Full-automatic pressing machine

A laminating machine, fully automatic technology, applied in the direction of connecting welt machines, clothing, footwear, etc., can solve the problems of complex structure and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

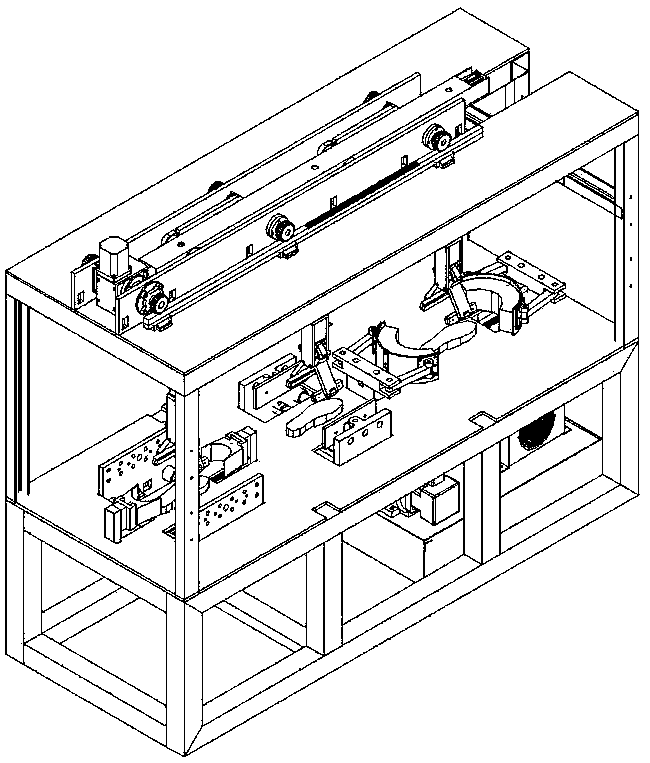

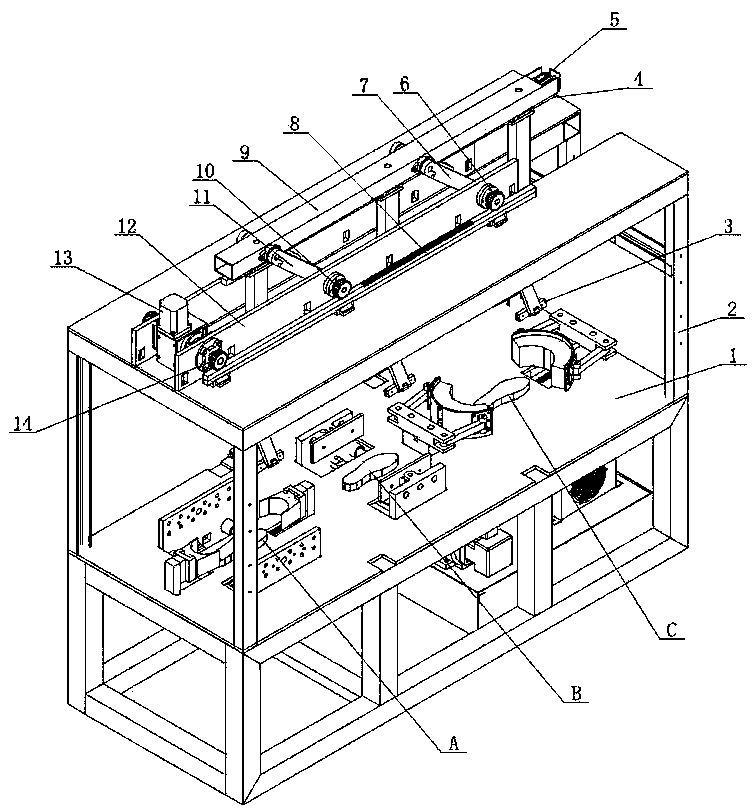

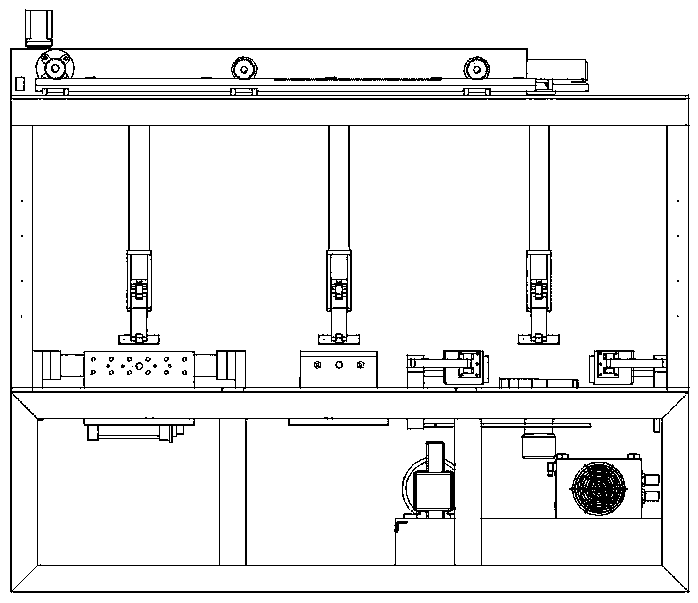

[0016] As shown in the figure, the fully automatic pressing machine of the present invention includes a fixedly installed frame 2 and a pressing workbench 1. Three pressing stations A, B, and C are arranged on the pressing workbench 1. The pressing mold corresponding to station A has front, rear, left and right pressing plates, the pressing mold corresponding to middle pressing station B has only left and right pressing plates, and the pressing mold corresponding to rear pressing station C has only front and rear pressing plates, front and rear pressing plates. The left and right pressing plates are movable; each pressing station is equipped with a corresponding gripper 3, and the grabbing action of the gripper 3 is pushed by the hydraulic cylinder 17, and the three grippers 3 are connected to the same gripper through the same adjustment plate 4. On the hand fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com