Patents

Literature

48results about How to "Reduce the transshipment link" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sea cucumber pretreatment technology for mechanically processing and corresponding equipment thereof

InactiveCN101617837AQuality improvementEasy to mechanize sievingFish washing/descalingMeat/fish preservation by heatingWater storageWater flow

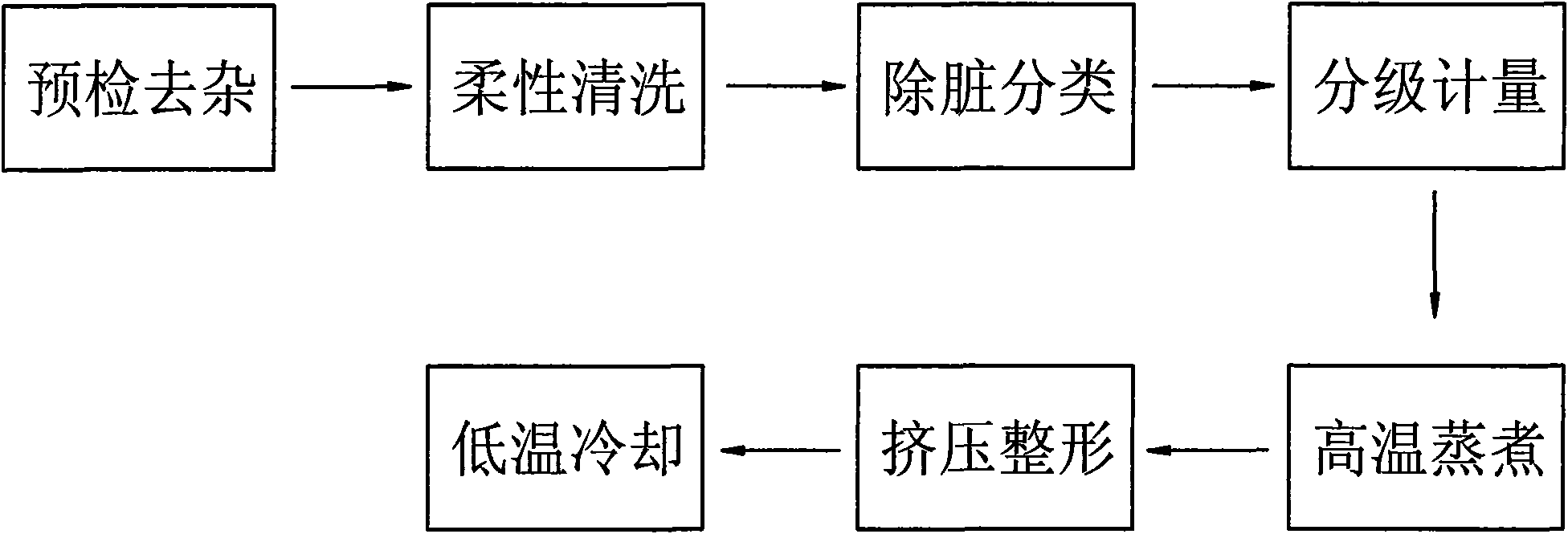

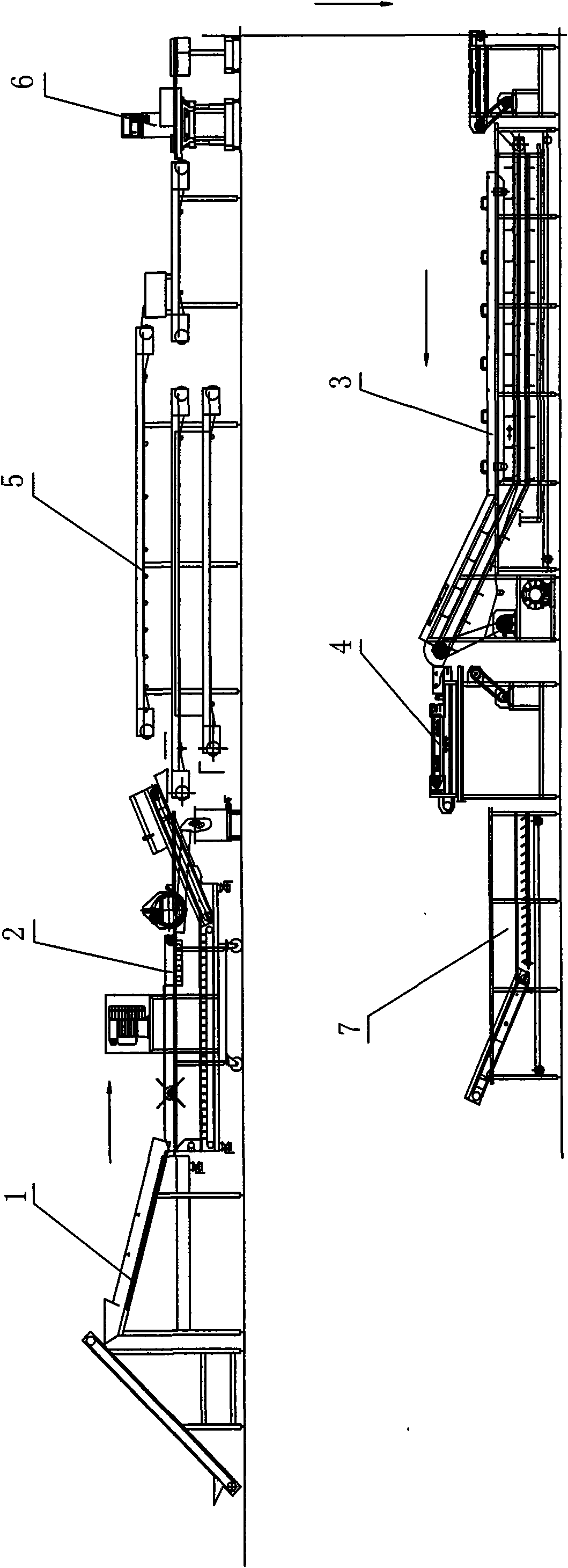

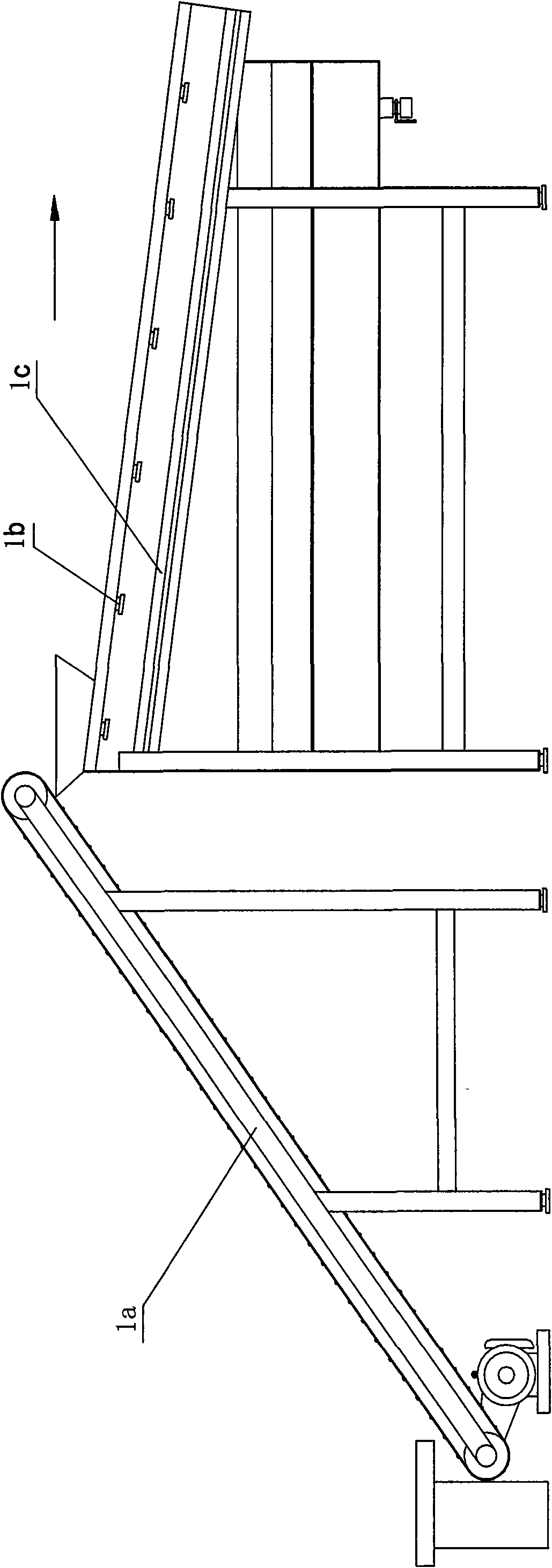

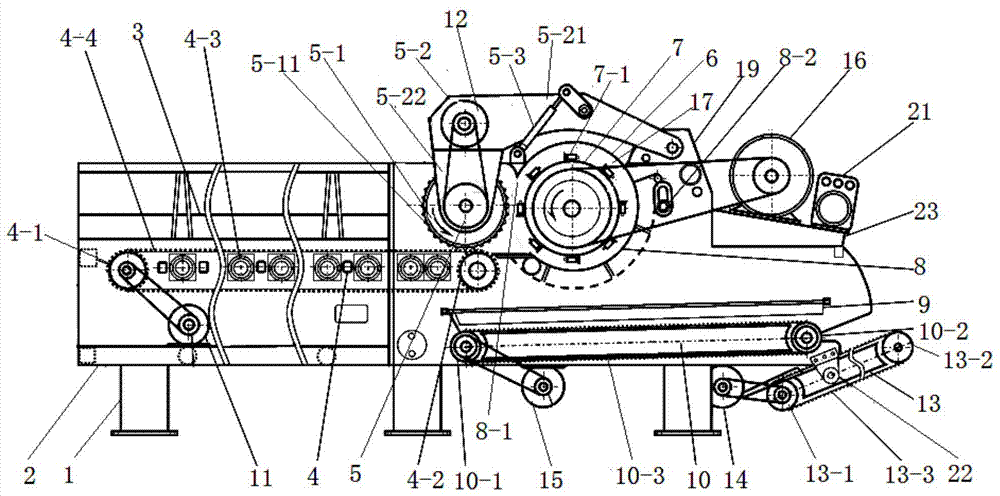

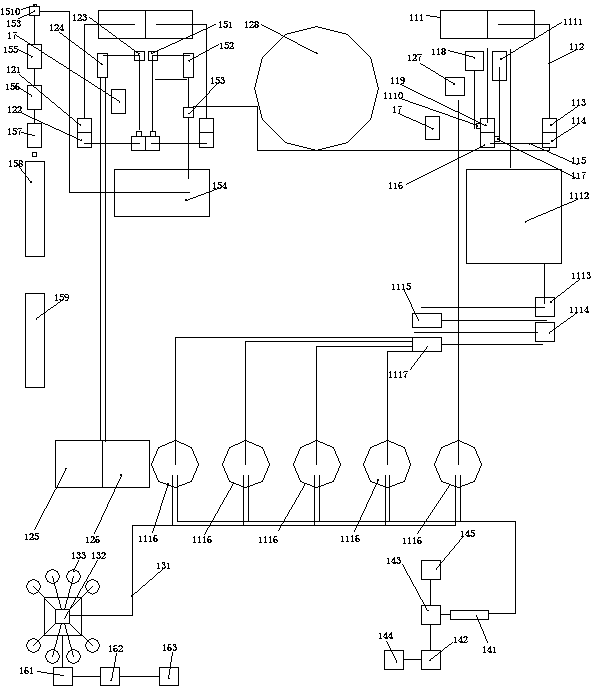

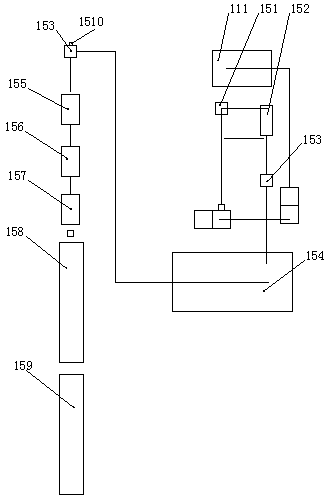

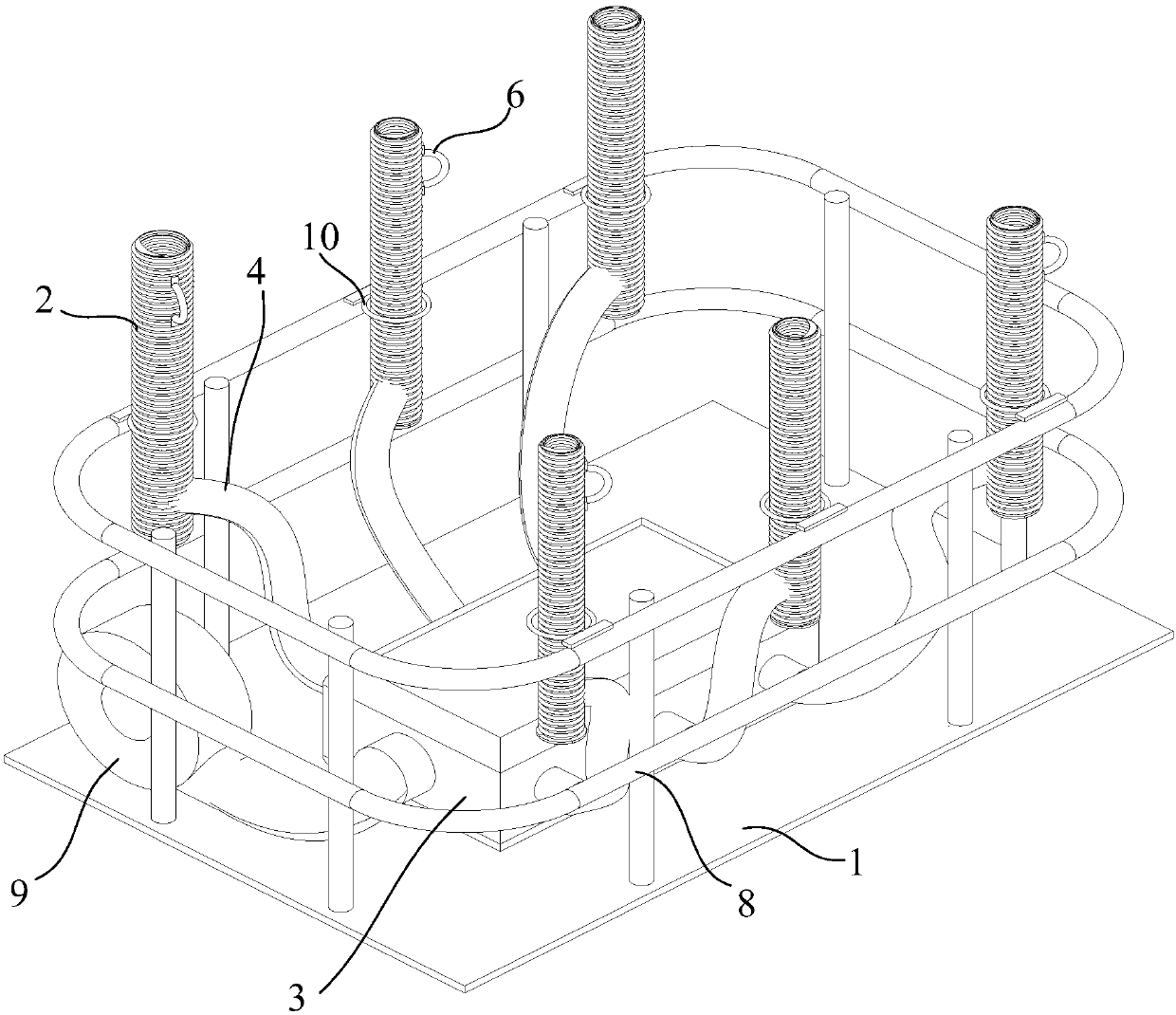

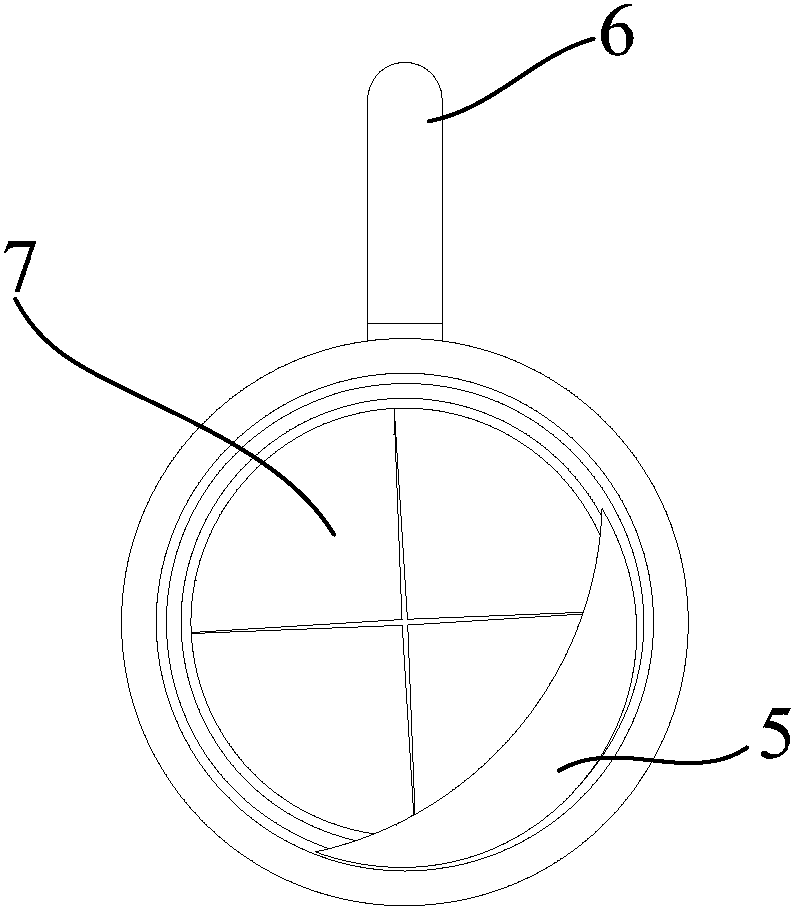

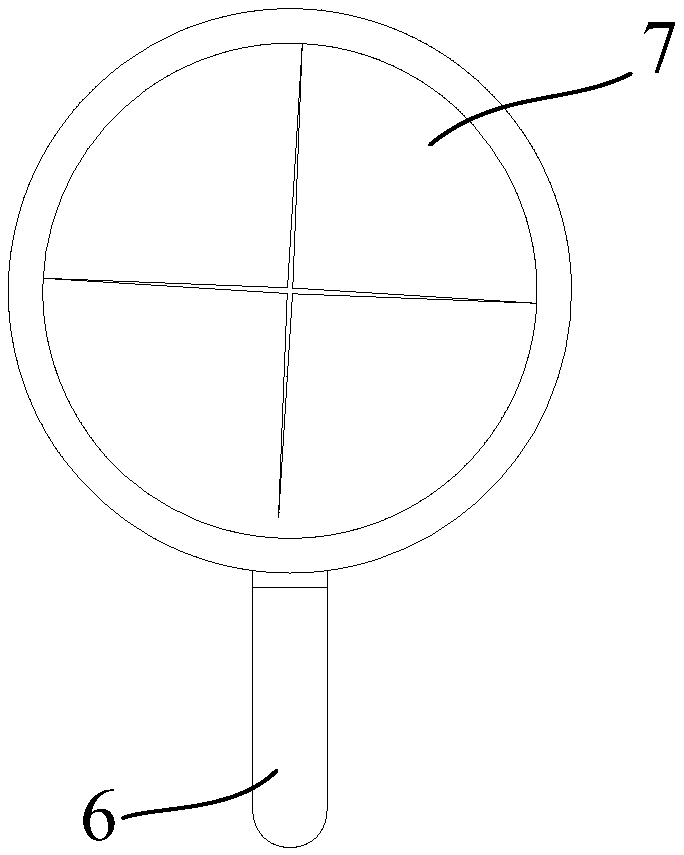

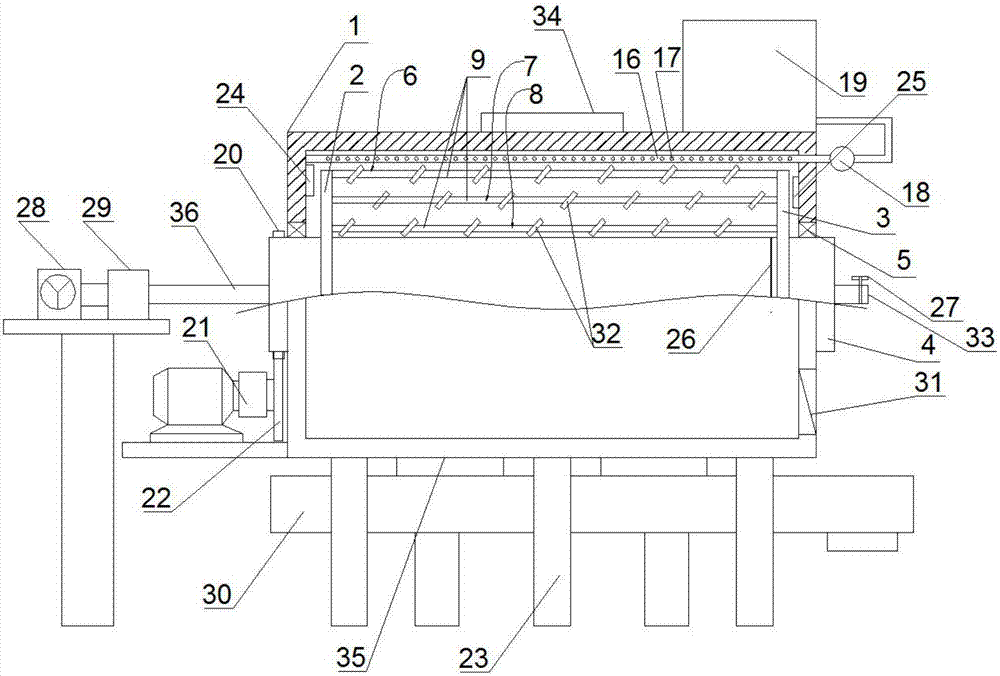

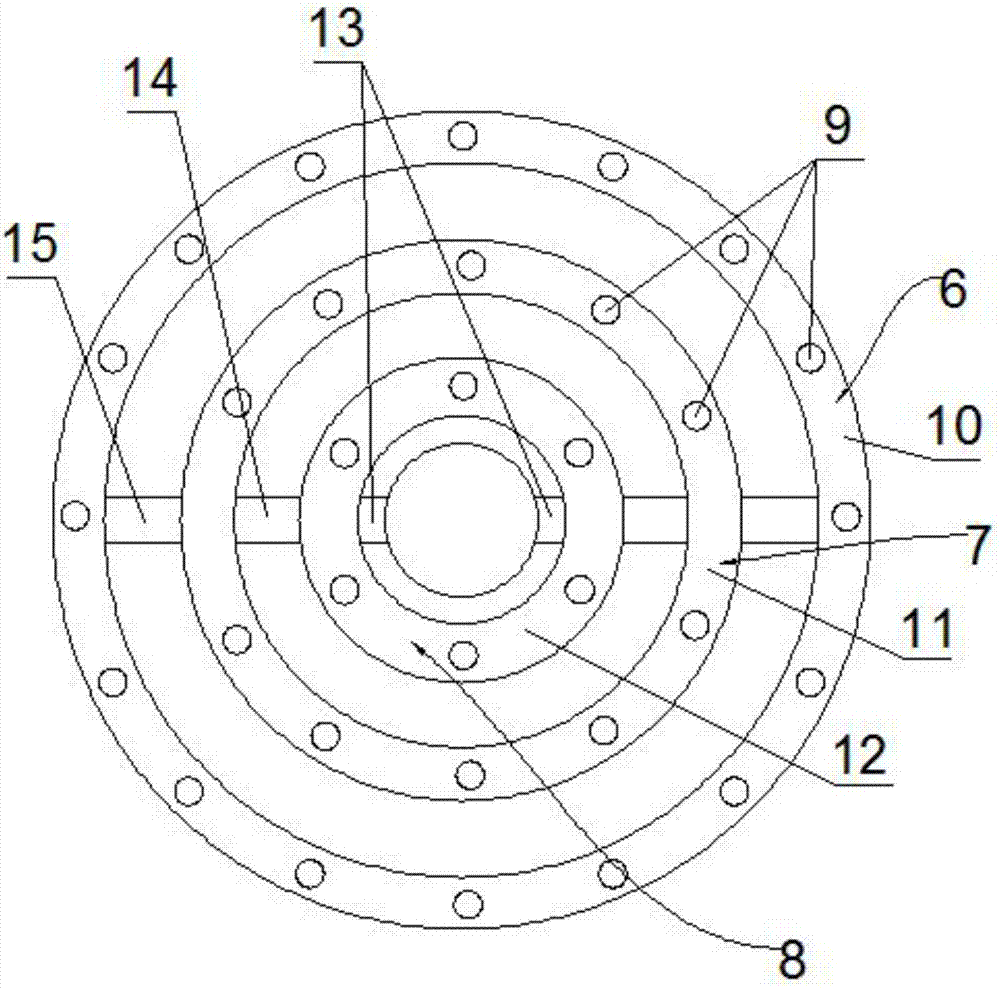

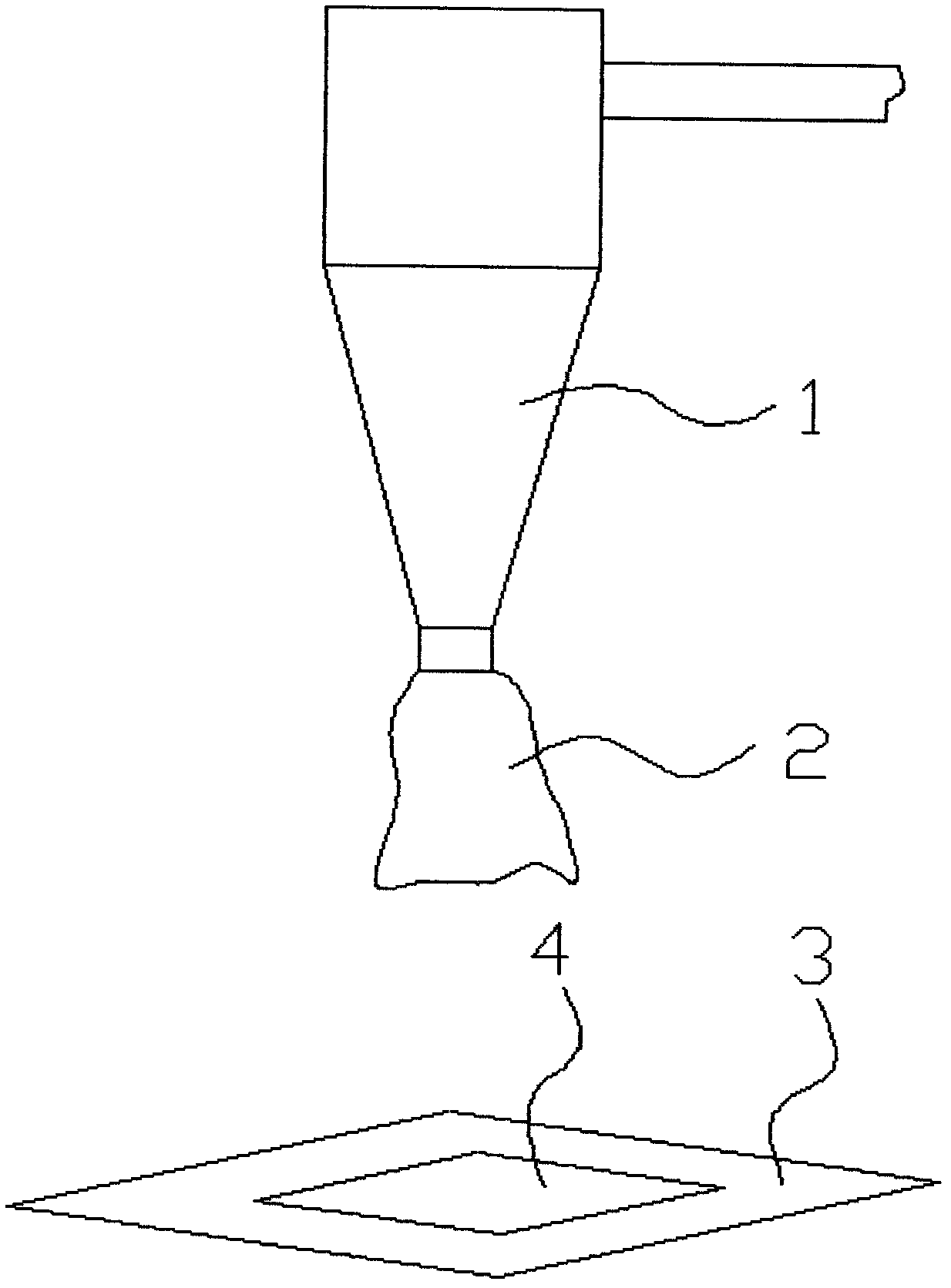

The invention relates to a sea cucumber pretreatment technology for mechanically processing and equipment thereof. The sea cucumber pretreatment technology for mechanically processing comprises the working procedures of pre-inspection impurity removal, flexible cleaning, dirty removal classification, grading measurement, high-temperature stewing, extrusion molding and low-temperature cooling; in the working procedure of the pre-inspection impurity removal, a sea cucumber is sprayed, wetted and washed by purified water and screened by taking a hole and a seam with a certain geometric dimension as boundaries; in the cleaning working procedure, the sea cucumber is placed into a water storage container of which the bottom is input with pressure gas from bottom to top and transported by pressure water flow; in the working procedure of the high-temperature stewing, the sea cucumber is advanced at a certain speed in the boiling water of a stewing groove, and after being gathered, the scum of the water surface is dispelled out of the stewing groove in a guide gathering and / or draining way; and in the working procedure of the extrusion molding, the sea cucumber is sprayed and cooled by low-temperature water and extruded by elastic flexible force during drainage. A pre-inspection device, a cleaning device, a stewing device and a molding device are manufactured and provided according to the sea cucumber pretreatment technology for mechanically processing, thereby the high working efficiency is achieved and the high quality of a finished product is ensured.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

Biomass fuel crusher

The invention discloses a biomass fuel crusher. The biomass fuel crusher comprises a supporting base, wherein a rack is arranged on the supporting base, a feeding bin is arranged at the front part of the rack, a crawler-type feeding conveyer is horizontally distributed in the feeding bin, a forced feeding roll is arranged at the top part of the rear end of the crawler-type feeding conveyer, a crushing compartment is arranged on the rack at the rear part of the forced feeding roll, a crushing roll is arranged in the crushing compartment, a crushing cutter bit is arranged on the surface of the crushing roll, a crushing separating screen is coaxially sheathed at the periphery of the crushing roll, a crushing feeding hole matched with the forced feeding roll is formed at the front part of the crushing separating screen, a discharging compartment communicated with the crushing compartment is arranged at the bottom of the crushing compartment, a discharging hole is formed at the bottom of the discharging compartment, and a discharging conveyer is arranged under the discharging hole. According to the biomass fuel crusher, the universality of the crusher is improved, various biomass fuels in wastes in the fields of agriculture, forest industry, industry, construction industry and the like can be subjected to crushing processing, the operating efficiency and the crushing quality of the crusher are improved, the service life of the crusher is prolonged, the power consumption is reduced, and the using cost and the operating expense are reduced.

Owner:格薪源生物质燃料有限公司

Furnace-free front storage bin feeding device for biomass power plant

InactiveCN102913935ALower the altitudePrevent bridgingFluidized bed combustionLump/pulverulent fuel feeder/distributionFailure ratePower station

The invention relates to a furnace-free front storage bin feeding device for a biomass power plant. The blanking is directly performed by employing a charging belt, a charging belt corresponds to a distributor, a distributor is provided with two discharge openings; the discharge openings of each distributor are butted with a spiral feeding device through a blanking pipe; and four spiral feeding devices respectively corresponds to four feeding holes of a corresponding boiler. The device is easy, convenient and high in adaptability, the transfer link is reduced, the failure rate of the system is reduced, the height of the charging belt is reduced, the bridging and bulking phenomena in the traditional stokehole storage bin are avoided, the floor area is saved, and the cost is saved; and meanwhile, the device has good practical using effect of various biomass fuels, the stability, reliability and the safety of equipment operation in a feeding system are improved, and the device can be widely applied to various boilers for biomass power generation, and are particularly applied to circulating fluidized bed boilers.

