Combined type intelligent turning and grinding integrated cutter and use method thereof

A smart car, combined technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of large fluctuations in processing quality, high requirements for the use environment, and high processing labor intensity, so as to eliminate workpiece processing errors and accumulated errors. Large, reduce labor intensity and cost, improve the effect of workpiece processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

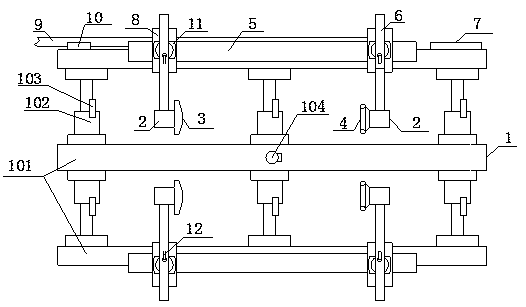

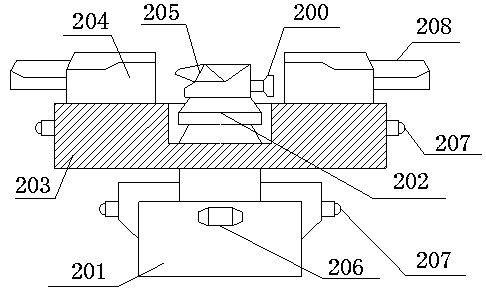

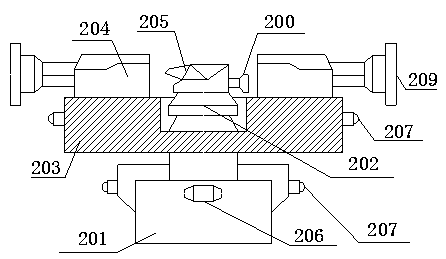

[0026] Such as figure 1 A combined intelligent turning and grinding tool shown in —3 includes a load-carrying keel 1, a feed table 2, a turning tool disc 3, a grinding tool disc 4, a driving guide rail 5, a linear displacement table 6 and a control circuit 7, Wherein the bearing keel 2 is a columnar frame structure, and its side surface is evenly distributed to two driving guide rails 5, and the driving guide rails 5 are evenly distributed around the axis of the bearing keel 1 and distributed parallel to the axis of the bearing keel 1, and the driving guide rail 5 passes through the slider 8 and at least two The linear translation stages 6 are slidingly connected, and the linear translation stages 6 on the same driving guide rail 5 are distributed along the axis of the bearing keel 1. The axes of the linear translation platforms 6 and the axis of the bearing keel 1 form an included angle of 0°-90°. 6 are all slidably connected with a feed table 2, and in the feed table 2, two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com