High-pressure difference stop valve with U-shaped groove in outlet throttling channel

A technology of throttling channels and concave grooves, which is applied in the field of high pressure differential cut-off valves, can solve problems such as short service life, affect the safety of boiler use, and unsatisfactory effects, and achieve the effects of reducing fluid velocity, improving overall sealing performance and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

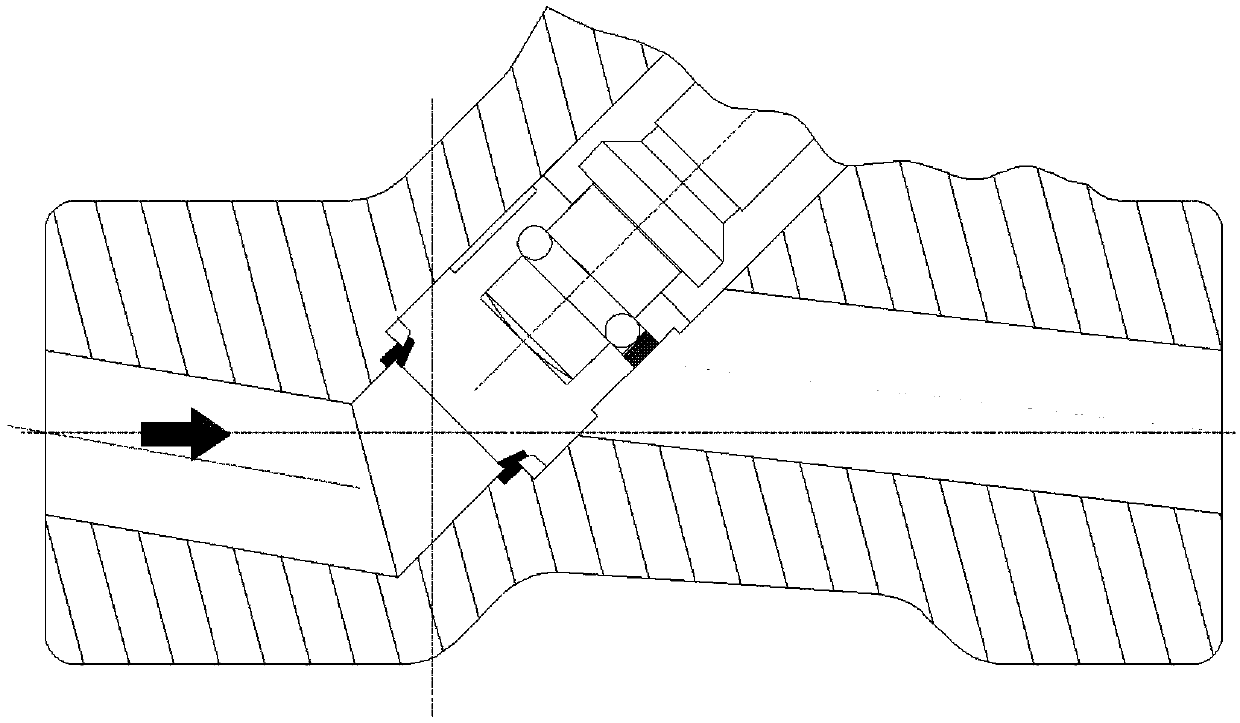

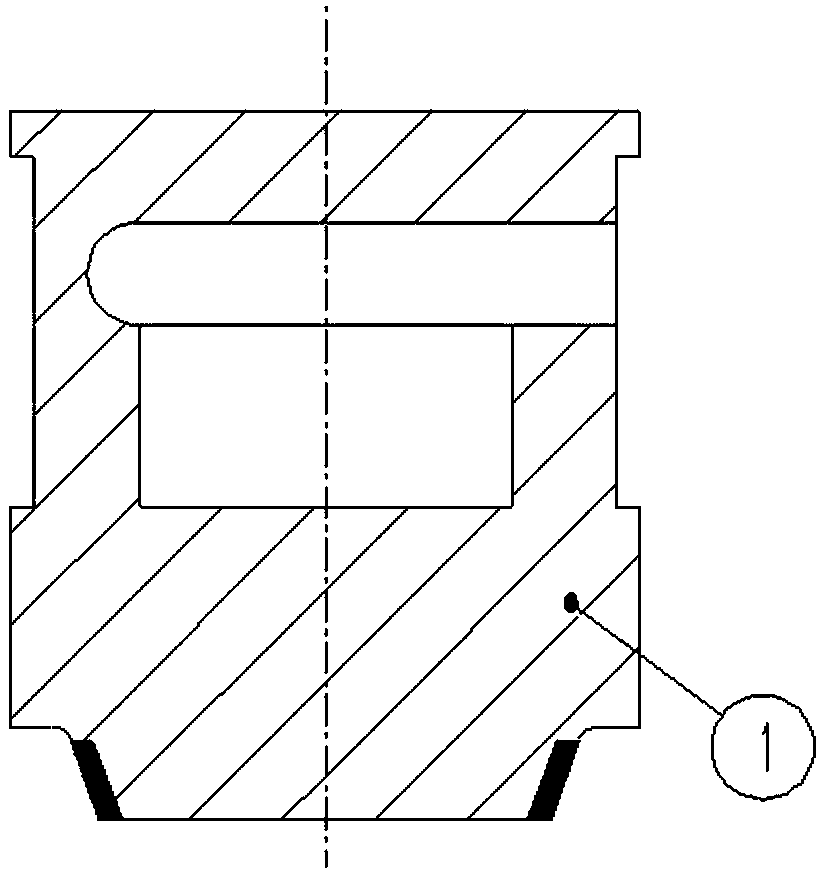

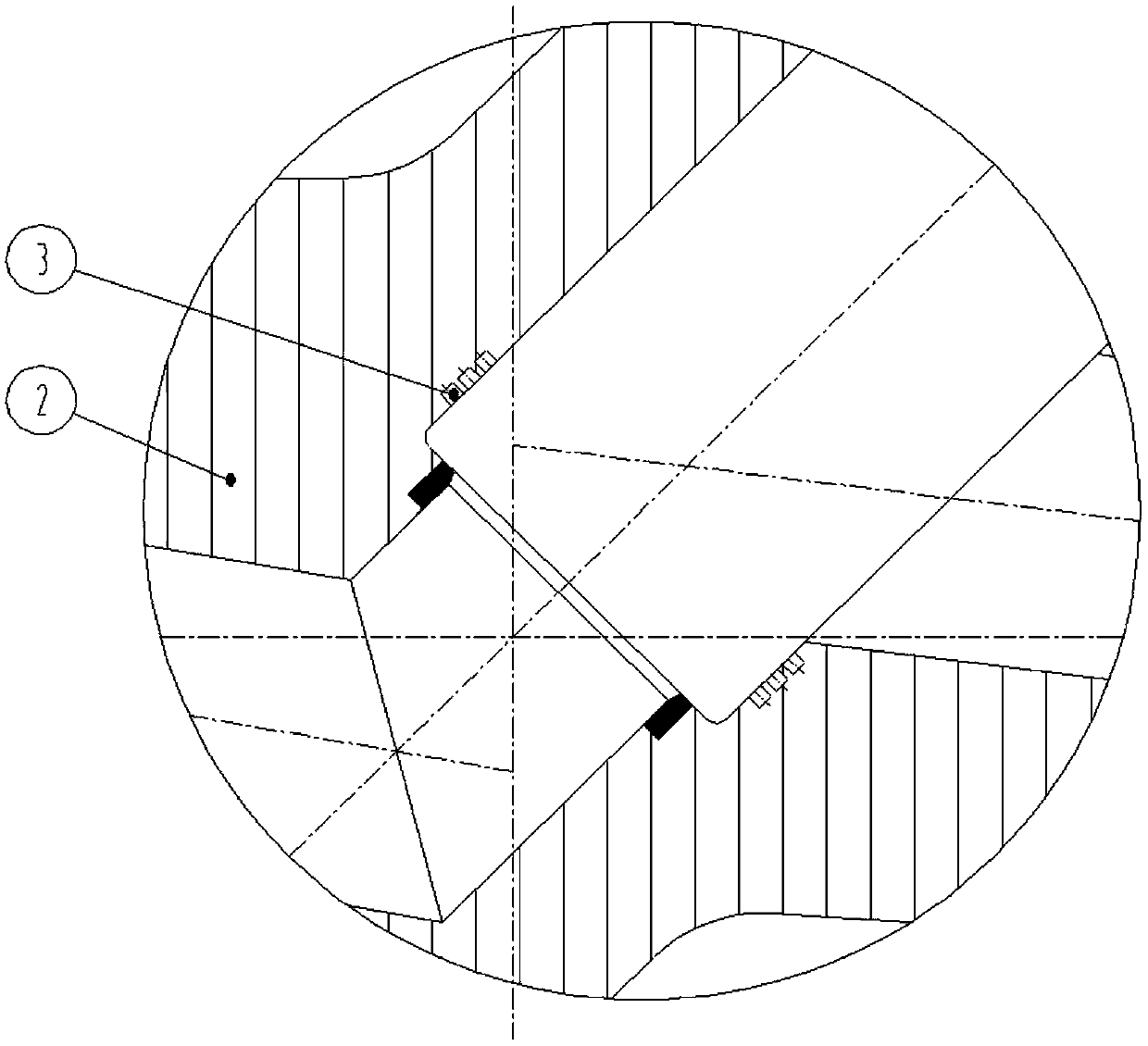

[0015] Such as figure 2 As shown, an anti-scour disc sealing structure of a high pressure differential globe valve with a concave groove in the throttling passage mainly includes a valve body 1, a valve disc 2, and a concave groove 3 at the outlet of the throttle passage of the valve body.

[0016] Such as figure 2 , 3 , As shown in 4, there are multiple labyrinth seal concave grooves at the outlet of the throttling channel of the valve body. It should be noted that because the valve disc only moves in the axial direction, the concave grooves cannot be formed by helical lines, but can only be processed into several complete concave grooves, and the number of concave grooves should be greater than or equal to 3, thus forming a straight-through labyrinth The principle of sealing, combined with the use of static sealing surface, enhances the anti-scouring performance.

[0017] Such as Figure 5 As shown, the schematic diagram of the fluid flow formed during the opening proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com