Owner:武汉丰盈能源技术工程有限公司

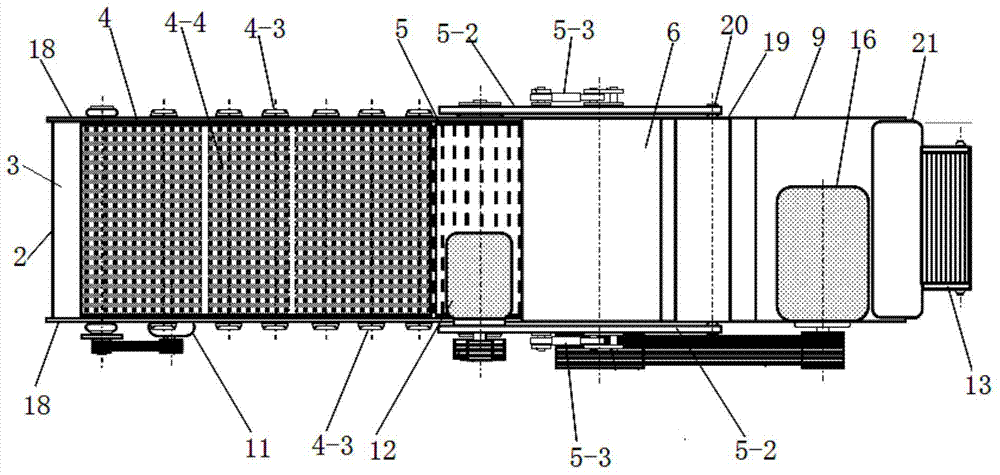

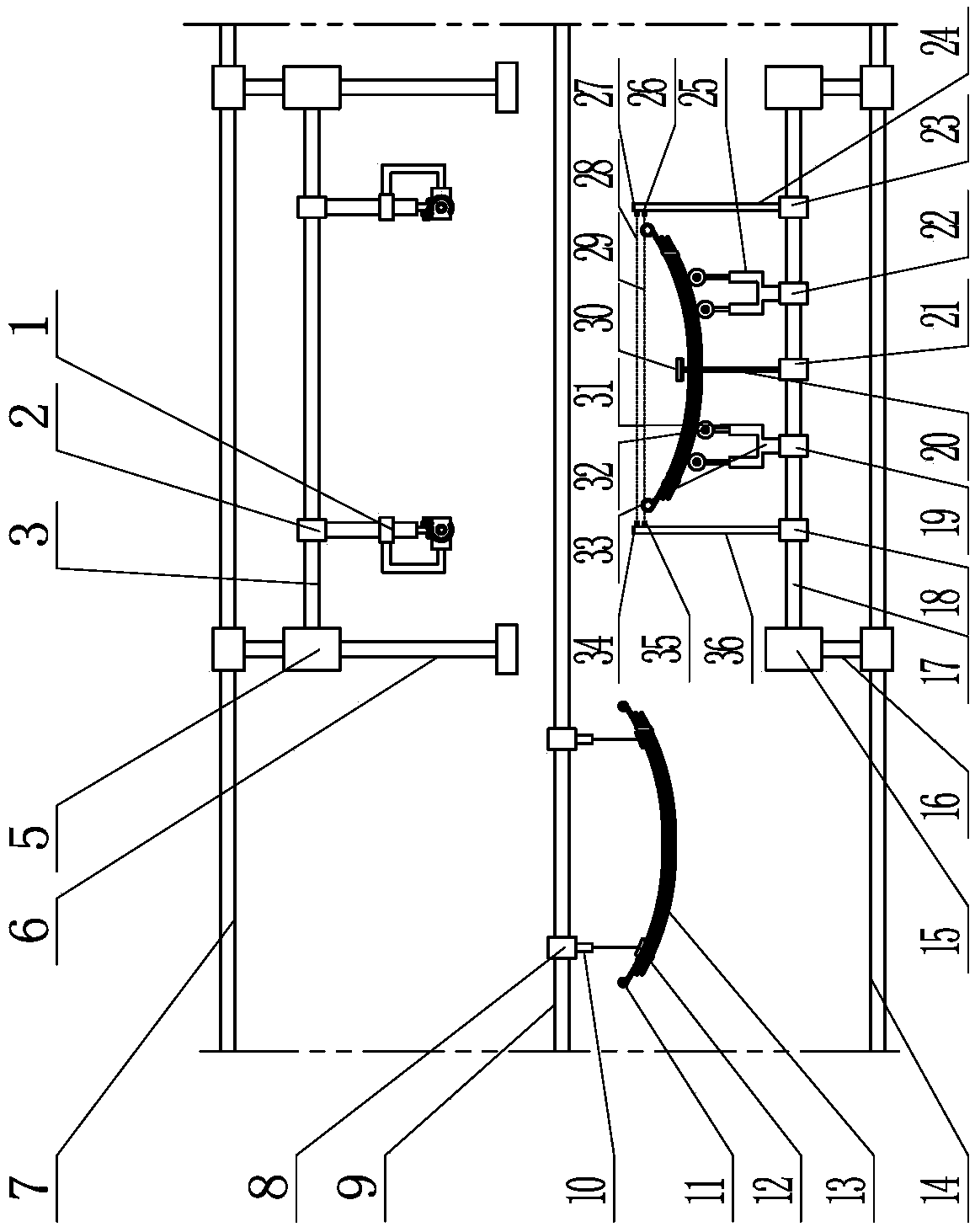

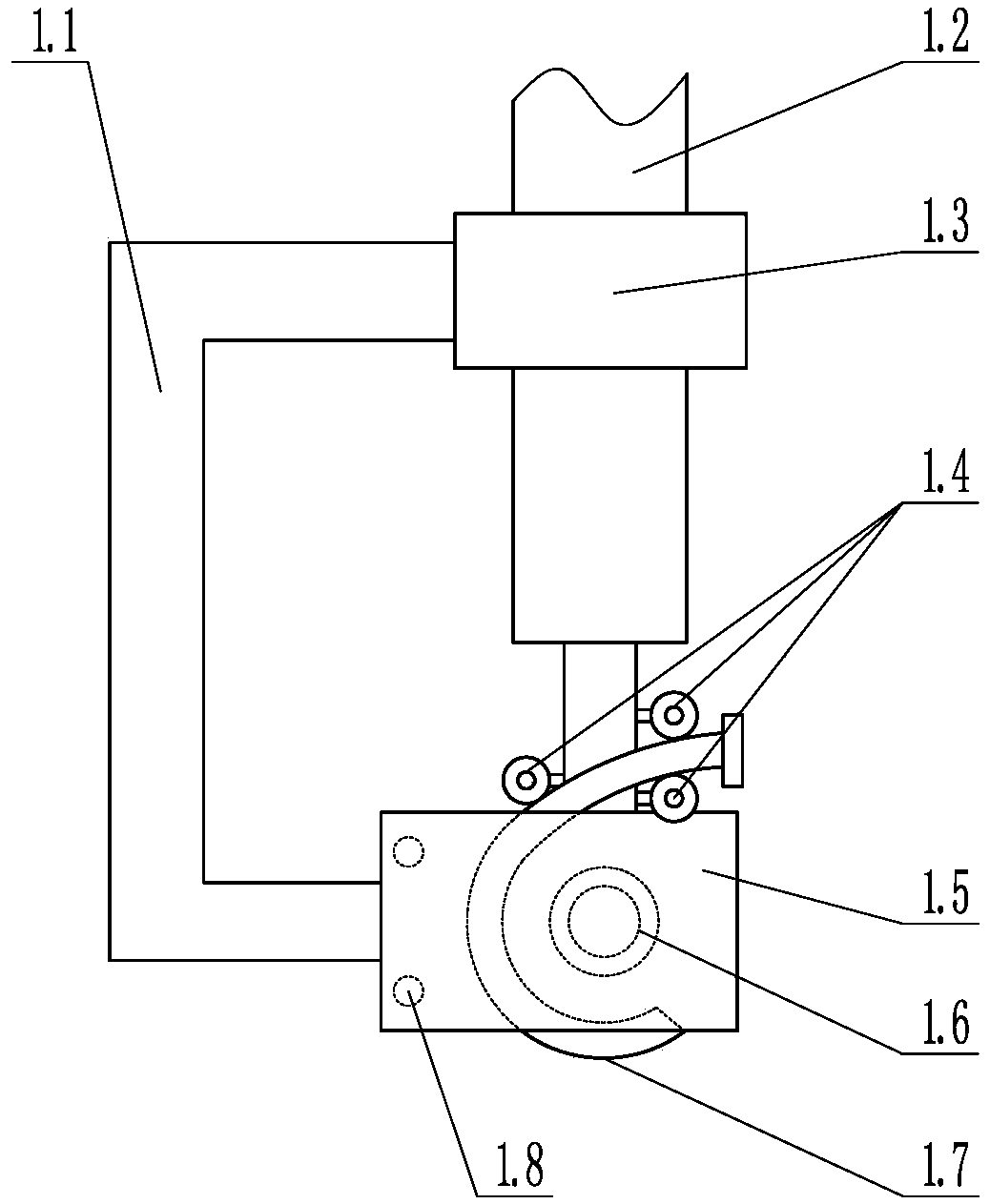

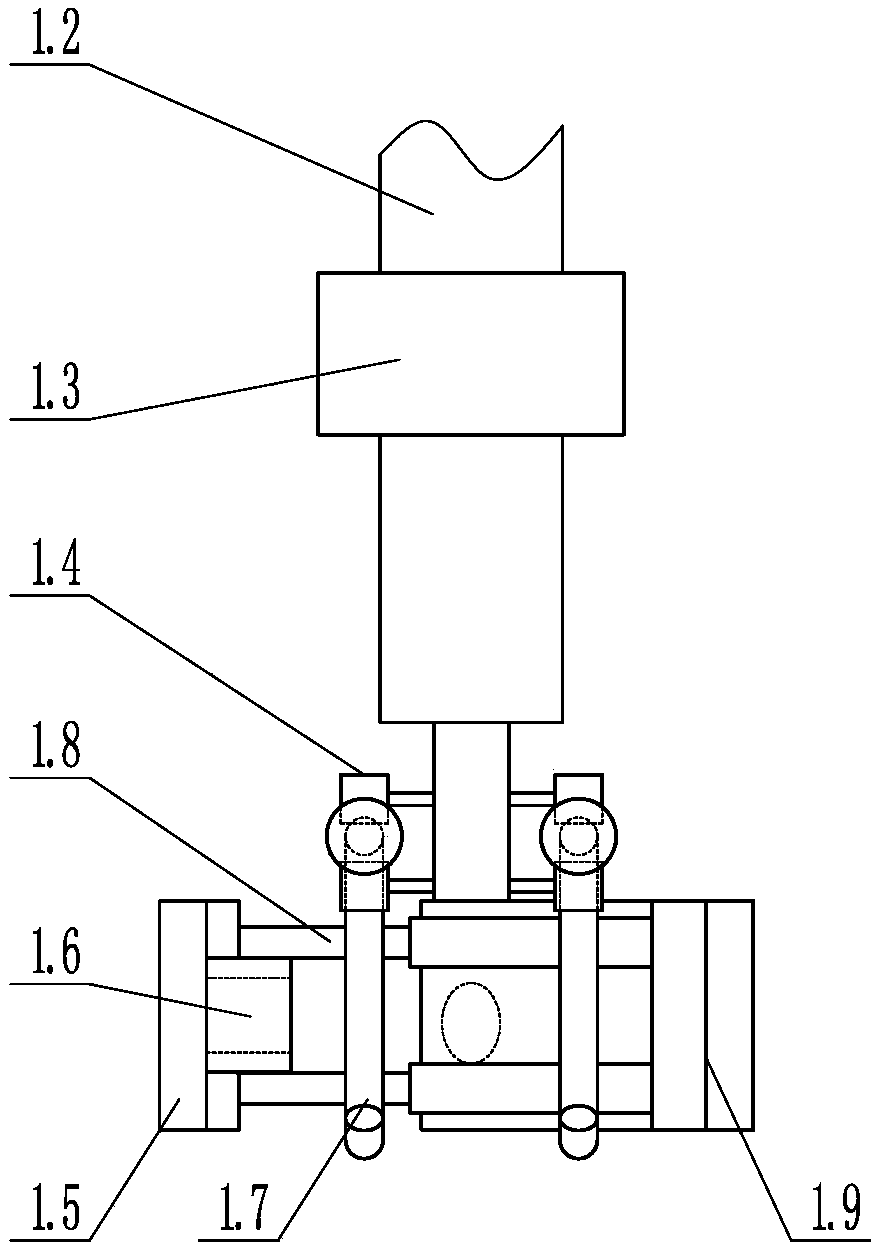

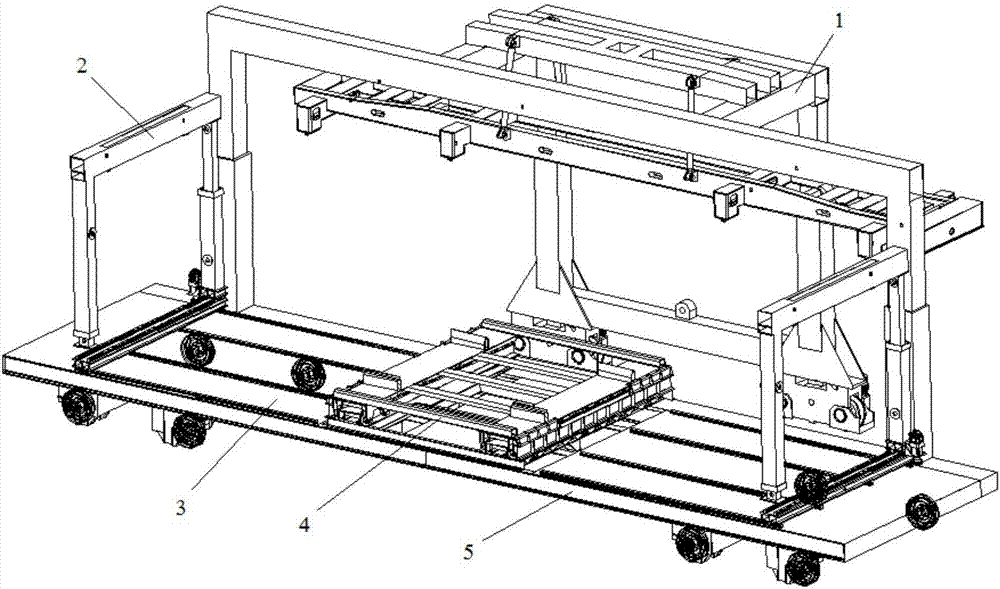

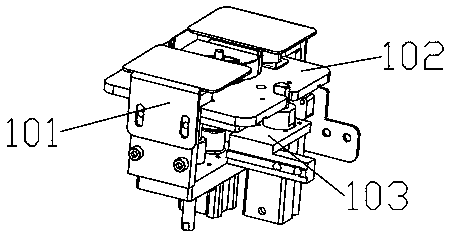

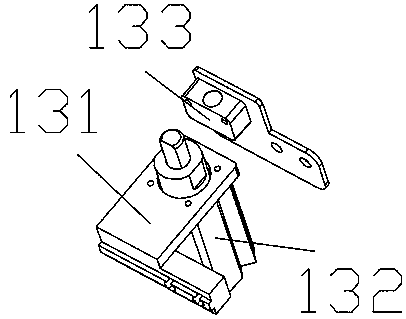

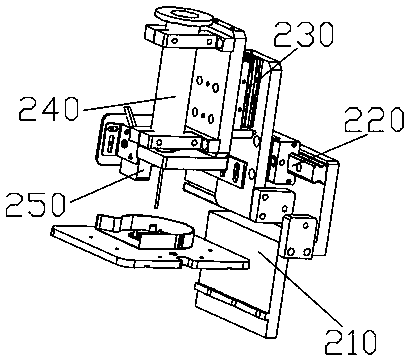

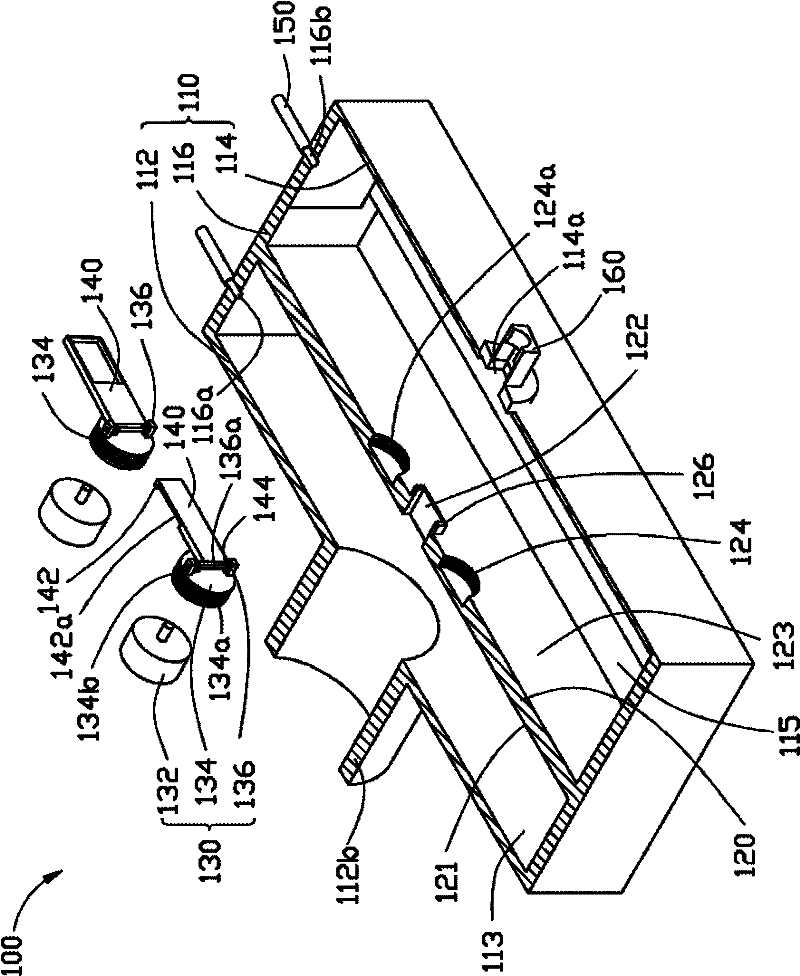

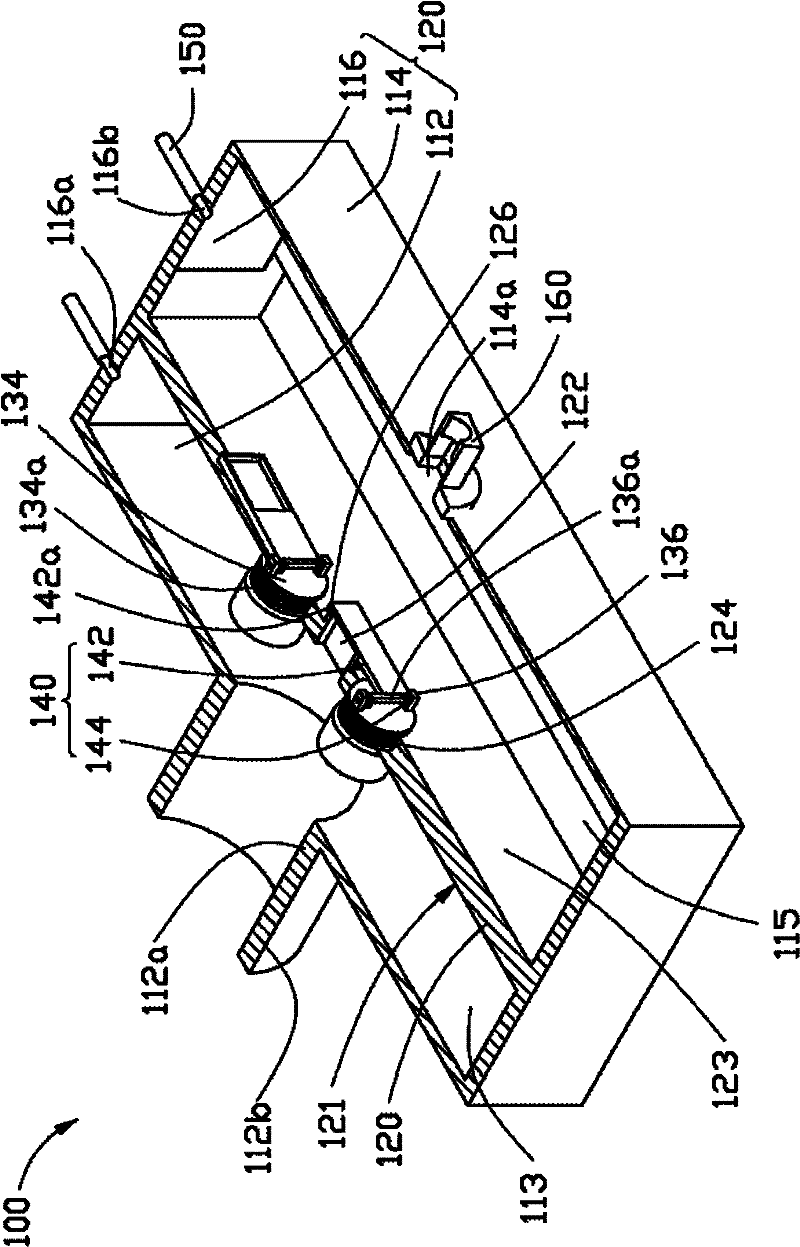

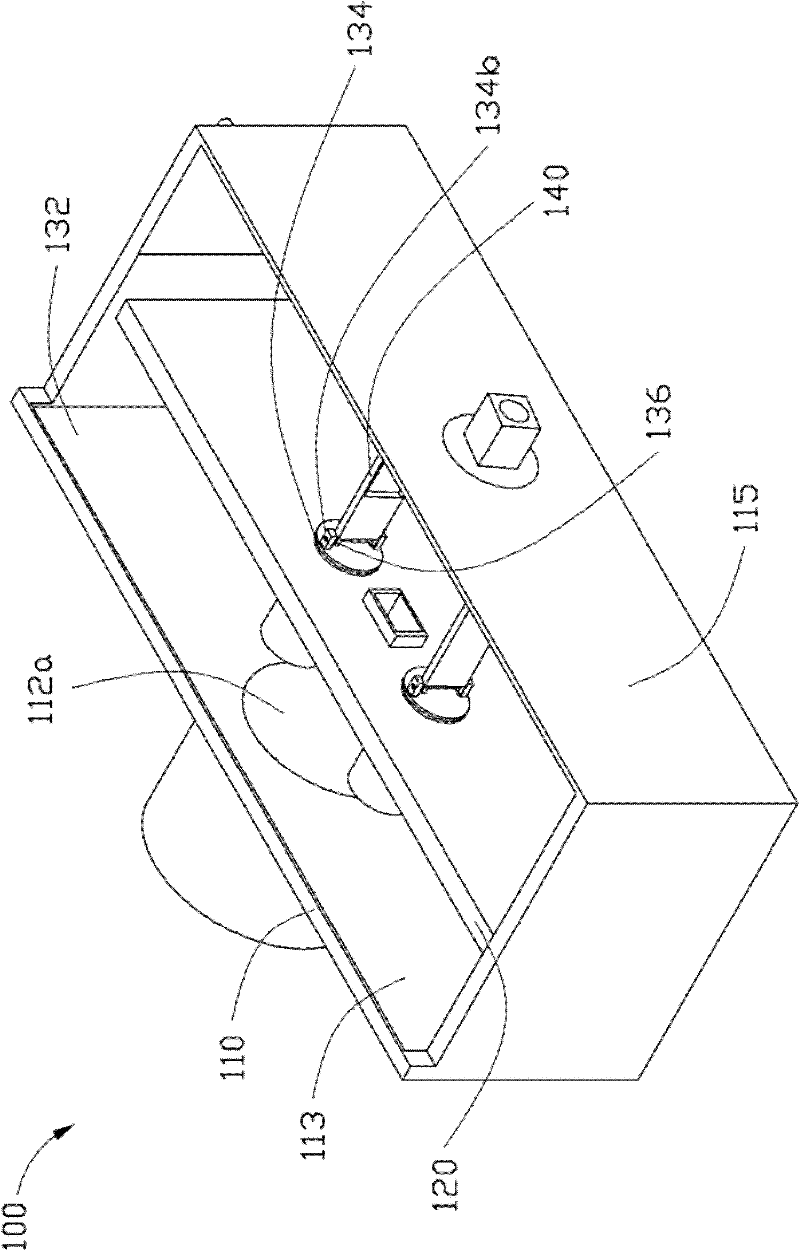

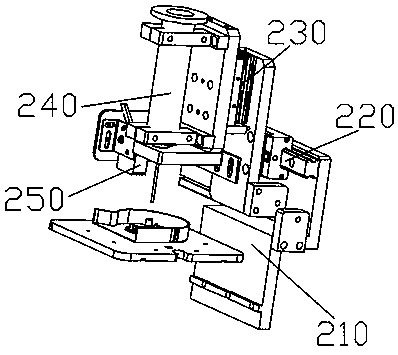

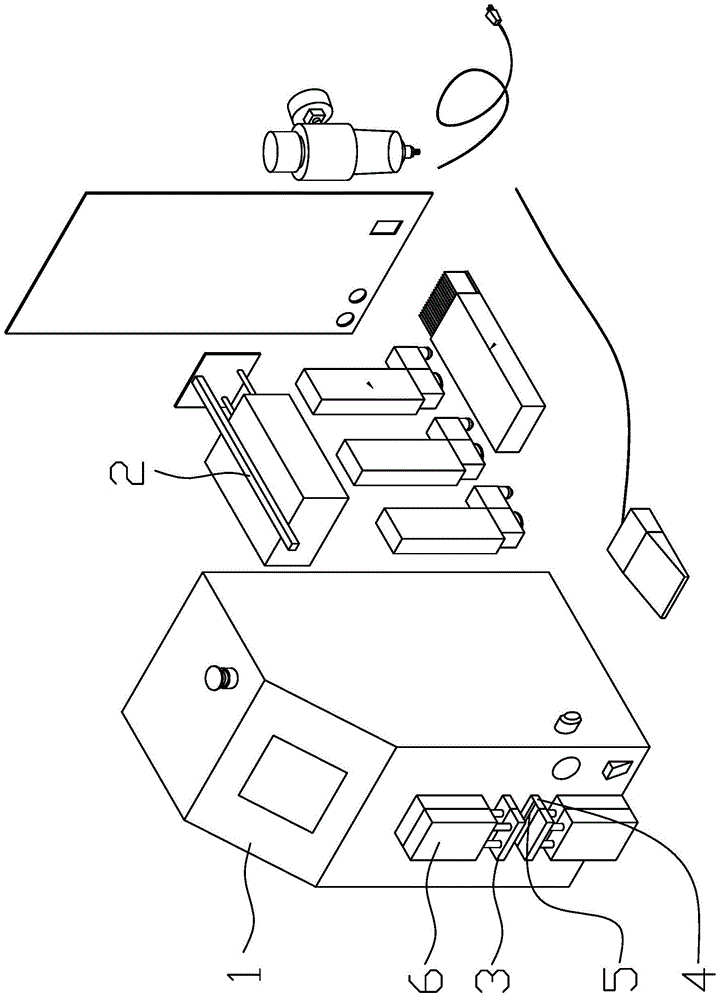

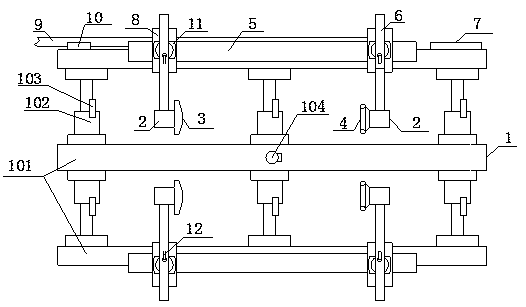

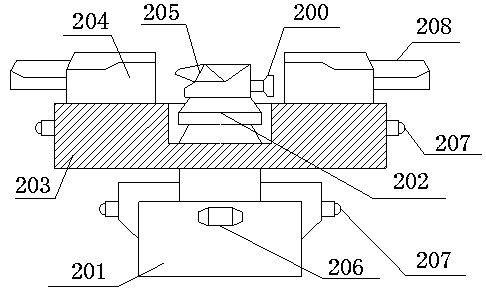

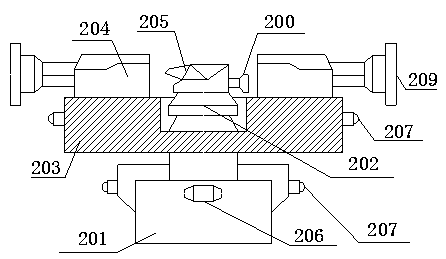

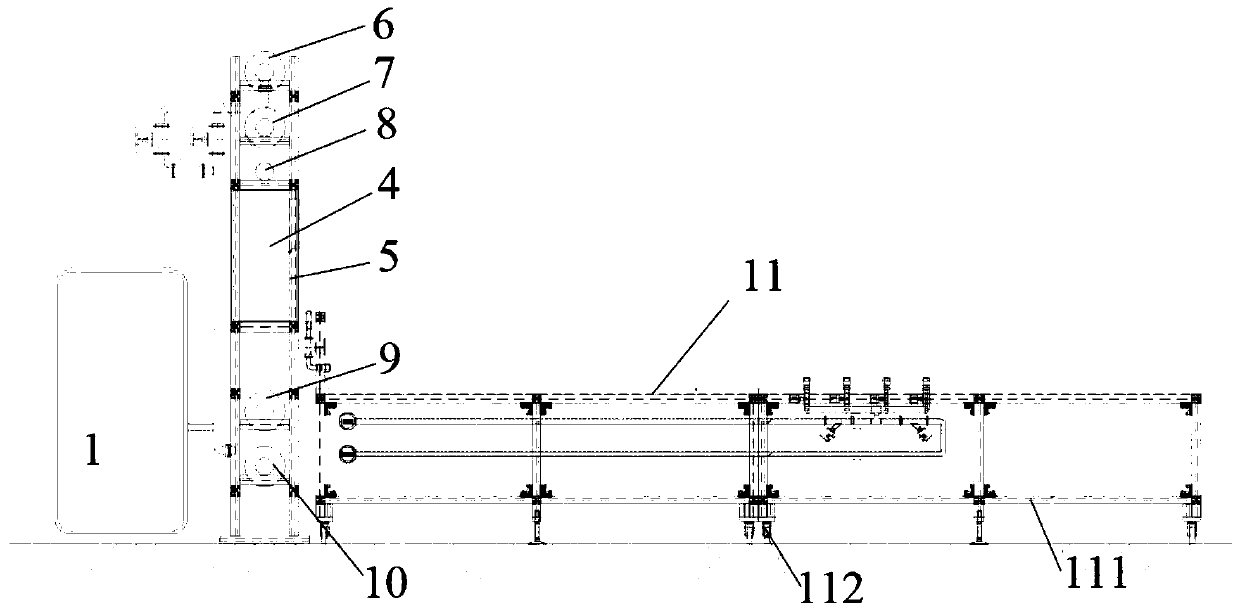

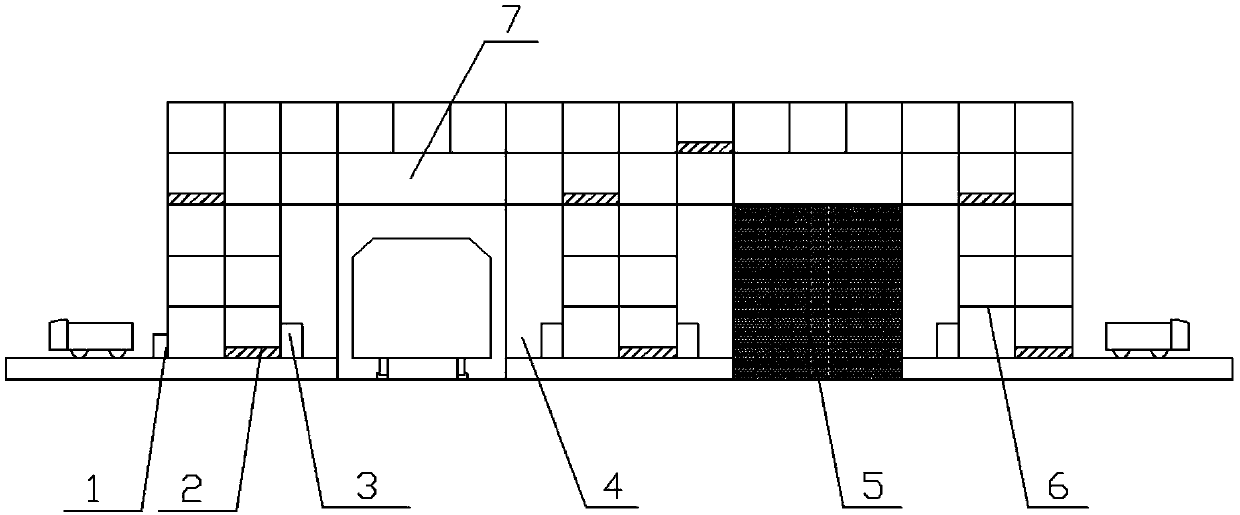

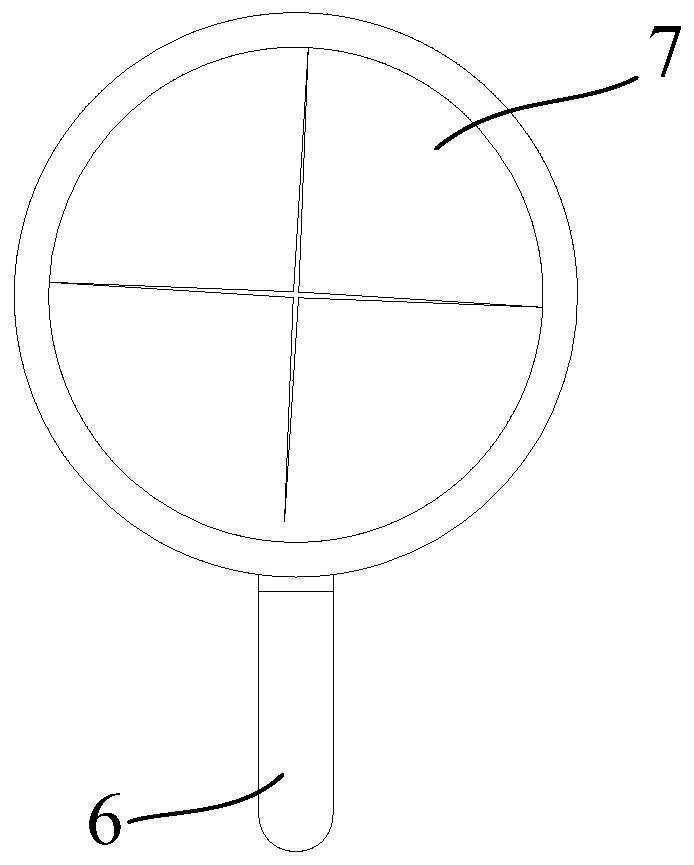

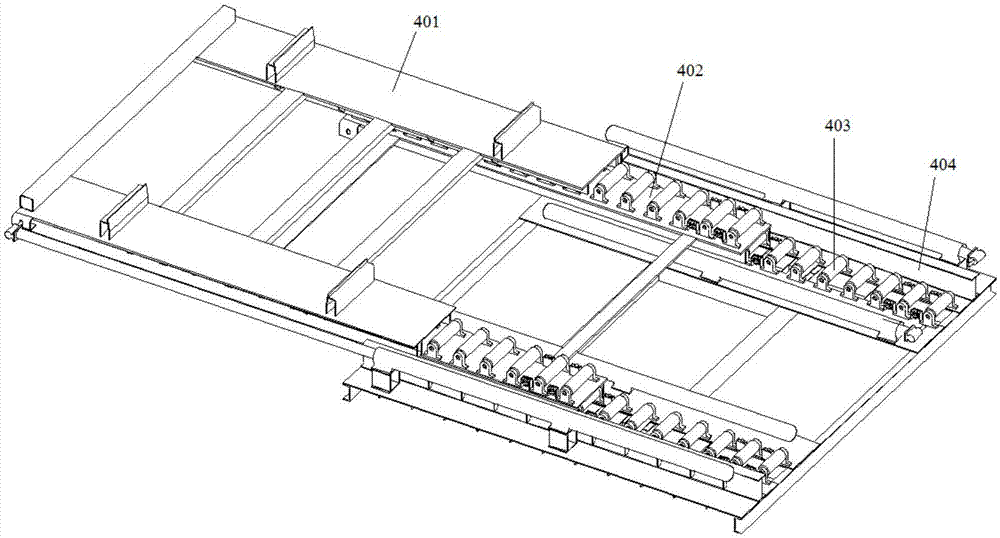

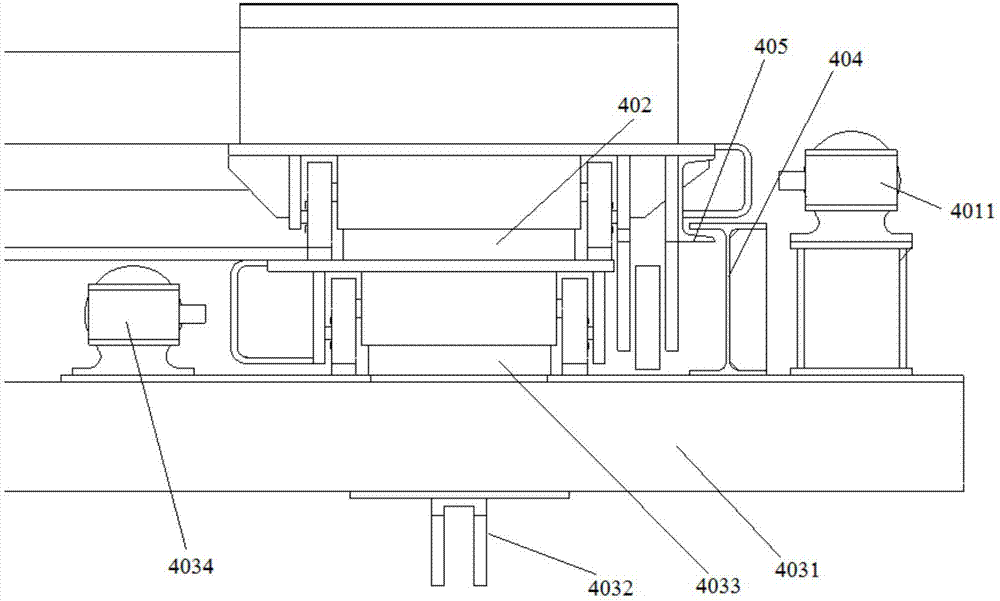

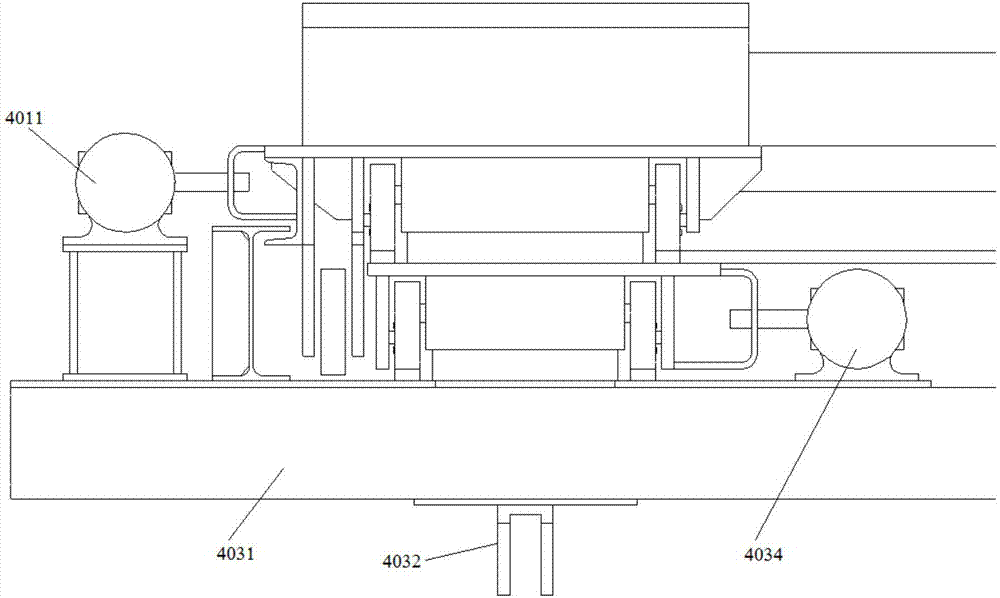

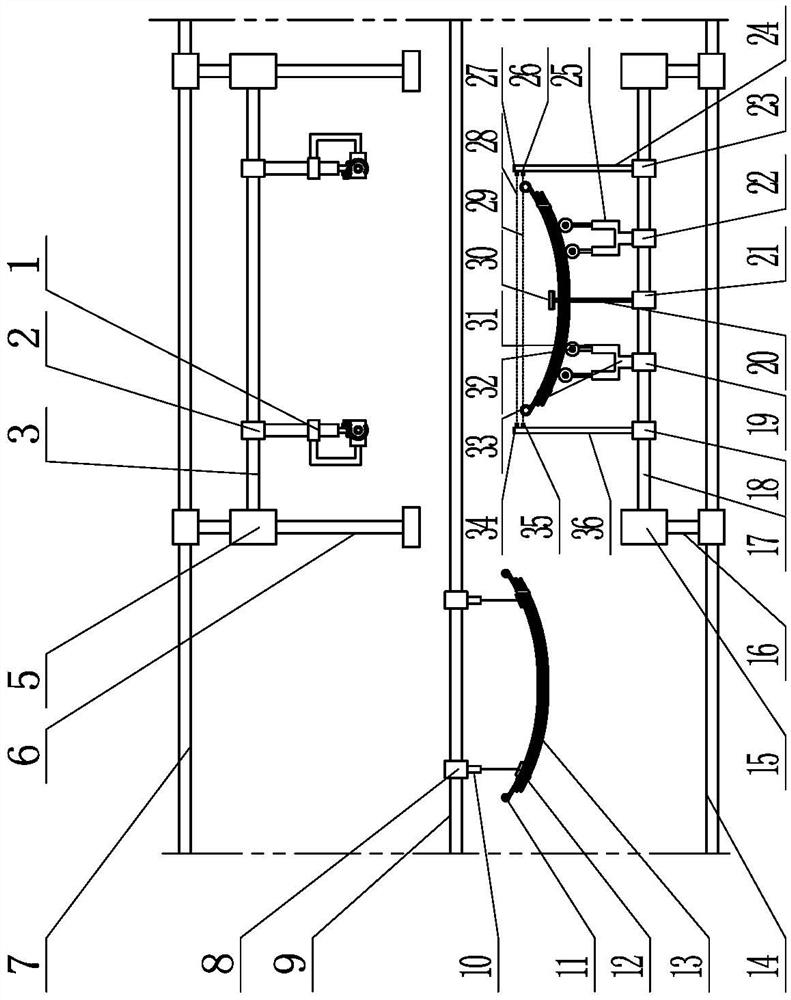

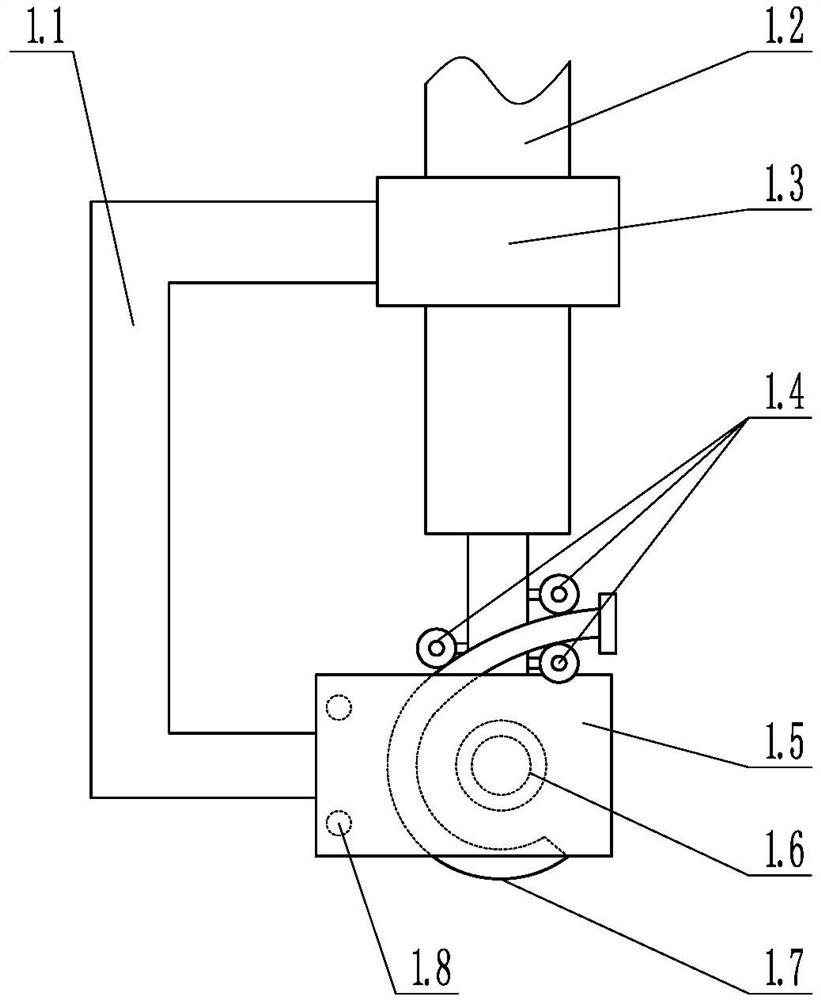

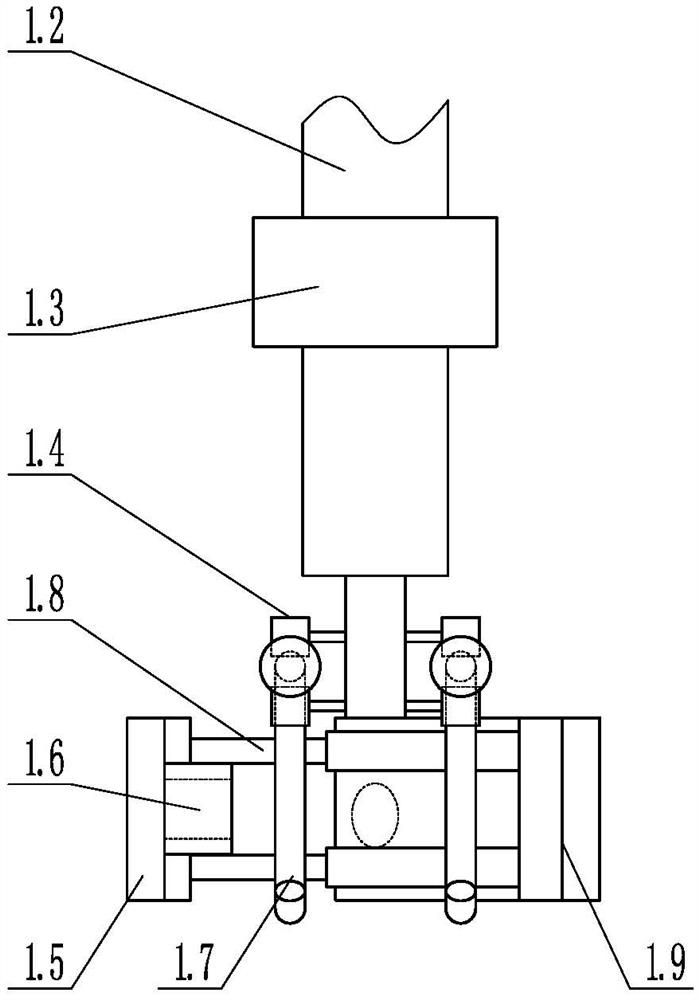

Plate spring online bush press-fitting equipment

ActiveCN108356502ARealize full automationReduce the transshipment linkMetal working apparatusProduction lineAssembly line

The invention provides plate spring online bush press-fitting equipment and belongs to the field of plate spring machining and assembly production equipment. The plate spring online bush press-fittingequipment is characterized by comprising a conveying line and an assembly production line. The conveying line can clamp and transport plate springs and place the plate springs onto the assembly production lines. The plate spring online bush press-fitting equipment conducts press-fitting operation on bushes to assemble the bushes onto lug holes of the two ends of the plate springs through the assembly production line. After completion of press-fitting operation, the conveying line can transfer out the plate springs from the assembly production line. The plate spring online bush press-fitting equipment can achieve full-process automation of plate spring lug and bush press-fitting. The equipment is integrated onto a multifunctional plate spring assembly line. Assembly line operation of the plate springs can be achieved. The product transfer links are reduced. Collisions to products is avoided as far as possible. The production efficiency is effectively improved, and the production cost is lowered.

Owner:SHANDONG LEOPARD AUTOMOTIVE HLDG

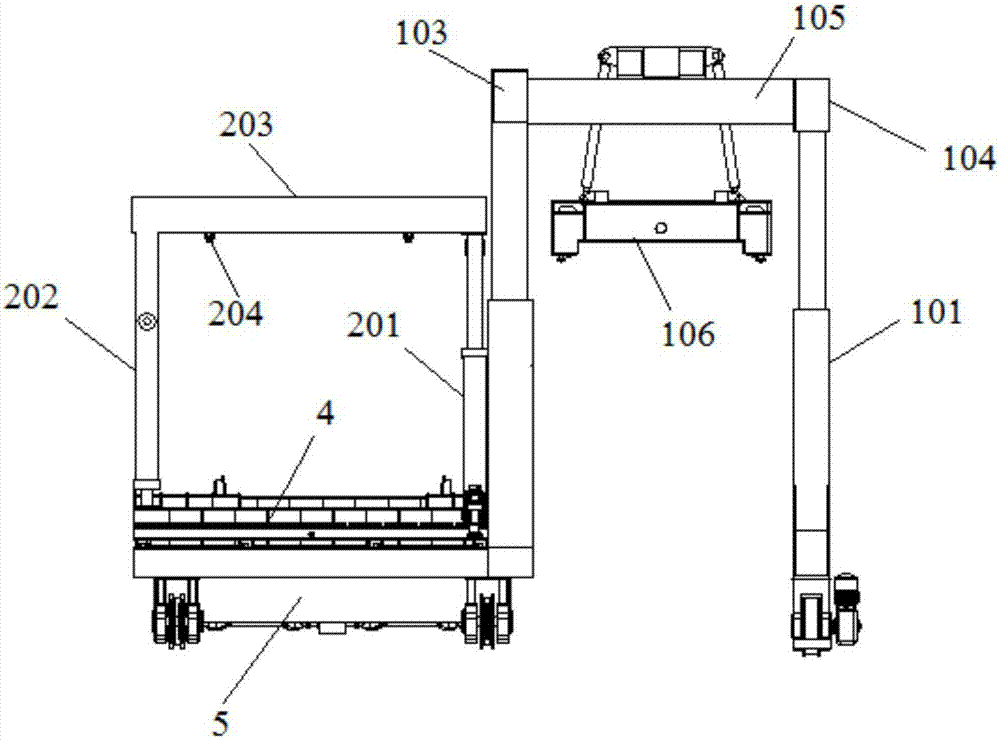

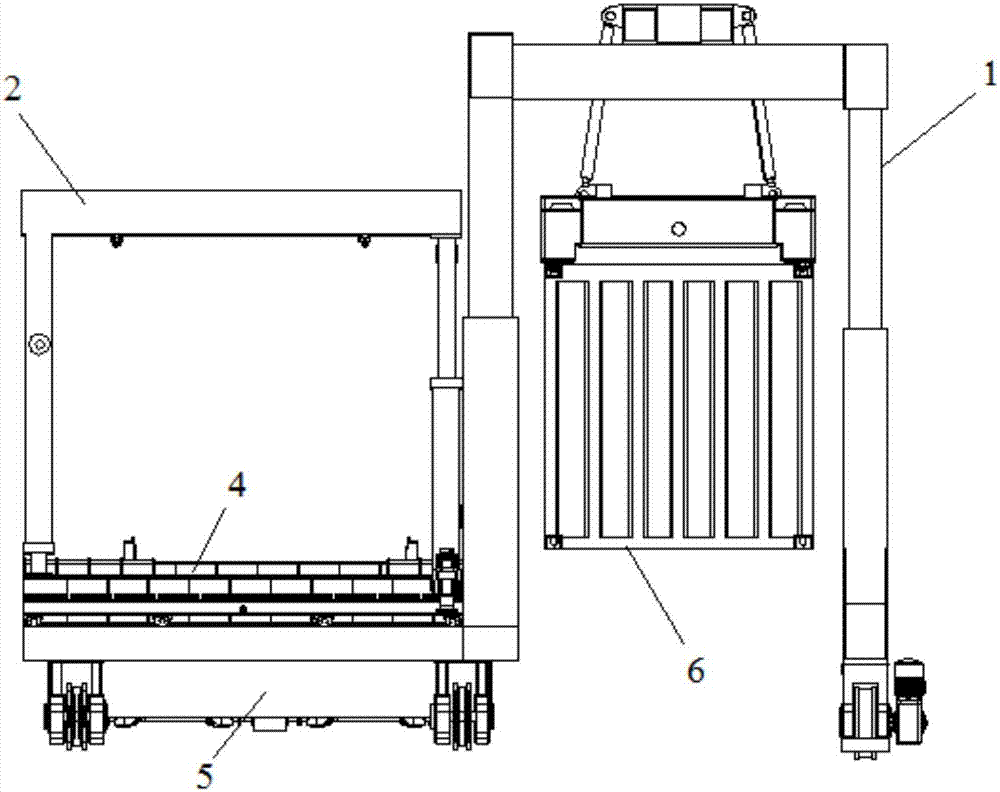

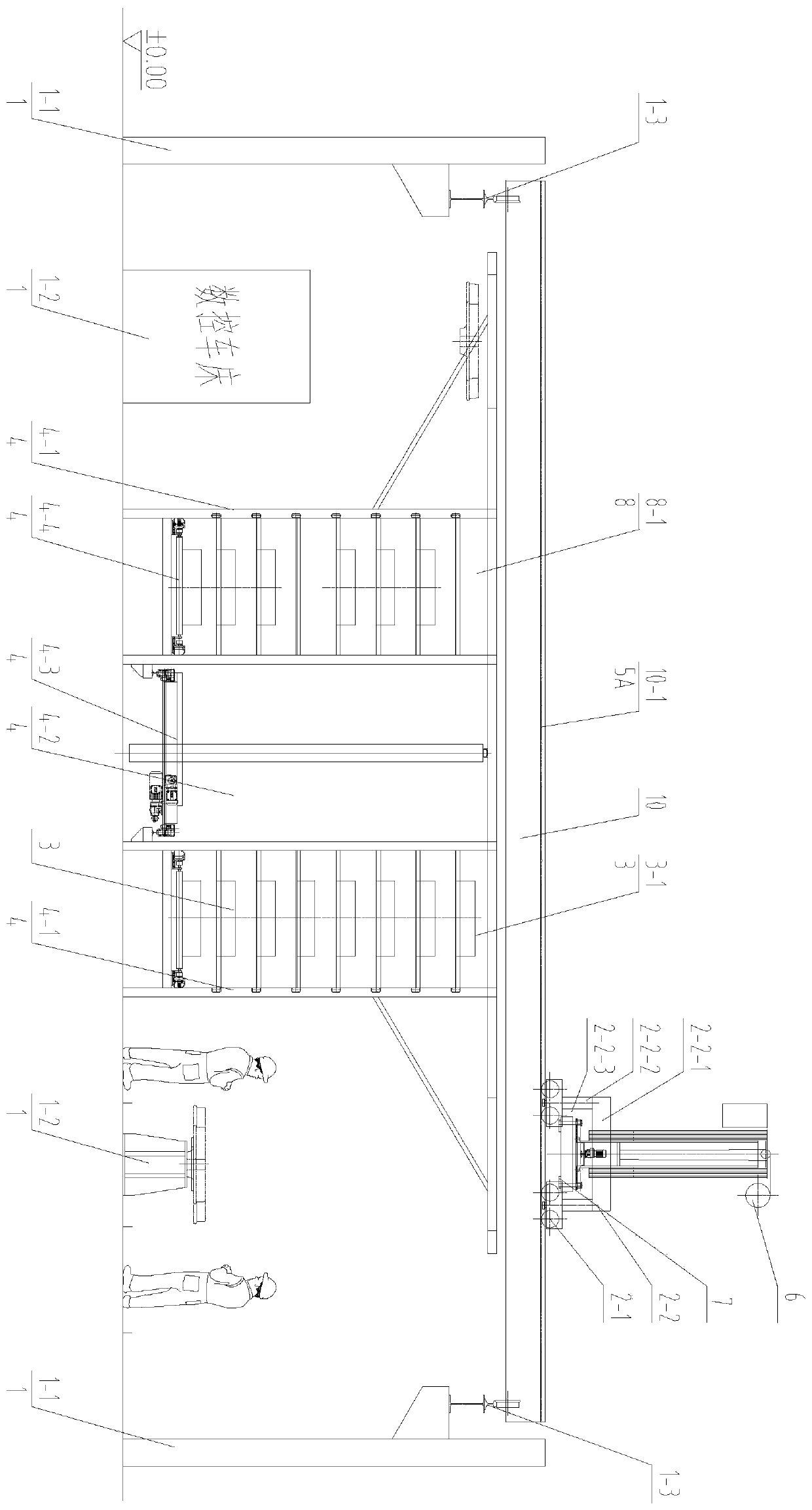

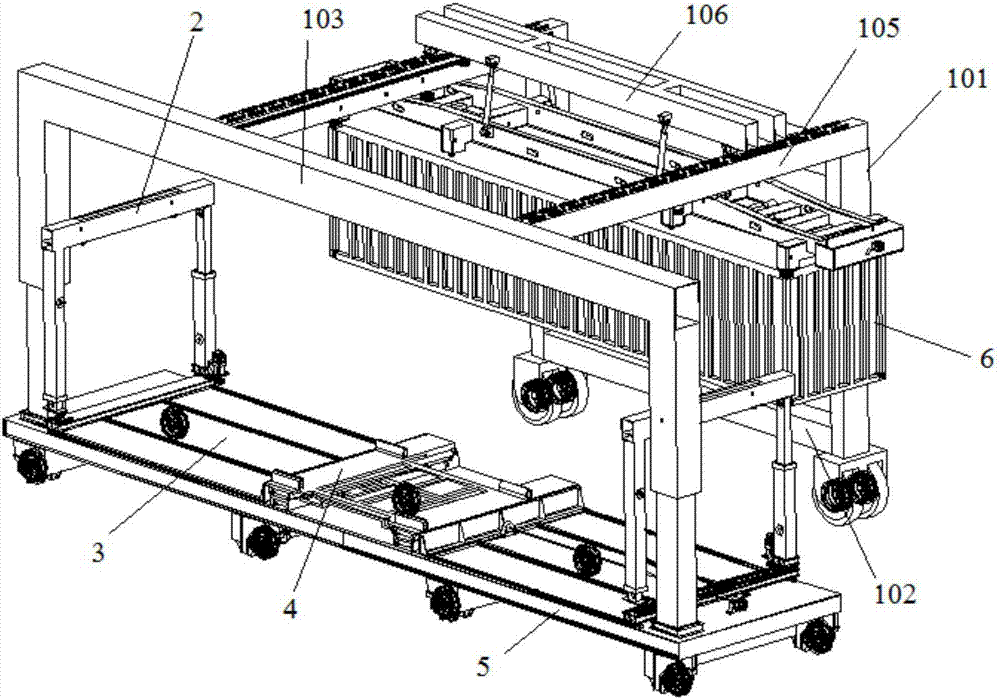

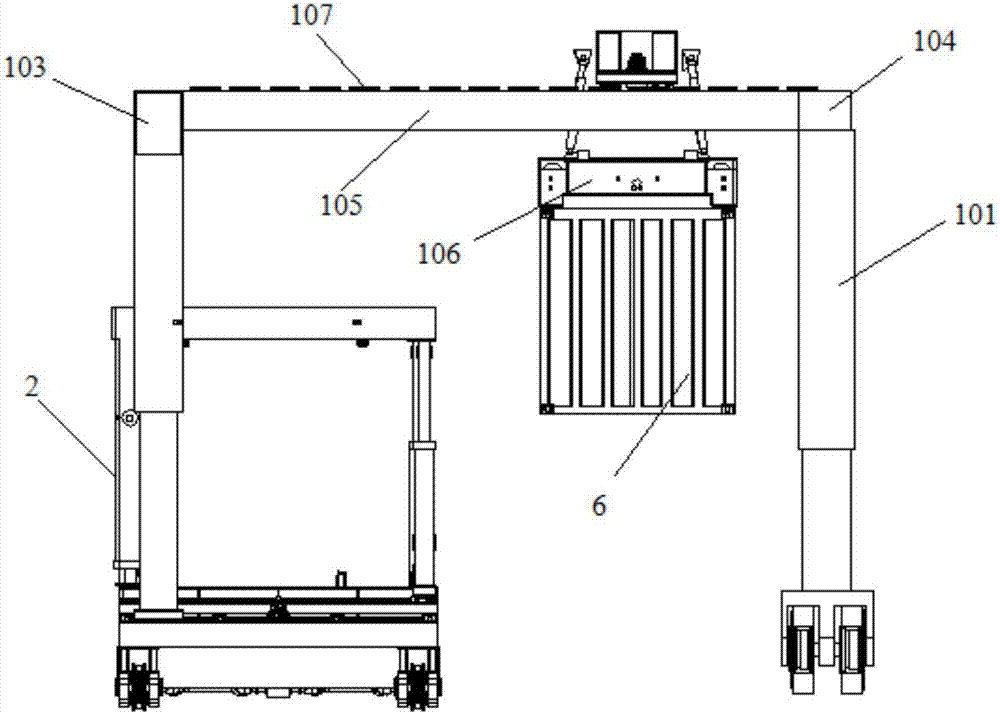

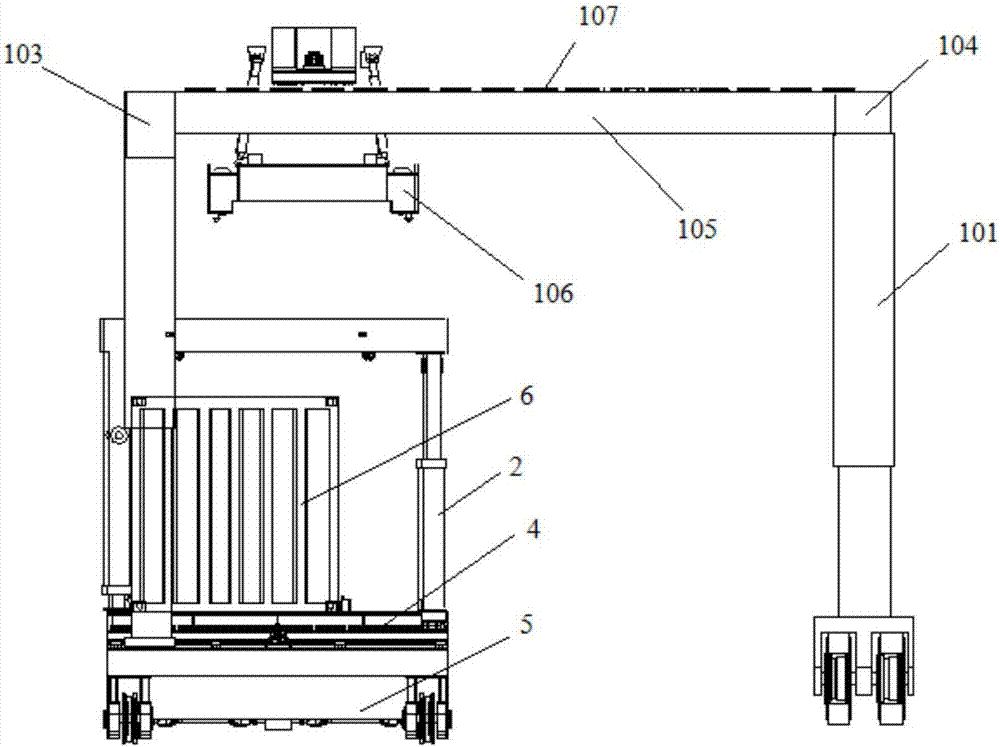

Container highway and railway transferring system

PendingCN108002056AGood fit designReduce space consumptionBase supporting structuresBraking devices for hoisting equipmentsMechanical engineeringUtilization rate

The invention relates to a container highway and railway transferring system. The container highway and railway transferring system comprises a lifting device, a bi-directional side taking device anda container lorry loading and unloading device. The bi-directional side taking device transfers containers corresponding to the position of the lifting device to the position corresponding to the container lorry loading and unloading device, and / or, transfers containers corresponding to the position of the container lorry loading and unloading device to the position corresponding to the lifting device; the lifting device lifts and puts containers on a railway vehicle onto the bi-directional side taking device, and / or lifts and puts the containers on the bi-directional side taking device to therailway vehicle; and the container lorry loading and unloading device lifts and puts the containers on a container lorry onto the bi-directional side taking device, and / or lifts and puts the containers on the bi-directional side taking device to the container lorry. According to the container highway and railway transferring system, it does not need to interfere with a railway electrified contactnet, the highway and railway transferring link is simplified, the equipment cost and the running cost are reduced, the space utilization rate of a work place is increased, and the highway and railwaytransferring efficiency is improved.

