Garden-type building material recycling plant

A building material and garden-like technology, applied in industrial buildings, mixing plants, ceramic molding workshops, etc., can solve the problems of high circulation and logistics costs, large waste of raw materials, and many ineffective production capacity, so as to improve material utilization and reduce production costs , the effect of reducing ineffective production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

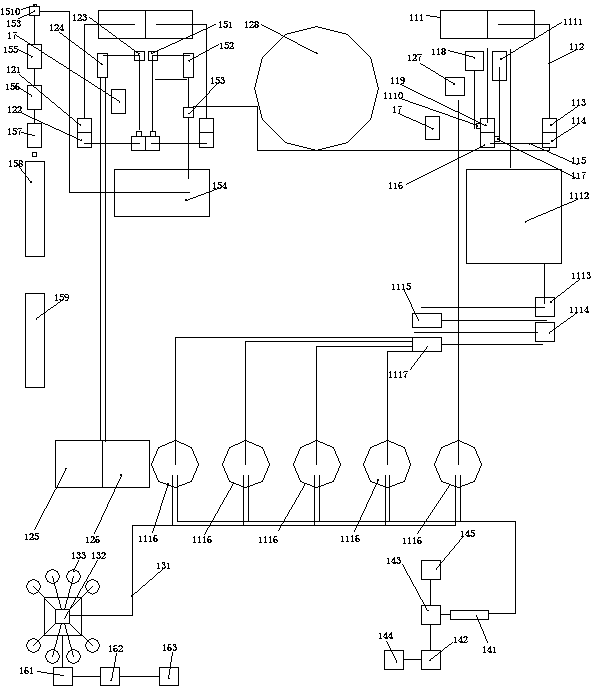

[0053] A garden-style building material recycling plant, including a production workshop 1, and also includes an aggregate finished product area 2, a central control room 3, a green landscape area 4 and a road system 5;

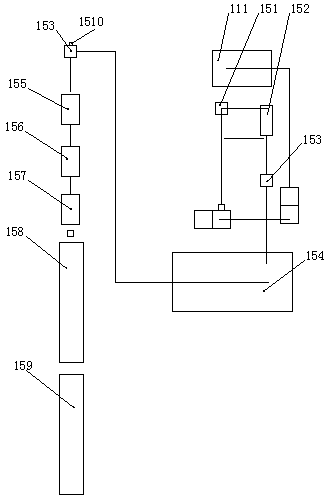

[0054] The production workshop 1 is a closed workshop located five meters underground, including a sand and gravel aggregate crushing production line 11, a construction waste crushing production line 12, a commercial concrete mixing station 13, an asphalt concrete mixing station 14, a brick production line 15 and a precast production line 16;

[0055] The finished aggregate area 2 is a storage area for finished sand and gravel aggregates, recycled sand and gravel aggregates from construction waste, and waste soil, including a plurality of fully enclosed concrete silos 21;

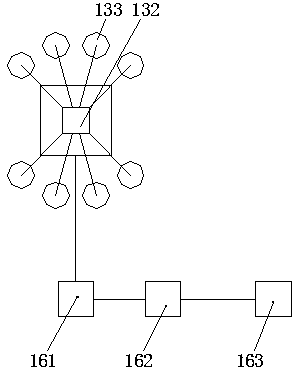

[0056] The central control room 3 includes an electrically connected equipment control system 31, an equipment operating parameter monitoring system 32, a real-time output monitoring syste...

Embodiment 2

[0061] A garden-style building material recycling plant, including a production workshop 1, and also includes an aggregate finished product area 2, a central control room 3, a green landscape area 4 and a road system 5;

[0062] The production workshop 1 is a closed workshop located five meters underground, including a sand and gravel aggregate crushing production line 11, a construction waste crushing production line 12, a commercial concrete mixing station 13, an asphalt concrete mixing station 14, a brick production line 15 and a precast production line 16;

[0063] The finished aggregate area 2 is a storage area for finished sand and gravel aggregates, recycled sand and gravel aggregates from construction waste, and waste soil, including a plurality of fully enclosed concrete silos 21;

[0064] The central control room 3 includes an electrically connected equipment control system 31, an equipment operating parameter monitoring system 32, a real-time output monitoring syste...

Embodiment 3

[0079] A garden-style building material recycling plant, including a production workshop 1, and also includes an aggregate finished product area 2, a central control room 3, a green landscape area 4 and a road system 5;

[0080] The production workshop 1 is a closed workshop located five meters underground, including a sand and gravel aggregate crushing production line 11, a construction waste crushing production line 12, a commercial concrete mixing station 13, an asphalt concrete mixing station 14, a brick production line 15 and a precast production line 16;

[0081] The finished aggregate area 2 is a storage area for finished sand and gravel aggregates, recycled sand and gravel aggregates from construction waste, and waste soil, including a plurality of fully enclosed concrete silos 21;

[0082] The central control room 3 includes an electrically connected equipment control system 31, an equipment operating parameter monitoring system 32, a real-time output monitoring syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com