A radiographic detection and positioning device for large-curvature hollow blades

A hollow blade, ray detection technology, applied in the field of ray detection, can solve the problems of inability to distinguish the quality of the inner cavity of the blade, image occlusion, etc., and achieve the effect of ensuring the detection quality and enhancing the image contrast.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

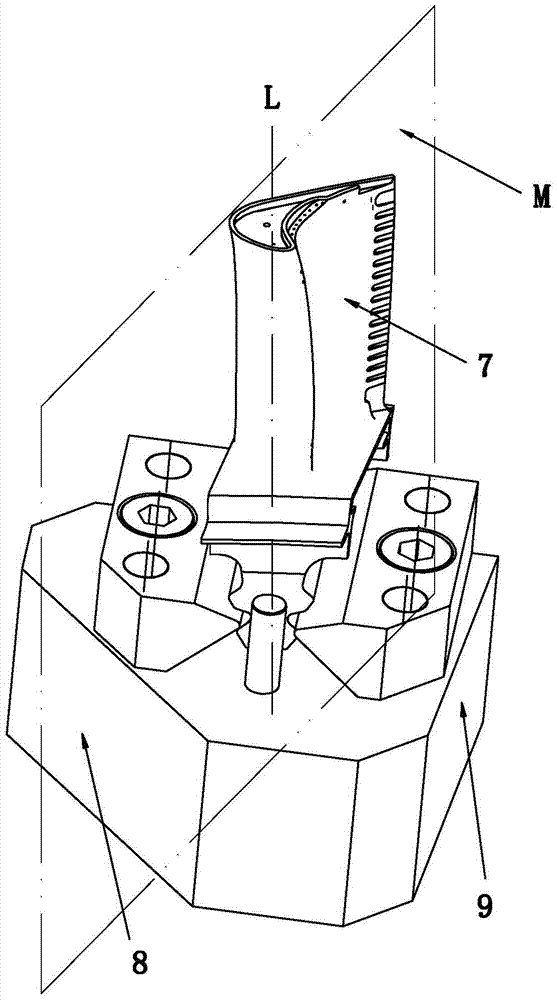

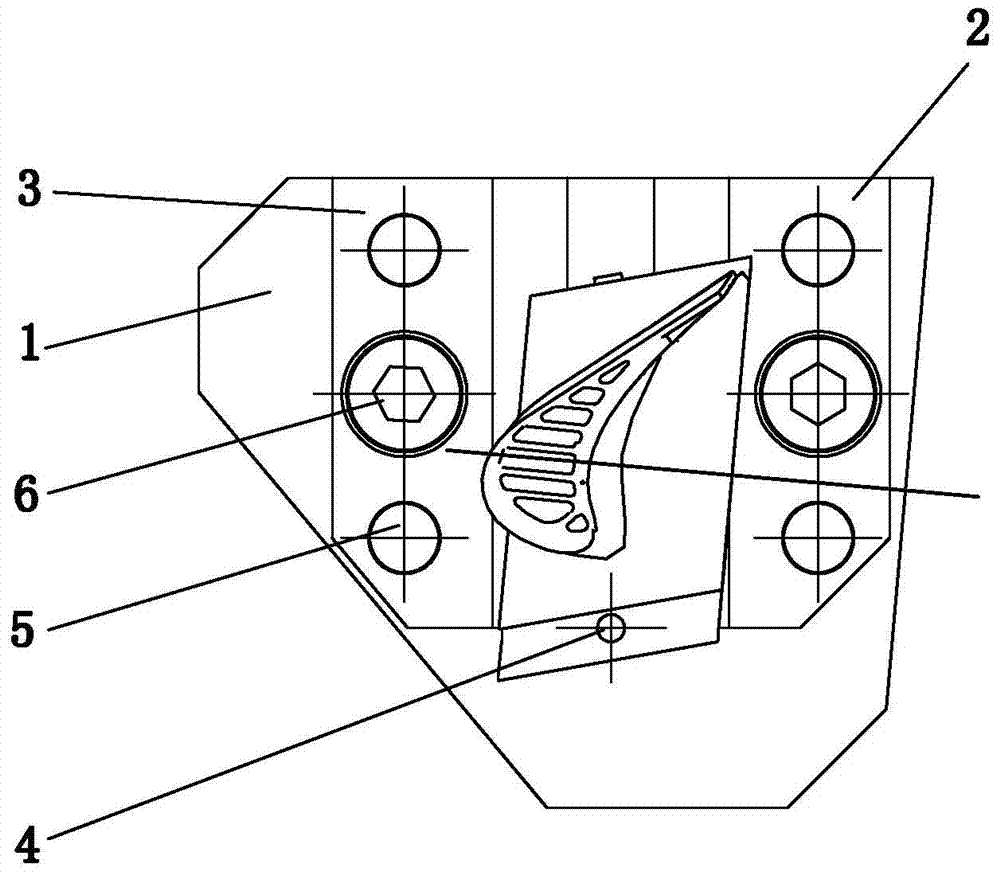

[0014] Example: such as Figure 1-Figure 3 As shown, the present invention includes a support 1, a positioning block I2, a positioning block II3 and a limit pin 4. The clamping ends of the positioning block I2 and the positioning block II3 are symmetrically placed on the support 1, and