Mixed stirring material conveying mechanism

A conveying mechanism, mixing and stirring technology, applied in the direction of the supply device, forming pressure head, manufacturing tools, etc., can solve the problems affecting the movement accuracy, etc., to achieve the effect of ensuring the compaction effect, simple manufacturing, and low movement accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

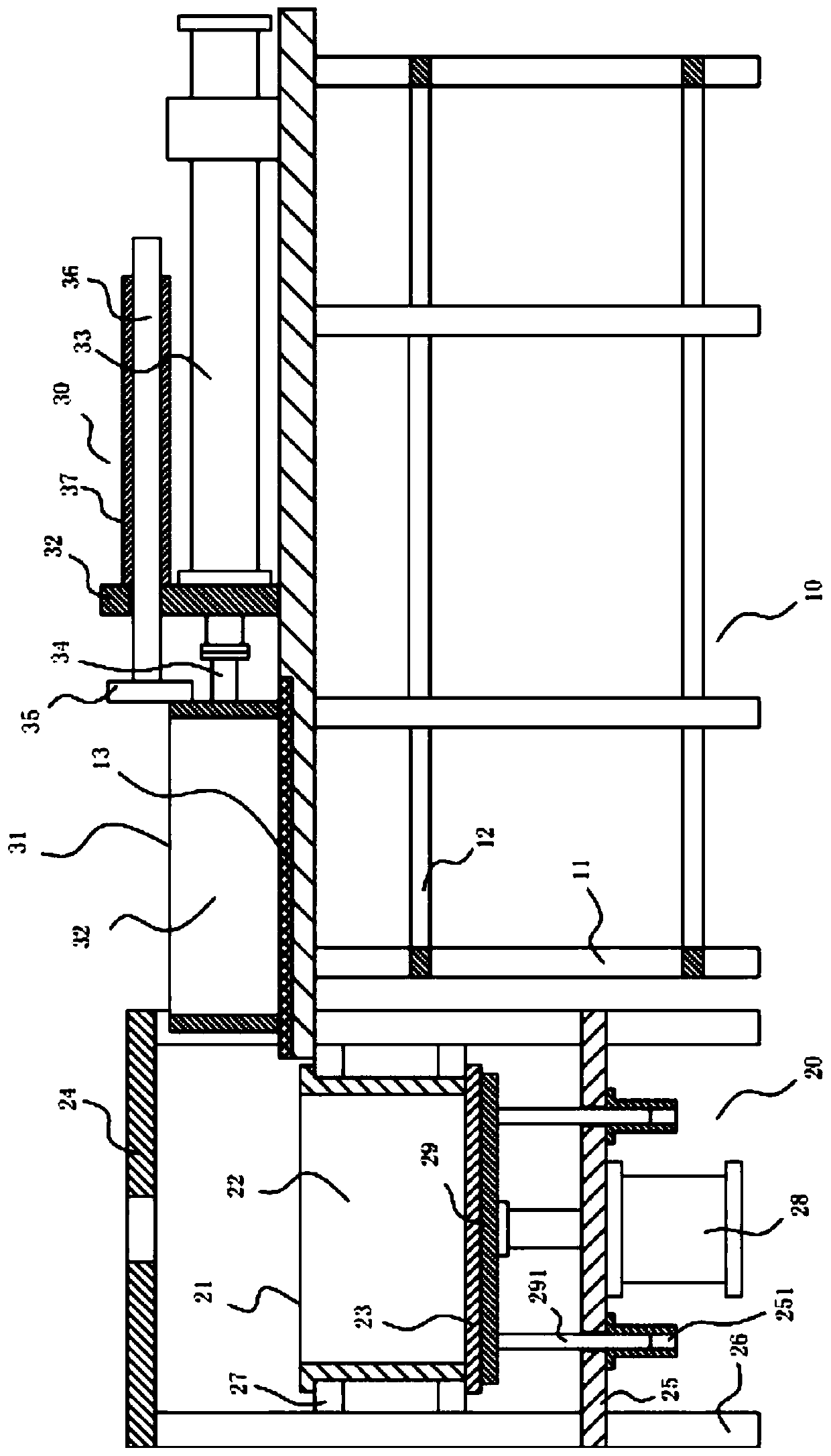

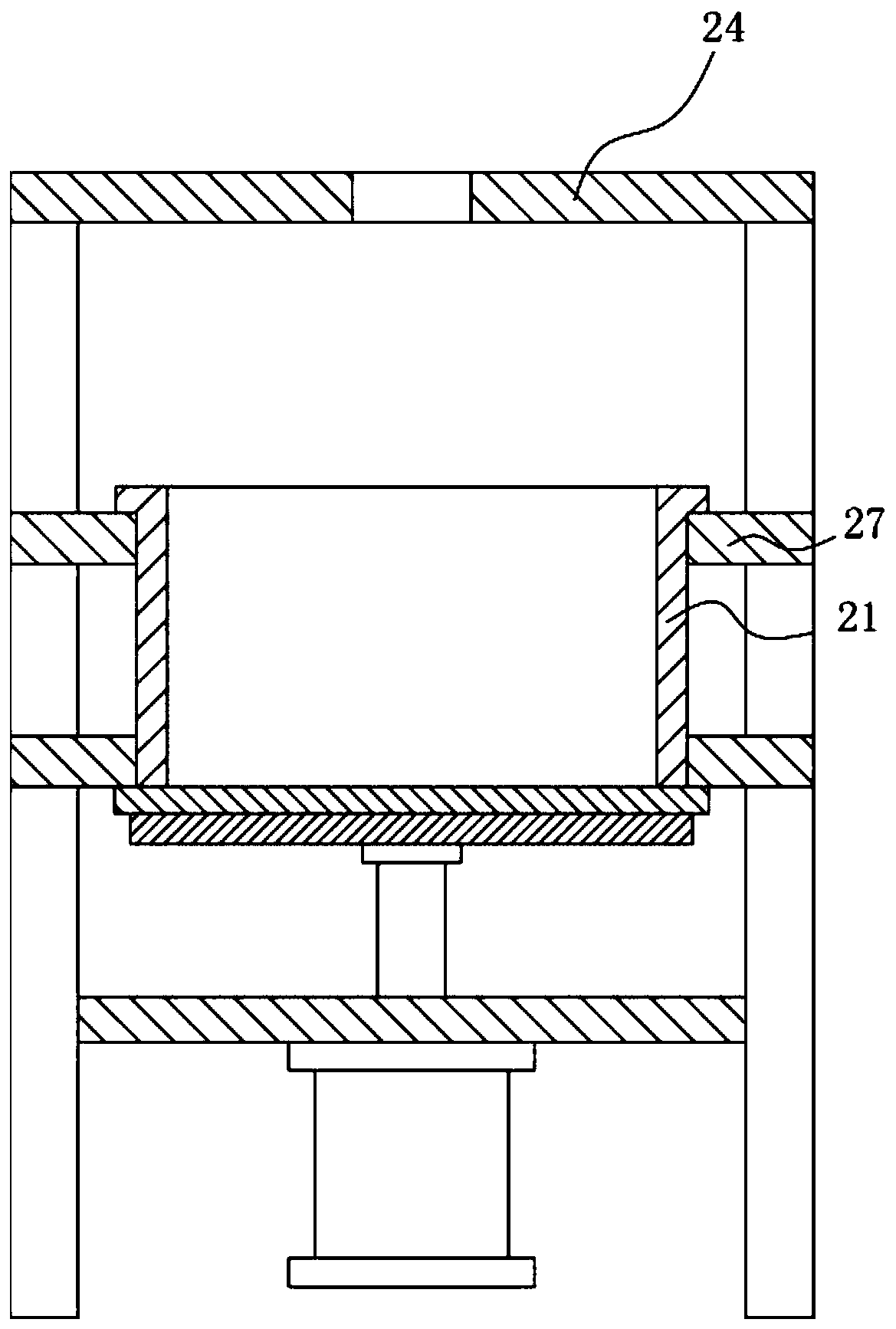

[0018] Example: see Figure 1 to Figure 2 As shown, a mixing and stirring material conveying mechanism includes a conveying frame 10 and a material receiving frame 20, and the conveying frame 10 is at the right side of the material receiving frame 20;

[0019] The top surface of the main top plate of the conveying mechanism 10 is fixed with a conveying and pushing mechanism 30, the transition housing 31 of the conveying and pushing mechanism 30 is on the top surface of the main top plate, and the interior of the transition housing 31 is provided with an inner transition cavity 32 , the middle part of the material receiving frame 20 is fixed with a material receiving housing 21, the inside of the material receiving housing 21 is formed with a material receiving cavity 22, and the bottom surface of the material receiving housing 21 is pressed against the top surface of the material receiving plate 23, The transition shell 31 corresponds to the receiving shell 21 .

[0020] Furt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com