Owner:CRRC YANGTZE CO LTD

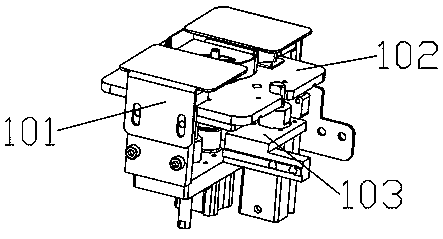

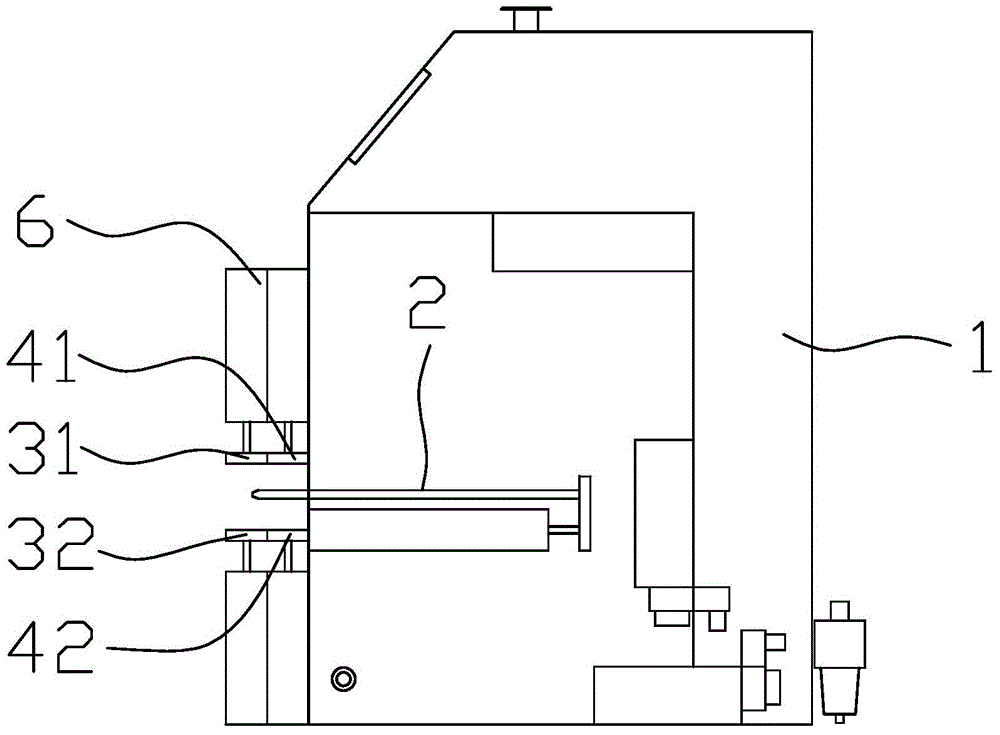

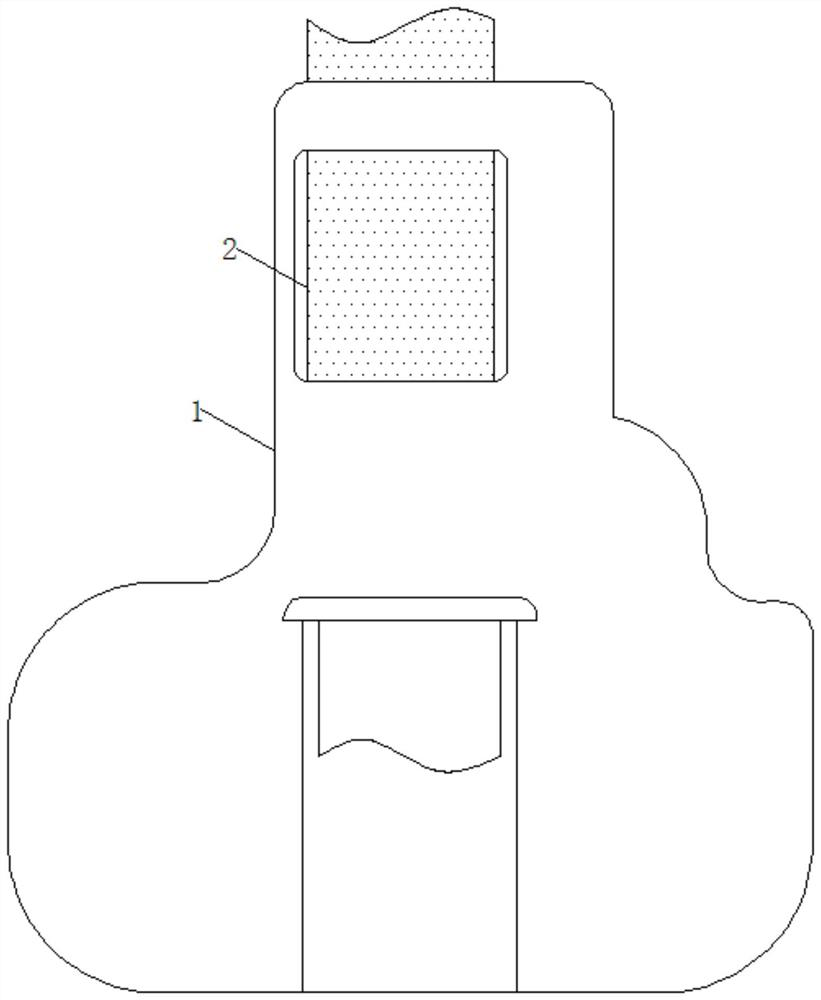

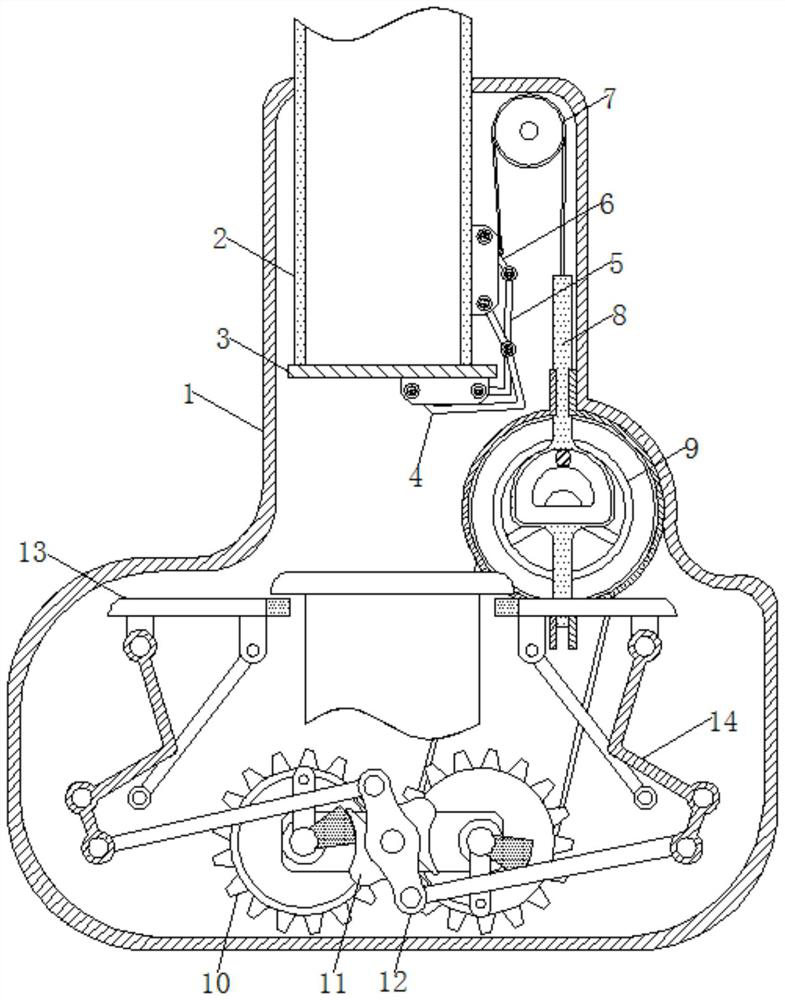

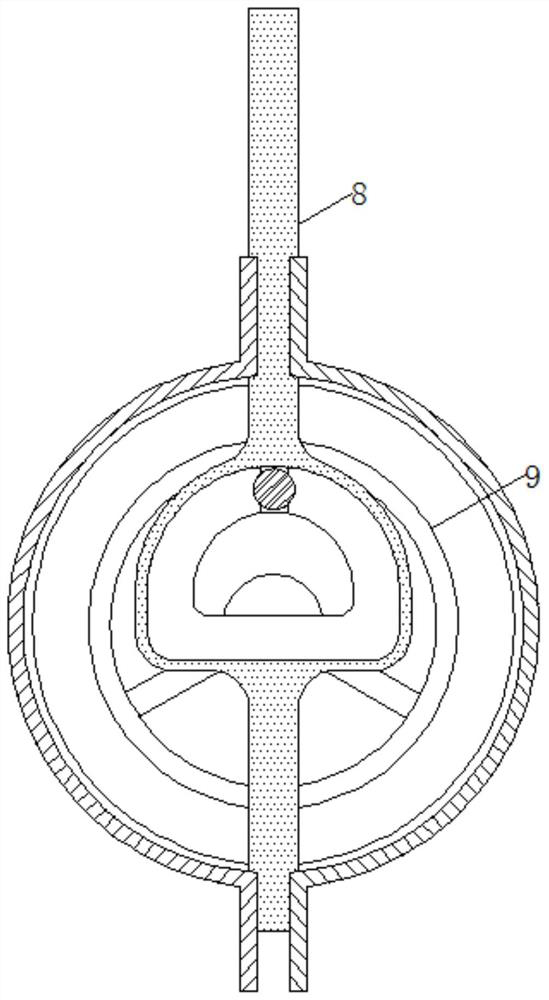

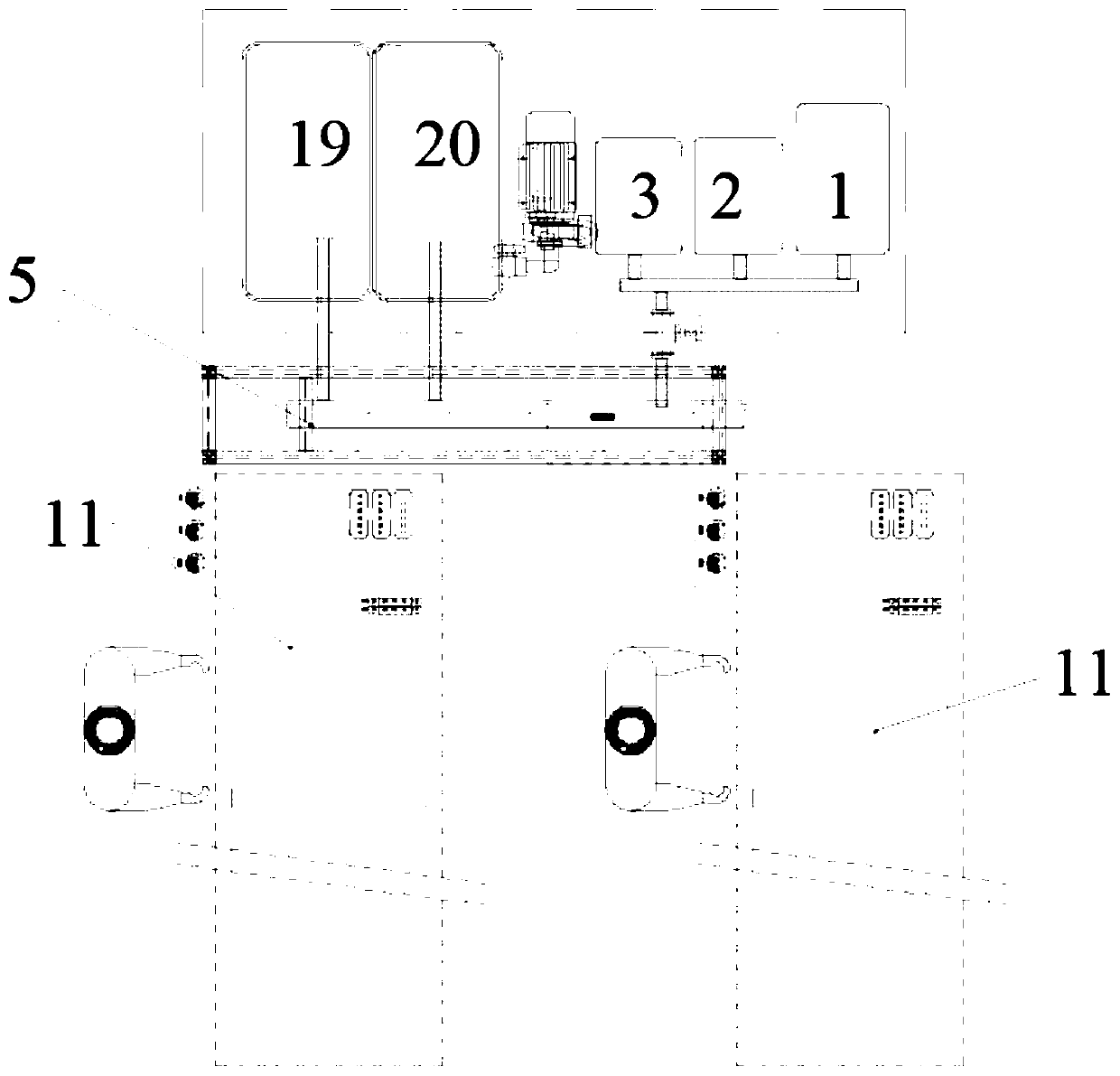

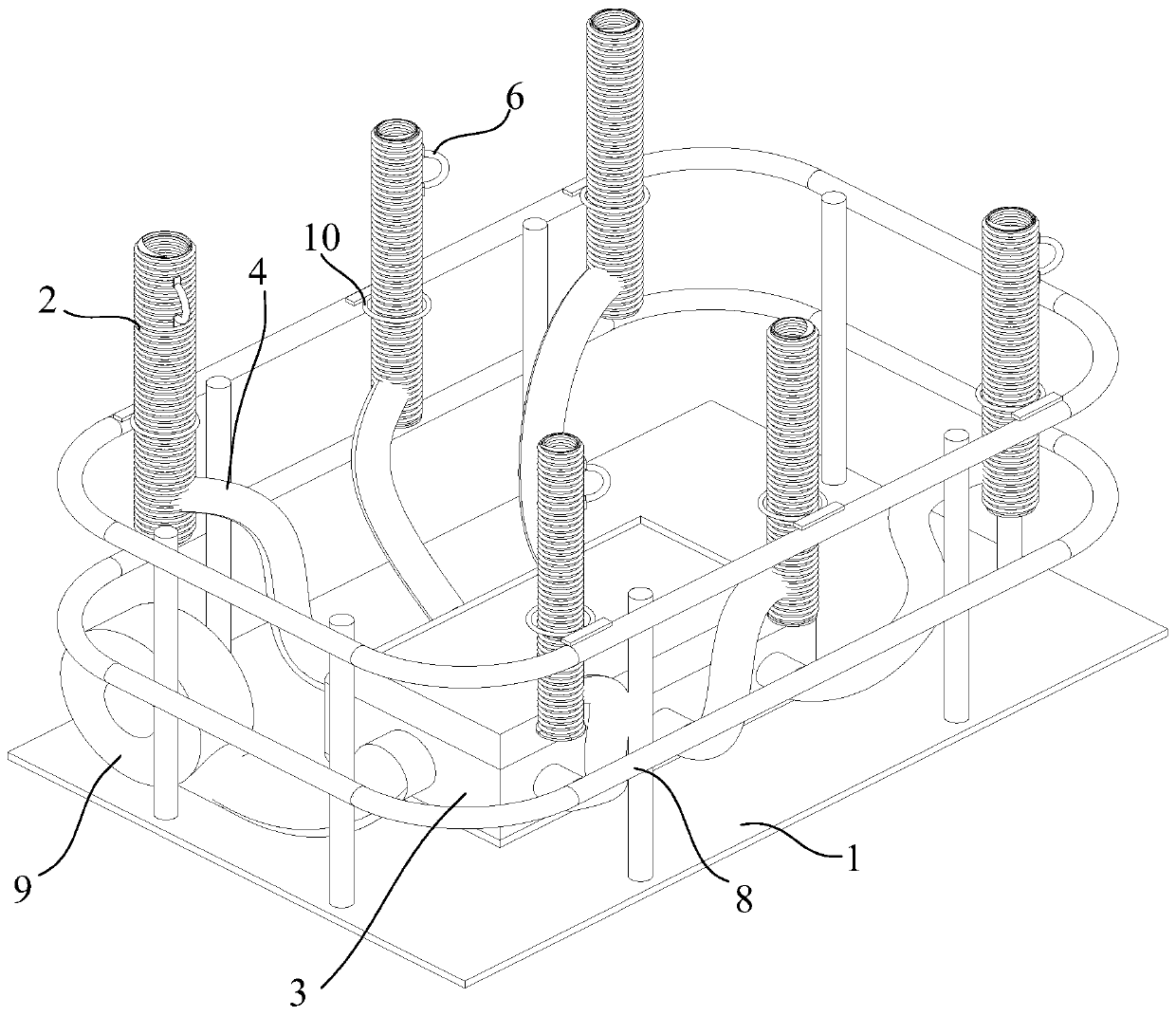

Automatic assembly equipment for radiator fan

InactiveCN109366174ARealize automatic assemblyReduce the transshipment linkAssembly machinesMetal working apparatusImpellerAutomatic test equipment

The invention discloses automatic assembly equipment for a radiator fan. The automatic assembly equipment comprises a supporting cabinet body, an intelligent control terminal, an electrical appliancecontrol cabinet and a protective housing. The automatic assembly equipment is characterized by further comprising a conveying device, wherein an upper friction plate, an upper locking ring, a dispensing device, an annular shaft installer, a motor loading installer, a pressing device, a rotary piston ring installer, and an impeller installer are sequentially arranged on the conveying device; and anarray take-place device is mounted at the side of the impeller installer, so that assembly of the radiator fan is realized, and therefore, assembly in the whole process is completed. The automatic assembly equipment realizes automatic assembly for the radiator fan, reduces the transfer link in an assembly production process, enables the production process to be centralized, is quick in assembly,is intelligent in operation, greatly improves production efficiency, and reduces labour cost.

Owner:深圳市阿尓法智慧科技有限公司

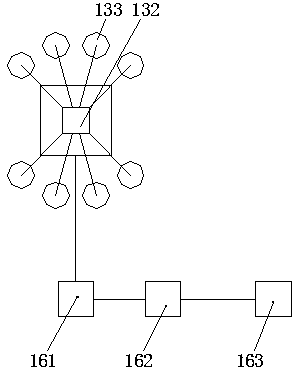

Intelligent four-way rail car coil conveying system

InactiveCN106915610ALight weightSimplify the shipping processControl devices for conveyorsMechanical conveyorsSteering wheelHigh energy

The invention discloses an intelligent four-way rail car coil conveying system, relates to a coil conveying system, and aims to solve such problems as high energy consumption, manual collision in transfer and low efficiency in the relay transportation by multiple transportation tools as an overhead crane and a striding flat car in traditional aluminum plate strip production and incapability of totally adapting to actual automatic quick production of aluminum plate strips by a coil conveying system produced on the traditional market. Ground rails for cars without axle generator are embedded in the ground; operation groove lanes for cars with axle generator are formed in the ground; rails for cars with axle generator are laid in the operation groove lanes for cars with axle generator; a ground steering wheel with a coil saddle is arranged in the junction of the ground rails for cars without axle generator, and is provided with rails for cars without axle generator of the ground steering plate; each steering wheel for cars without axle generator is positioned in the center of an upper base surface of a corresponding car with axle generator, rails for cars without axle generator of steering wheel for cars without axle generator are embedded into the steering wheel for cars without axle generator; and the rails for cars without axle generator of steering wheel for cars without axle generator can respectively realize linear alignment to four sets of rails for cars without axle generator of upper base surfaces of cars with axle generator on the upper base surfaces of the cars with axle generator along with rotation of the steering wheel for cars without axle generator. The intelligent four-way rail car coil conveying system is suitable for coil transportation.

Owner:开洪利

Garden-type building material recycling plant

PendingCN108149966AReduce pollutionReduce transshipment costsCeramic shaping plantsGrain treatmentsLandscapingEngineering

The invention discloses a garden-type building material recycling plant and belongs to the field of building material preparation. The garden-type building material recycling plant includes a production workshop, an aggregate finished product area, a central control room, a green landscape area, and a road system; the aggregate finished product area is a storage area for finished gravel aggregates, construction-waste recycling gravel aggregates and spent clay, and includes a plurality of fully enclosed concrete storage silos; the central control room includes an equipment control system, an equipment operation parameter monitoring system, an output real-time monitoring system, an environmental monitoring system, and a self-service sales system for the gravel aggregates which are electrically connected; the green landscape area includes ground greening, artificial landscaping, and waterscape; and the road system includes finished product transport roads, raw material transport roads, and fire-fighting roads. The garden-type building material recycling plant integrates the whole industrial chain of production of concrete from gravel aggregate production to prefabricated component production, intermediate road transport links are reduced, and energy consumption, environmental pollution, and transportation costs are reduced.

Owner:CHENGDU DAHONGLI MACHINERY

High-performance carbon nano-material adsorbent and preparation and application thereof

ActiveCN106824073ANot easy to mergeHigh specific surface areaOther chemical processesSolid sorbent liquid separationGas phaseAdhesive

The invention discloses a high-performance carbon nano-material adsorbent and preparation and application thereof. The high-performance carbon nano-material adsorbent is composed of a carbon nano-material and an adhesive. Mass fraction of the carbon nano-material is 80-97 wt%. Specific surface area of the adsorbent is 800-2200 m<2> / g. The pore volume ratio of micropore to mesopore to macropore is (1-3): (1-6): (1-10). The invention also discloses a method for directly preparing the adsorbent by the utilization of a compound of the carbon nano-material obtained during the chemical vapor deposition process and an inorganic compound carrier. The adsorbent has advantages of long service life, large handling capacity, low preparation cost, etc., and is especially suitable for adsorption of low-concentration nonpolar organic matter in a fluid.

Owner:TSINGHUA UNIV

Three-dimensional warehouse

PendingCN111137608ASmooth entry and exitEfficient in and out of storageStorage devicesVehicle frameIndustrial engineering

The invention provides a three-dimensional warehouse. A factory building of the three-dimensional warehouse comprises plant stand columns, equipment, a top transport vehicle, articles, three-dimensional warehouses and a track, wherein the equipment and the three-dimensional warehouses are positioned below the track, and the top transport vehicle comprises walking devices and a vehicle body; the vehicle body comprises a frame, stand columns, a cavity, a lifting device and a take-and-place device, the cavity with a downward opening is the bottom space in the frame, the stand columns are positioned at four corners of the frame, the walking devices are positioned at the bottoms of the stand columns, the lifting device is fixed on the frame, the take-and-place device is installed at the bottomof the lifting device, and lifting operation of the take-and-place device is achieved through the lifting device; and each three-dimensional warehouse comprises three-dimensional shelves, roadways, astackers and transport devices. The invention has the advantages that the transport vehicle is utilized to increase top-level channels of in and out of the warehouse, the transport devices are arranged in the three-dimensional shelves for direct in and out of the warehouse, so that the in and out of the three-dimensional warehouse are smoother and more efficient; and the articles are directly conveyed from the warehouse to the equipment, and the transfer link is reduced.

Owner:王燏斌

Container highway and railway transfer system

PendingCN108002057AConvenient and flexible transportationSafe and stable transferBase supporting structuresBraking devices for hoisting equipmentsTransfer systemTruck

The invention relates to a container highway and railway transfer system. The container highway and railway transfer system comprises lifting devices, a lateral taking device and container truck handling devices. The lateral taking device is used for transferring containers corresponding to the positions of the lifting devices to the positions of the corresponding container truck handling devicesand / or transferring the containers corresponding to the positions of container truck handling devices to the positions of the corresponding lifting devices. The lifting devices are used for lifting the containers on railway vehicles, placing the containers on the lateral taking device, and / or for lifting the containers on the lateral taking device and placing the containers on the railway vehicles. The container truck handling devices are used for limiting the containers on container trucks and placing the containers on the lateral taking device, and / or for lifting the containers on the lateral device and placing the containers on the container trucks. The container highway and railway transfer system does not need to interfere with an electrified railway overhead line system, the highwayand railway transfer links are simplified, the equipment and operation cost is reduced, and the highway and railway transfer efficiency is improved.

