A multi-layer mold press

A mold and press technology, applied in presses, manufacturing tools, etc., can solve the problems of long time, inconvenient operation, low production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

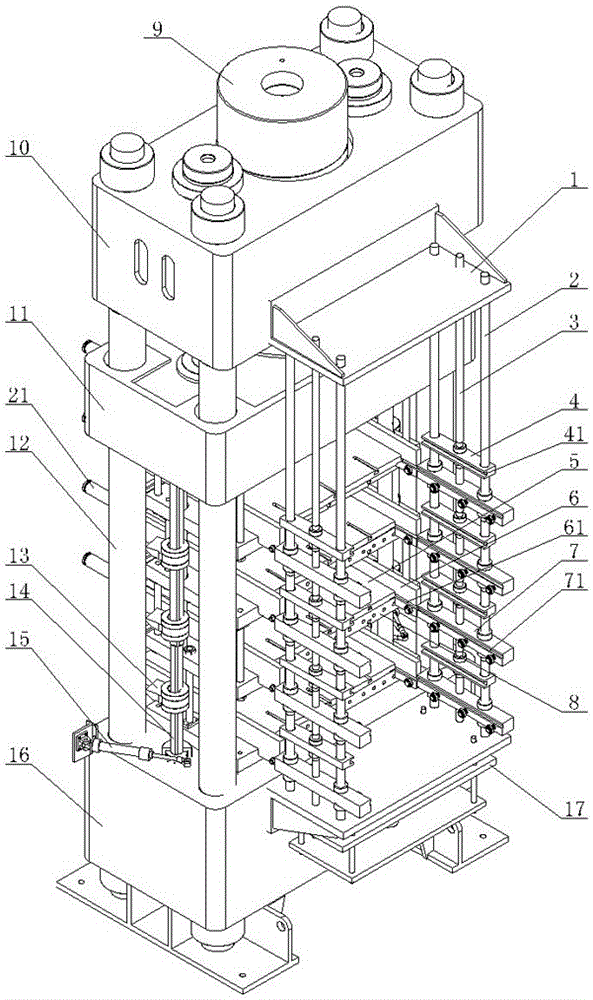

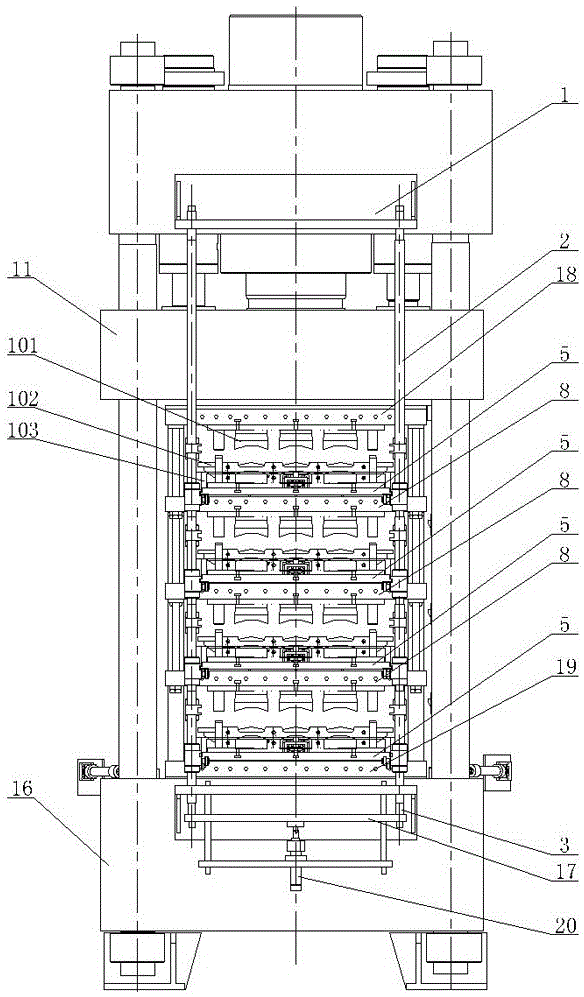

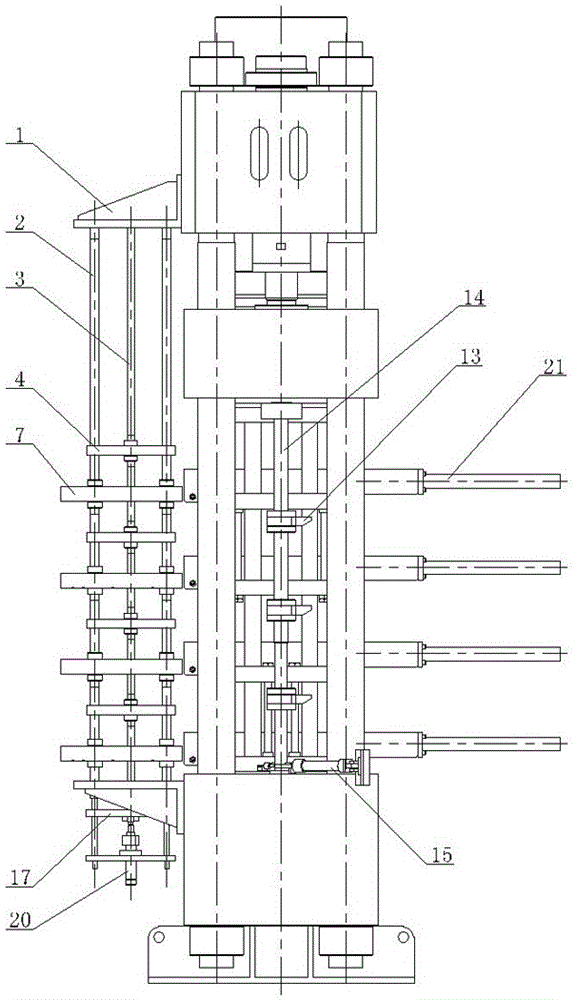

[0018] As shown in the figure, the multi-layer mold press of the present invention includes a lower machine base 16, a column 12, a top plate 10, a movable beam 11 and a synchronous exhaust mechanism for multi-layer molds, and the column 12 is fixedly installed on the lower machine base 16, and the top plate 10 Fixedly installed on the top of the column 12, the movable crossbeam 11 is set up and down under the top plate 10 and is pushed by the main oil cylinder 9, and the upper heating plate 18 arranged up and down between the movable crossbeam 11 and the lower machine base 16, three layers The middle heating plate 8 and the lower heating plate 19, the upper heating plate 18 is installed on the bottom of the movable beam 11, the lower heating plate 19 is installed on the lower machine base 16, and the middle heating plate 8 is movable up and down between the upper and lower heating plates. Sliding guide is carried out, the uppermost middle heating plate 8 is articulated below t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com