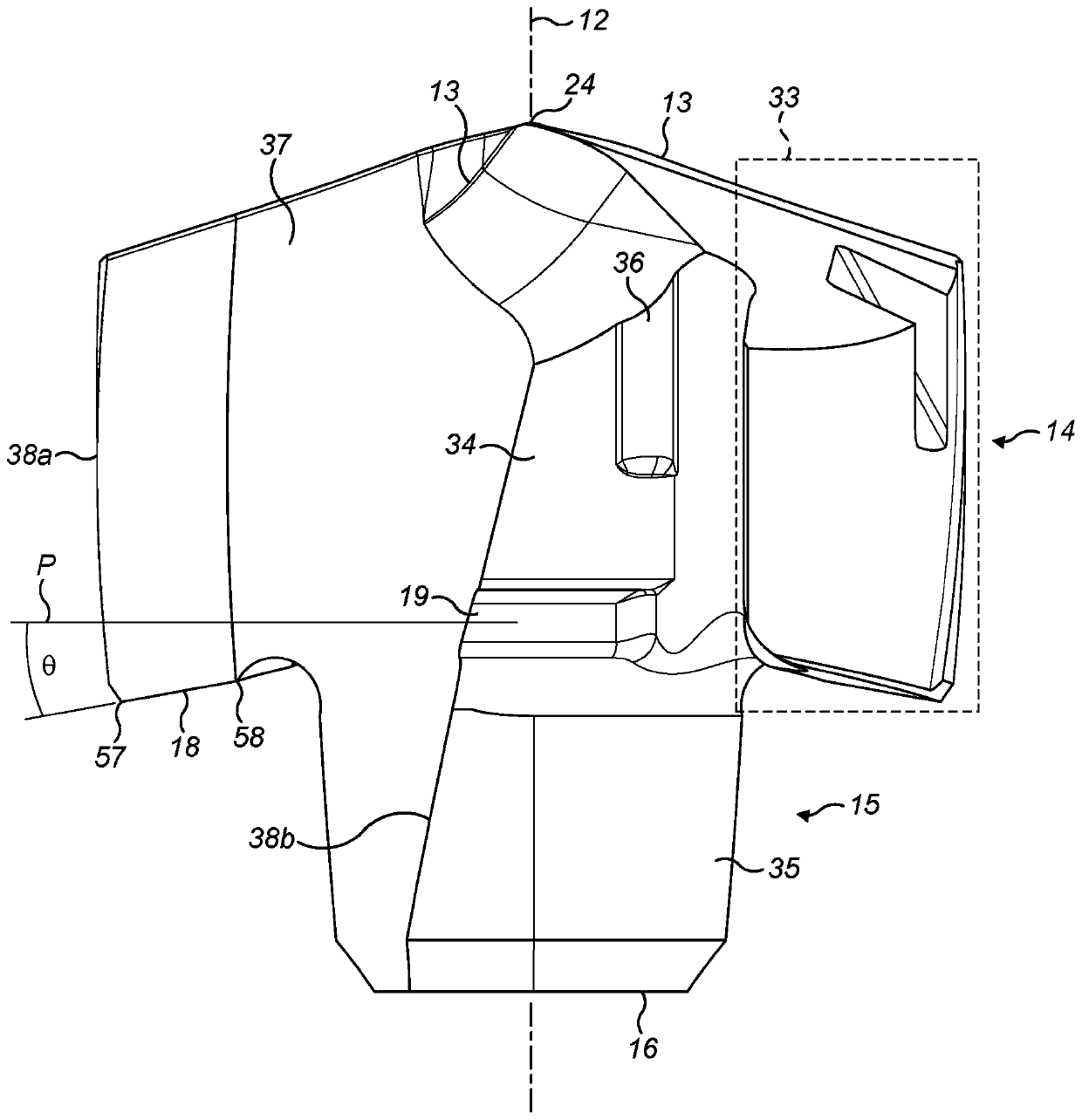

[0037] refer to figure 2 , the blade 10 may be considered to include an axially forward head 14 radially enlarged relative to a generally cy...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap