Energy concentrating type horizontal axis wind turbine used for improving wind energy utilization rate and application method thereof

A wind turbine and utilization technology, which is applied to wind turbines, wind turbines, and control of wind turbines that are consistent with the wind direction. To achieve the effect of realizing continuous power generation and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

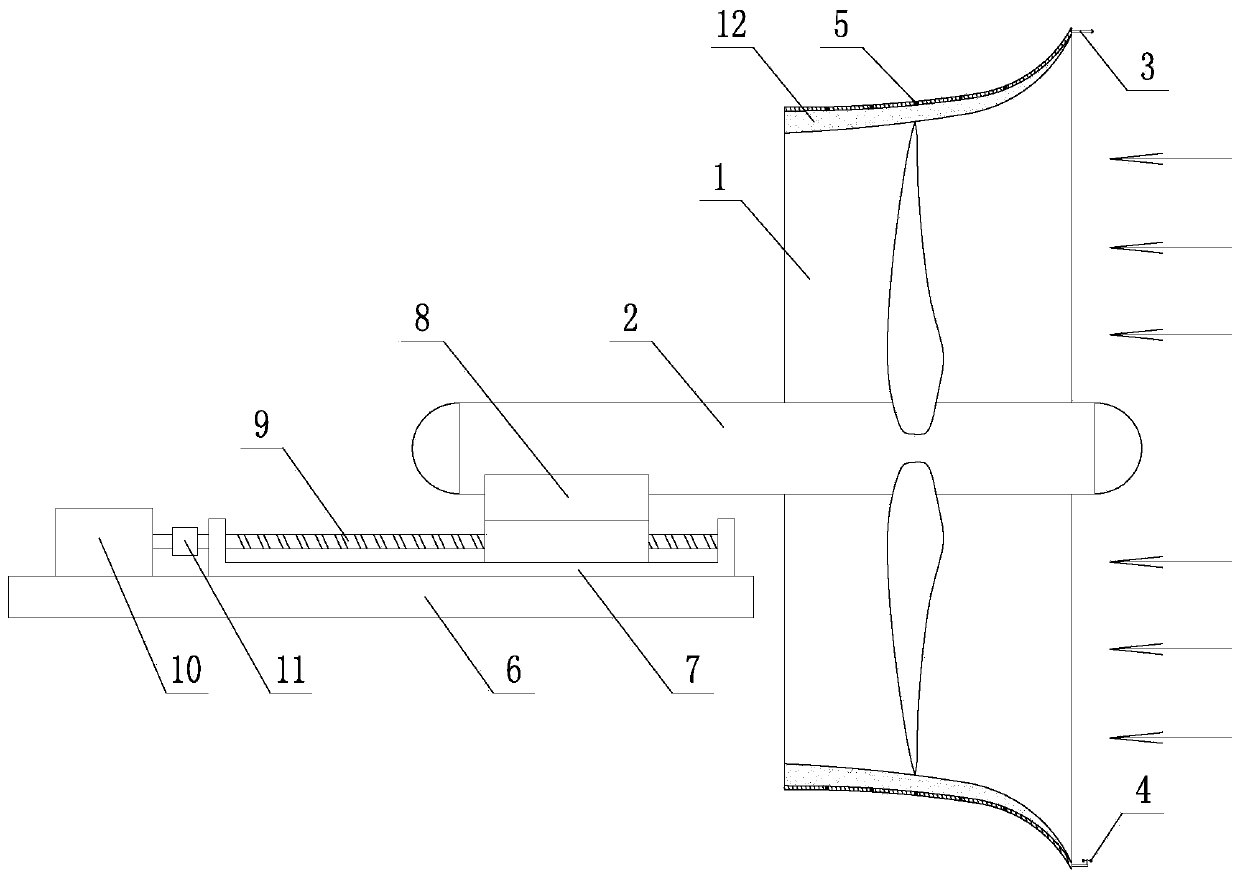

[0027] like figure 1 As shown, an energy-gathering horizontal-axis wind turbine for improving the utilization rate of wind energy includes an energy-gathering cover 1, a wind turbine impeller 2, an axial position adjustment mechanism for the wind turbine impeller, a temperature sensor 3, a wind speed sensor 4 and an attachment surface layer probe 5; the energy gathering cover 1 is coaxially sleeved on the outside of the wind turbine impeller 2, and the temperature sensor 3 and the wind speed sensor 4 are all installed on the windward side cover body of the energy gathering cover 1; 1 is provided with a number of boundary layer detection holes along the axial direction, and each boundary layer detection hole is equipped with a boundary layer probe 5; the axial position adjustment mechanism of the wind turbine impeller includes a base 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com