Owner:CRRC YANGTZE CO LTD

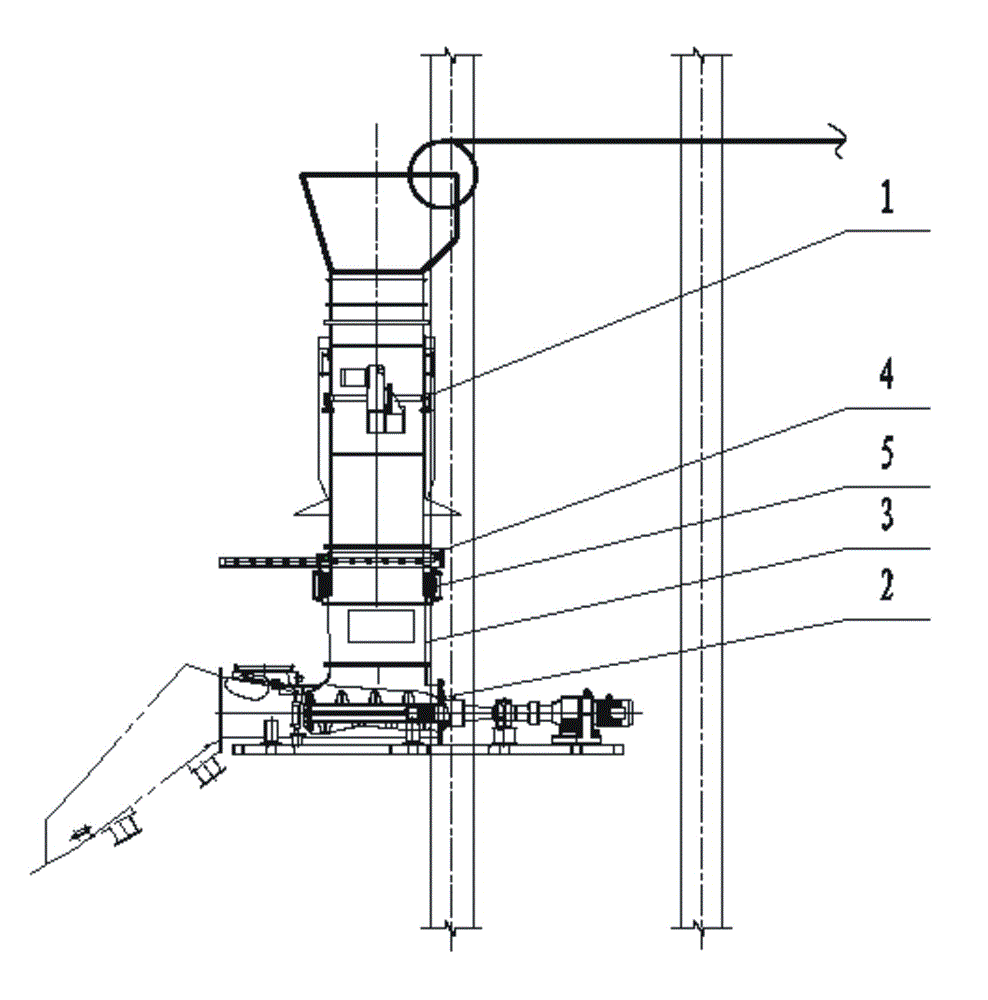

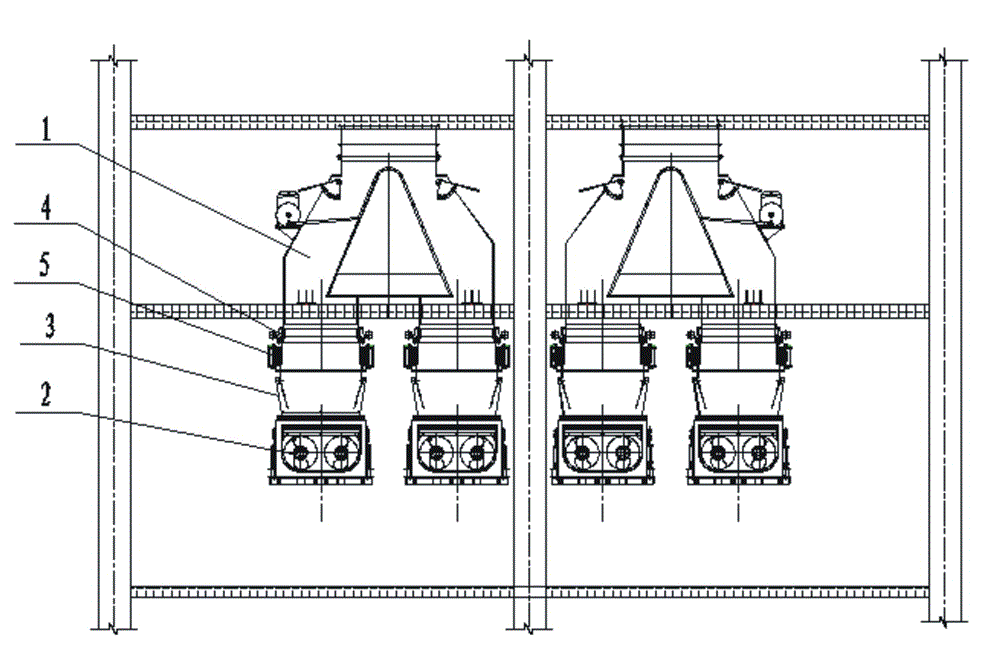

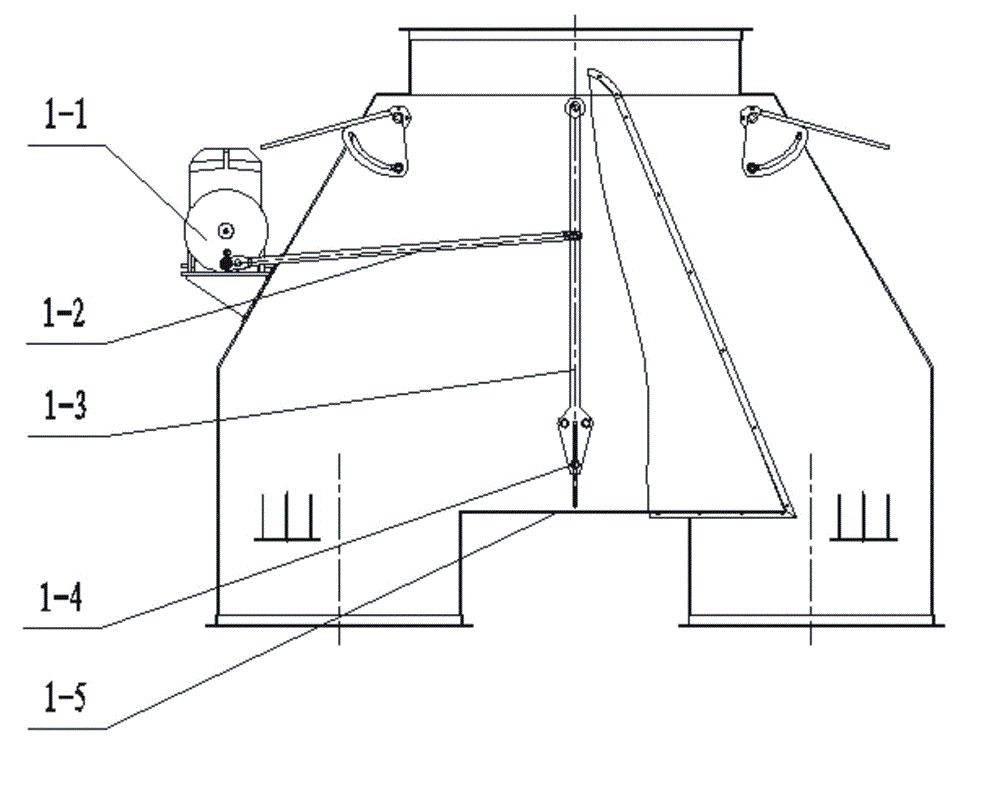

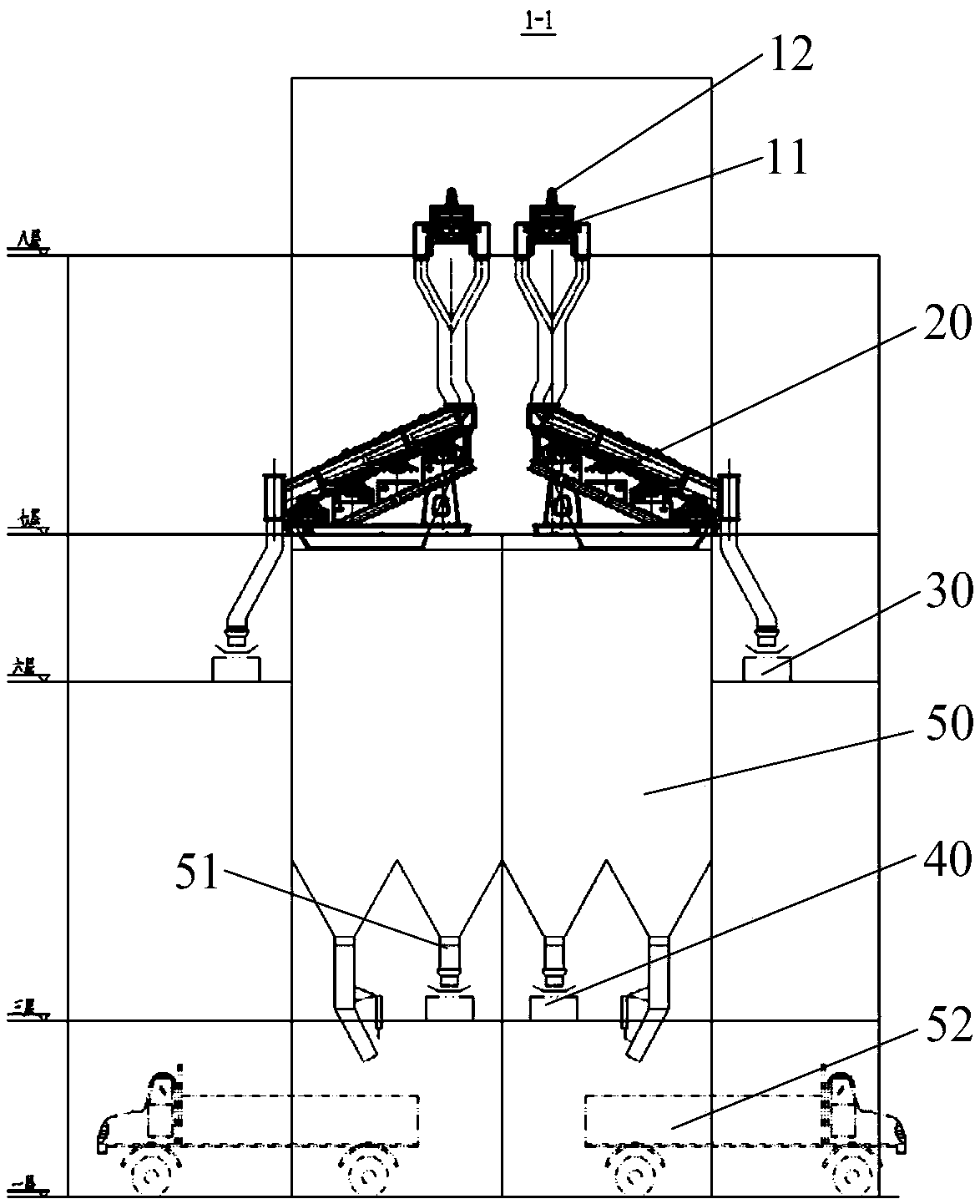

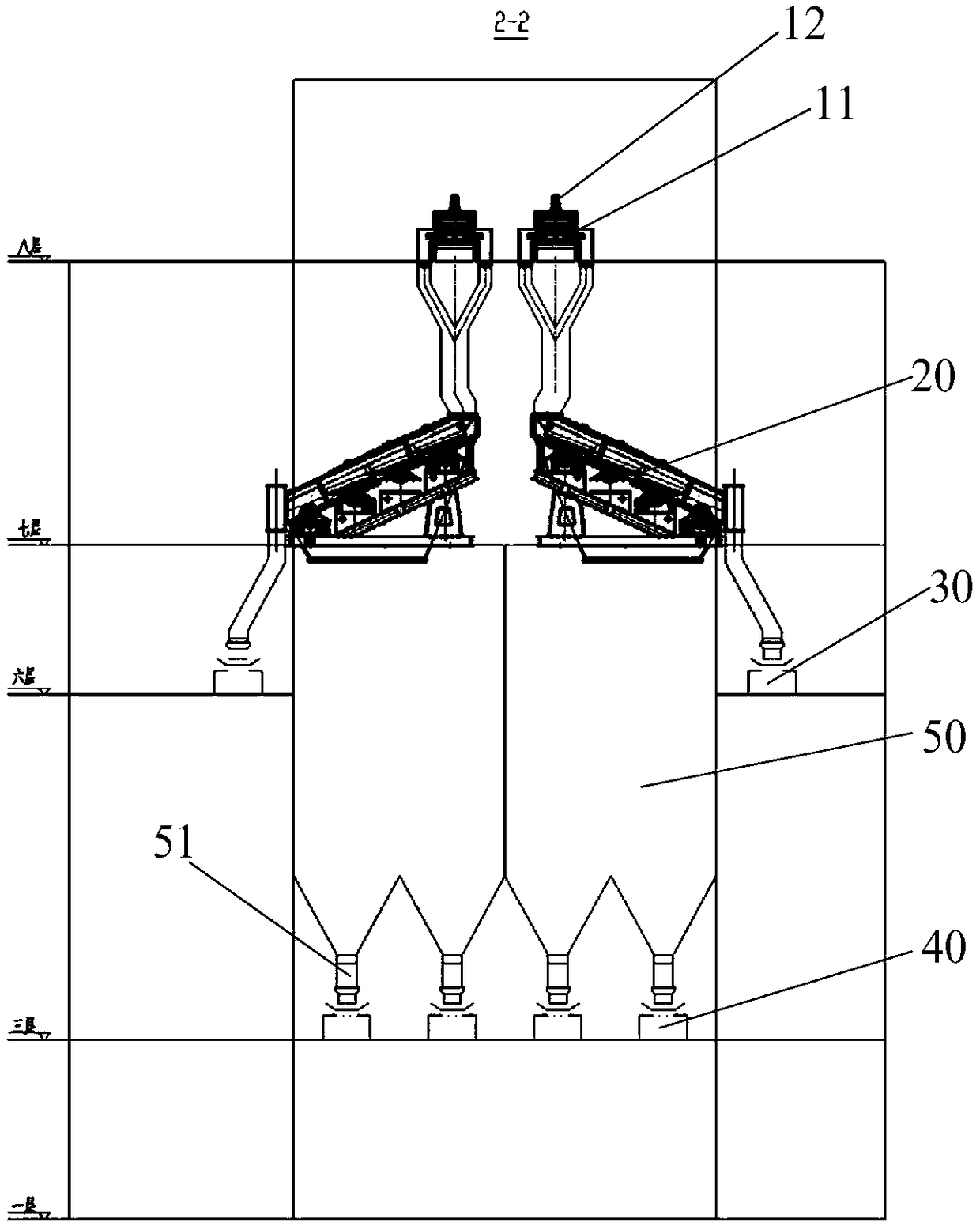

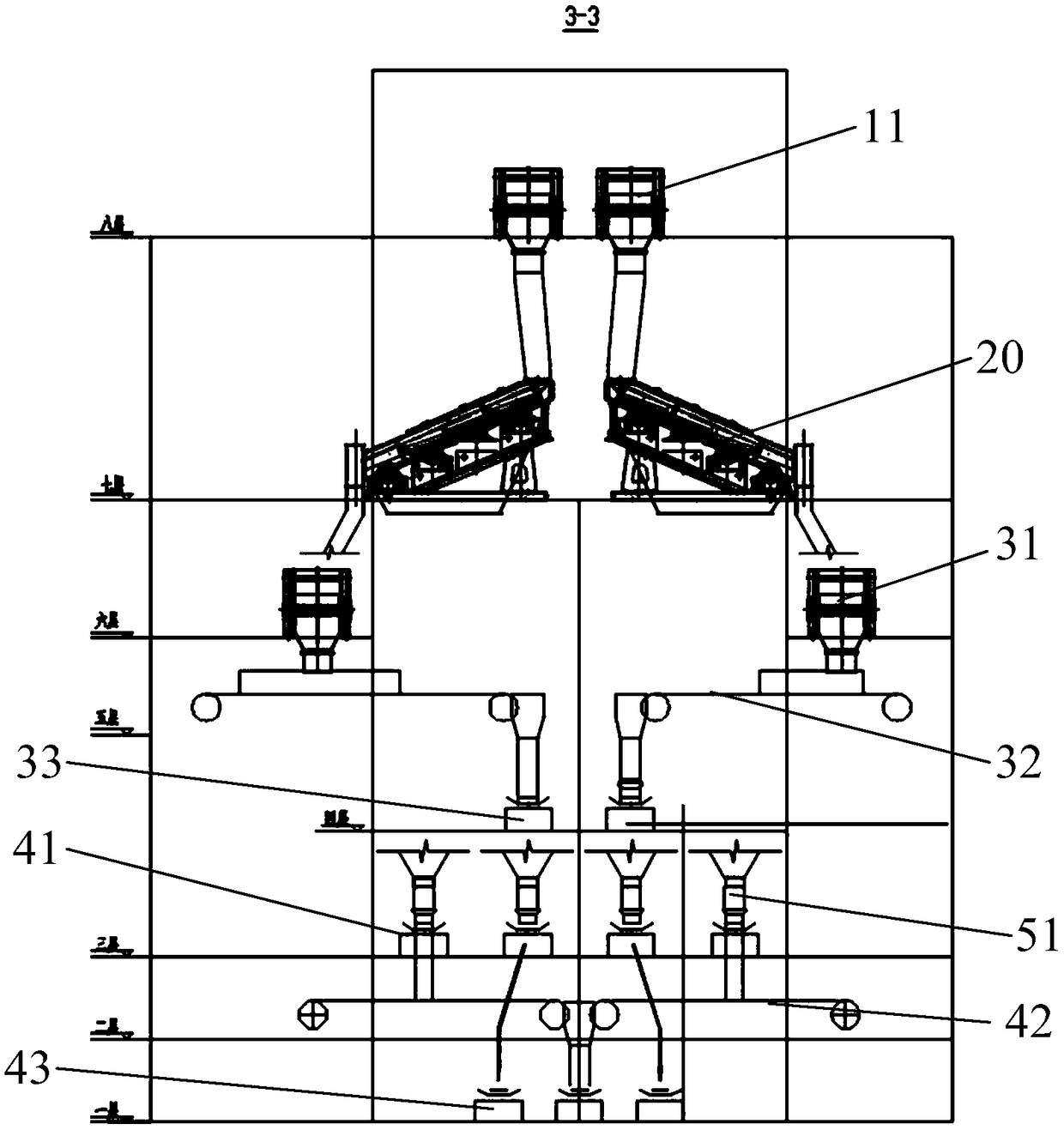

Screen tower and screening building distribution structure

PendingCN109178891ASimple structureReduce the transshipment linkSievingScreeningCoal chemical industryEngineering

The invention relates to bulk material conveying, in particular to a screen tower and a screen tower distribution structure. The screen tower comprises a supply device, a distribution device, screening devices and conveying device, wherein the supply device comprises a belt conveyor; the distribution device comprises a plurality of plow discharger matched with the belt conveyor to unload materials. The coulter lifting height of the multiple plow dischargers is sequentially decreased in the conveying direction of the belt conveyor so that the materials at different height positions can be unloaded. The screening devices are connected to the lower portions of the plow dischargers and used for receiving materials. The conveying devices are connected with the screening devices and each comprise a coarse material conveying device for conveying coarse materials and a fine material conveying device for conveying fine materials. By means of the technical scheme, the requirement for screening and conveying a large amount of coal at the same time is met, and the requirement of a screening and conveying system of a multivariate coal chemical industry device is met.

Owner:HUADIAN HEAVY IND CO LTD

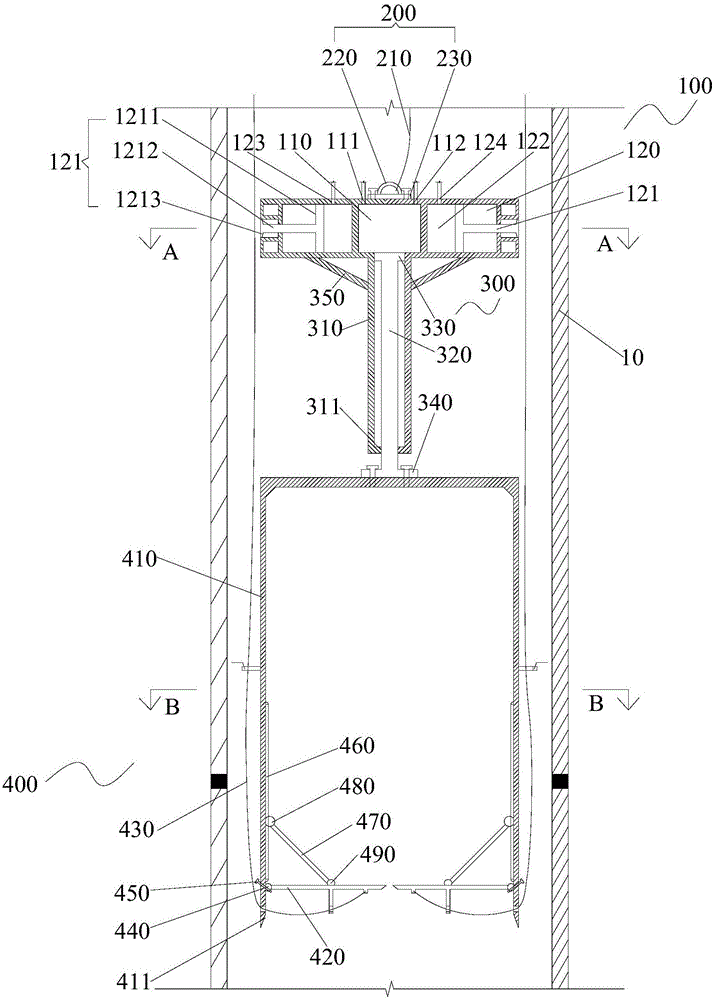

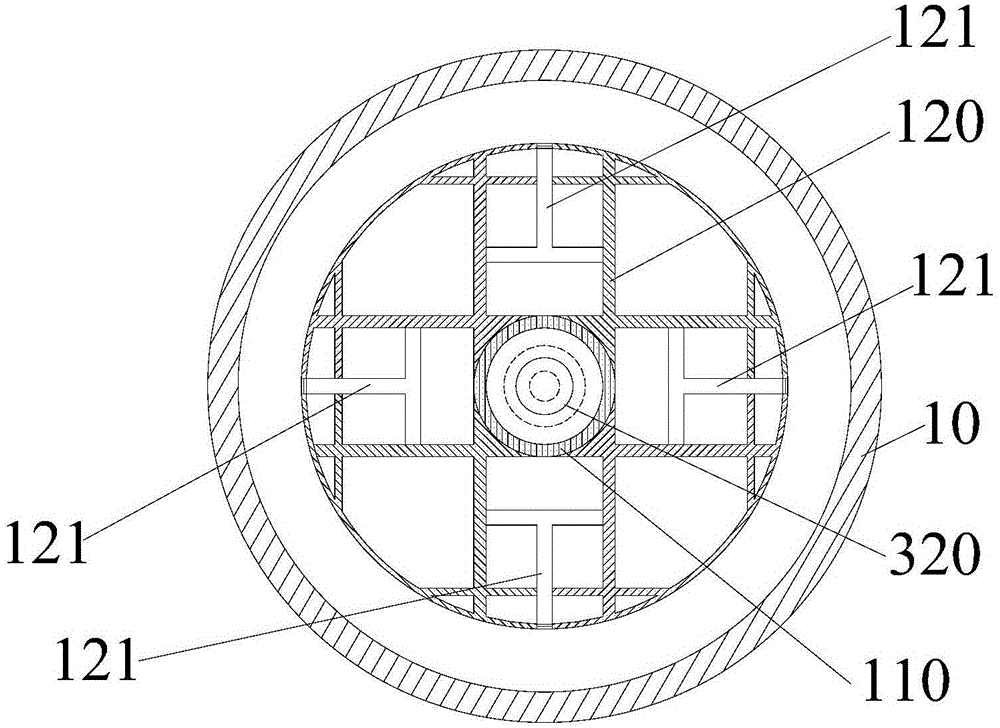

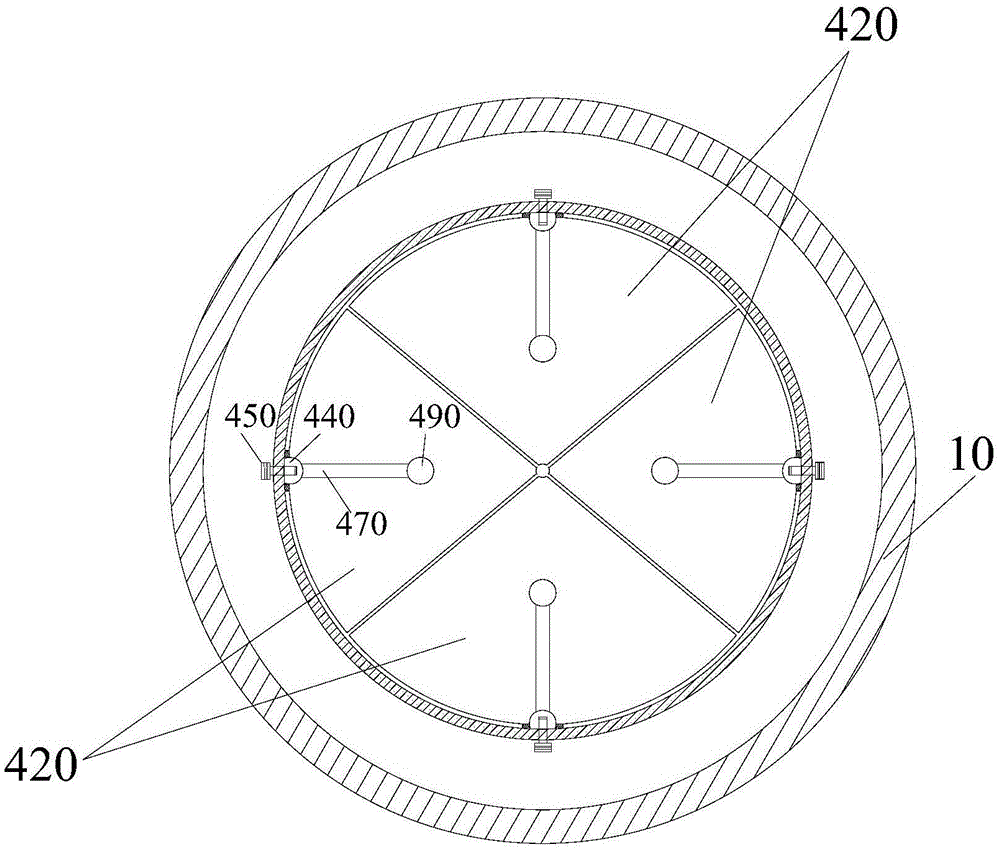

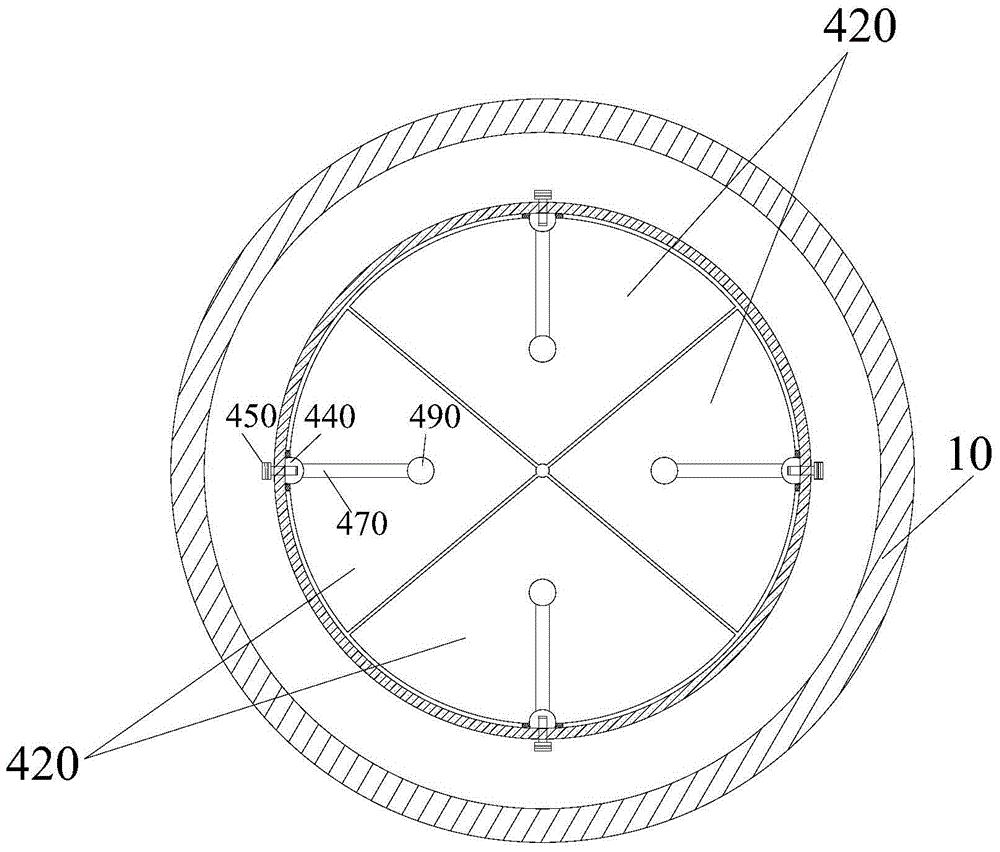

Equipment for removing sediments in small-diameter pipe pile and application method thereof

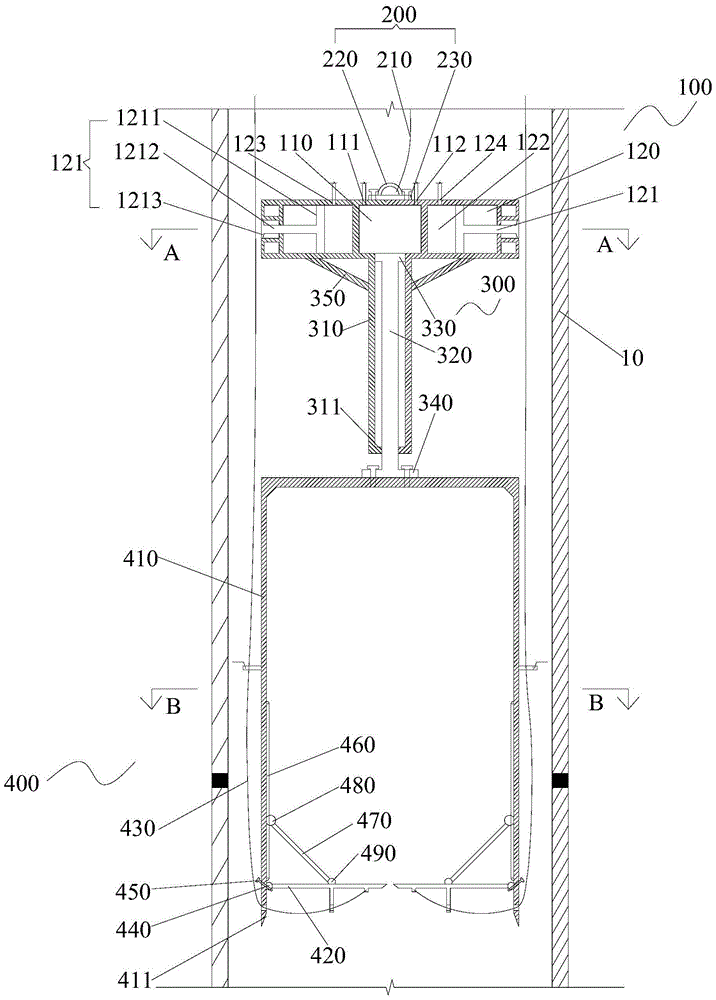

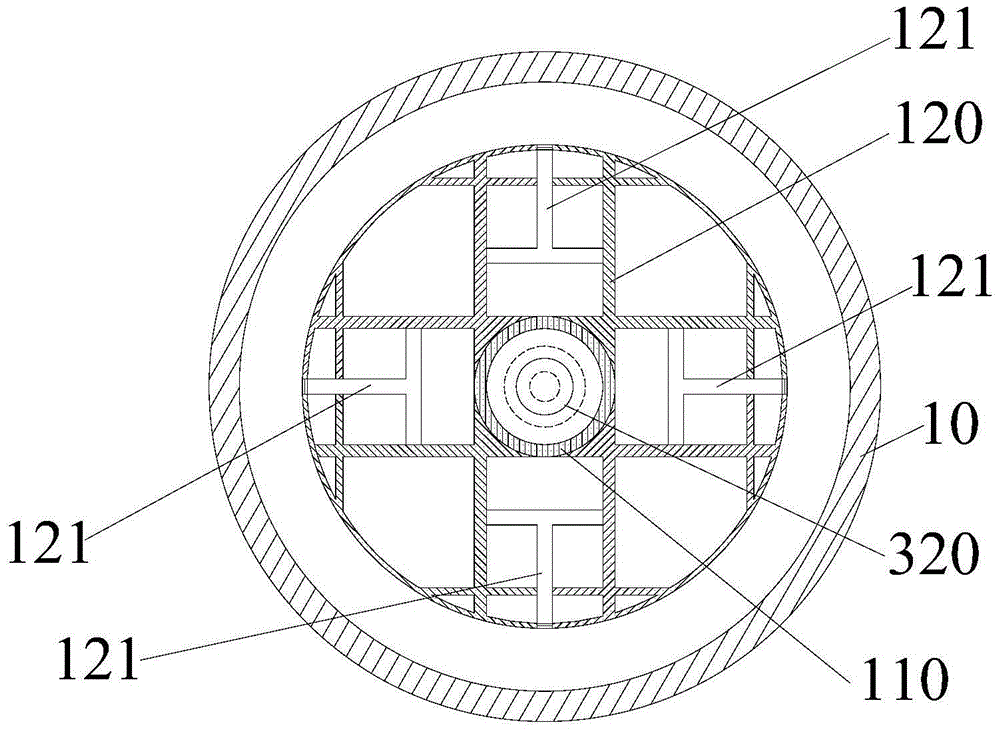

ActiveCN105040700AOvercome problems that cannot be removed manuallySolve hard-to-clear puzzlesBulkheads/pilesHydraulic cylinderBrick

The invention relates to the technical field of sediment discharge equipment, and provides equipment for removing sediments in a small-diameter pipe pile and an application method of the equipment. The equipment comprises a hydraulic power device, a traction sinking device, a vertical push device and a residue storage device. The hydraulic power device comprises a vertical drive hydraulic cylinder. The outer portion of the vertical drive hydraulic cylinder is provided with a horizontal supporting hydraulic cylinder. At least two fixing supporting feed are arranged in the horizontal supporting hydraulic cylinder. The traction sinking device comprises a traction rope. The traction rope is connected with the vertical drive hydraulic cylinder. The vertical push device comprises a connection cylinder. The connection cylinder is arranged at the bottom of the vertical drive hydraulic cylinder and communicated with the vertical drive hydraulic cylinder. A vertical thrust shaft is arranged in the connection cylinder and can move in the connection cylinder in the vertical direction. The residue storage device comprises a residue storage cylinder. The residue storage cylinder is movably connected with the vertical thrust shaft. A bottom sealing plate is hinged to the bottom of the residue storage cylinder. A residue storage portion rope is connected with the bottom sealing plate. The equipment is easy to operate, convenient to assemble and capable of removing rock blocks and brick residues in the pipe pile.

