A kind of backlight module and display device

A technology of backlight module and display device, which is applied in the direction of identification device, printing device, projection device, etc., can solve the problems of increasing manufacturing cost, and achieve the effect of saving cost and avoiding glue dispensing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

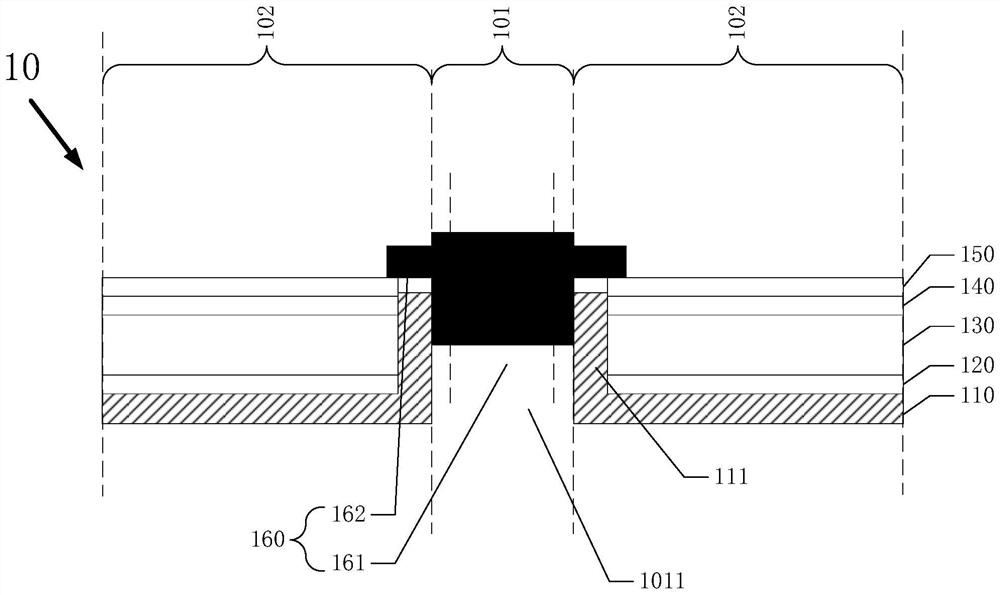

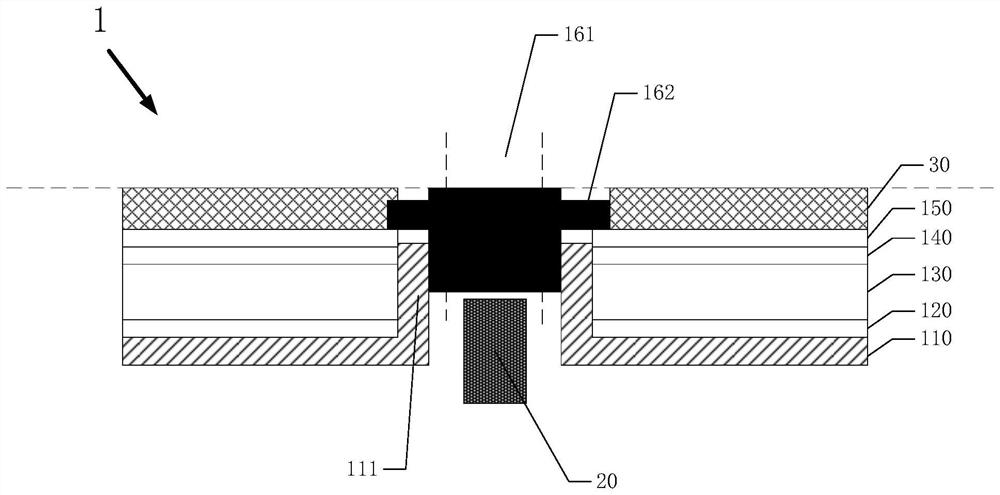

[0032] In this embodiment, the backlight module 10 of the present invention includes an imaging area 101 and a light emitting area 102 surrounding the imaging area 101 .

[0033] like figure 1 As shown, the backlight module 10 further includes an outer frame 110 , a reflective sheet 120 , a light guide plate 130 , a first prism sheet 140 and a second prism sheet 150 .

[0034] The outer frame 110 is disposed in the light-emitting area 102, wherein the outer frame 110 includes a bent portion 111, and the bent portion 111 is upward from the boundary between the imaging area 101 and the light-emitting area 102. Bend to block light.

[0035] The reflective sheet 120 is disposed on the outer frame 110 to reflect light directed toward the outer frame 110 to reduce light loss of the backlight module 10 and improve luminous efficiency.

[0036] The light guide plate 130 is arranged on the reflection sheet 120, and the material of the light guide plate 130 is acrylic or PC material, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com