Remote transmission equipment and multipoint driving method

A technology of long-distance transmission and equipment, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of limited and inability to achieve ultra-long distance transportation, and achieve the effect of reducing transportation costs, reducing inspection difficulty, and reducing transfer links.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

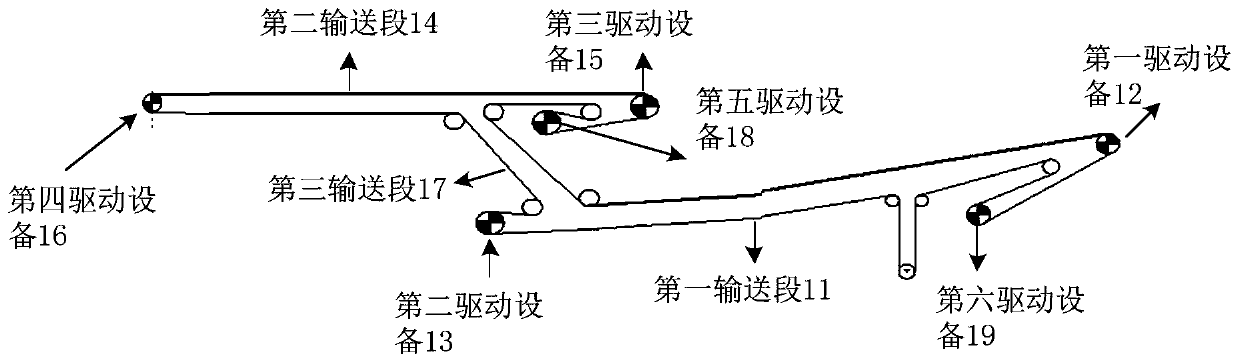

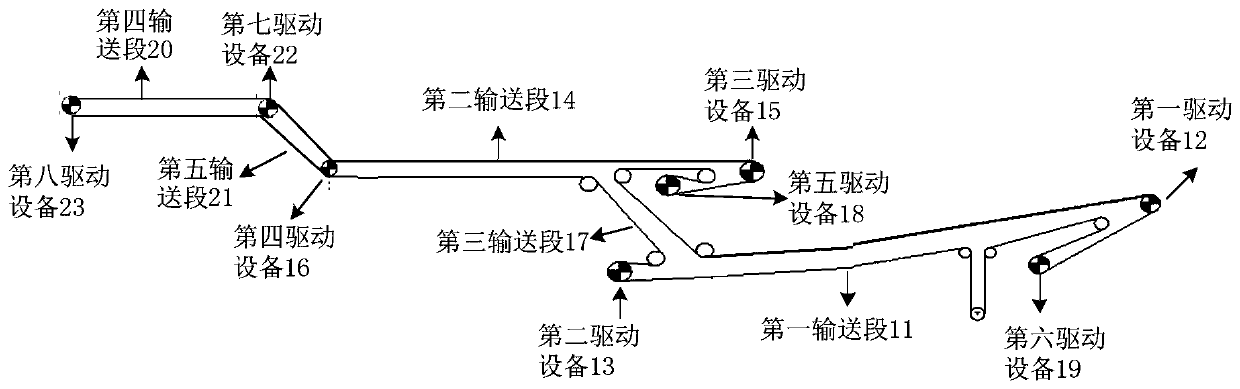

[0034] This embodiment provides a remote transmission device, which can be used in material conveying systems, such as figure 1 As shown, it includes: a first conveying section 11, a first driving device 12 and a second driving device 13 are respectively arranged at both ends of the first conveying section; a second conveying section 14 is not on the same straight line as the first conveying section, A third driving device 15 and a fourth driving device 16 are respectively arranged at both ends of the second conveying section; the third conveying section 17, its two ends are respectively connected with the first conveying section and the second conveying section, so that the goods can be moved from the first conveying section to the second conveying section. Conveyance of a conveying segment to said second conveying segment.

[0035] For example, in the process of material transportation, a single conveyor belt can be divided into three sections: the first conveying section, t...

