Fluid level sensor apparatus with inter-digitated planar capacitor

A technology of liquid level sensor and capacitor, which is applied to the liquid level indicator, lubrication indicating device, measuring device and other directions of physical variable measurement, which can solve the problems affecting the reliability and accuracy of the equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

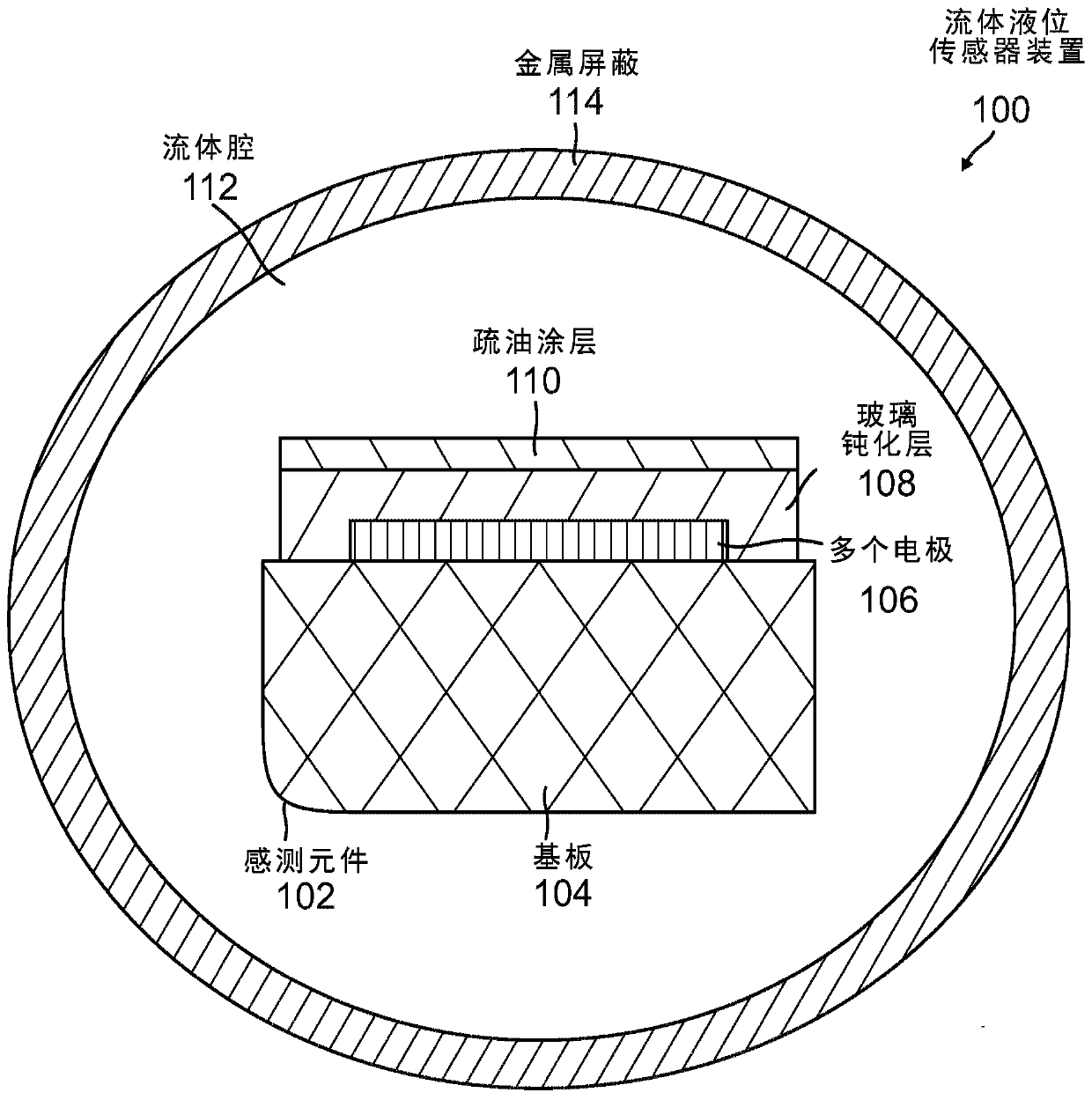

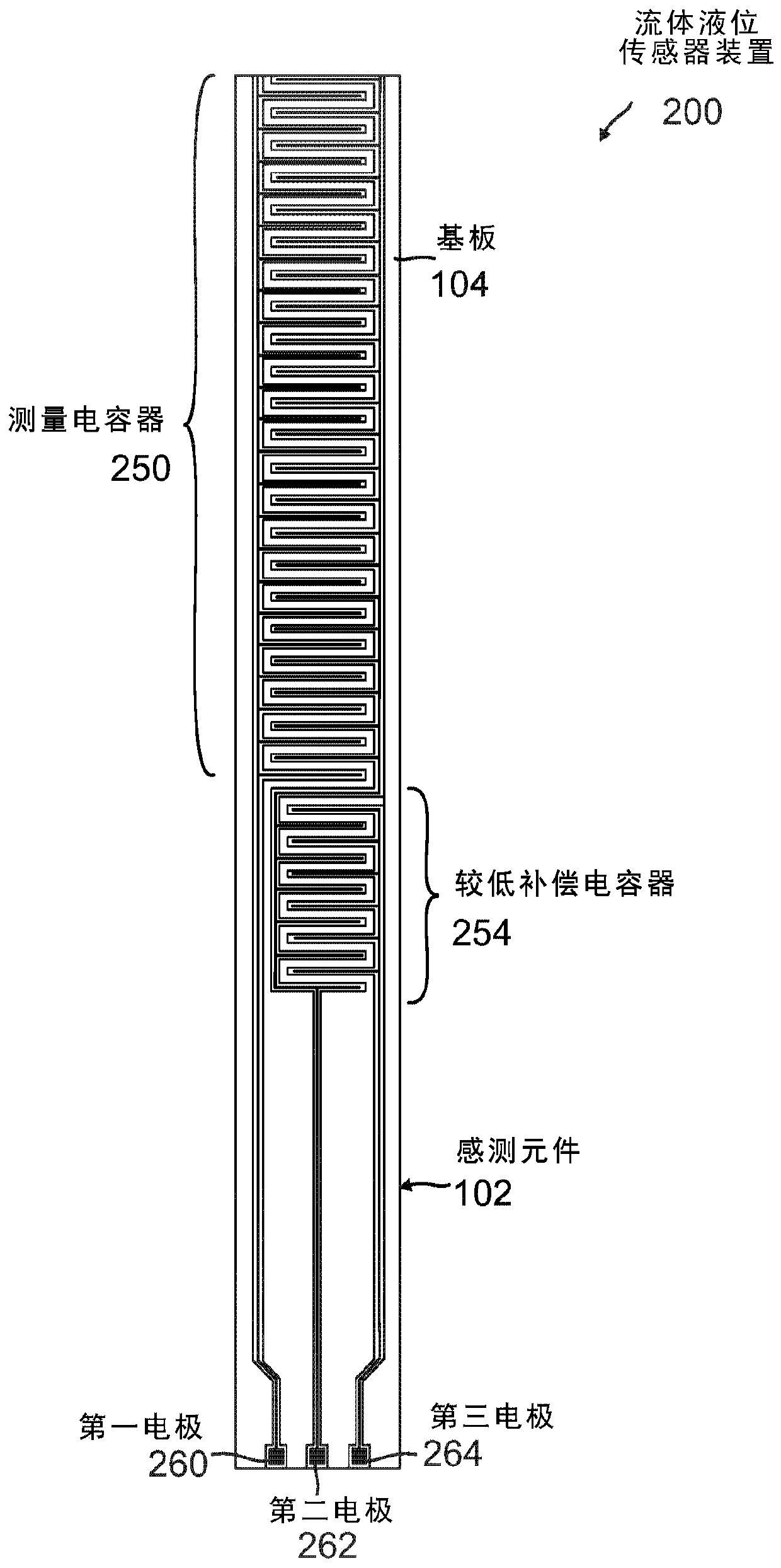

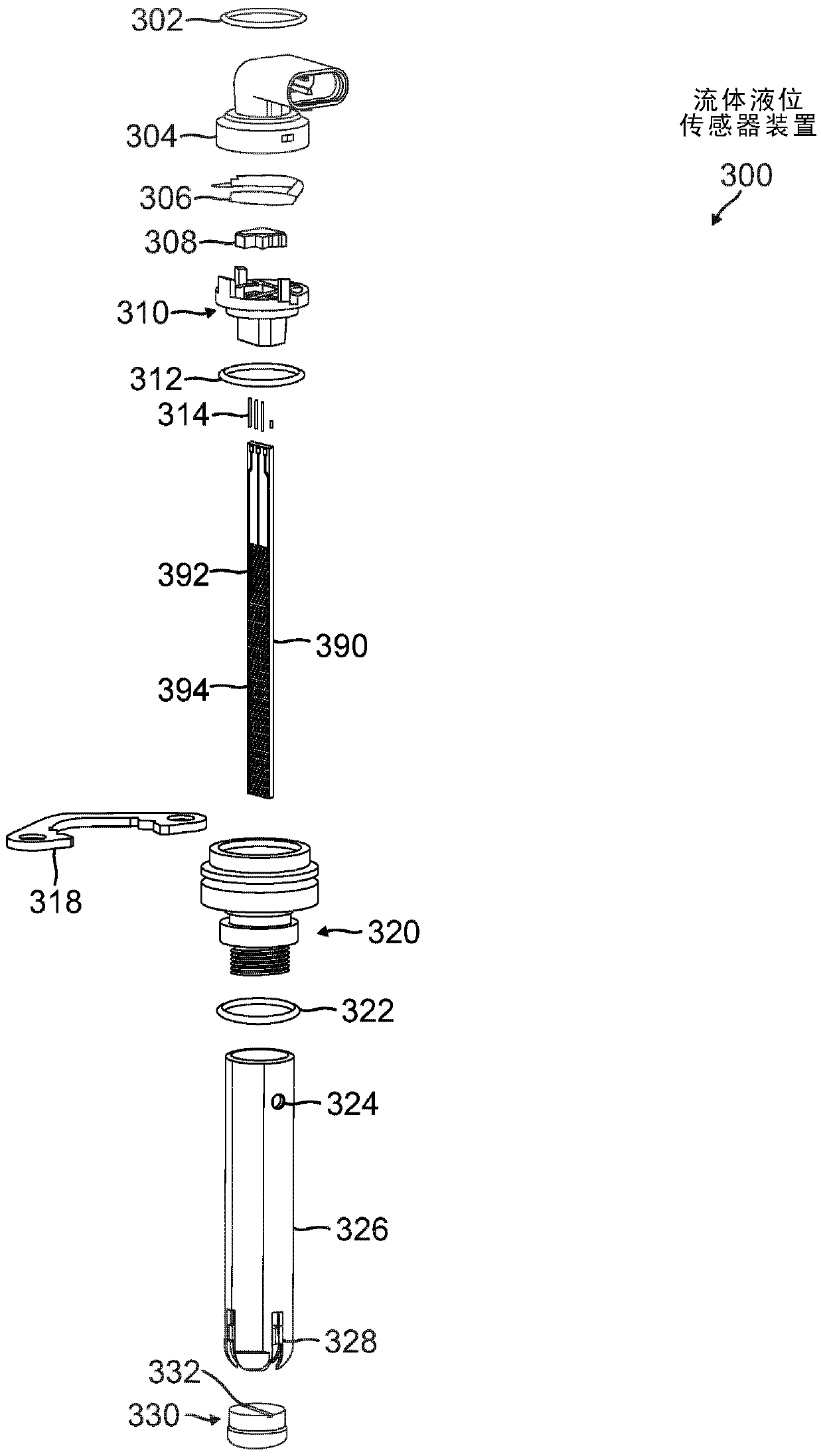

[0018] The present disclosure describes a fluid level sensor device including an interdigitated planar capacitor for direct insertion into the fluid. In a particular embodiment for oil-based fluids, interdigitated planar capacitors are passivated and an oleophobic coating is applied over the passivation layer. In this embodiment, the oleophobic coating reduces the shedding time of the oil-based fluid from at least one capacitor of the device, which improves the reliability, accuracy of the device when the device is used to measure the level of the oil-based fluid in the reservoir and response time.

[0019] Still another embodiment is described below wherein the fluid level sensor arrangement includes a metal shield for supporting and reducing electromagnetic interference with interdigitated planar capacitors. Reducing interference is beneficial because it protects interdigitated planar capacitors from stray capacitance and provides environmental isolation. A metal shield th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com