Bending-resistant cable with anti-interference function and manufacturing method thereof

A technology of bending resistance and cables, which is applied in the direction of bendable cables, cable/conductor manufacturing, insulated cables, etc., can solve the problems of lack of bending resistance and anti-interference, and achieve the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

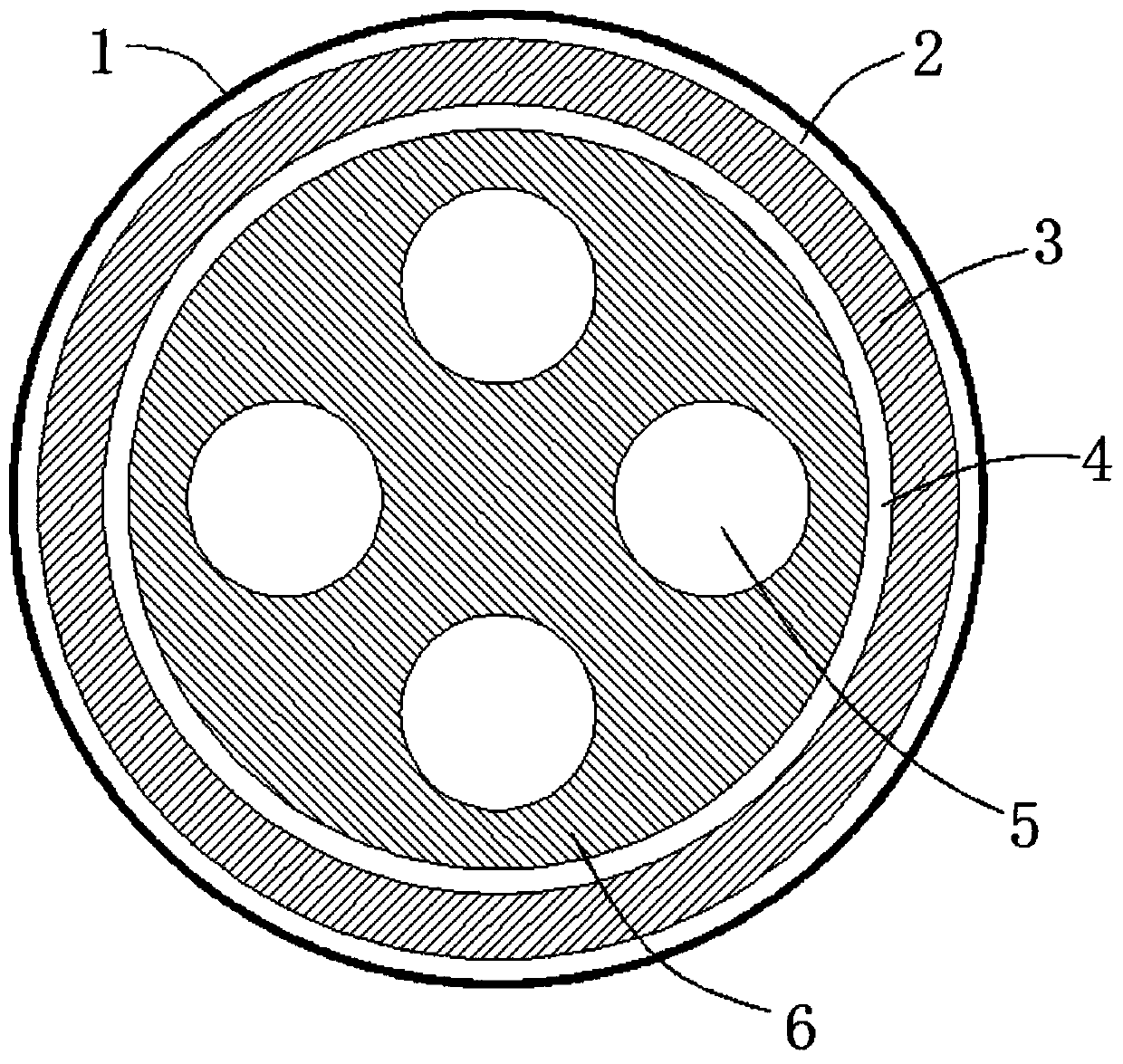

[0025] refer to Figure 1-2 , a bending-resistant cable with anti-interference function, comprising an outer protective shell 2 and an inner protective shell 4, the inner protective shell 4 is located inside the outer protective shell 2, and multiple sets of inner cores 5 are arranged inside the inner protective shell 4, the inner protective shell 4 A filling layer 6 is provided between the core 5 and the inner side of the inner protective shell 4, and the filling layer 6 is specifically an insulating rubber particle layer, and the inner surface of the outer protective shell 2 and the outer surface of the inner protective shell 4 are compositely bonded with an extension layer 3;