Owner:SHANGHAI INVESTIGATION DESIGN & RES INST

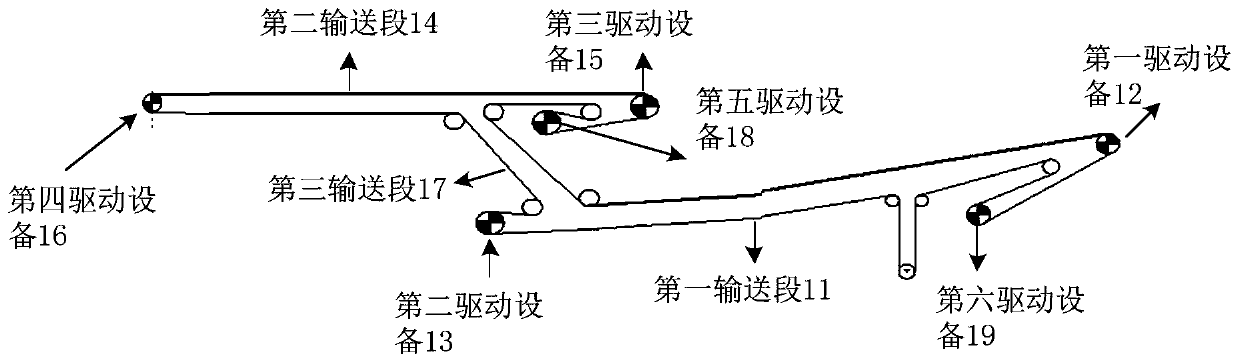

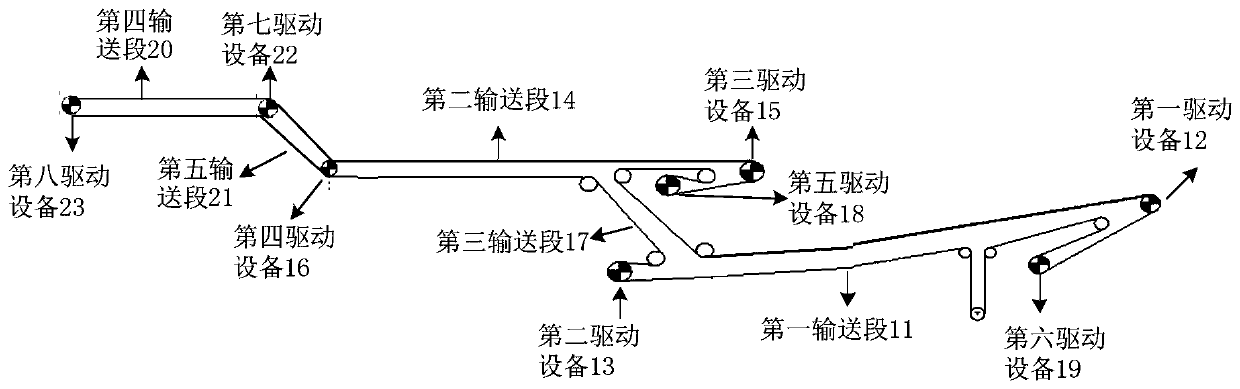

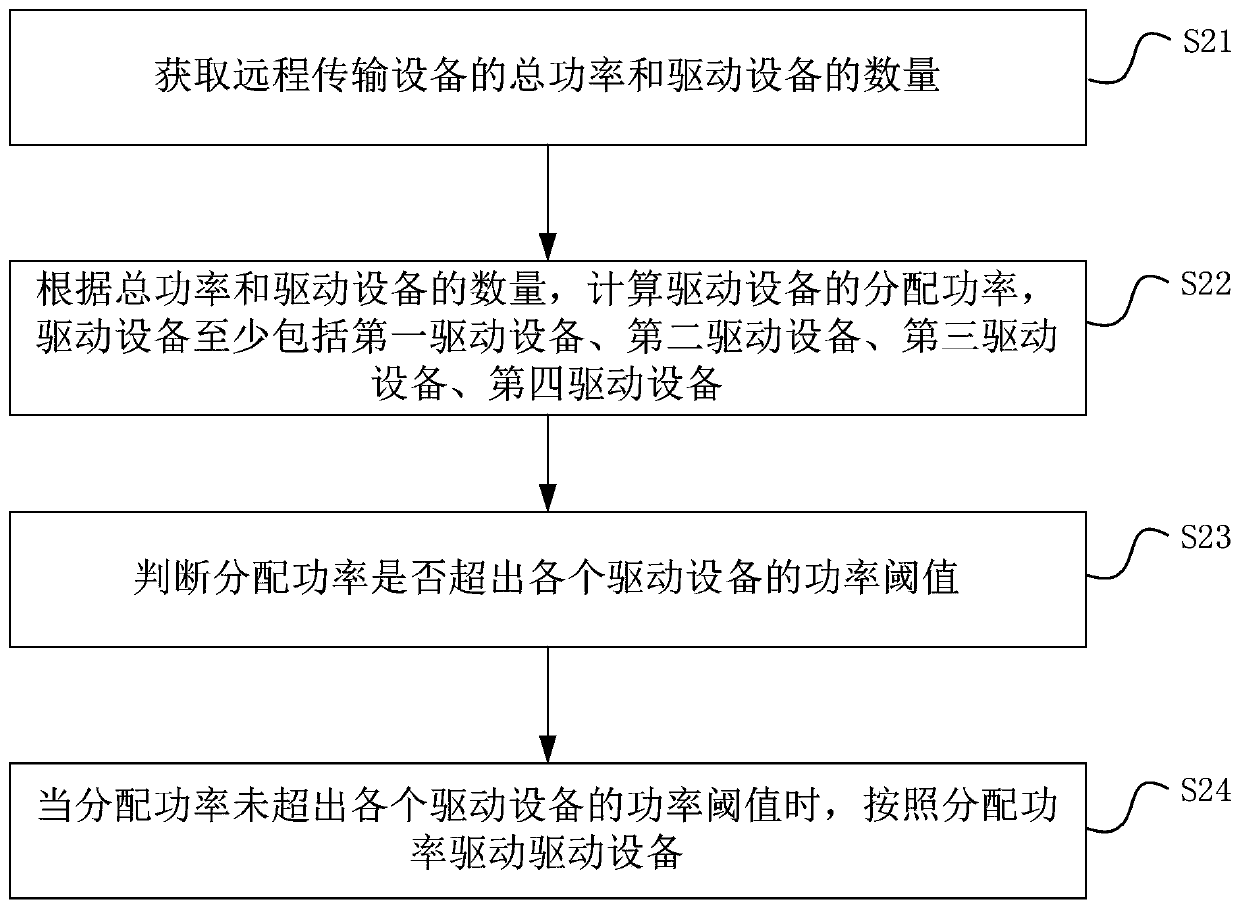

Remote transmission equipment and multipoint driving method

PendingCN110877816ANo limit strengthRealize ultra-long distance transportationConveyor partsControl theoryMechanical engineering

The invention discloses remote transmission equipment and a multipoint driving method. The equipment includes a first conveying section, a second conveying section and a third conveying section; a first driving device and a second driving device are respectively arranged at two ends of the first conveying section; the second conveying section and the first conveying section are not on a same straight line, and a third driving device and a fourth driving device are respectively arranged at two ends of the second conveying section; and two ends of the third conveying section are respectively connected to the first conveying section and the second conveying section to realize the conveying of goods from the first conveying section to the second conveying section. The method includes the following steps: obtaining total power of the remote transmission equipment and the number of the driving devices; calculating allocated power of the driving devices according to the total power and the number of the driving devices; determining whether the allocated power exceeds a power threshold of the driving devices; and when the allocated power does not exceed the power threshold of the driving devices, driving the driving devices according to the allocated power. The equipment and method realize ultra-long-distance conveying, reduce a transfer link, and reduce costs.

Owner:HUADIAN HEAVY IND CO LTD

Treatment method for rubber plug used for aspirin-dl-lysine production

InactiveCN109731832AReduce the transshipment linkIncrease productivityDrying gas arrangementsCleaning using liquidsAspirin DL-LysineVacuum pumping

The invention relates to a treatment method for a rubber plug used for aspirin-dl-lysine production. The treatment method includes the steps that firstly, the rubber plug is cleaned, wherein a full-automatic wet process gas rushing type rubber plug cleaning machine is used for conducting cleaning and disinfecting on the rubber plug, the technology conditions include that rough cleaning is conducted for 2 min to 5 min, rinsing is conducted for 3 min to 8 min, fine cleaning is conducted for 8 min to 12 min, silicification is conducted for 3 min to 6 min, flushing and draining are conducted for 3min to 8 min, pure steam sterilizing is conducted for sterilizing for 25 min to 35 min under the temperature of 121 DEG C, vacuum drying is conducted for 15 min to 25 min, hot air drying is conductedfor 20 min at the temperature of 105 DEG C, and vacuum pumping is conducted for 10 min at the temperature of 105 DEG C; and secondly, plug discharging is conducted, wherein sealing barrels are movedinto an isolation cabinet at the discharging end of the rubber plug in a paired manner, self cleaning is conducted for 10 min, and then the sealing barrels are taken out and transported into a split packaging machine to be in horizontal butt joint with a tabletop of a storage material barrel. The treatment method is adopted for treating the rubber plug used for aspirin-dl-lysine powder injection production, the transfer link is emitted under the condition that the sterile state of the rubber plug is ensured, and the production efficiency is improved.

Owner:YANGZHOU YIYANG PHARMA

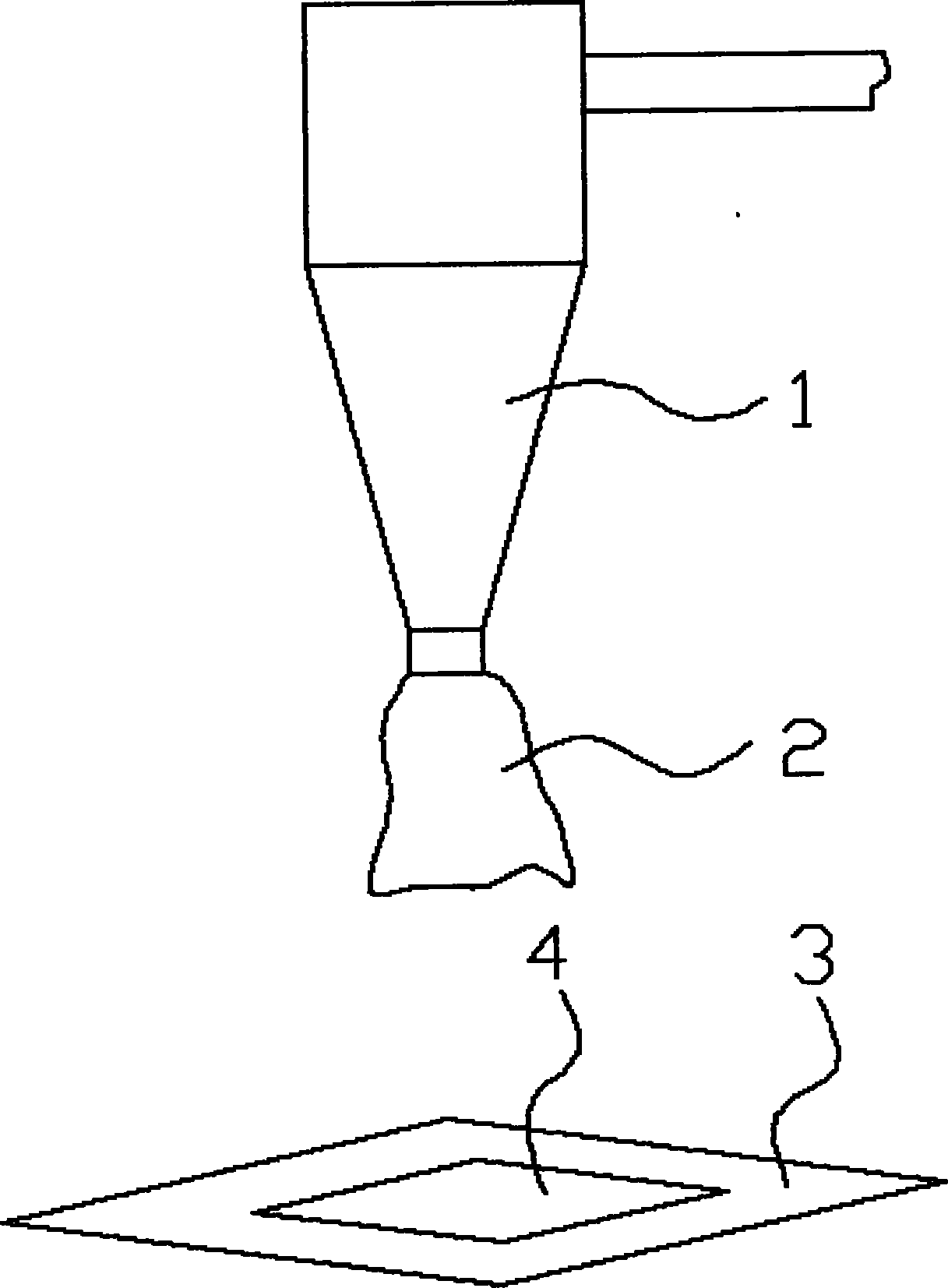

Immersion type coating device

InactiveCN102233310AReduce the transshipment linkLow costLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention provides an immersion type coating device. The immersion type coating device comprises a coating box body, a partition board, at least one driving device, at least one coating base and an air inlet pipe, wherein the partition board is arranged in the coating box body and divides the coating box body into a first accommodating chamber and a second accommodating chamber which are independent of each other; a hole running through the partition board is formed in the partition board; the at least one driving device is arranged on the partition board; the at least one coating base is connected to the driving device and positioned in the second accommodating chamber; the coating base is driven by the driving device to cover the hole of the partition board; and the at least one air inlet pipe is arranged on the side wall, corresponding to the first accommodating chamber, of the coating box body. The coating box body of the immersion type coating device is divided into two independent accommodating chambers by the partition board and the coating and drying are performed in the two accommodating chambers sequentially, so that a transfer link of coated products is saved, the cost is effectively reduced, and the quality of the products is improved.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

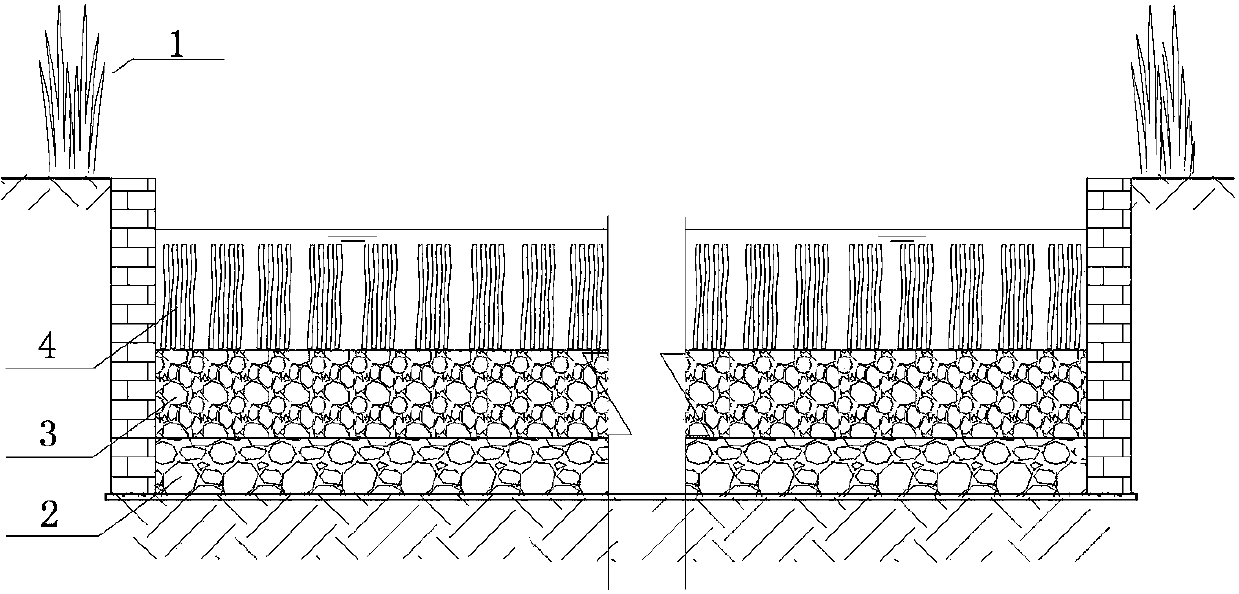

In-situ treatment method for shallow flow rejuvenated water riverway

InactiveCN102966071BIncrease dissolved oxygen contentGood removal effectMultistage water/sewage treatmentStream regulationFiberComposite nanofibers

The invention relates to an in-situ treatment method of a shallow flow rejuvenated water riverway. According to the method, a roundstone bed shallow flow riverway is constructed, and an artificial biological filler and a compound nano fiber filler are arranged in a roundstone bed, so as to perform in-situ advanced treatment on river water which utilizes rejuvenated water as a water supplement source. According to the method, an in-situ treatment technology is adopted, the river water is not needed to be guided out of a river water system, and the water body can be directly treated in the waterway, so that the sewage transportation link is omitted, and secondary pollution can be prevented from being caused.

Owner:TONGJI UNIV

Automatic assembling machine for cooling fan

InactiveCN109759838AReduce the transshipment linkCentralized production processAssembly machinesImpellerComputer fan

The invention discloses an automatic assembling machine for a cooling fan. The automatic assembling machine for the cooling fan comprises a supporting cabinet body, an intelligent control terminal, anelectric appliance control cabinet and a protective shell. The automatic assembling machine for the cooling fan is characterized in that the automatic assembling machine for the cooling fan further comprises a conveying device, a friction sheet feeding device, a buckle ring feeding device, glue dispensing devices, an annular shaft installing device, a motor feeding and installing device, a pressing device, a rotary piston ring installing device and an impeller installing device are sequentially arranged on the conveying device, an array taking and putting device is installed on the side of the impeller installing device, therefore, assembling of the cooling fan is achieved, and assembling of the whole process is completed. According to the automatic assembling machine for the cooling fan,automatic assembling of the cooling fan is achieved, the transferring link in the flow production process is reduced, therefore, the production process is concentrated, and the assembling speed is high; and meanwhile, operation is intelligent, the production efficiency is greatly improved, and the labor cost is reduced.

Owner:XUCHANG UNIV

Fruit picking device

The invention relates to a fruit picking device, which comprises a fruit placement platform, at least one picking conveying pipe, an air storage tank, stem cutters, handles, damping valve plates and operating platforms. The air storage tank is arranged on the fruit placement platform, and flexible air outlet pipes which extend from the air storage tank are connected to side walls of the picking conveying pipes and communicated with inner cavities of the picking conveying pipes; the stem cutters are arranged at top openings of the picking conveying pipes; the handles are arranged on the side walls of the picking conveying pipes and close to top ends of the picking conveying pipes; the damping valve plates are arranged at bottom ends of the picking conveying pipes, the bottom ends of the picking conveying pipes are closed by the damping valve plates when fruits are not contacted with the damping valve plates, and the damping valve plates are opened when the fruits fall on the damping valve plates; the operating platforms are fixedly connected to the fruit placement platform and in one-to-one correspondence to the picking conveying pipes. The fruit picking device has advantages that convenience in fruit picking is improved, potential safety risks in a picking process are reduced, fruit damages can be effectively avoided, and accordingly fruit quality is greatly improved.

Owner:河北绿阳农业科技股份有限公司

Inflating and encapsulating equipment for producing bubble packs

InactiveCN105058863AImprove air tightnessImprove protectionBox making operationsPaper-makingControl systemEngineering

The invention discloses inflating and encapsulating equipment for producing bubble packs. The inflating and encapsulating equipment comprises a base, an air injection opening, a clamping module, an encapsulating module and a control system, wherein the air injection opening can expand and contract relative to the base and is used for injecting air in the bubble packs; the clamping module is used for fixing the bubble packs; a heating device is arranged on the encapsulating module; the encapsulating module is used for sealing the mouths of the bubble packs after air injection is completed; the clamping module and the encapsulating module are positioned in the same plane and are arranged in the telescoping direction of the air injection opening; the clamping module is positioned on the outer side of the encapsulating module. Through the adoption of the inflating and encapsulating equipment disclosed by the invention, the inflating step and the encapsulating step for the bubble packs can be integrally completed, so that the workload of workers is effectively reduced, and the production efficiency can be improved; the conveying links of materials can be reduced, so that the storage cost and the management cost are reduced; the air tightness after the bubble packs are encapsulated can be improved, so that the air leaking speed is greatly lowered; therefore, the bubble packs can have a good protecting effect in a long time.

Owner:SHENZHEN DINGLISHENG TECH

Combined type intelligent turning and grinding integrated cutter and use method thereof

InactiveCN110814773AImprove processing efficiencyEliminate processing errorsOther manufacturing equipments/toolsNumerical controlKeel

The invention relates to a combined type intelligent turning and grinding integrated cutter. The cutter comprises a bearing keel, feeding tables, turning tool cutter discs, grinding cutter discs, driving guide rails, linear displacement tables and a control circuit, wherein the side surfaces of the bearing keel are uniformly provided with two driving guide rails, and the driving guide rails are insliding connection with at least two linear displacement tables through a sliding block; each linear displacement table is slidably connected with one feeding table, and two adjacent feeding tables distributed on the same driving guide rail are correspondingly connected with one turning tool cutter disc and one grinding cutter disc; and the control circuit is located on the outer surface of the bearing keel and is electrically connected with the feeding tables, the turning tool cutter discs, the grinding cutter discs, the driving guide rails and the linear displacement tables correspondingly.The use method comprises the following three steps of equipment assembling, inputting machining programs, and machining operations. The cutter and the use method can effectively meet the matching operation with a plurality of different types of numerical control lathes and meet the machining operation of various structural work pieces, and meanwhile the turning and grinding are carried out synchronously.

Owner:JIAOZUO UNIV

Automatic quantitative separation paper cup packaging equipment utilizing gravity principle for packaging

ActiveCN111605841AIncrease linkageConsistent dropPaper recyclingWrapper twisting/gatheringPaper cupIndustrial engineering

The invention relates to the technical field of paper product manufacturing, and discloses automatic quantitative separation paper cup packaging equipment utilizing the gravity principle for packaging. The automatic quantitative separation paper cup packaging equipment comprises a shell, and the interior of the shell is fixedly connected with a discharging pipe. According to the automatic quantitative separation paper cup packaging equipment utilizing the gravity principle for packaging, a movable rod moves up and down to enable a baffle to move to the right side of the discharging pipe to behorizontally placed and then move to the position below the discharging pipe, intermittent discharging is achieved, it is guaranteed that the falling amount of paper cups is consistent, the processedpaper cups directly fall into packaging bags, two hands are liberated, the middle transferring link is omitted, the probability that the paper cups are polluted is reduced, and the working efficiencyis improved; a gear rotates to enable a fourth rotary disc to rotate intermittently in a reciprocating mode, and a power source is provided for subsequent cutting operation, so that operation is moreconvenient and faster; and a first connecting rod rotates to enable cutting plates to get close to each other and then get away from each other, the packaging bags containing the paper cups are directly cut off and sealed, and different batches of paper cups are separated in time, so that the situation that the paper cup number is inconsistent is avoided, and equivalent packaging of the paper cupsis achieved.

