Shape memory composite material with both electrical response and temperature response as well as preparation method and application of shape memory composite material in immobilized cells

A composite material, temperature-responsive technology, applied in the direction of immobilization on or in inorganic carriers, immobilized enzymes, microorganism-based methods, etc. The effect of fast response rate and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] Embodiment 1: Photoetching of silicon wafers and shape memory composite materials are prepared according to the following method:

[0088] (1) After the clean silicon wafer is soaked in a mixed solution of 98% concentrated sulfuric acid and 30% hydrogen peroxide (7:4, v / v), the surface is ablated point by point with a picosecond pulse laser, and the wavelength of the picosecond pulse laser is set The frequency is 1064nm, the frequency is 0.4MHz, the scanning speed is 190μm / s, the pulse width is 12ps, and the surface micropattern with a length of 10μm, a width of 12μm, a height of 30μm, and an array spacing of 650nm is obtained, and the photoetched silicon piece.

[0089] (2) Take a certain amount of N,N-dimethylformamide (DMF), add two-dimensional graphene to make a 1mg / mL suspension, and disperse evenly by ultrasonication for 1h; into a 50mg / mL solution, magnetically stirred until completely dissolved; then the two-dimensional graphene dispersion and thermoplastic pol...

Embodiment 2

[0091] Example 2: Grafting poly-N-isopropylacrylamide on the surface of the shape memory composite material is prepared according to the following method:

[0092] The reversible shape memory composite material with micropatterns obtained in Example 1 was treated with aminopropyltrimethoxysilane to modify amino groups. Specifically, include the following steps:

[0093] (1) Adjust the mass fraction of the mixed solution of aminopropyltrimethoxysilane and anhydrous toluene to 7wt%, and immerse the reversible shape memory composite material with micropatterns obtained in Example 1 in the mixed solution, at 110°C , under the protection of nitrogen atmosphere, toluene was refluxed for 18 hours, and after the reaction was completed, it was blown dry with nitrogen to obtain a shape memory composite material with surface-modified amino groups;

[0094](2) Subsequently, using a dry dichloromethane solution containing 2% (v / v) pyridine as a solvent, the shape memory composite material...

Embodiment 3

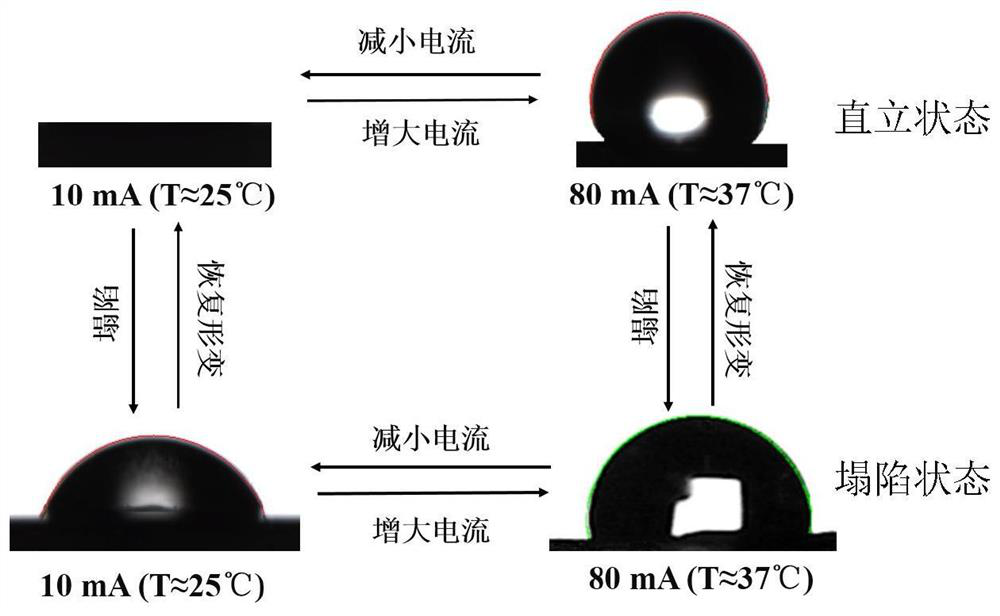

[0096] Example 3: Analysis of surface wettability switching of thermoplastic polyurethane composite materials with both electrical and temperature responses:

[0097] Detection method: refer to the literature Chemical Engineering Journal, 382(2020) 122989.

[0098] Such as figure 1 As shown, when the columnar array on the surface of the composite material remains in an upright state, the surface contact angle of the composite material is 165±2° at a current of 80mA (temperature T≈37°C), showing superhydrophobicity. ≈25℃), the surface contact angle of the composite material is close to 0°, showing superhydrophilicity.

[0099] When the columnar array structure collapses due to external force, the surface contact angle of the composite material is 115±2° under the condition of current of 80mA (T≈37℃), showing hydrophobicity. Under the conditions, the surface contact angle of the composite material is 40±1°, showing hydrophilicity.

[0100] When the columnar array structure co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com