Erecting mechanism and operation vehicle with erecting mechanism

A frame and vehicle technology, which can be used in the direction of inclined load-carrying vehicles, vehicle maintenance, lifting vehicle accessories, etc. It can solve the problems of cumbersome, mechanical self-locking of the vehicle body support device, and complex operation of the system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

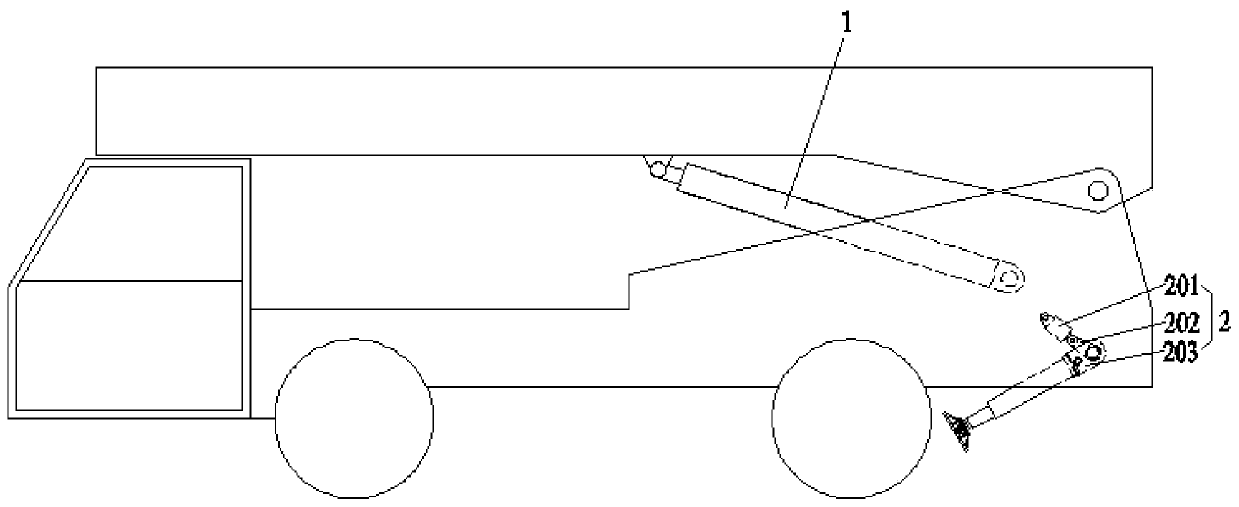

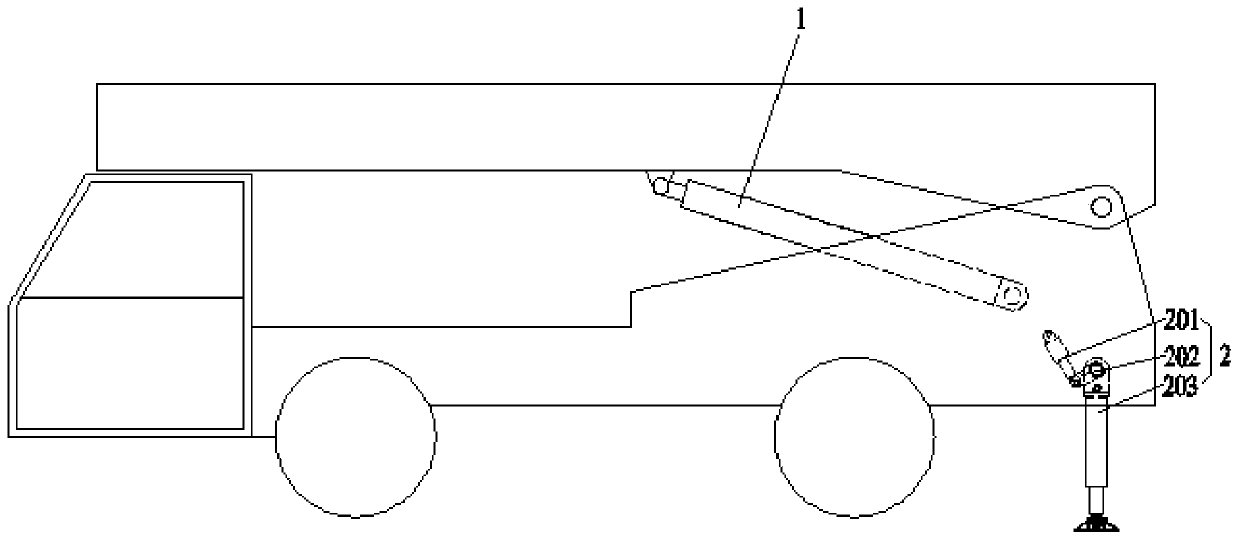

[0049] Such as figure 1 and figure 2 as shown, figure 1 It is a structural schematic diagram of the initial state of the swinging support leg 203 of the existing erecting mechanism, figure 2 It is a structural schematic diagram of the state that the support leg 203 of the existing erecting mechanism has completed the swing, from figure 1 and figure 2 It can be seen that this existing erecting mechanism is divided into two independent systems, one is the support of the car body, and the other is erecting the top.

[0050] The vehicle body support device 2 is used to support the vehicle to prevent the vehicle from overturning when it is toppled. The support leg 203 is connected with the swing hydraulic cylinder 201 of the outrigger, and an intermediate link 202 is also arranged between