Owner:福建益百利包装材料有限公司

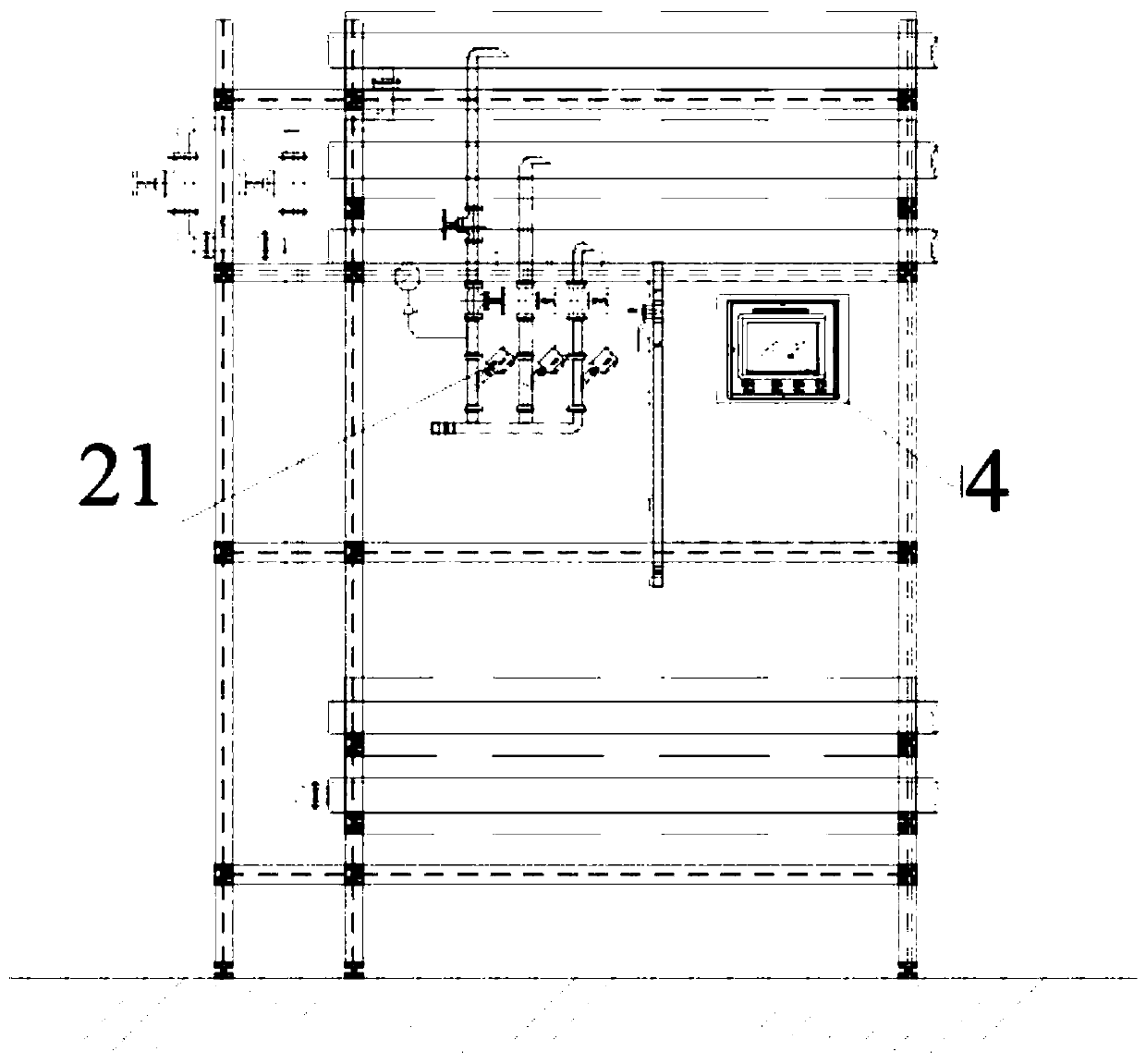

Steam forming furnace for automobile pipeline

InactiveCN111531766AReduce the transshipment linkShorten the timeDomestic articlesTubular articlesProcess engineeringElectric control

A steam forming furnace for an automobile pipeline comprises a heating and cooling system, a pipeline system and an operation table surface. The heating and cooling system comprises a steam furnace, acooling water tank and a gas tank. The heating and cooling system is further provided with an electric control screen, and the electric control screen is internally provided with a PLC. The pipelinesystem comprises a support, a steam main pipe, a cold water main pipe, a compressed air main pipe, a compressed air / clod water drainage pipe and a steam exhaust pipe. The operation table surface comprises an operation table surface support. The steam furnace is connected to the steam main pipe. The cooling water tank is connected to the cold water main pipe. The gas tank is connected to the compressed air main pipe. The heating and cooling system is connected with the pipeline system through an electromagnetic valve. By the adoption of the steam forming mode, a plastic pipe is clamped into a mold and then formed and fixed by using a steam forming mode, the plastic pipe is directly formed and taken down, the transfer link is reduced, and the time can be saved; steam is generated by burningnatural gas, and the cost can be reduced compared with electric heating; and the pollution of oil and gas can be remarkably reduced by using steam forming compared with electric heating.

Owner:上海迅美工业设备有限公司

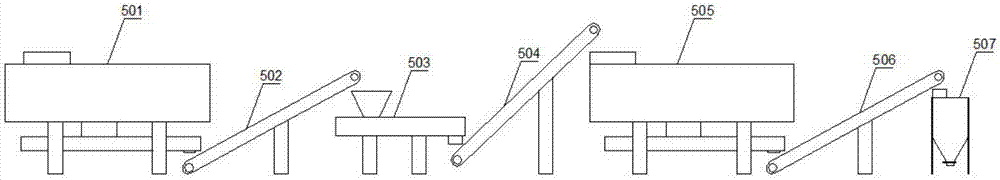

Centralized feed production line

ActiveCN107397241AUniform fermentationFully fermentedFeeding-stuffTransportation and packagingProduction lineEngineering

A centralized feed production line comprises a fermentation device, a belt conveyer I, a hardening and tempering device, a belt conveyer II, a drying device, a lifter and a stirring device which are sequentially arranged from left to right. A screw conveyer I is arranged at the lower portion of a supporting cylinder of the fermentation device, a feeding port of the screw conveyer I is connected with a discharging port I of the supporting cylinder through a pipe. The feeding end of the belt conveyer I is located below a discharging port of the screw conveyer I. A feeding hopper of the hardening and tempering device is located below the discharging end of the belt conveyer I. The feeding end of the belt conveyer II is located below a discharging port II of the hardening and tempering device. The belt conveyer II is fixedly arranged at the lower portion of an outer cylinder of the drying device through a supporting column, and a feeding port of a screw conveyer II is connected with a discharging port III of the outer cylinder through a pipe. The feeding end of the lifter is located below a discharging port of the screw conveyer II, and a feeding port III of the stirring device is located below a discharging port of the lifter. Intermediate transfer links of the production line can be decreased, and the production efficiency can be improved.

Owner:丰县新中牧饲料有限公司

Equipment for removing sediment inside small-diameter pipe piles and its application method

ActiveCN105040700BOvercome problems that cannot be removed manuallySolve hard-to-clear puzzlesBulkheads/pilesHydraulic cylinderBrick

The invention relates to the technical field of sediment discharge equipment, and provides equipment for removing sediments in a small-diameter pipe pile and an application method of the equipment. The equipment comprises a hydraulic power device, a traction sinking device, a vertical push device and a residue storage device. The hydraulic power device comprises a vertical drive hydraulic cylinder. The outer portion of the vertical drive hydraulic cylinder is provided with a horizontal supporting hydraulic cylinder. At least two fixing supporting feed are arranged in the horizontal supporting hydraulic cylinder. The traction sinking device comprises a traction rope. The traction rope is connected with the vertical drive hydraulic cylinder. The vertical push device comprises a connection cylinder. The connection cylinder is arranged at the bottom of the vertical drive hydraulic cylinder and communicated with the vertical drive hydraulic cylinder. A vertical thrust shaft is arranged in the connection cylinder and can move in the connection cylinder in the vertical direction. The residue storage device comprises a residue storage cylinder. The residue storage cylinder is movably connected with the vertical thrust shaft. A bottom sealing plate is hinged to the bottom of the residue storage cylinder. A residue storage portion rope is connected with the bottom sealing plate. The equipment is easy to operate, convenient to assemble and capable of removing rock blocks and brick residues in the pipe pile.

Owner:SHANGHAI INVESTIGATION DESIGN & RES INST

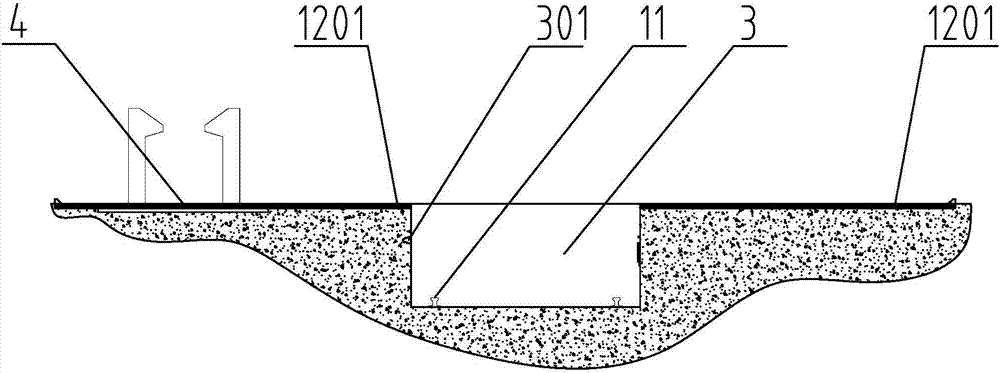

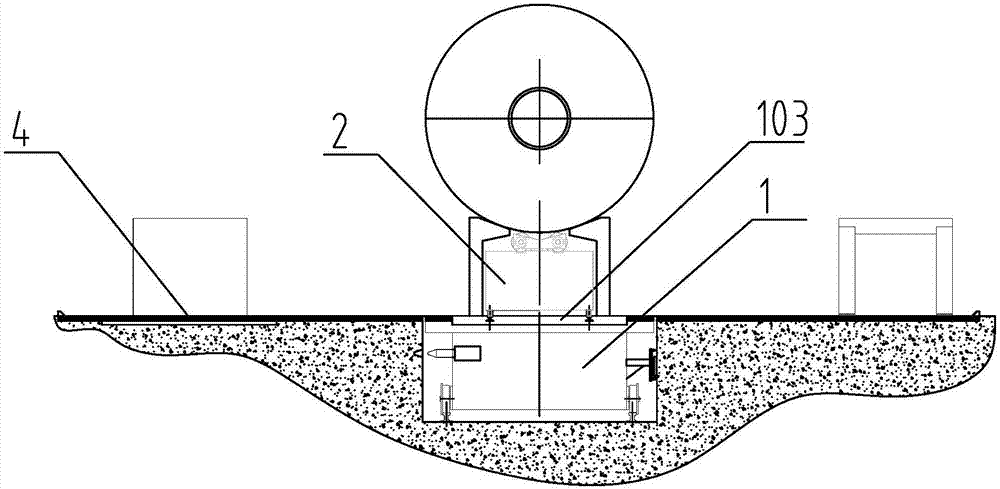

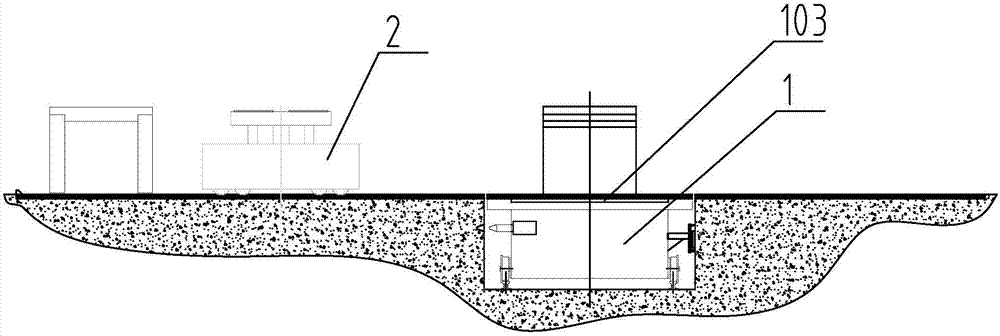

Storehouse-platform integrated railway cold chain logistics system

ActiveCN109650077AQuick loading and unloadingQuick store jobConveyorsRailway componentsCivil engineering

The invention belongs to the technical field of cold chain logistics, and discloses a storehouse-platform integrated railway cold chain logistics system. The storehouse-platform integrated railway cold chain logistics system is of a three-dimensional storehouse frame structure, and comprises a cold chain storehouse which is arranged on the two sides of platforms and above or below the platforms ina straddling mode; loading and unloading operation areas are arranged between the cold chain storehouses and one sides, close to tracks, of the platforms; the outermost sides of the cold chain storehouse are provided with loading and unloading station platforms used for interacting with road cold chain transport vehicles; the cold chain storehouse and the platforms of trains are integrated as a whole, so that the cold chain storehouse serves as a part of the train platforms; after a cold chain train arrived and stopped in the platforms, detachable cold chain collectors are directly stored inthe cold chain storehouse; goods needing to be distributed by the road cold chain transport vehicles are loaded from the cold chain storehouse so that the cold-chain goods can be seamlessly transferred in full-cold environment between the cold-chain train and the road cold chain transport vehicles; and the platform and the cold storehouse are integrally designed into three-dimensional storehouse frame, so that space above or below the platform is fully utilized, the investment is saved and the fast loading and unloading and storage operation of the cold-chain goods is realized.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

A fruit picking device

ActiveCN108040603BImprove convenienceAvoid bumpingPicking devicesAgricultural engineeringStructural engineering

The invention relates to a fruit picking device, which comprises a fruit placement platform, at least one picking conveying pipe, an air storage tank, stem cutters, handles, damping valve plates and operating platforms. The air storage tank is arranged on the fruit placement platform, and flexible air outlet pipes which extend from the air storage tank are connected to side walls of the picking conveying pipes and communicated with inner cavities of the picking conveying pipes; the stem cutters are arranged at top openings of the picking conveying pipes; the handles are arranged on the side walls of the picking conveying pipes and close to top ends of the picking conveying pipes; the damping valve plates are arranged at bottom ends of the picking conveying pipes, the bottom ends of the picking conveying pipes are closed by the damping valve plates when fruits are not contacted with the damping valve plates, and the damping valve plates are opened when the fruits fall on the damping valve plates; the operating platforms are fixedly connected to the fruit placement platform and in one-to-one correspondence to the picking conveying pipes. The fruit picking device has advantages that convenience in fruit picking is improved, potential safety risks in a picking process are reduced, fruit damages can be effectively avoided, and accordingly fruit quality is greatly improved.

Owner:河北绿阳农业科技股份有限公司

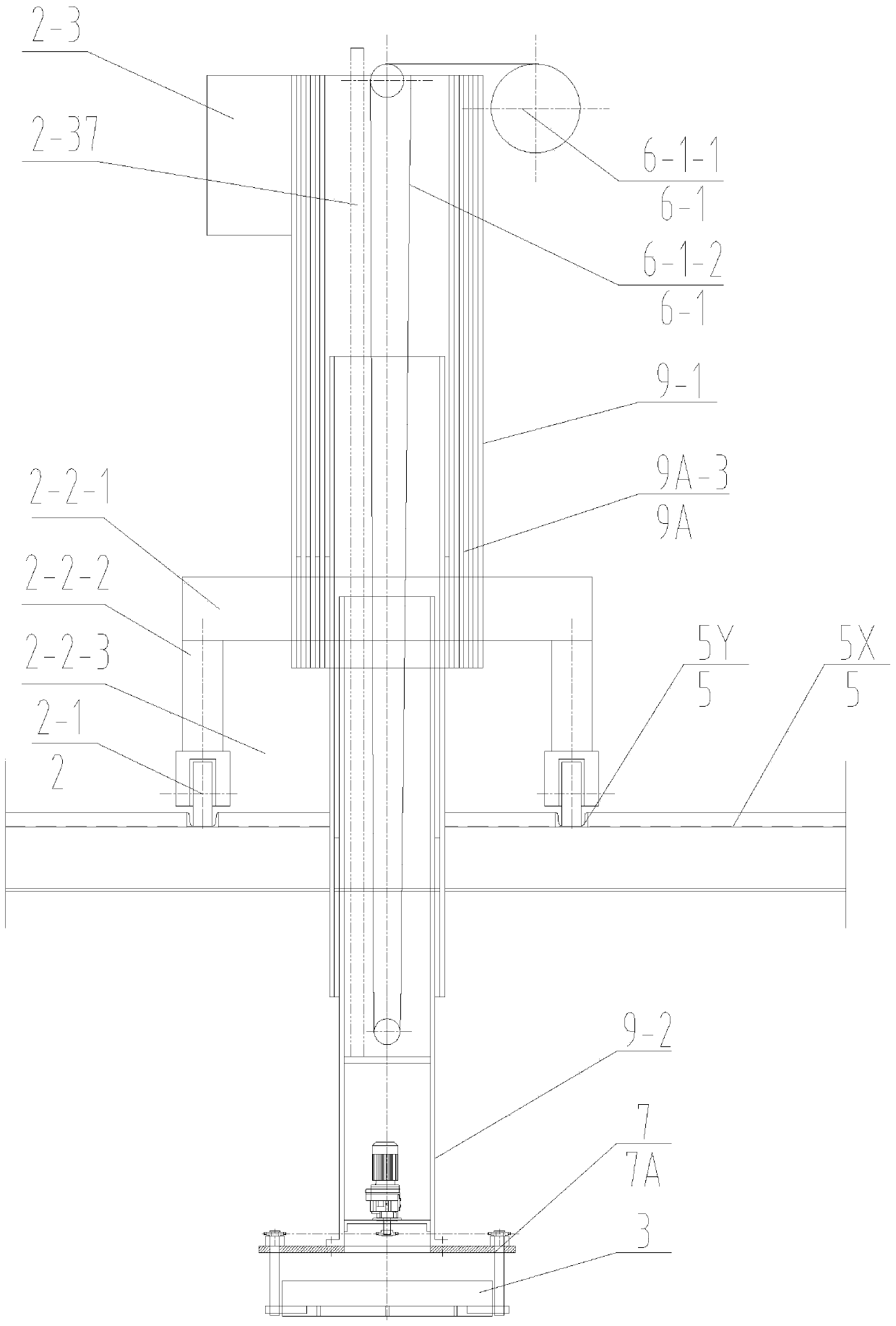

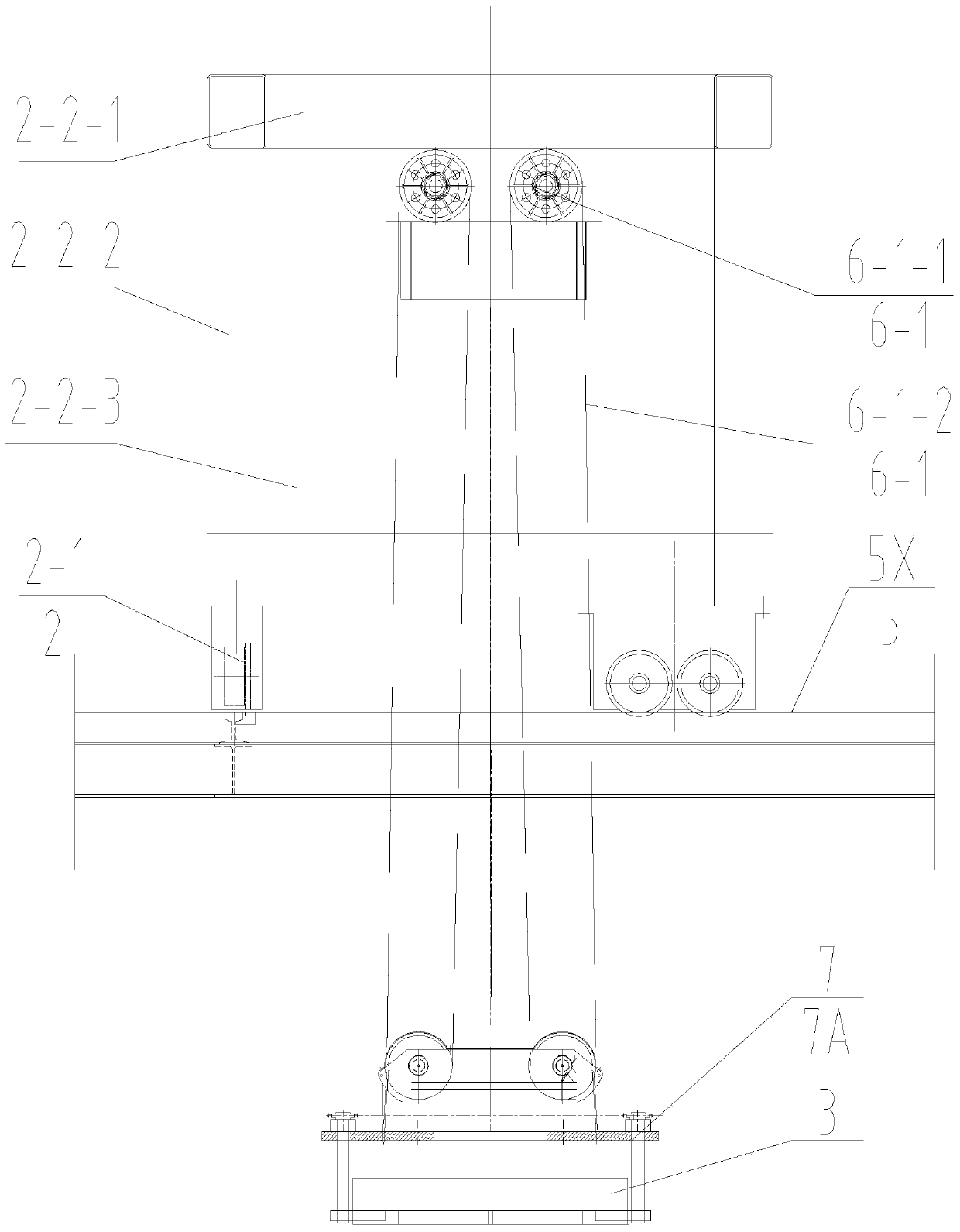

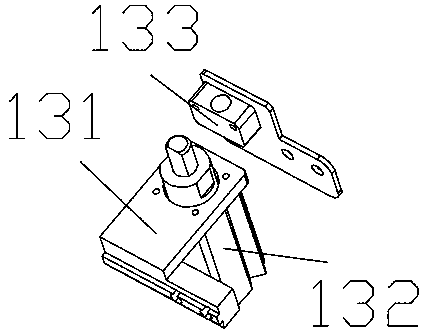

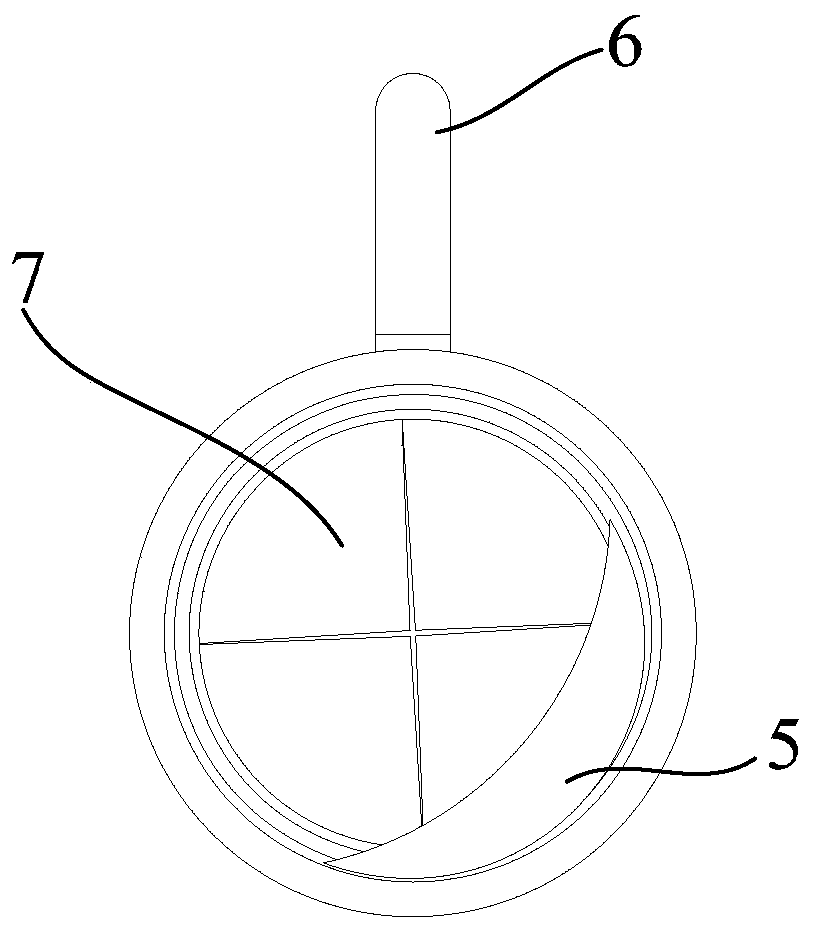

Two-way lateral taking device

PendingCN107963572ASafe and stable transferAvoid Interfering EffectsSafety devices for lifting equipmentsLifting framesContact networkEngineering

The invention relates to a two-way lateral taking device. Containers on a railway container flat car are transferred onto a container lorry, and / or, the containers on the container lorry are transferred onto the railway container flat car; the two-way lateral taking device is arranged on a bearing platform between railway rails and a parking position of the container lorry, and comprises a bridgepassing mechanism, a tray mechanism and a lifting mechanism; the tray mechanism is slidingly arranged on the bridge passing mechanism; the tray mechanism can slide to a position corresponding to a loading and unloading position of the container lorry, and / or, can slide to a position corresponding to the lifting device; and the lifting mechanism is arranged below the bridge passing mechanism, is positioned on the bearing platform, and bears and drives the bridge passing mechanism and the tray mechanism to ascend or descend. The two-way lateral taking device enables the railway container flat car and the container lorry under a railway electrification contact network to join with each other, simplifies railway-highway transfer links, reduces the equipment and operation costs, and improves the working field space utilization rate and the railway-highway transfer efficiency.

Owner:CRRC YANGTZE CO LTD

A leaf spring online bushing press-fitting equipment

ActiveCN108356502BRealize full automationReduce the transshipment linkMetal working apparatusProduction lineCompression device

The utility model relates to an online bush press-fitting device for a leaf spring, which belongs to the field of leaf spring processing and assembling production equipment. It is characterized in that it includes a transportation line and an assembly production line, the transportation line can clamp and transport the leaf spring and place the leaf spring on the assembly line, and press the bushings on the ear holes at both ends of the leaf spring through the assembly line to complete the pressing After the assembly operation, the transport line can move the leaf spring out of the assembly line. The invention can realize the full automation of the press-fitting operation of the leaf spring lug bushing. The equipment is integrated on the multifunctional leaf spring assembly line, which can realize the assembly flow of the leaf spring, reduce the product transfer link, avoid product bumping as much as possible, and effectively improve production. efficiency and reduce production costs.

Owner:SHANDONG LEOPARD AUTOMOTIVE HLDG

Weighing device for quantitative filling of broken plastic

InactiveCN102673810AReasonable structural designReduce the transshipment linkSolid materialEngineeringMechanical engineering

Owner:ANHUI JINZHENG PLASTIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com