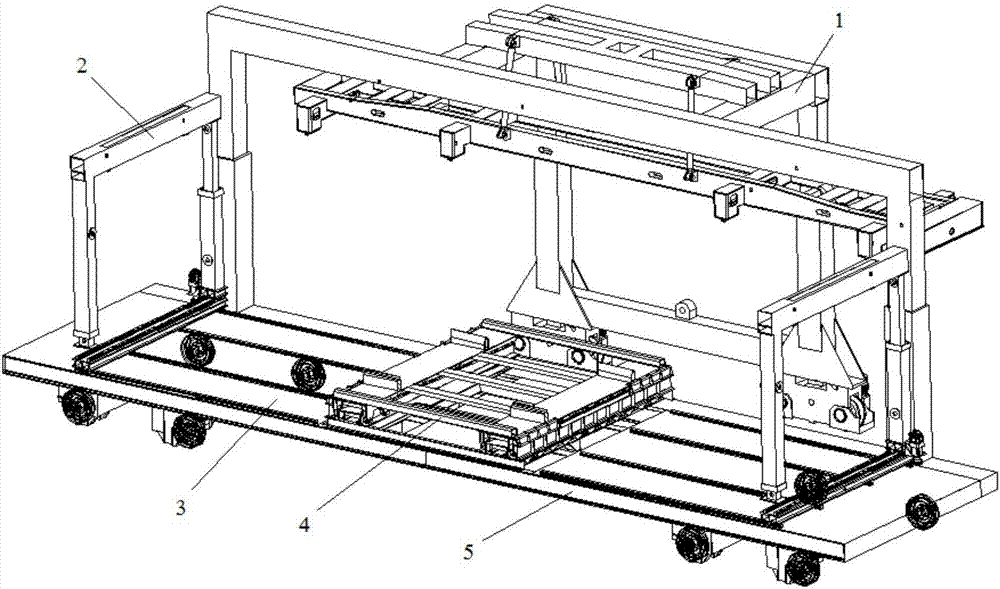

Container highway and railway transferring system

A container, road-rail technology, applied in the direction of hoisting device, storage device, hoisting device, etc., can solve the problems of low road-rail transfer efficiency and low utilization rate of workplace space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

