Variable-diameter self-adaptive banana stalk carding cutter based on linear cutting

A wire-cutting and drop-comb technology is applied in the field of wire-cut variable-diameter adaptive banana fruit shaft drop-comb cutters, which can solve the problems of short radial expansion stroke, long tool recovery time, large cutting gap, etc. , to provide the effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with specific examples.

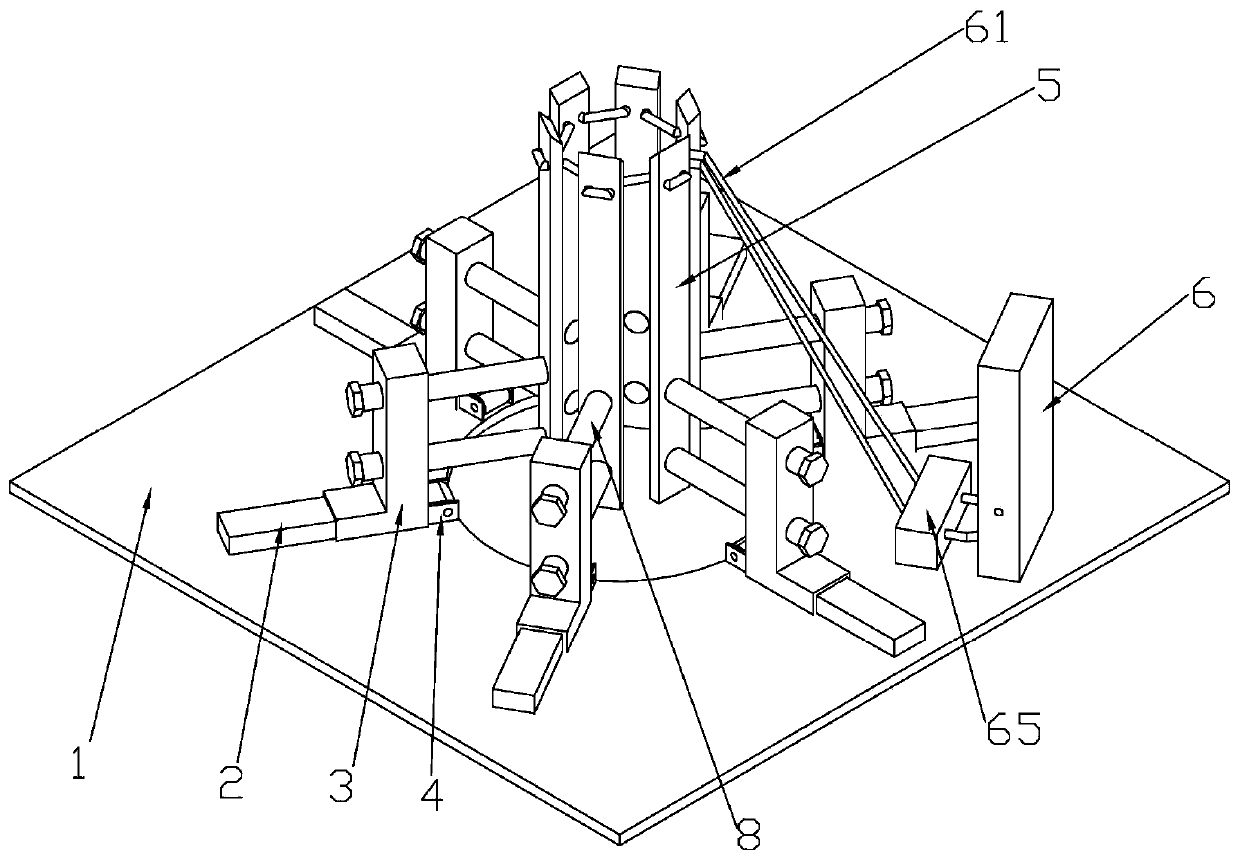

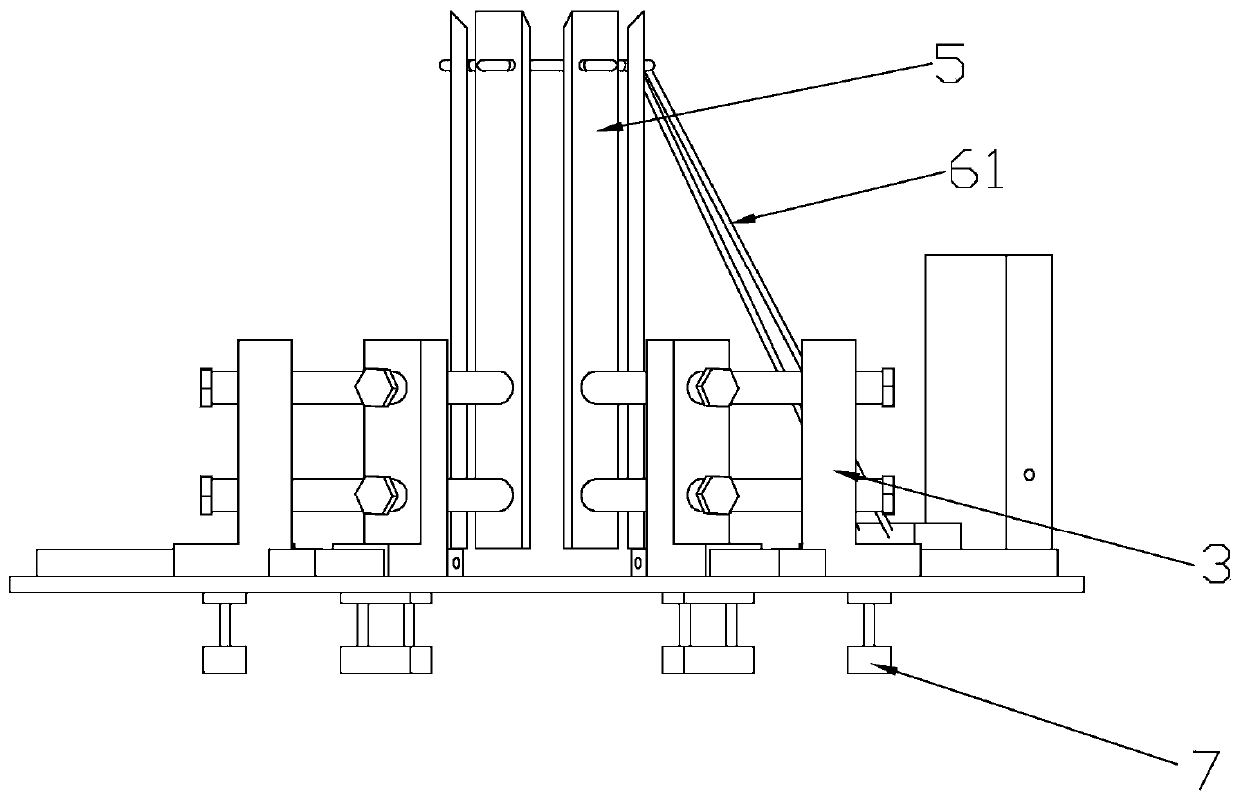

