Fabricated type indoor partition wall structure and construction method thereof

An internal partition wall, prefabricated technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of difficult reuse of building materials and material waste, and achieve the effects of easy maintenance, reduced waste, and easy protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings.

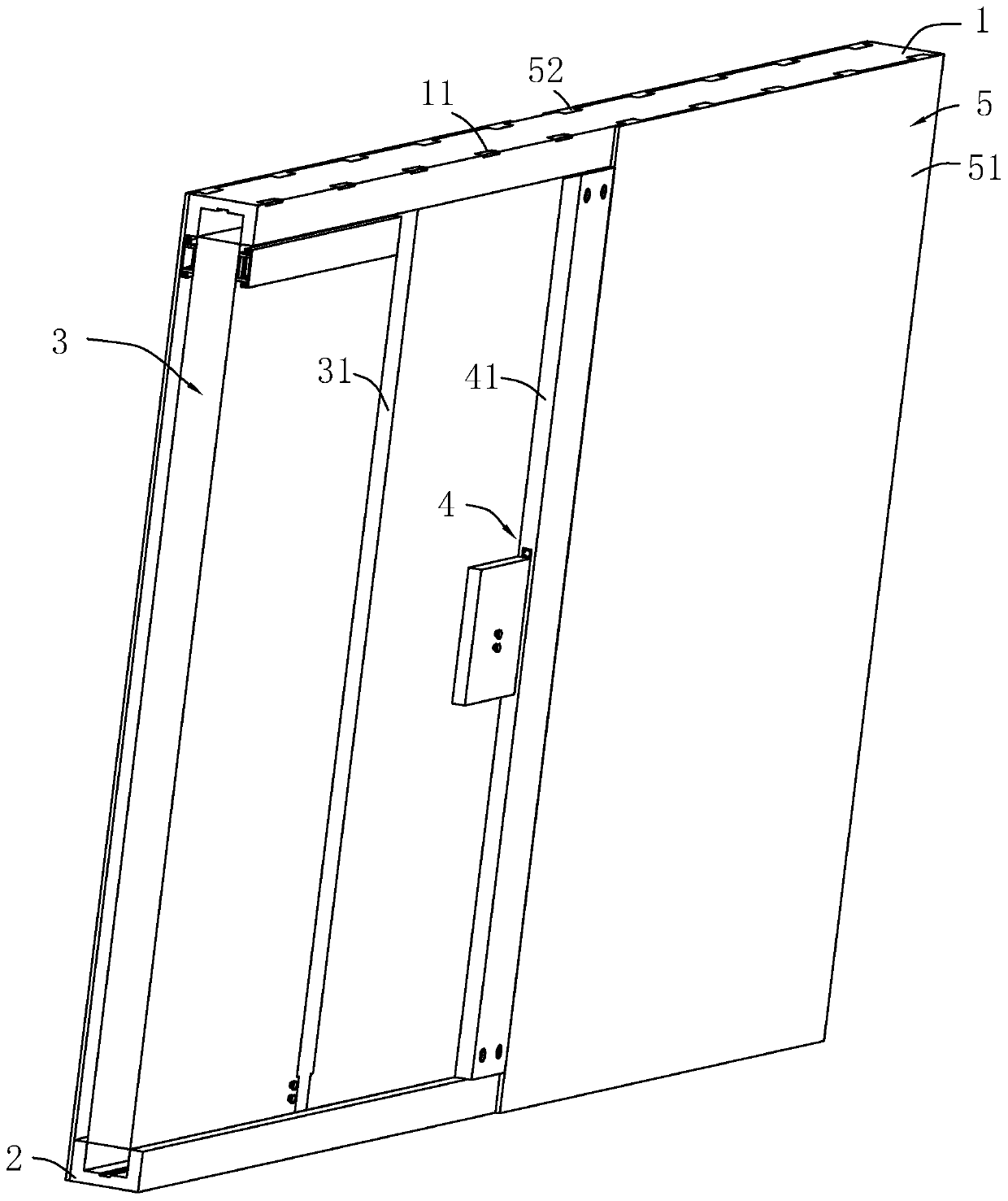

[0044] refer to figure 1 , which is a prefabricated indoor partition wall structure disclosed in this embodiment, the first rail 1 and the second rail 2 with opposite openings are respectively connected on the ceiling and the ground, and the vertical sections of the first rail 1 and the second rail 2 are U-shaped.

