Tobacco material belt conveyer

A technology for belt conveyors and tobacco materials, applied to conveyors, conveyor objects, transportation and packaging, etc., can solve problems such as increased labor intensity of workers, poor flexibility of use, and changes in the ratio of shredded tobacco, so as to improve silk production The effect of technological processing level, convenient use and maintenance, and reliable operation of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

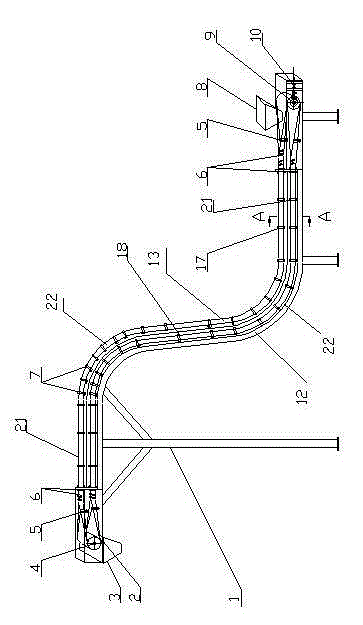

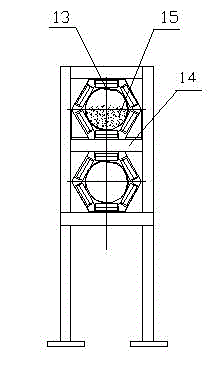

[0041] Such as figure 1 Shown, the present invention comprises frame 14, and it is the framework that light-duty tobacco round pipe belt conveyor rolls, feed hopper 8, discharge hopper 3, driving roller 4, driven roller 9, tensioning device 10, cleaning scraper 2 Parts such as trough roller 5, circle forming device 6, turning roller 7, hexagonal roller 17, dust collecting tank 12, supporting leg 1 are all installed on the frame 14. The frame 14 is made of profiles, and the structure of the frame can be rectangular or triangular.

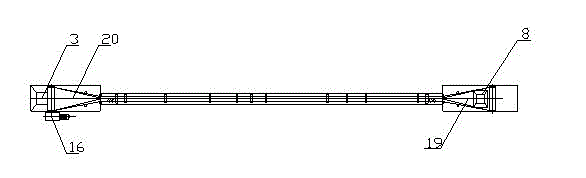

[0042] Such as figure 1 , 2 As shown, the drive roller 4 is installed on the frame 14, and the motor speed reducer 16 is installed on one side of the drive roller 4; the discharge hopper 3 is set near the bottom of the drive roller 4; A feed hopper 8 is arranged above the roller 9 , and a tensioning device 10 is arranged outside the driven roller 9 .

[0043] Such as figure 1 As shown, according to the requirements of the design of the conveying...

Embodiment 2

[0052] Such as Figure 4 As shown, this embodiment is basically the same as Embodiment 1, the only difference is that the return conveyor belt 13 is flat, and the conveyor belt returns to the feeding section through the idler roller 11. In the entire return section, a dust collector is arranged below the idler roller 11. Slot 12. The device thus formed has a large width, but a small thickness and relatively low conveying resistance.

[0053] Working principle and process of the present invention are as follows:

[0054] After the equipment is installed and adjusted for use, the motor reducer 16 drives the driving roller 4 to drive the conveyor belt 13 to run, and the tobacco material 15 with a constant flow rate controlled by the belt scale enters the conveyor belt 13 from the feed hopper 8, and the conveying at this time The belt 13 is squeezed into a U shape by the trough roller 5, and when it reaches the gradual change roller table 6, the rollers in the gradual change rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com