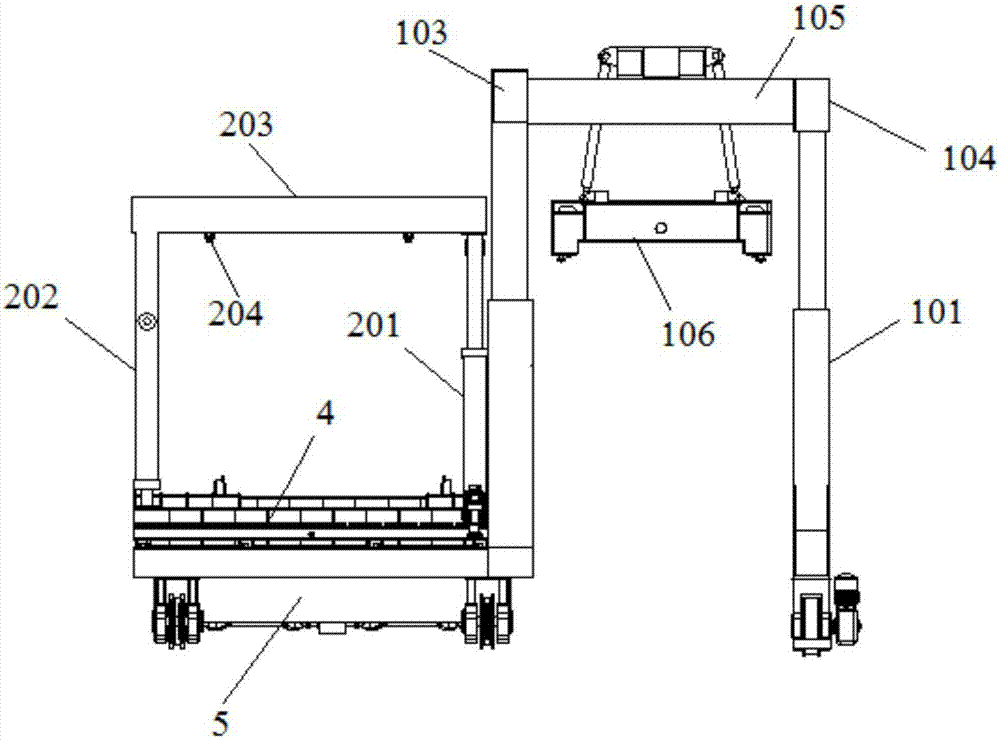

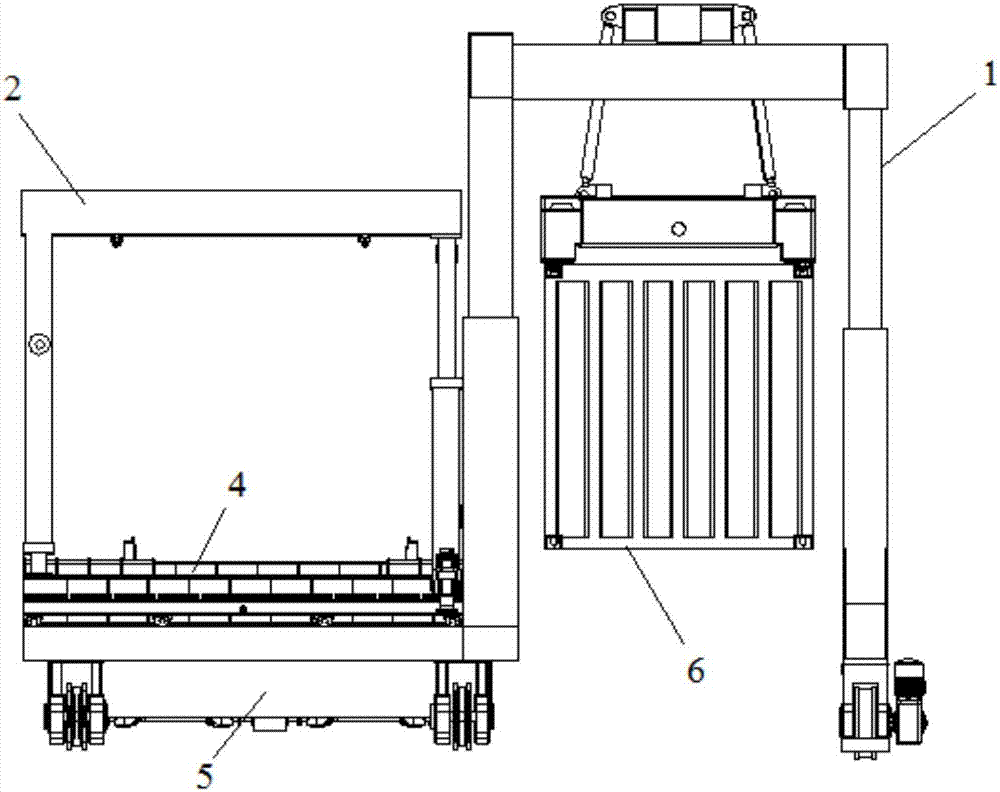

[0104] Introduce the concrete structure of two-way side fetching device 4 in the present embodiment below:

[0105] See attached Figure 12-20 The two-way side fetching device 4 includes: a bridge mechanism 402 and a tray mechanism 401, the tray mechanism 401 is slidably arranged on the bridge mechanism 402; the tray mechanism 401 can slide to the position corresponding to the card loading and unloading device 1, and / or, slide Move to the position corresponding to lifting device 2. The two-way side fetching device 4 also includes: a lifting mechanism 403, which is arranged below the bridge mechanism 402 and on the carrying platform 3, and is used to carry and drive the bridge mechanism 402 and the tray mechanism 401 to rise or fall.

[0106] The lifting mechanism 403 includes: a lifting platform 4031, 4 first telescopic cylinders 4032 and two first slideways 4033 arranged side by side. The 4 first telescopic cylinders 4032 are arranged at the bottom four corners of the liftin...

Embodiment 2

[0108] See attached Figure 19 , the lifting mechanism 403 also includes: 12 sets of first limit wheels 4035, 6 sets of first limit wheels 4035 are set on one first slideway 4033, and the two first limit wheels 4035 of each group are respectively arranged on the first On both sides of the slideway 4033, 12 sets of first limiting wheels 4035 can ensure that the bridge passing mechanism 402 at the upper end moves along a fixed straight line. There are at least two sets of first limiting wheels 4035 to play the role of fixed limiting in the bridge mechanism 402 .

[0109] A specific first slideway structure is introduced below:

Embodiment 3

[0111] The first slideway 4033 includes a plurality of first roller assemblies arranged side by side, and the first roller assembly includes: a first wheel seat fixed on the lifting platform 4031 and a first roller whose two ends are hinged on the first wheel seat , the bridge passing mechanism 402 slides on the first roller of the first slideway 4033 to reduce frictional resistance and ensure sufficient container transfer force.

[0112] Another specific structure of the first slideway 4033 is introduced below:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com