Telescopic decelerating and limiting wheel for mini tiller

A technology of limit wheel and micro-tiller, which is applied in the field of micro-tiller, can solve the problems that the four-wheel drive micro-tiller cannot be used normally, the downforce pressure is not suitable to be controlled, and the operation is inconvenient to use, etc., to achieve clever design and elongated push rod Effects that are fast and easy to transform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

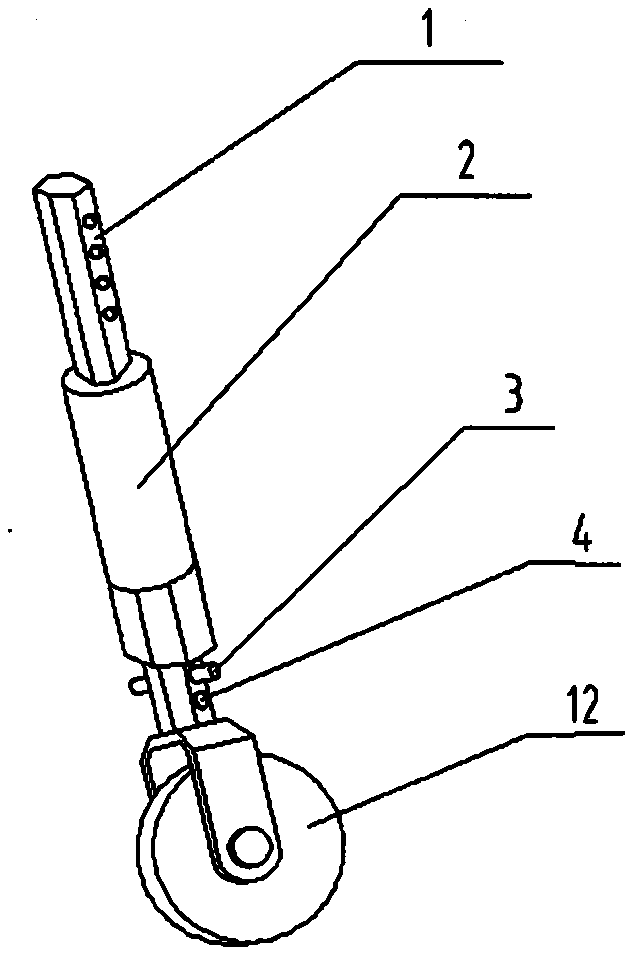

Embodiment 1

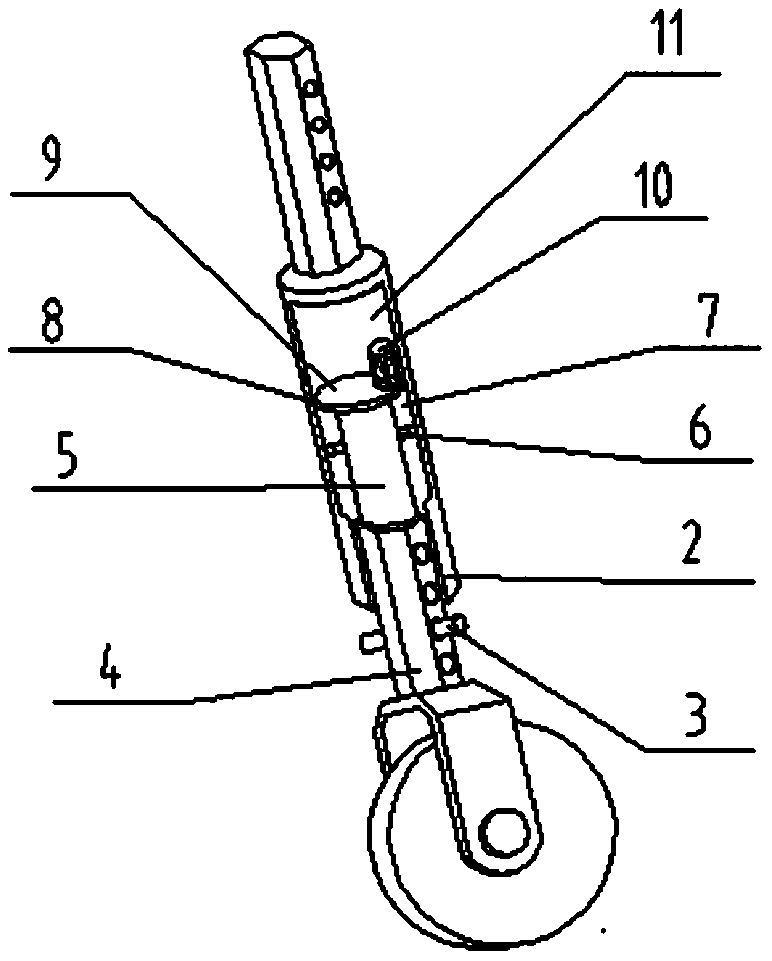

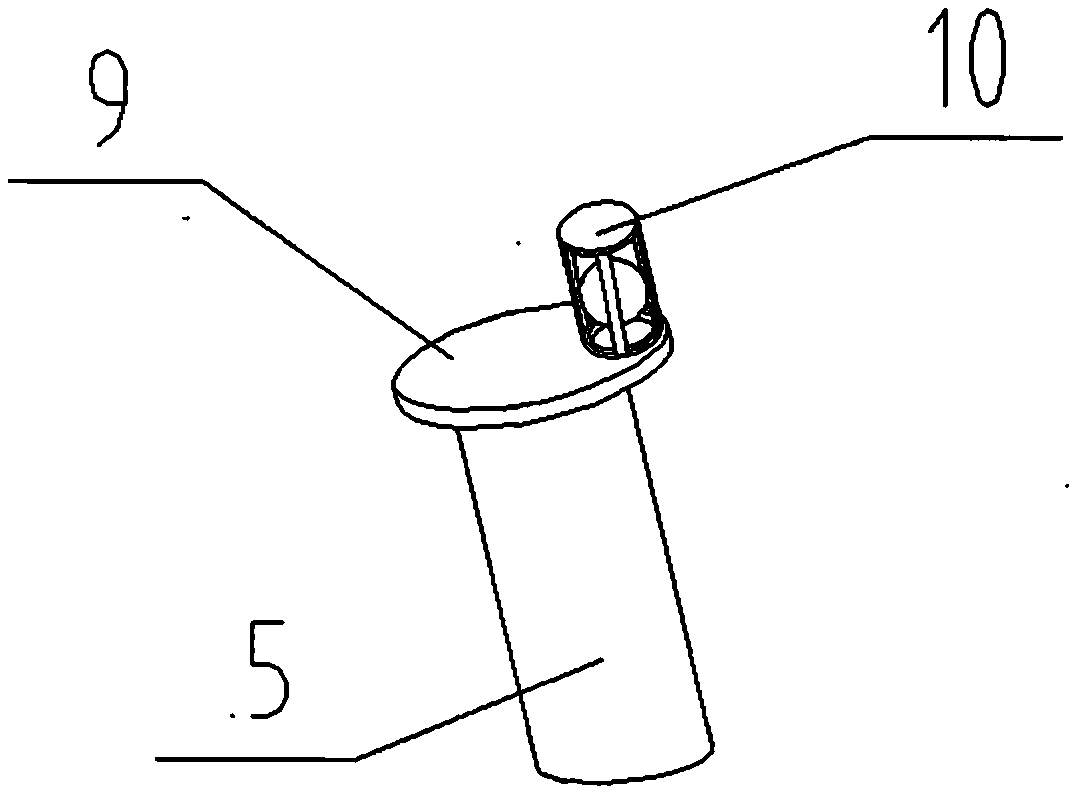

[0033] The elongation process of the telescopic and slow-moving limit wheel of the micro-tiller: During the operation of the four-wheel drive micro-tiller, when the rear transmission box and the tiller touch the hard ground, the tiller will generate an upward elastic force , the rear cultivating knife will move up, so that the limit wheel is suspended. The gravity of the push rod and the limit wheel acts on the push plate, which pulls the push plate to move downward, so that the hydraulic oil in the lower cavity flows upward through the gap between the push plate and the cavity inner wall and the hydraulic oil one-way flow device. Because the two passages flow at the same time, the hydraulic oil flows quickly and the push rod elongates quickly. The push rod elongates to make the roller contact the ground, and the stop push plate moves downward after the limit wheel contacts the ground, and the hydraulic oil flow in the cavity stops. At this time, the cutter enters the soil sh...

Embodiment 2

[0036] The shortening process of the telescopic and slow-moving limit wheel of the micro tillage machine: During the operation of the four-wheel drive micro tiller, when the rear transmission box and the tiller touch the soft ground, the tiller will produce a force of gravity to move down. When the limit wheel is squeezed by the ground, the limit wheel will move up, and the limit wheel will exert the extrusion force on the push plate through the push rod, and push the push plate to move upward, so that the hydraulic oil in the upper cavity passes through the push plate and the air cavity. Slits in the inner wall of the cavity flow down the cavity. The hydraulic oil one-way flow device is closed, because the hydraulic oil flows in one channel, the hydraulic oil flows slowly, and the push rod shrinks slowly. Because of the slow shortening speed of the push rod, the downward movement speed of the rear cultivator is slow. In order to avoid excessive engine load, causing the engin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com