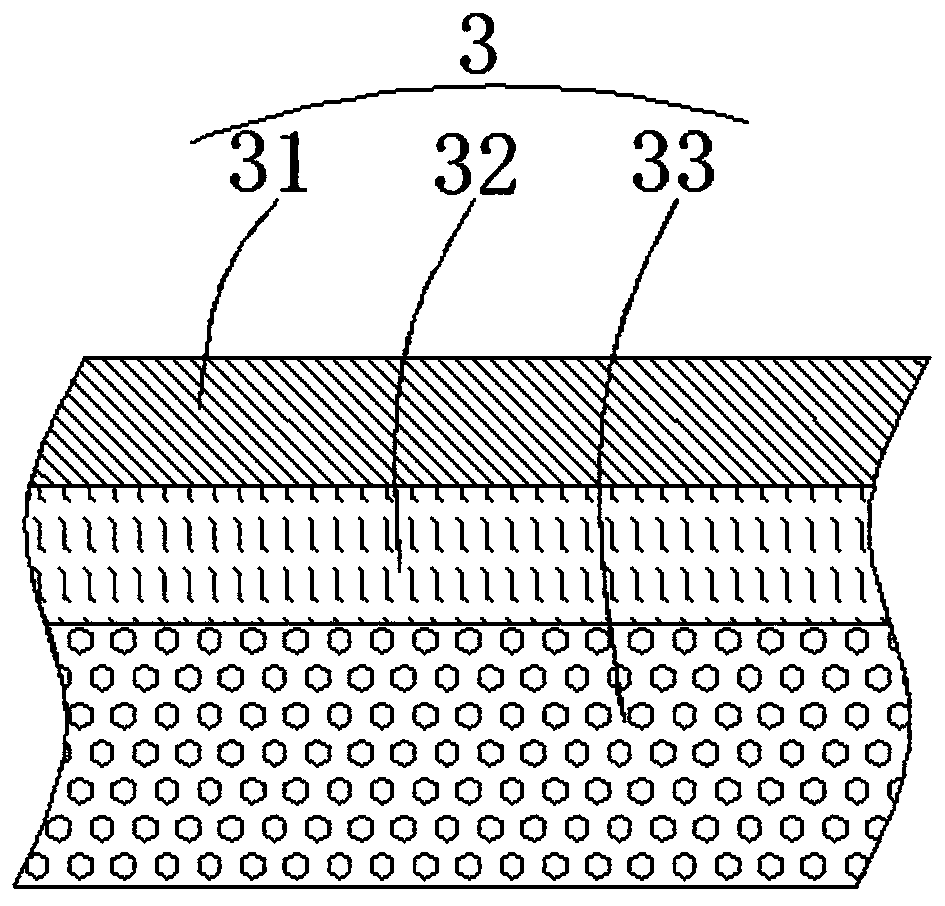

[0026] The extension layer 3 includes a natural fiber layer 33 compositely bonded to the outer surface of the inner protective shell 4 and a TPE layer 31 compositely bonded to the inner surface of the outer protective shell 2, and a glass fiber layer 32 is filled between the TPE layer 31 and the natur...

Embodiment 2

[0034] refer to Figure 1-2 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that a bending-resistant cable with anti-interference function includes an outer protective shell 2 and an inner protective shell 4, and the inner protective shell 4 is located in the outer protective shell 2, the inside of the inner protective shell 4 is provided with multiple groups of inner cores 5, and a filling layer 6 is arranged between the inner core 5 and the inner side of the inner protective shell 4, and the filling layer 6 is specifically an insulating rubber particle layer, and the outer protective shell 2 The inner surface and the outer surface of the inner protective shell 4 are compositely bonded with an extension layer 3;

[0035] The extension layer 3 includes a natural fiber layer 33 compositely bonded to the outer surface of the inner protective shell 4 and a TPE layer 31 compositely bonded to the inner surface of the outer protective ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com