A bearing assembly and a retaining ring

A technology of bearing components and retaining rings, applied in the direction of bearing components, bearings, ball bearings, etc., can solve the problems of uneven grinding process, unevenness, broken geometric structure, etc., and achieve the effect of uniform grinding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

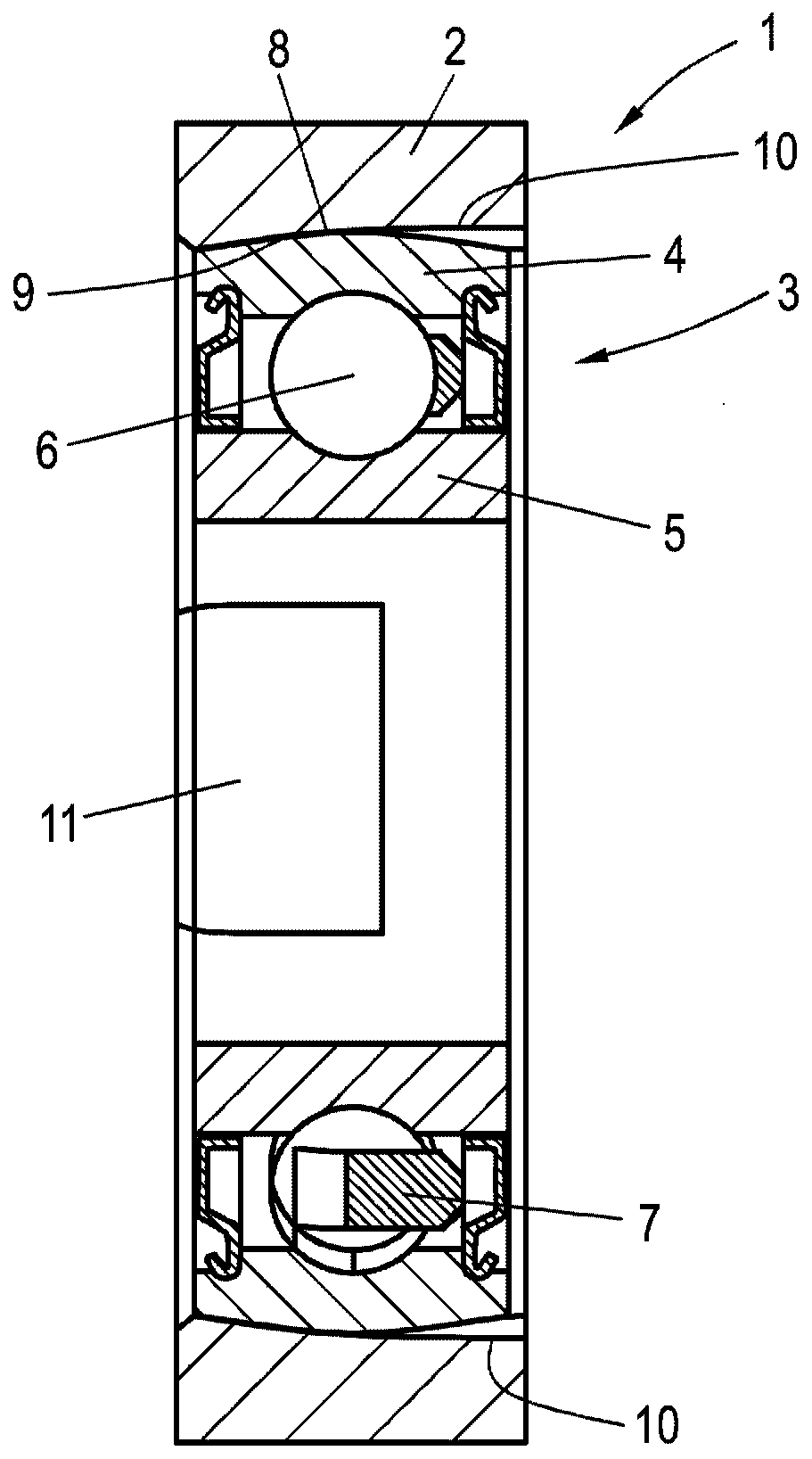

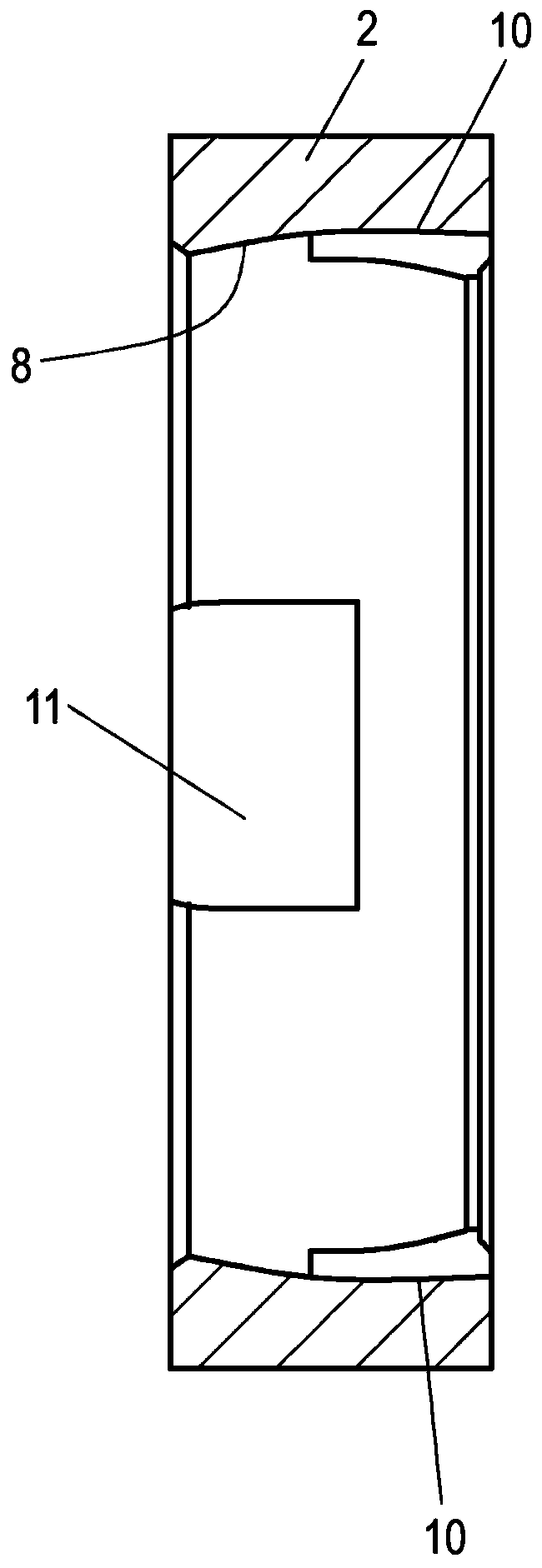

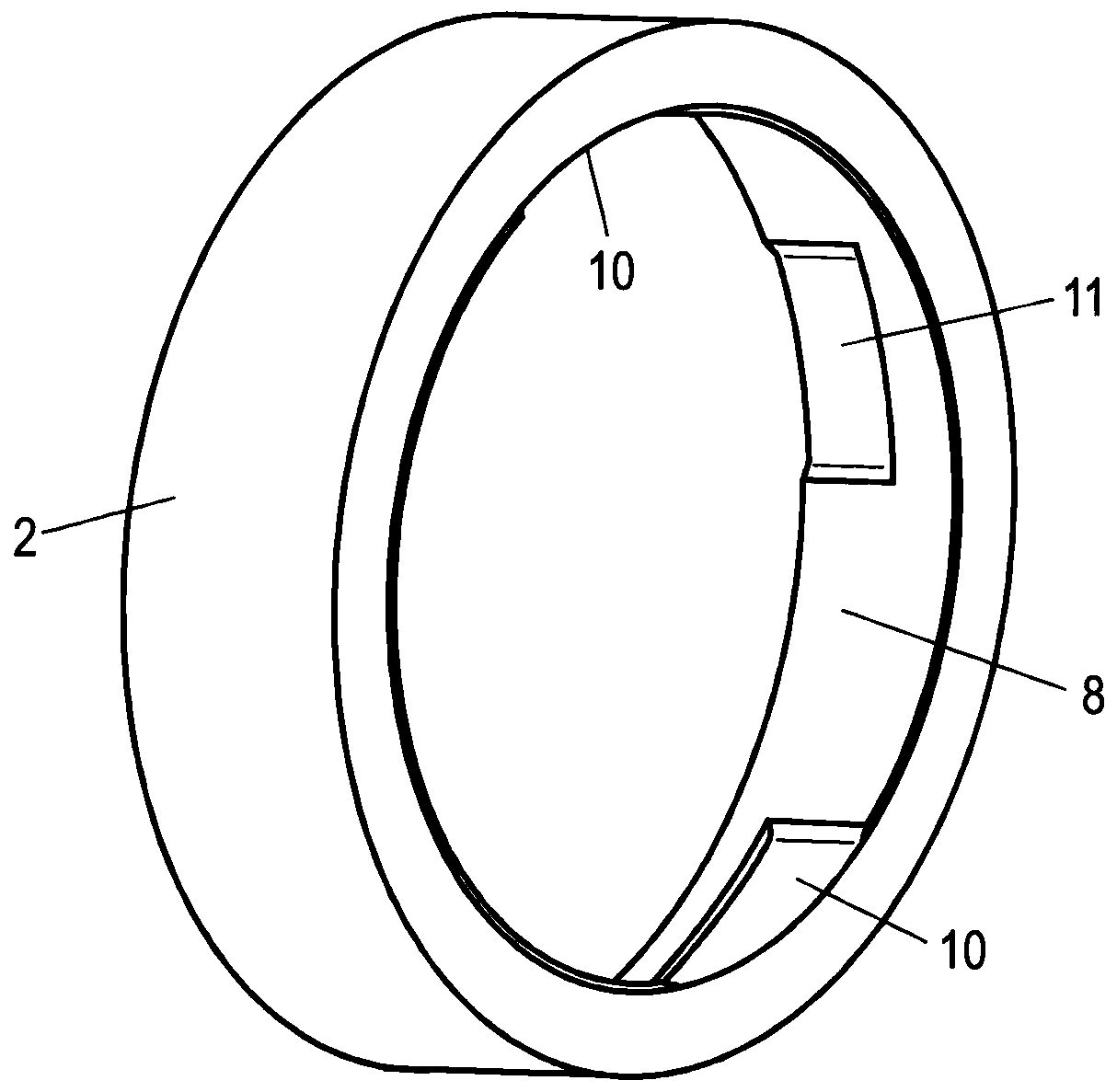

[0024] figure 1 A bearing assembly 1 according to the invention is shown, which comprises a retaining ring 2 which is inserted into the stationary surrounding structure of the component to be supported. Arranged in the cage ring 2 is a rolling bearing 3 comprising an outer ring 4 and an inner ring 5 between which rolling bodies 6 guided in a cage 7 roll. In the example shown the rolling bodies are balls which roll in corresponding ball grooves of the outer and inner rings 4 , 5 .

[0025] The shown bearing assembly 1 is a pivot bearing assembly, ie the rolling bearing 3 is pivotable relative to the retaining ring. For this purpose, the inner side 8 of the retaining ring 2 is curved coronally inwardly, while the outer side 9 spherically of the outer ring 4 is curved outwardly.

[0026] In order to be able to mount the rolling bearing 3 in the retaining ring 2, in the example shown, two mounting grooves 10 (in the figure 1 center on the right end side) and two mounting slots ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com