[0045] refer to figure 1 and Figure 4 , on the first rail 1 and the second rail 2, the inner plate mechanism 3 formed by splicing each other is slidably connected through the sliding assembly 6 .

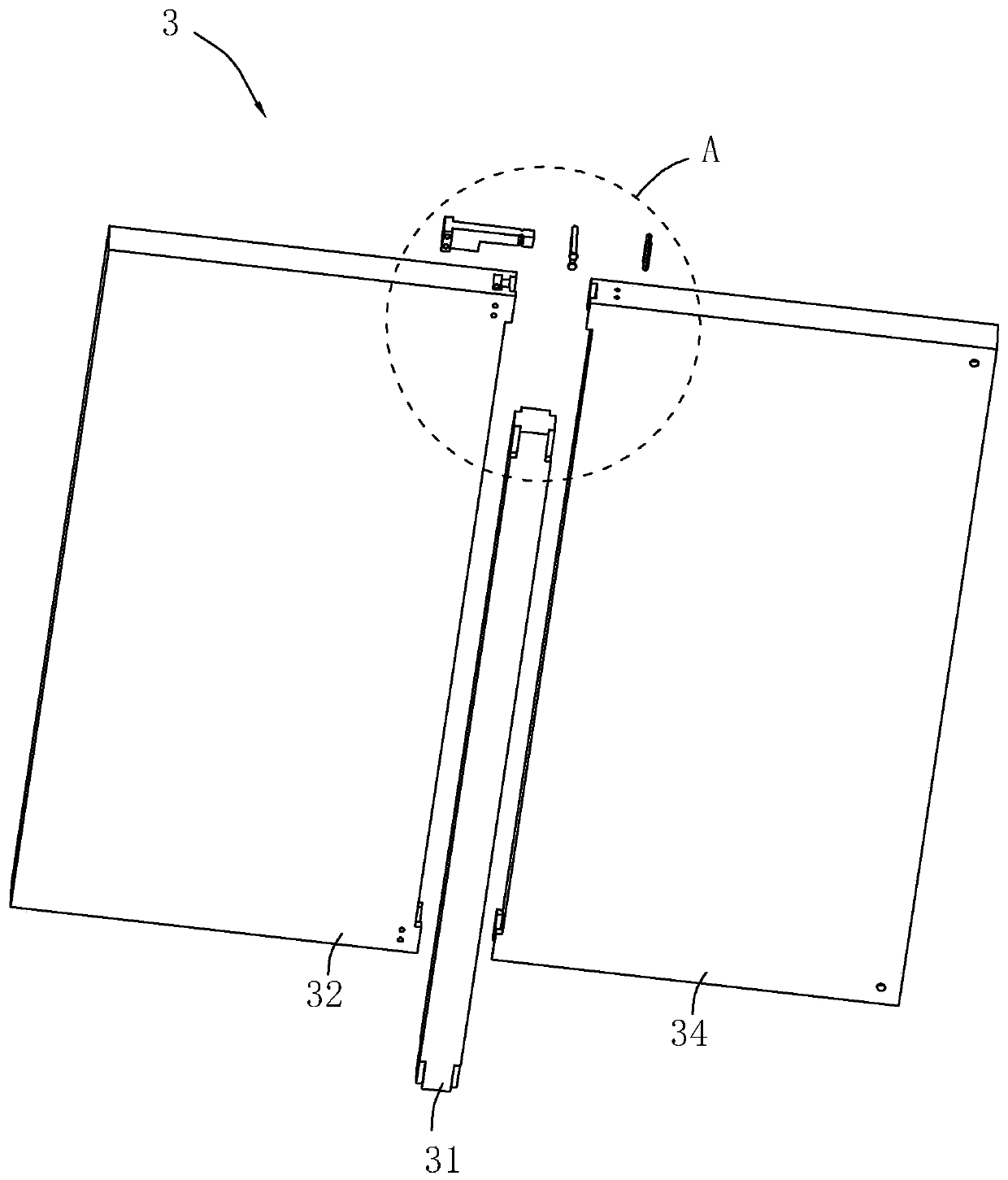

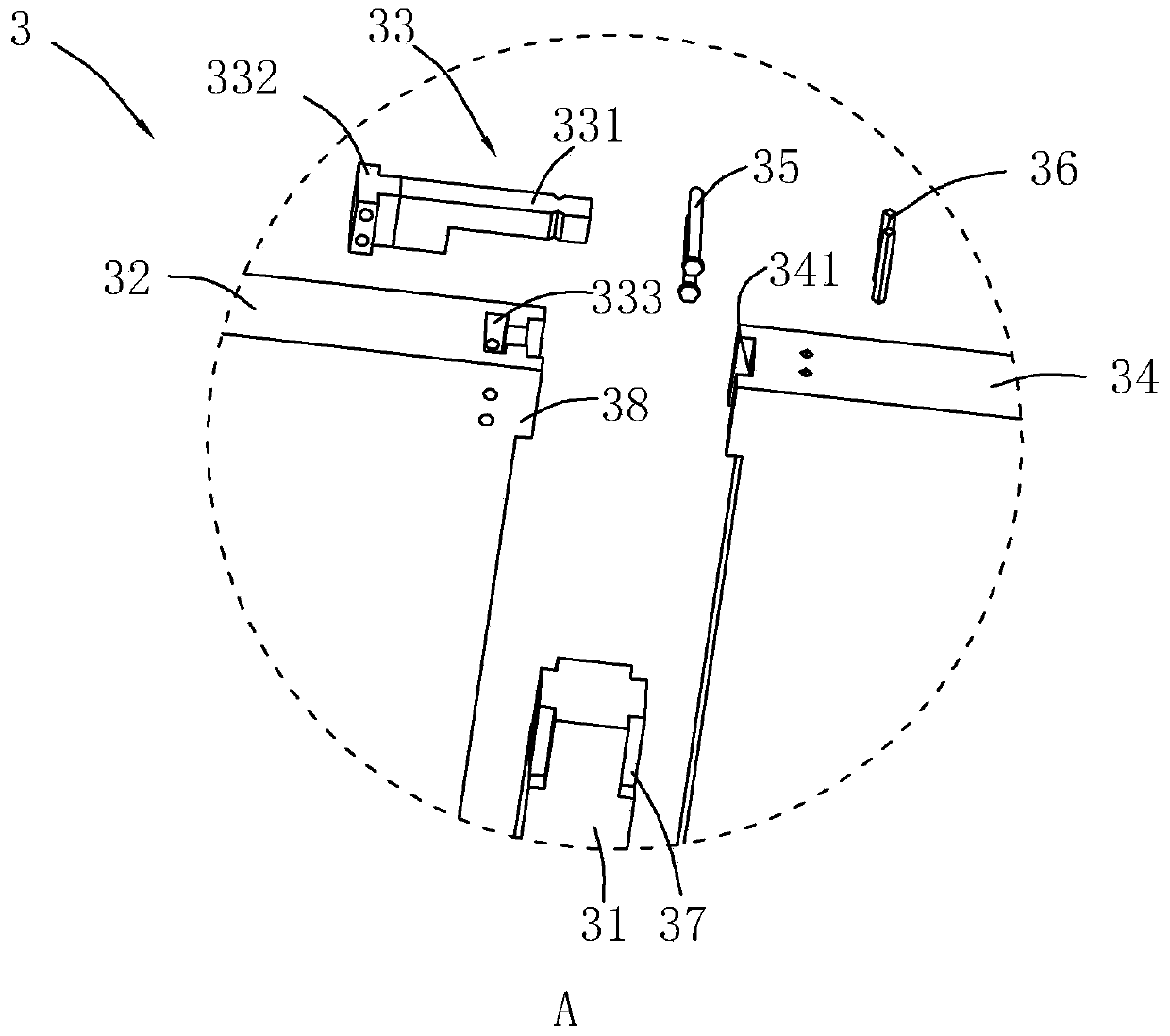

[0046] refer to figure 2 and image 3 , the inner plate mechanism 3 includes a first connecting rod 31, a first inner plate 32, a second inner plate 34, an inner plate assembly 33, a first fastening assembly 35 and a second fastening assembly 36, on the same first connecting rod 31 Two inner panel assemblies 33 are connected.

[0047] refer to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com