Corner glue injection seal and glue injection method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

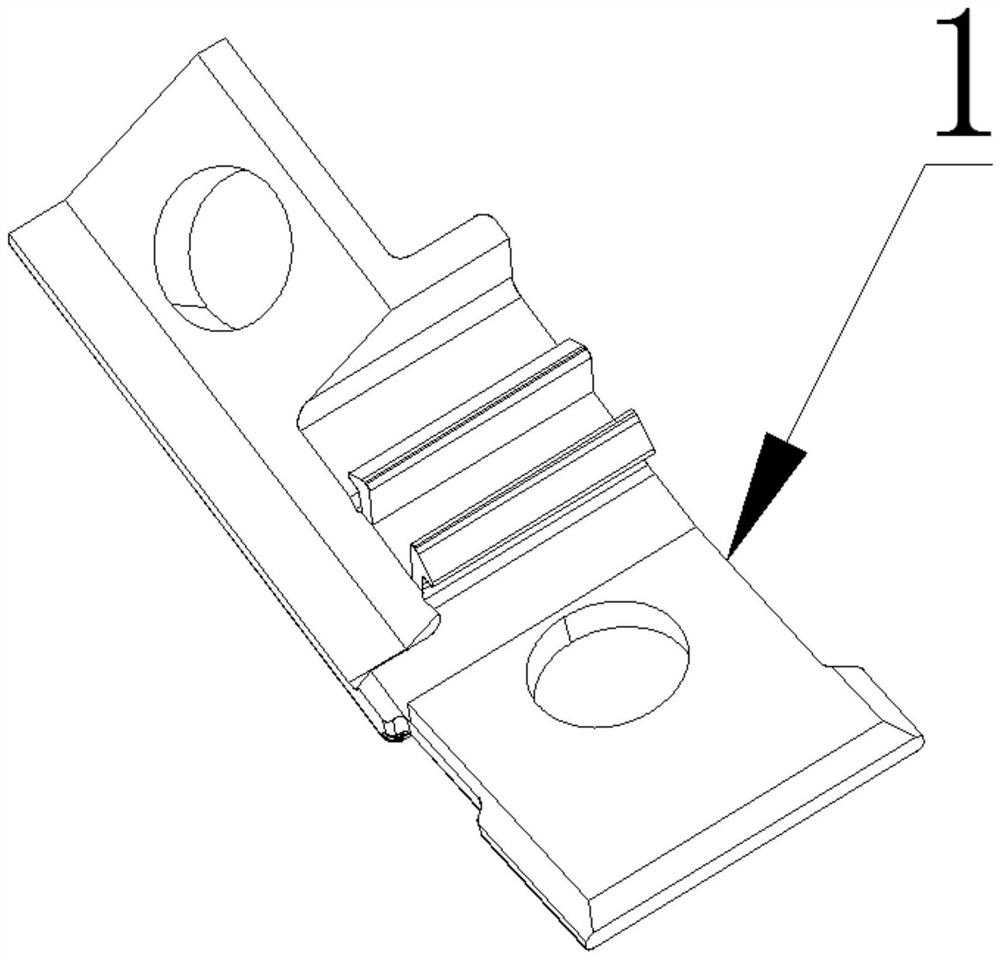

[0043] A corner glue injection seal is used for standard glue injection at the splicing joints of profile opening fans and fixed fans, including a seal body 1 and a number of glue injection ports 2 opened on the seal body 1 and the glue injection A number of glue injection grooves 3 connected by holes, and an overflow glue port 4 is provided at the end of the glue injection groove 3; wherein,

[0044] The seal main body 1 is used to block the sealant and plan the flow direction of the sealant;

[0045] The glue injection port 2 is used to inject sealant into the sealant main body 1 and the matching position of the door and window profiles for the glue injection equipment;

[0046] The glue injection groove 3 is used to divert the sealant to complete the sealing process between the door and window profiles;

[0047] The glue overflow port 4 is used to observe whether the sealant fills the glue injection groove and between the door and window profiles.

[0048] The seal body 1...