Embodiment 2

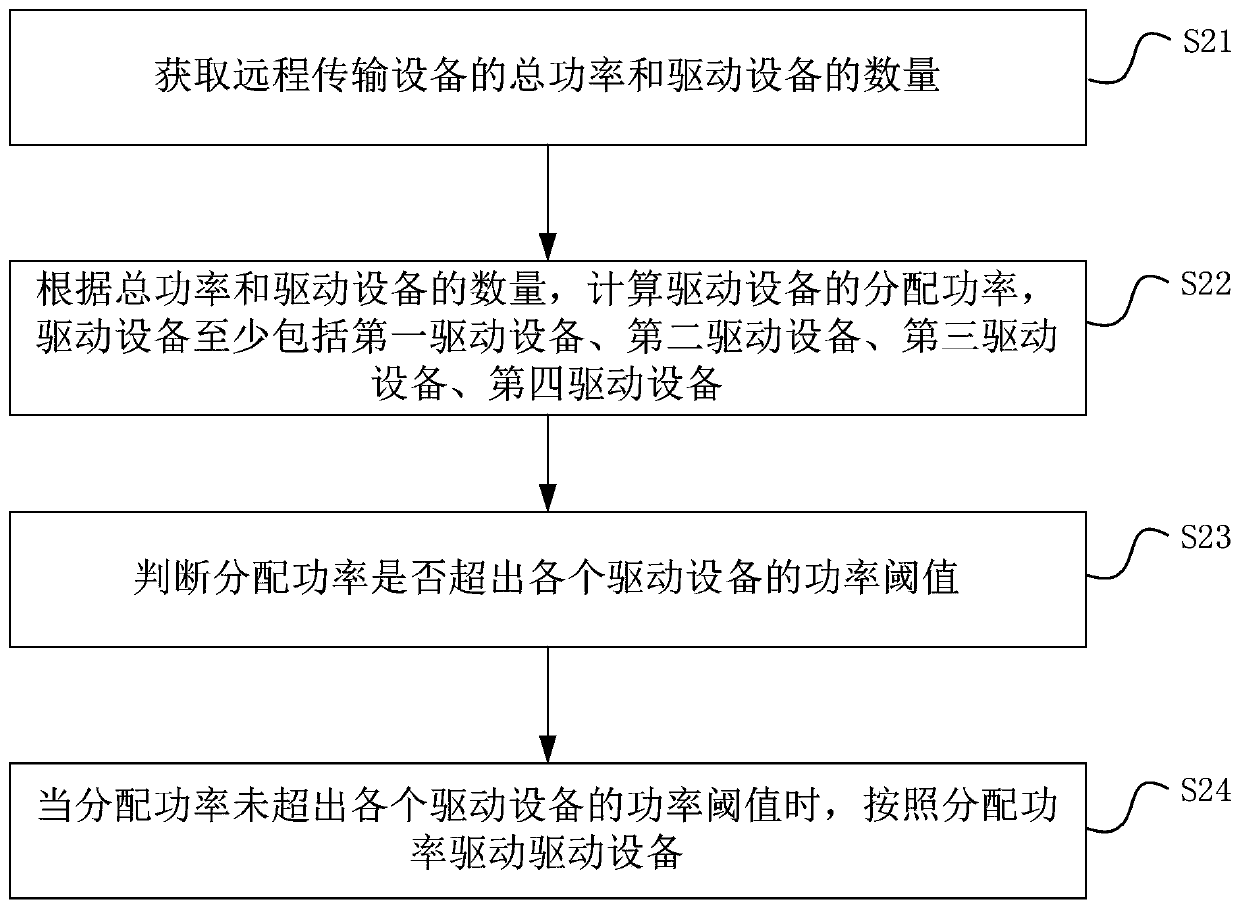

[0048] This embodiment provides a multi-point driving method for driving the remote transmission device described in the above embodiment, such as image 3 As shown, the method includes:

[0049] S21. Obtain the total power of the remote transmission equipment and the number of driving equipment.

[0050] Exemplarily, the total power of the remote transmission equipment may be determined by factors such as the distance the equipment needs to transport the material and the force between the material and the conveying section, or it may be determined according to actual operating conditions. The present application does not limit the way of obtaining the total power of the remote transmission equipment, and those skilled in the art can determine it according to actual needs. The number of driving devices is the number of driving devices required to drive the remote transmission device. For example, if a single conveyor belt is divided into three sections, then 2 driving devices...

Embodiment 3

[0090] This embodiment provides a multi-point driving device, such as Figure 4 shown, including:

[0091] An acquisition module 31, configured to acquire the total power of the remote transmission equipment and the number of driving equipment.

[0092] The distribution module 32 is configured to calculate the distributed power of the driving devices according to the total power and the number of driving devices. The driving devices include at least a first driving device, a second driving device, a third driving device and a fourth driving device.

[0093] A judging module 33, configured to judge whether the allocated power exceeds the power threshold of each driving device.

[0094] The driving module 34 is configured to drive the driving devices according to the distributed power when the distributed power does not exceed the power threshold of each driving device.

[0095] The multi-point driving device provided in this embodiment obtains the total power of the remote tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com