Crankshaft flange coupling device

A coupling and big head technology, which is applied in the field of crankshaft big head coupling devices, can solve the problems of crankshaft flange, crankshaft flange surface damage, labor force, engine assembly, etc., and achieve simple operation, uniform force, and satisfying crankshaft rotation The effect of speed requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in combination with specific embodiments. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

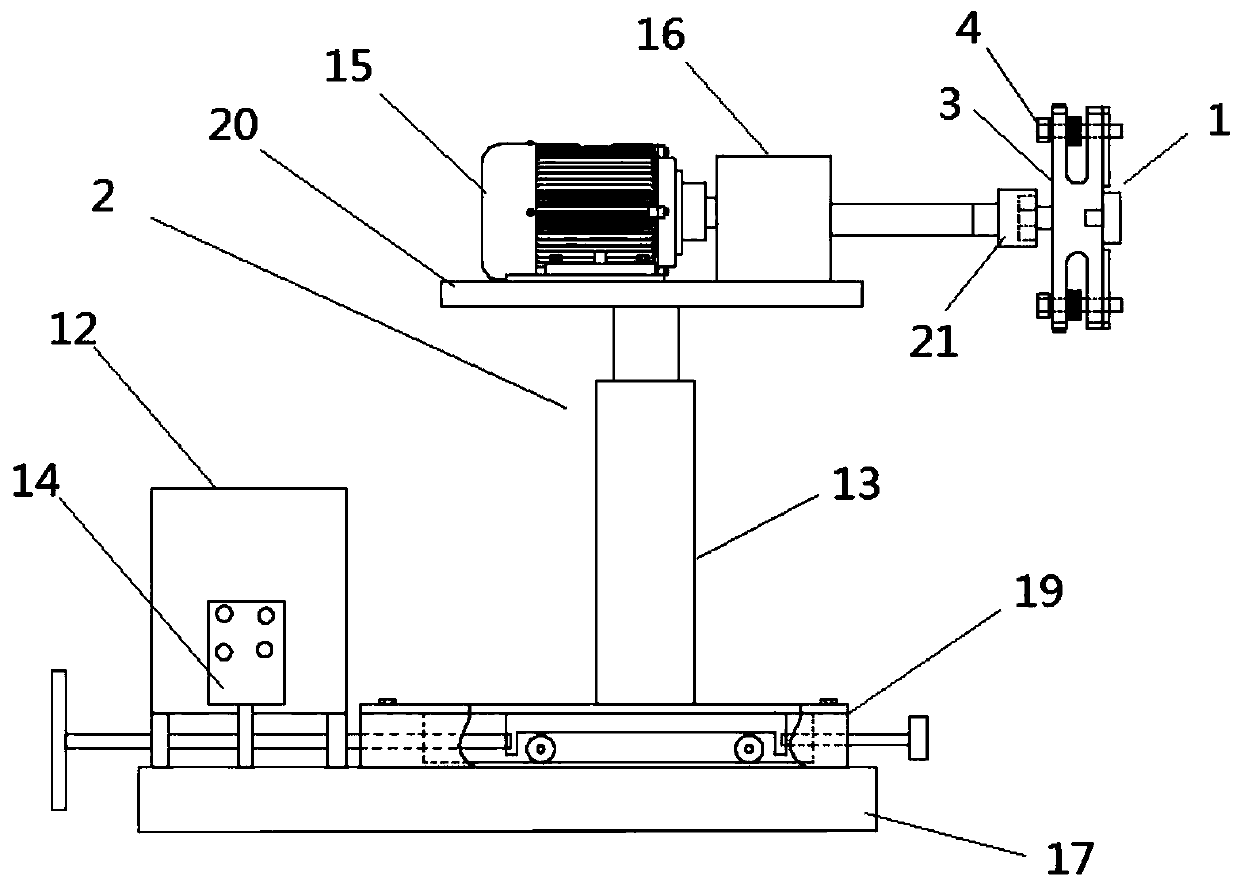

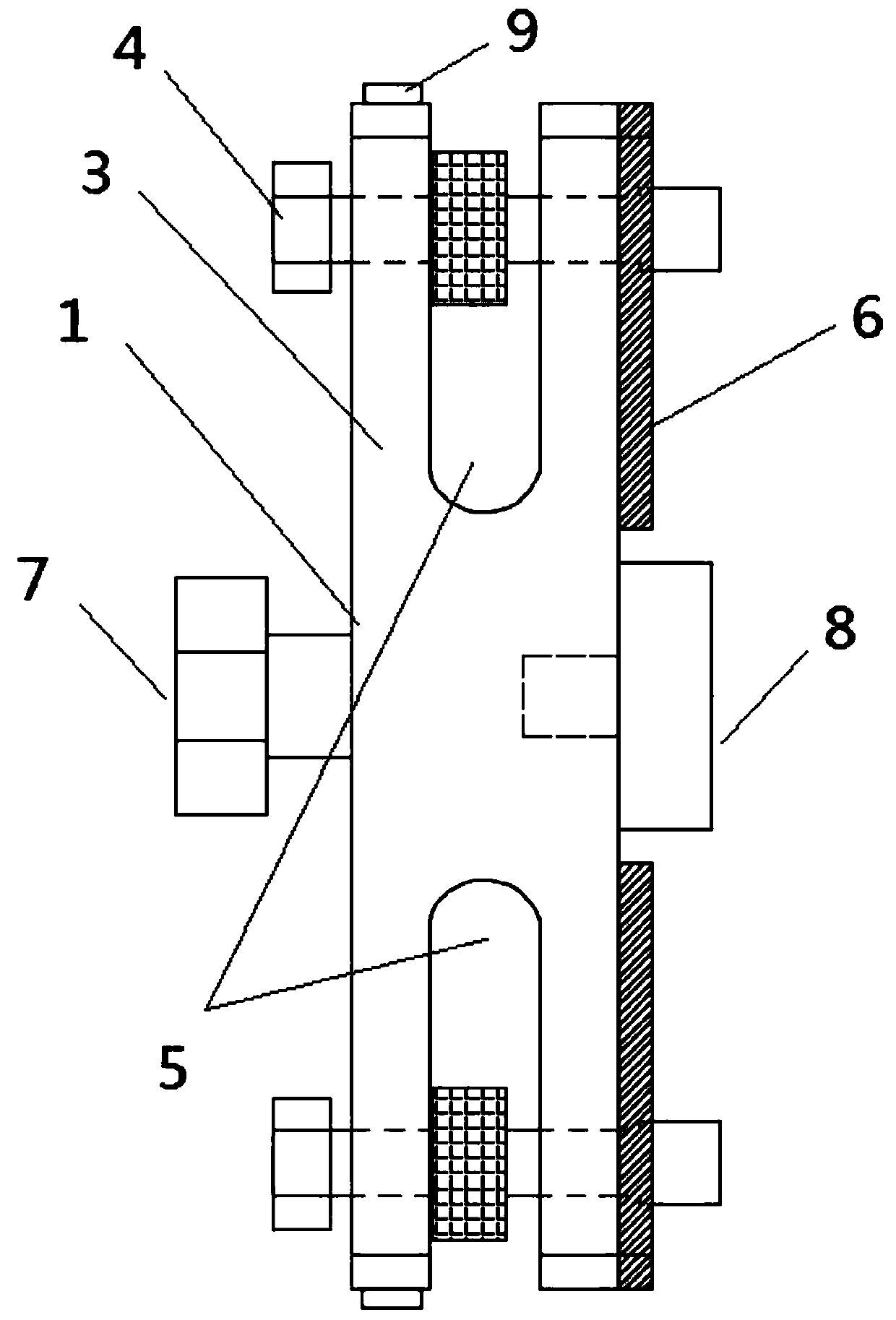

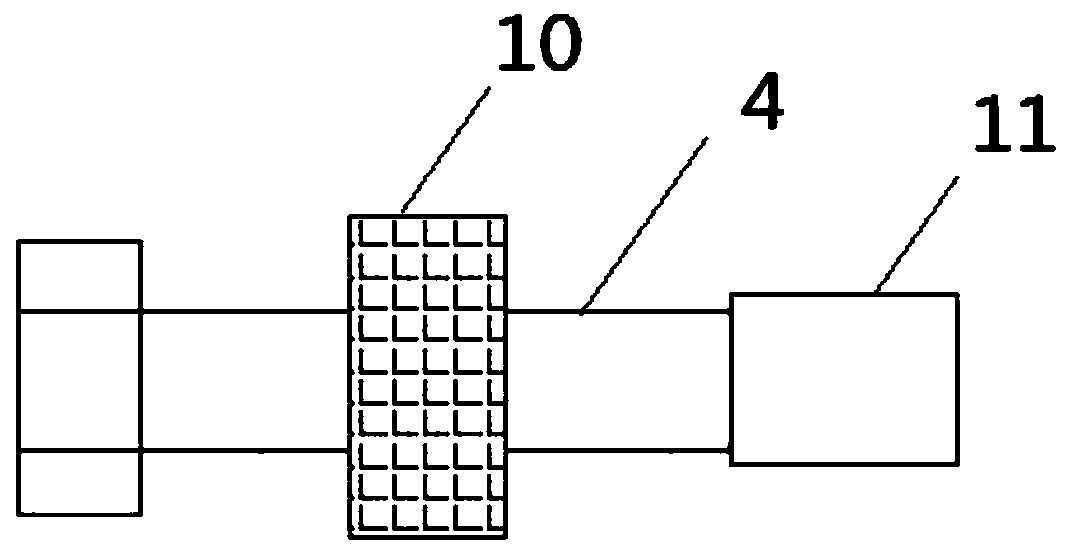

[0029] like Figure 1-9 As shown, a crankshaft large end coupling device is characterized in that: it includes a rotating arm frame assembly 1 and a rotating power group 2; the rotating arm frame assembly 1 includes a rotating arm 3 and a connecting bolt 4; the upper part of the rotating arm 3 and the lower part are respectively provided with symmetrical cross grooves 5, which are used to cooperate with the connecting bolts 4, and U-shaped rubber pads 6 are respectively arranged beside the cross grooves on the right side of the rotating arm 3, which are used to prevent the rotating arm 3 from contacting the crankshaft flange and causing Wear and tear, the U-shaped rubber pad 6 is larger than the cross notch, in order t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com