Magnetic separation device for solid ferromagnetic wastes

A magnetic separation and magnetic separation device technology, applied in solid separation, magnetic separation, chemical instruments and methods, etc., can solve the problems of shortening the service life of magnetic separation equipment, energy waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

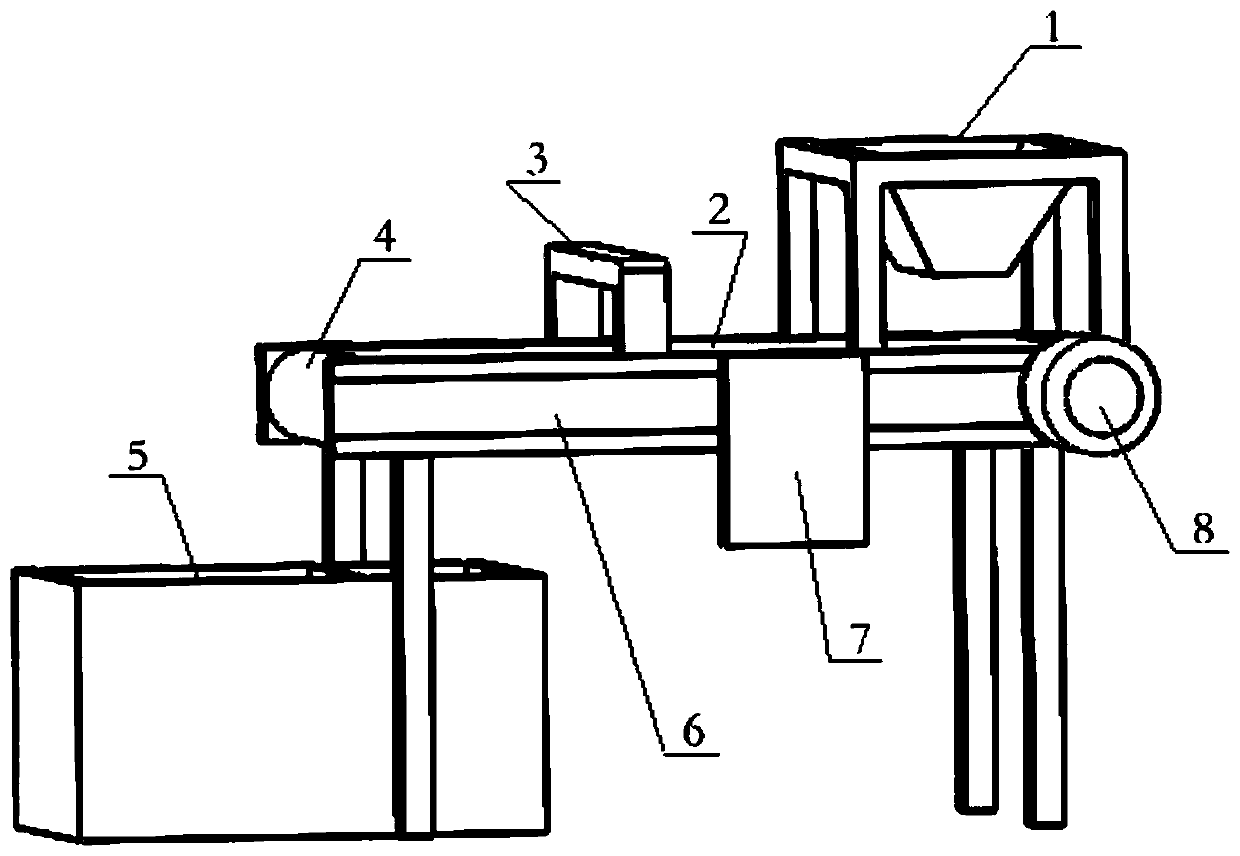

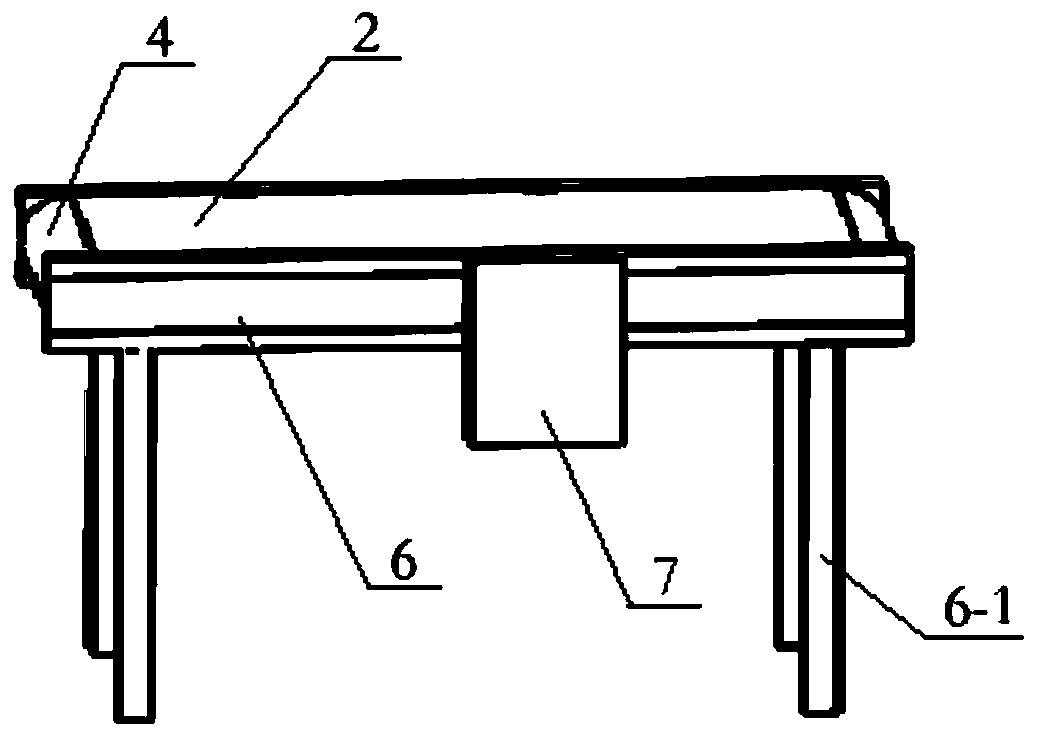

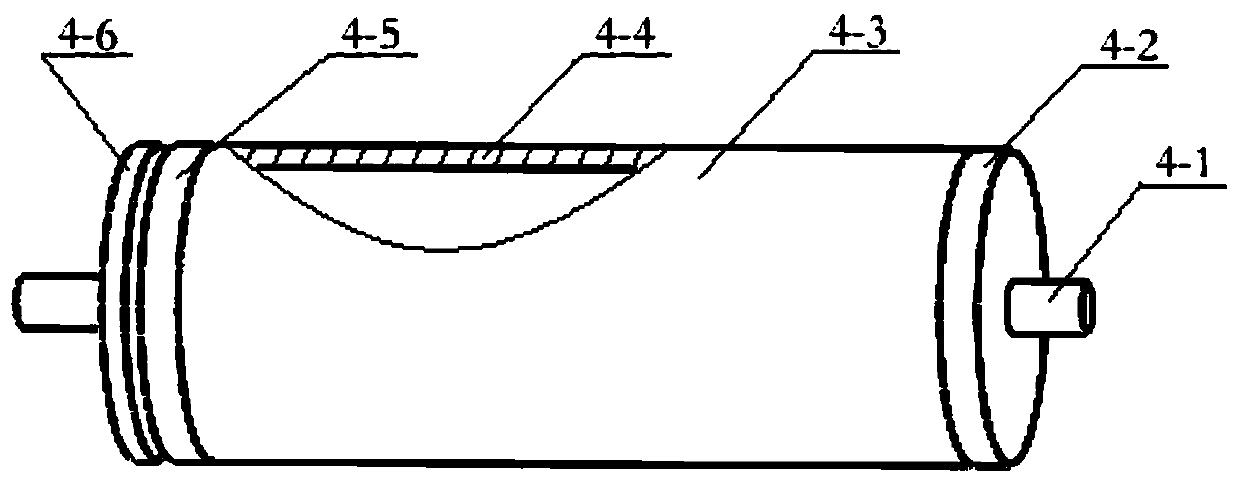

[0028] A magnetic separation device for solid ferromagnetic waste according to the present invention, when the magnetic separation is started, the waste to be separated is evenly distributed on the feeding conveyor belt (2) through the feeding port (1); When the waste moves forward with the feeding conveyor belt (2) and passes the metal detection device (3), the metal detection device (3) can detect the amount of ferromagnetic materials contained in the waste when it passes through, and will detect The signal is transmitted to the controller (7); the controller (7) judges the required magnetic field strength and the magnitude of the magnetic field force according to the received signal of the ferromagnetic material content, and accordingly changes the input coil core (4-4)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com