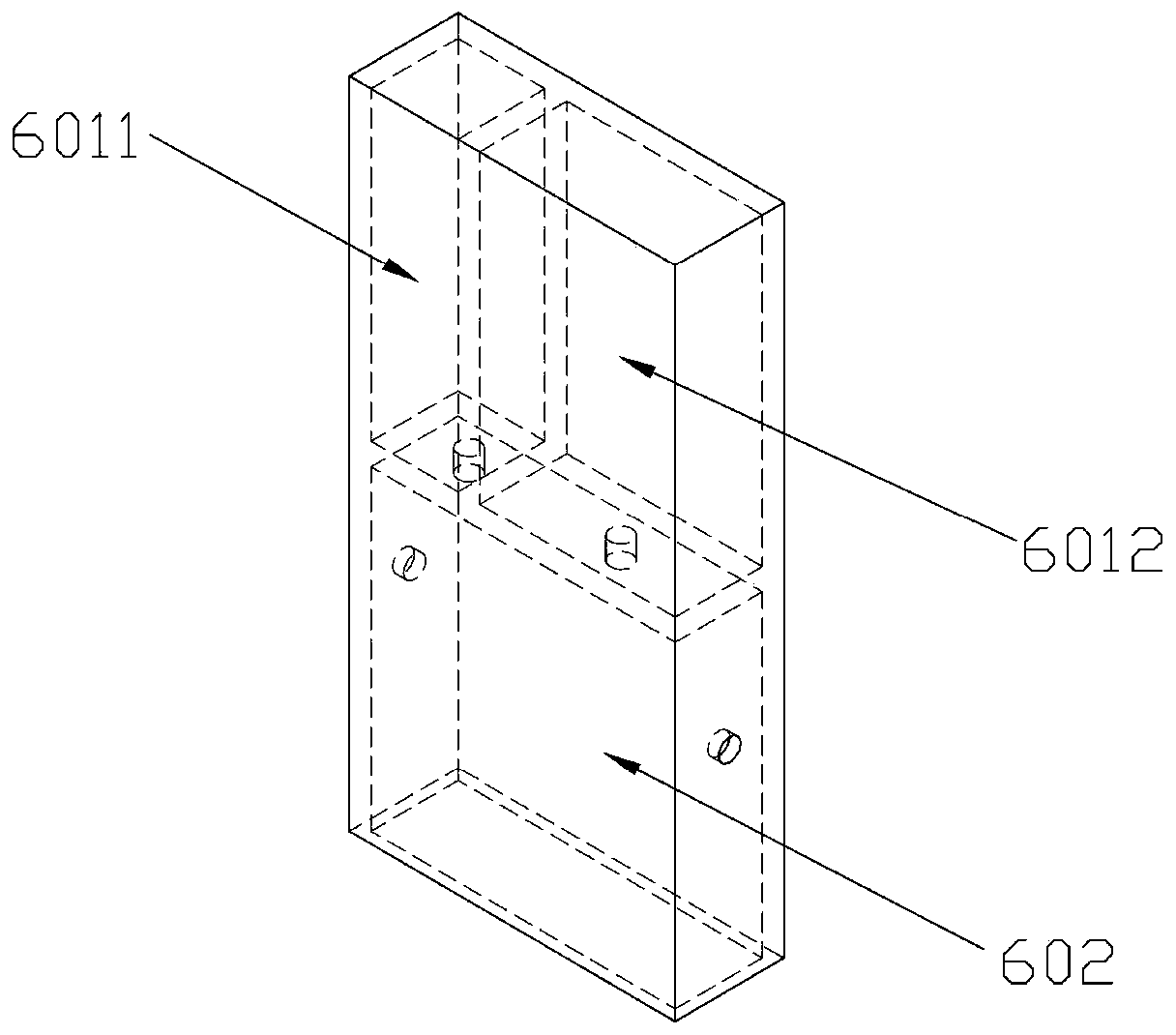

[0015] Such as Figure 1 to Figure 2 As shown, the self-adaptive banana fruit shaft combing tool based on wire cutting variable diameter described in this embodiment includes a cutter head 1, a power source 7 (this embodiment is an impact cylinder), a linear guide rail 2, an L-shaped slide block 3, Constant force coil spring 4, comb blade 5, retractor 6 with metal wire 61; the center of the cutter head 1 has a through hole for the banana fruit shaft after combing to pass through, and the linear guide rail 2 There are multiple, and the center of the through hole of the cutter head 1 is a circular array on the cutter head 1, and an L-shaped slider 3 is installed on each linear guide rail 2, and each L-shaped slider 3 is close to the through hole One side of the center is connected with a constant force coil spring 4, and the constant force coil spring 4 is fixed on the cutterhe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com