the two. Driving the middle link 202 to rotate, the middle link 202 drives the support leg 203 fixedly connected to the middle link 202 to rotate, and the support leg 203 can support the ve...

Embodiment 2

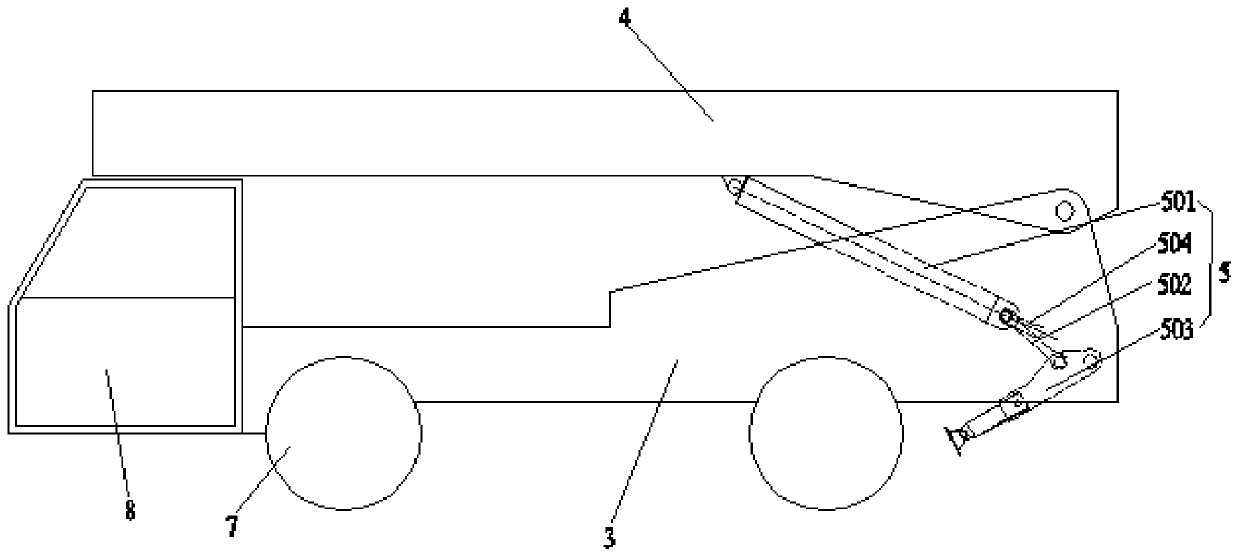

[0083] Such as image 3 and Figure 4 As shown, the work vehicle with the erecting mechanism is applied with the erecting mechanism described in Embodiment 1:

[0084] One end of the erecting telescopic member 501 is hinged with the top 4 of the vehicle, and the other end is hinged with one end of the connecting rod 502, and the other end of the connecting rod 502 is connected with the shaft or supporting end of the leg 503 , the end of the support leg 503 opposite to the support end is hinged to the frame 3, and the frame 3 and the bodywork 4 are hinged at the tails of both;

[0085] The erecting mechanism also includes a bar-shaped stop structure 504, and the range of movement of the hinge 505 connecting the erecting telescopic member 501 and the connecting rod 502 is limited by the bar-shaped stop structure 504 to control the The swing angle of the leg 503;

[0086] The hinged part 505 is fixed to the erecting telescopic part 501, and the limiting end point of the strip-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com