Automatic box sealing machine for tongue box

A tongue-button and automatic technology, which is applied in the field of automatic box-sealing machines for tongue-button boxes, can solve the problems that the production line cannot get rid of manual box sealing, cannot realize continuous work, and hinders production automation, and achieves simple structure, small errors, and simple and reliable actions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

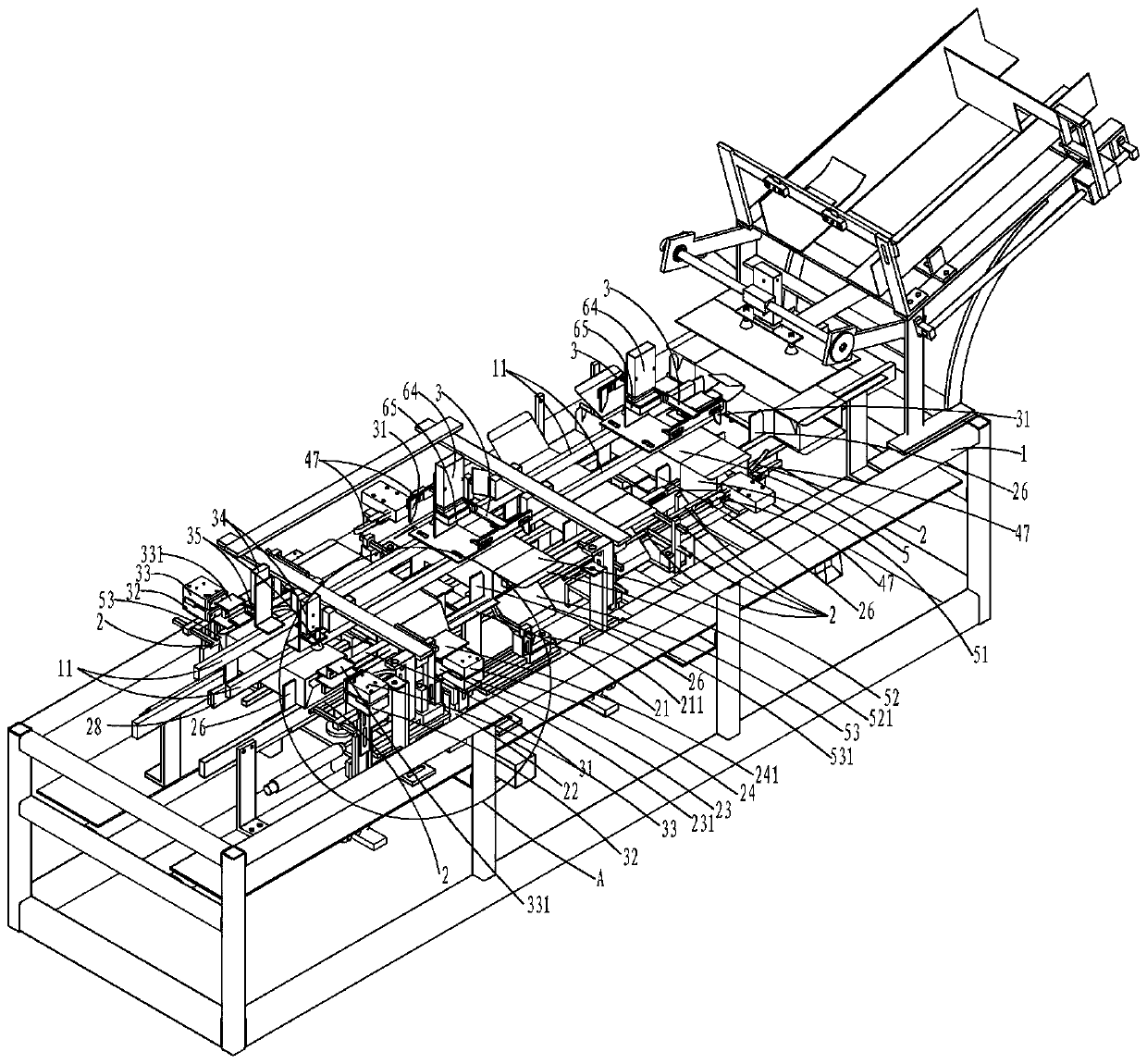

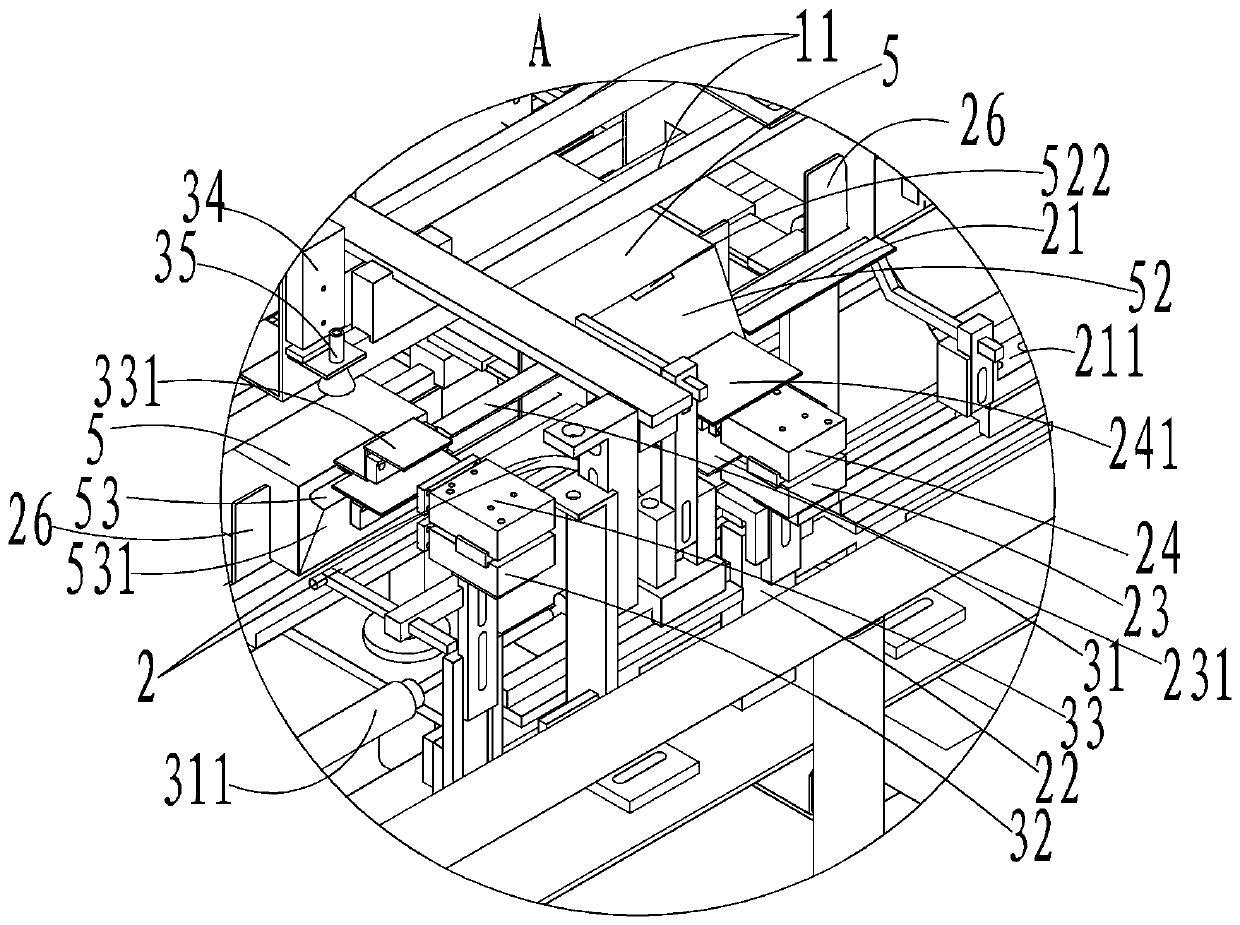

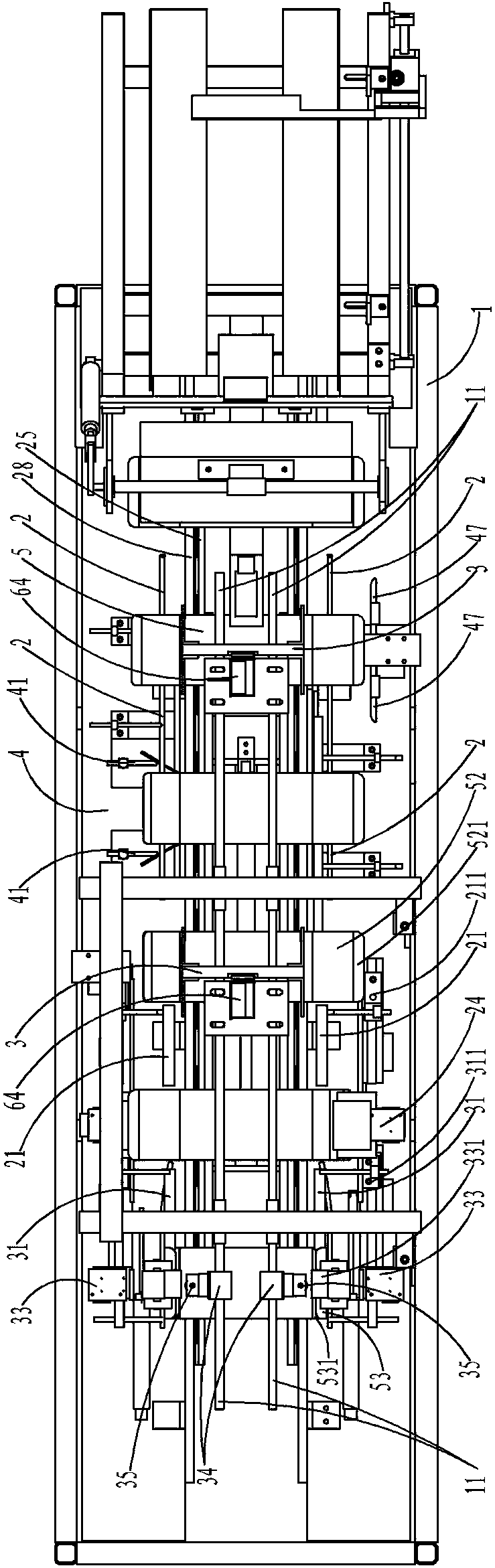

[0035] Attached below Figure 1-12 The invention is described in further detail with specific embodiments:

[0036] as attached Figures 1 to 3 As shown, the present invention is an automatic box sealing machine for tongue boxes, which includes a frame 1, a transport rack 10 arranged on the frame 1, a guide rail 11 for limiting the position of the box body 5, and a transport rack 10 arranged on the frame 1. Two symmetrically arranged closing mechanisms for closing the cover of the box body 5 on both sides and a plurality of guide rods 2 for guiding the cover. The top sheet closing mechanism for closing the top sheet 52 and the bottom sheet closing mechanism for closing the bottom sheet 53, the transport rack 10 includes a conveying rail 25, a plurality of pairs of positioning teeth 26 arranged on the conveying rail 25, and a conveying mechanism for pushing the conveying rail 25 to reciprocate. Mechanism, the inner side of the automatic box sealing machine is provided with an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com