Draw shaft intelligent monitoring device

A technology of intelligent monitoring and equipment, applied in mechanical equipment, TV, color TV, etc., can solve the problems of low monitoring efficiency, stop of conveying operation, danger of monitoring personnel, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

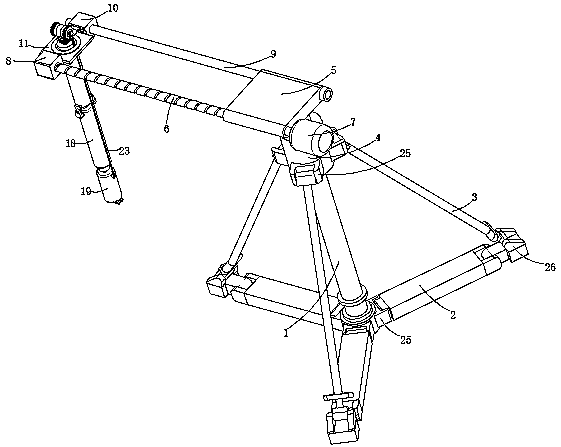

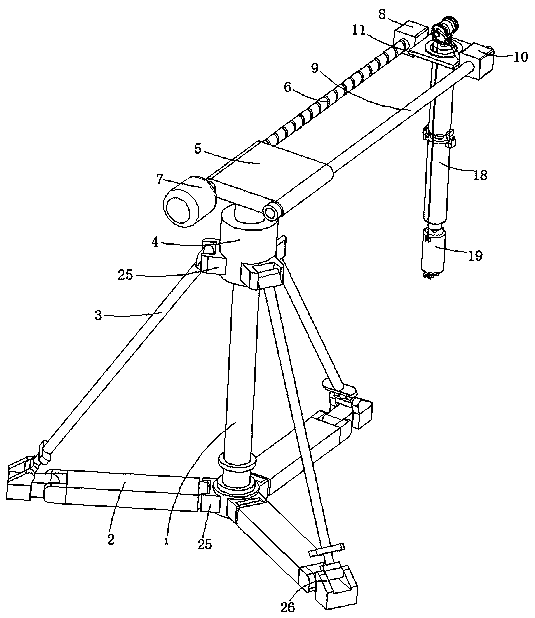

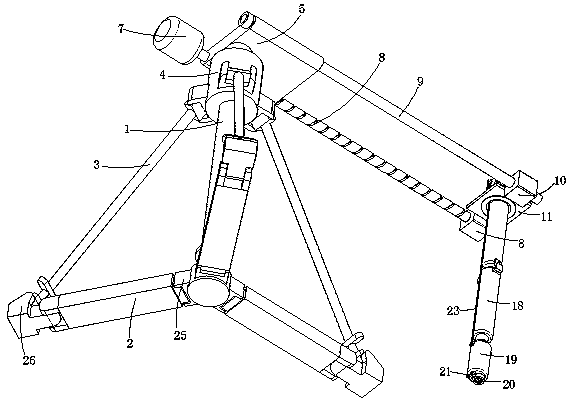

[0034] refer to Figure 1-7 , an intelligent monitoring device for a chute, comprising a vertical rod 1, the outer wall of the bottom end of the vertical rod 1 is rotatably connected with a circumferentially distributed bottom rod 2, the end of the bottom rod 2 away from the vertical rod 1 is rotatably connected with a side support rod 3, and the vertical rod 1 The top of the mounting block 4 is fixedly provided with a mounting block 4, and the end of the side support rod 3 away from the bottom rod 2 is connected to the mounting block 4 in rotation; the top of the mounting block 4 is fixed with a fixed block 5, and one side of the fixed block 5 is rotatably connected with a ball screw 6 , one end of the ball screw 6 is provided with a drive motor 7, the other end of the ball screw 6 is provided with a screw nut 8 used in conjunction with it, and the other side of the fixed block 5 is fixed with a limit rod 9, and the limit rod 9 is arranged in parallel with the ball screw 6, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com