Left wheel shifting rod lubricating grease atomization spraying system

A technology of lubricating grease and atomizing spray guns, which is applied in spraying devices, liquid spraying devices, etc., and can solve problems such as uneven spraying and low spraying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

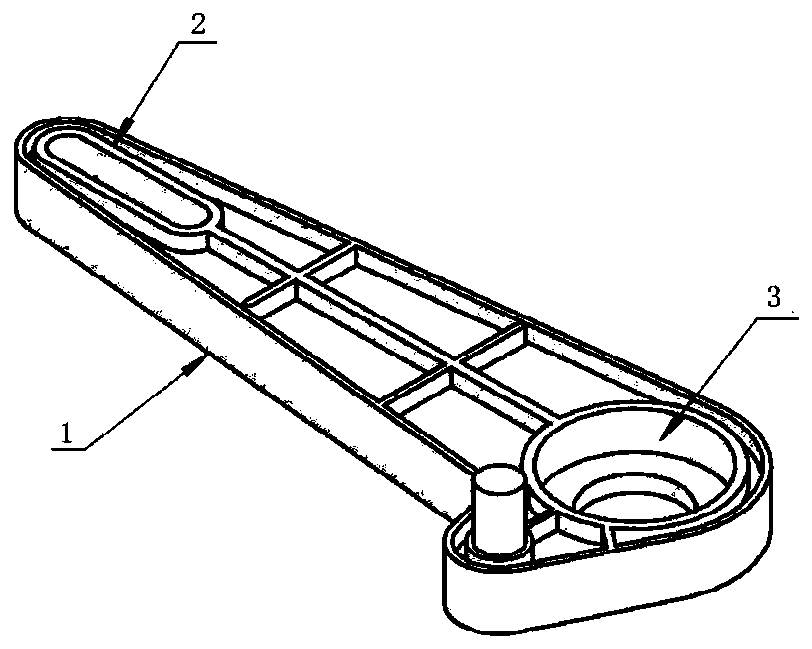

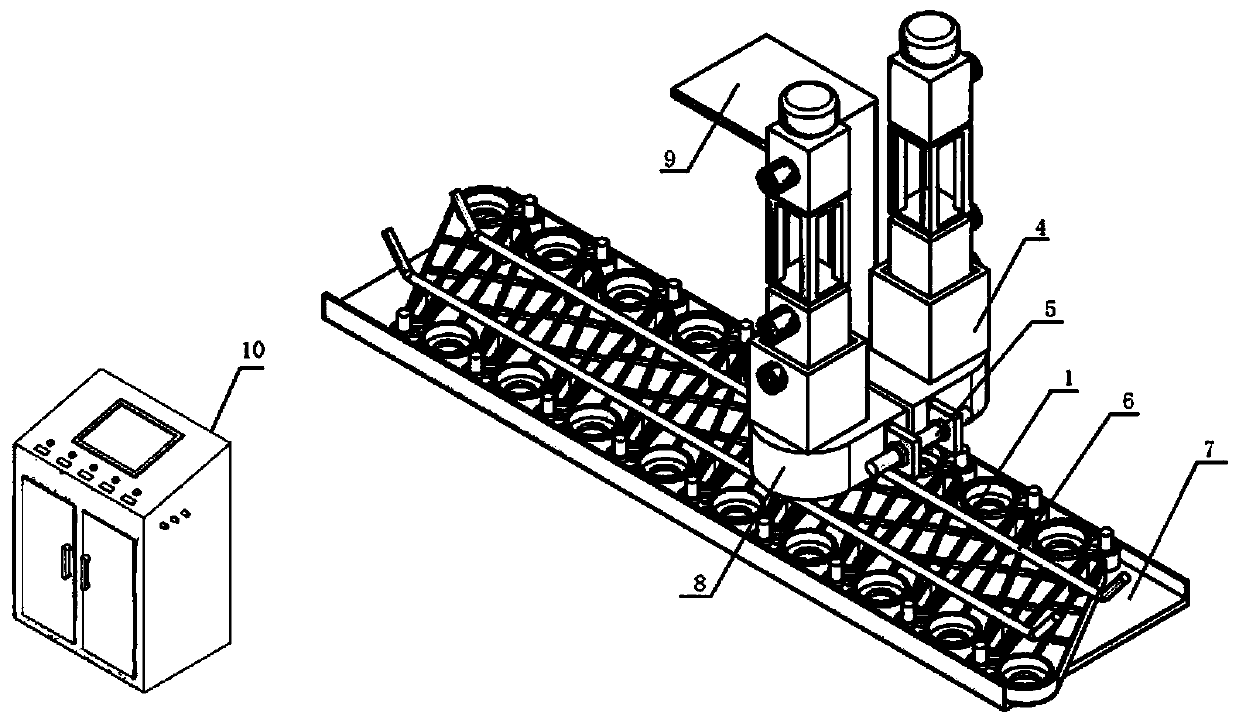

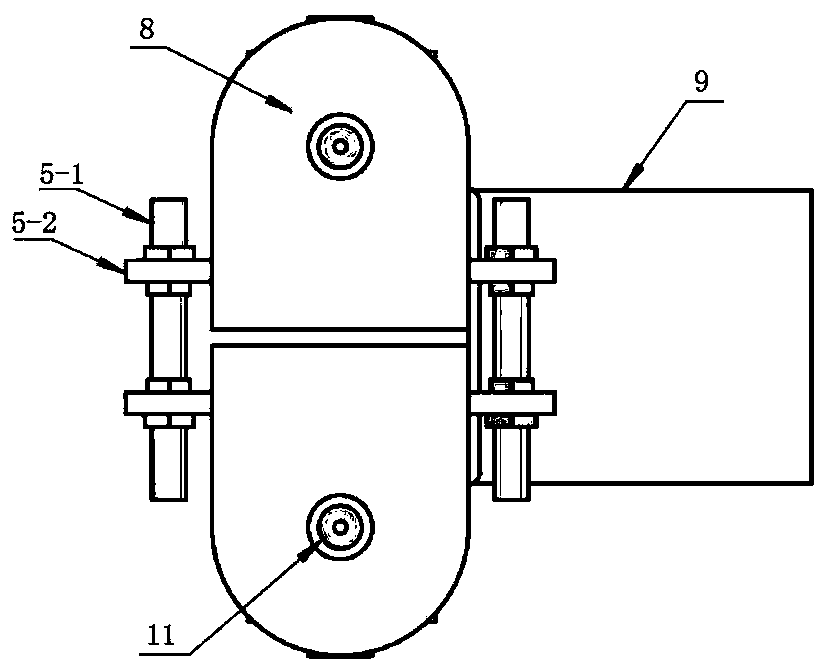

[0017] A lubricating grease atomization and spraying system for a lever of a left wheel comprises a grease storage tank, a high-pressure grease delivery unit 10, a grease atomization and spraying unit, an automatic conveyor belt unit 7 and a PLC control system. The grease storage tank is connected to the high-pressure grease delivery unit through pipelines, and the high-pressure grease delivery unit is connected to the grease atomization spray unit. The grease atomization spray unit is fixed by a hanger 9 and includes two atomization spray guns 4 1. Two atomizing spray guns are respectively fixed by spray gun brackets 8, and the distance between the two spray guns is adjusted by the distance adjustment mechanism 5 installed on both sides of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com