Embodiment 2

[0062] A corner glue injection seal, used for standard glue injection at the joint of profile opening and fixed fans, including a seal main body 1 and several glue injection ports 2 opened on the seal main body 1 and the glue injection A number of glue injection grooves 3 connected by holes, and an overflow glue port 4 is provided at the end of the glue injection groove 3; wherein,

[0063] The seal main body 1 is used to block the sealant and plan the flow direction of the sealant, so as to ensure the overall appearance of the joint between the profile opening fan and the fixed fan, and the overall thickness is consistent;

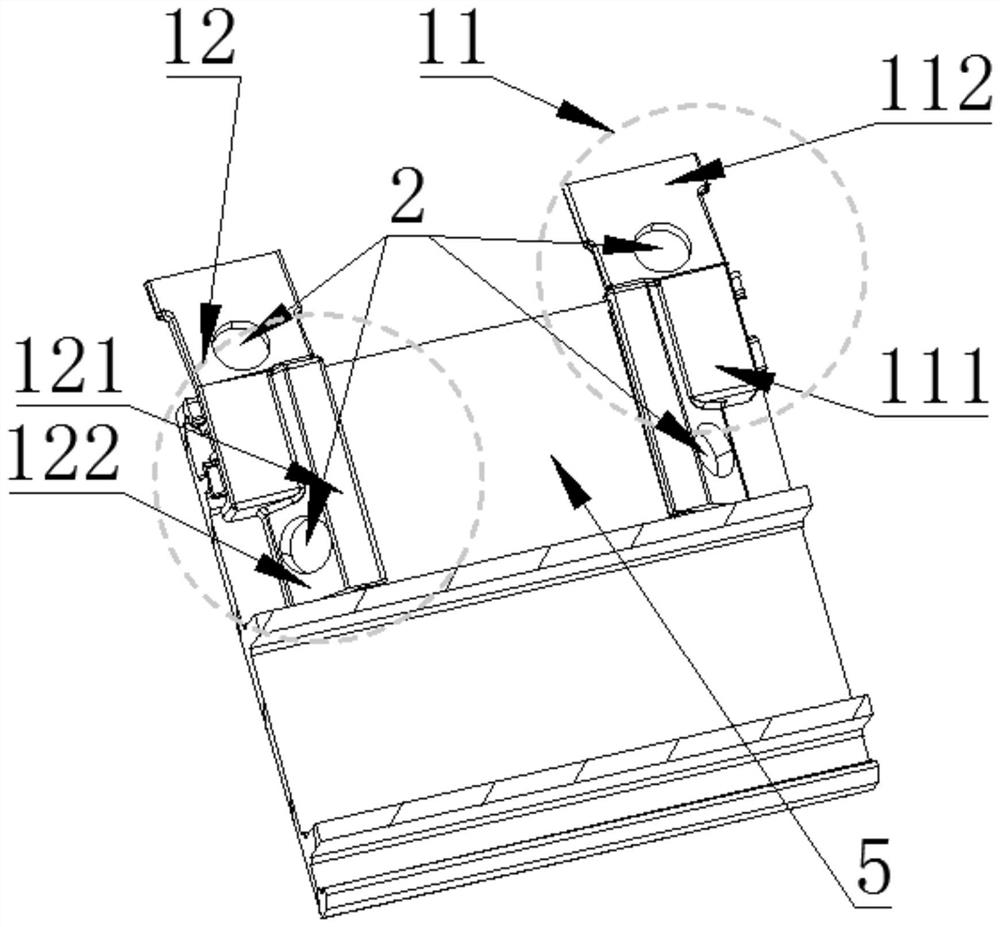

[0064] The seal body 1 includes an upper sealing structure 11 and a lower sealing structure 12 connected to the upper sealing structure 11, the upper sealing structure 11 and the lower sealing structure 12 are integrally formed, and can be molded;

[0065] The upper sealing structure 11 includes a vertical sealing part 111 and an upwardly inclined sealing...

Embodiment 3

[0085] A corner glue injection seal, used for standard glue injection at the joint of profile opening and fixed fans, including a seal main body 1 and several glue injection ports 2 opened on the seal main body 1 and the glue injection A number of glue injection grooves 3 connected by holes, and an overflow glue port 4 is provided at the end of the glue injection groove 3; wherein,

[0086] The seal main body 1 is used to block the sealant and plan the flow direction of the sealant, so as to ensure the overall appearance of the joint between the profile opening fan and the fixed fan, and the overall thickness is consistent;

[0087] The seal body 1 includes an upper sealing structure 11 and a lower sealing structure 12 connected to the upper sealing structure 11, the upper sealing structure 11 and the lower sealing structure 12 are integrally formed, and can be molded;

[0088] The upper sealing structure 11 includes a vertical sealing part 111 and an upwardly inclined sealing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com