are respectively passed through a cylindrical pin 5 and a The hexagonal socket head screw 6 is fixed, the support 1 has two profiles with different angles, and one end between the two positioning blocks I2 and the positioning block II3 on the angled end of the support 1 is provided with a limit pin 4, two The clamping end surface of the positioning block cooperates with the tenon of the blade.

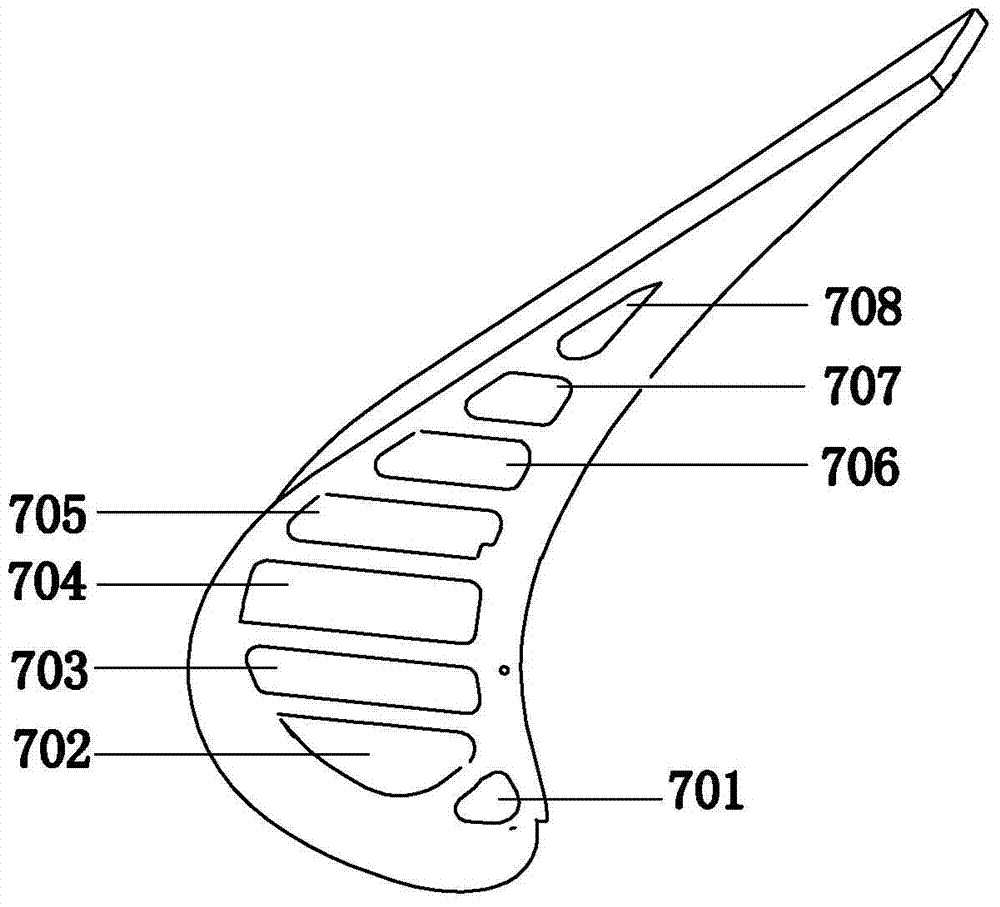

[0015] Such as figure 2 As shown, the profiles I8 and II9 are respectively parallel to the axis L of the blade cavity, and the vertical plane M of the profile containing the axis L of the blade cavity does not intersect any cavity of the blade body. Profile I8 is used to detect cavities 701 and 702 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com