A variable-diameter self-adaptive combing tool for banana fruit shafts based on wire cutting

A technology of wire cutting and combing, which is applied in the field of wire cutting variable-diameter self-adaptive banana fruit shaft combing cutter, which can solve the problems of short radial expansion stroke, long tool recovery time, and large cutting gap, so as to reduce the recovery time , to provide the effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with specific examples.

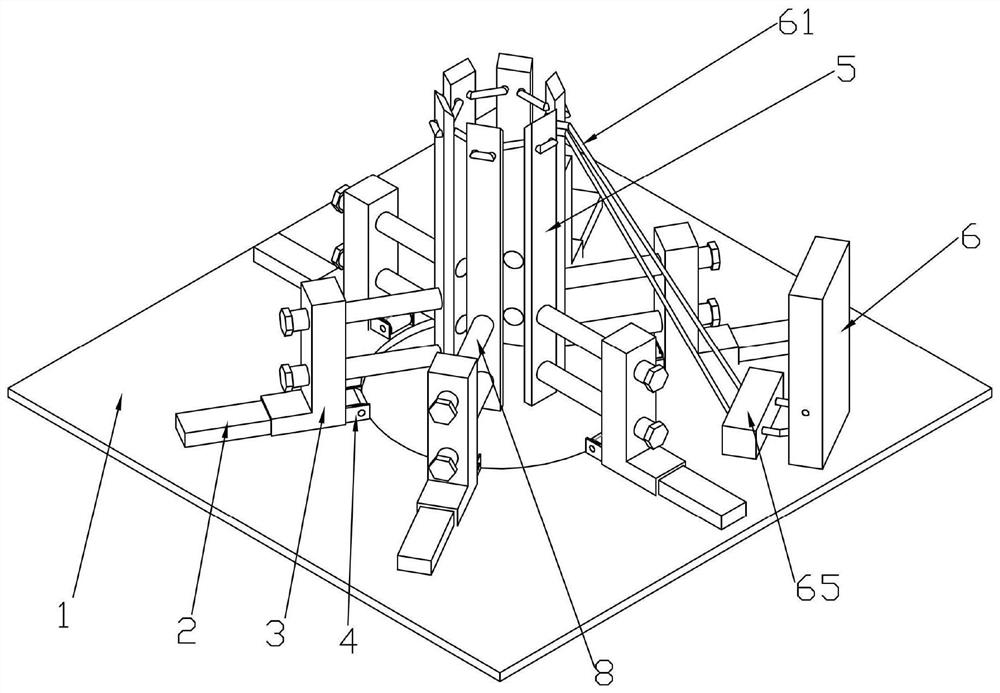

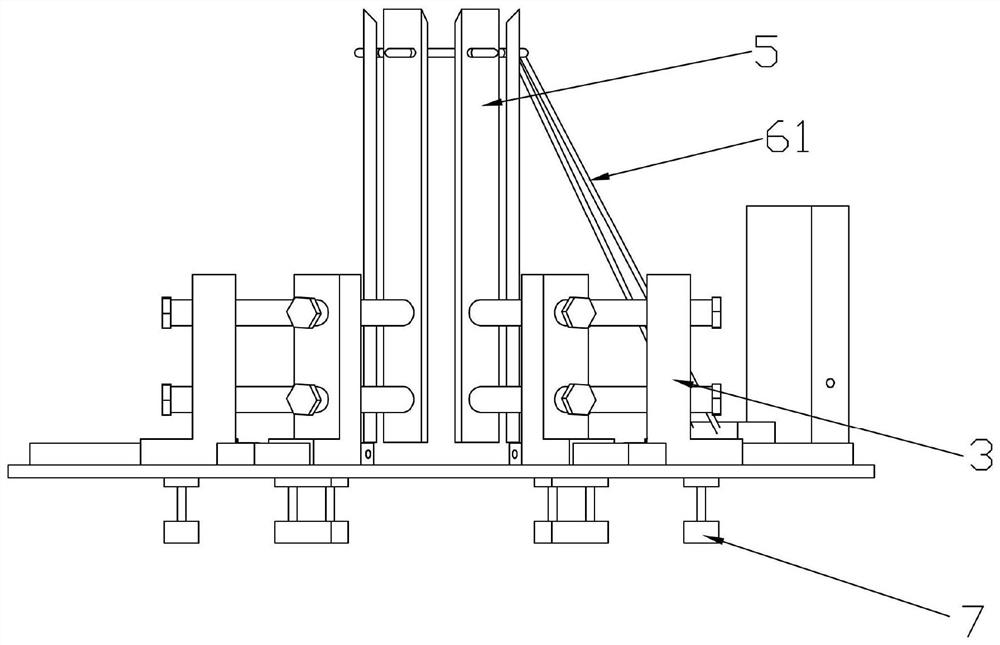

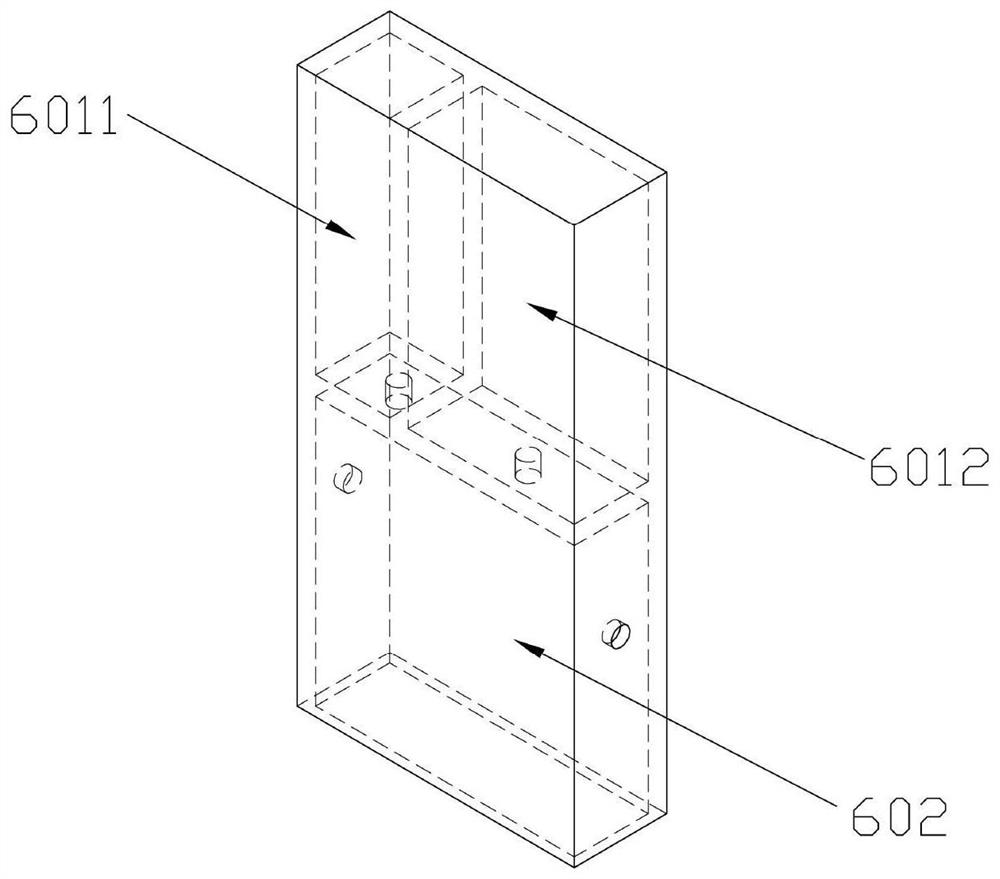

[0015] like Figure 1 to Figure 2 As shown, the self-adaptive banana fruit shaft combing tool based on wire cutting variable diameter described in this embodiment includes a cutter head 1, a power source 7 (this embodiment is an impact cylinder), a linear guide rail 2, an L-shaped slide block 3, Constant force coil spring 4, comb blade 5, retractor 6 with metal wire 61; the center of the cutter head 1 has a through hole for the banana fruit shaft after combing to pass through, and the linear guide rail 2 There are multiple, and the center of the through hole of the cutter head 1 is a circular array on the cutter head 1, and an L-shaped slider 3 is installed on each linear guide rail 2, and each L-shaped slider 3 is close to the through hole One side of the center is connected with a constant force coil spring 4, and the constant force coil spring 4 is fixed on the cutterhead ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com