Weighing device for quantitative filling of broken plastic

A weighing device and plastic technology, which is applied in the field of plastic machinery, can solve the problems of time-consuming and labor-intensive transfer of materials, and labor-intensive up and down, and achieve the effect of reducing labor intensity and reasonable structure design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

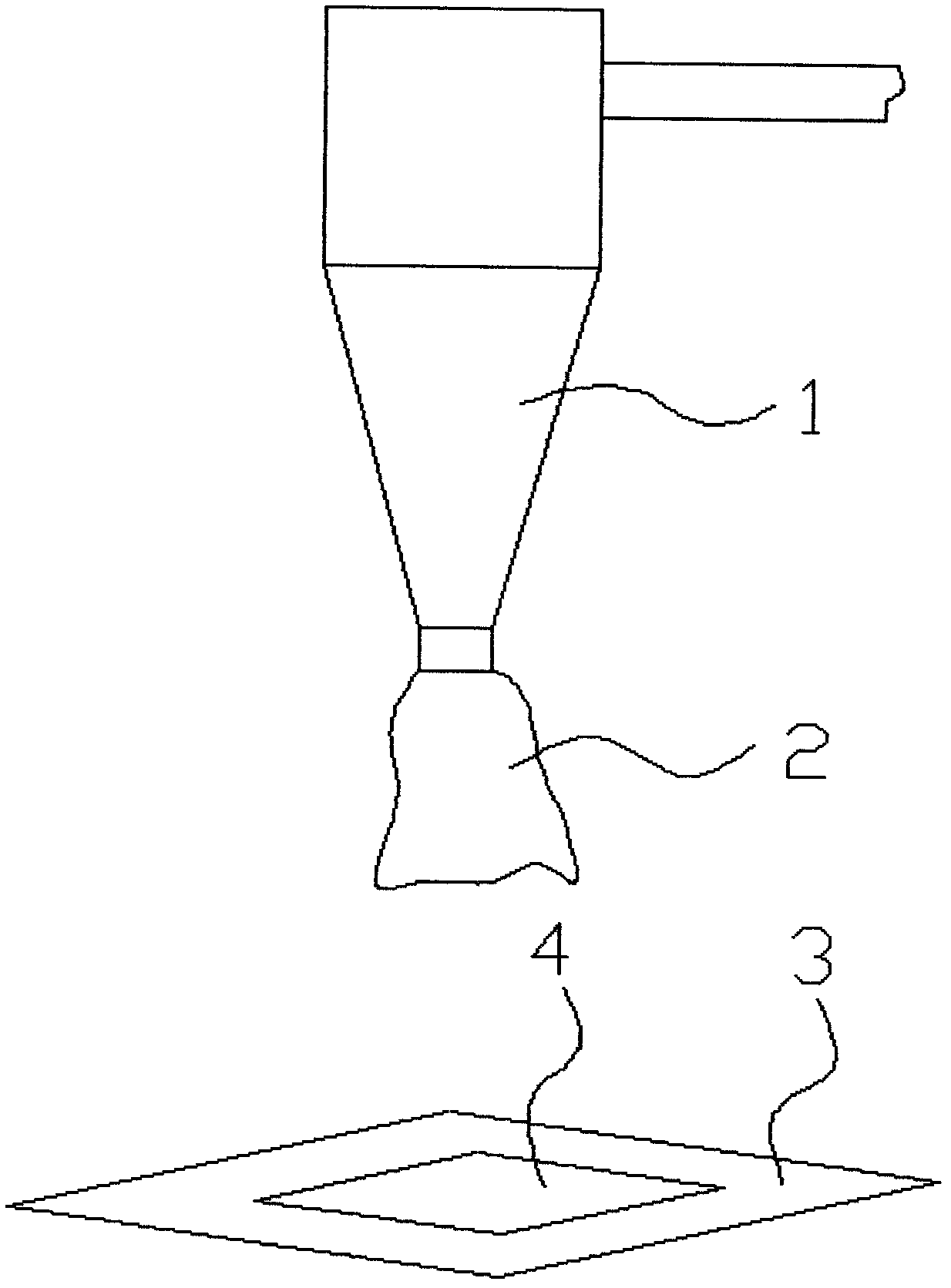

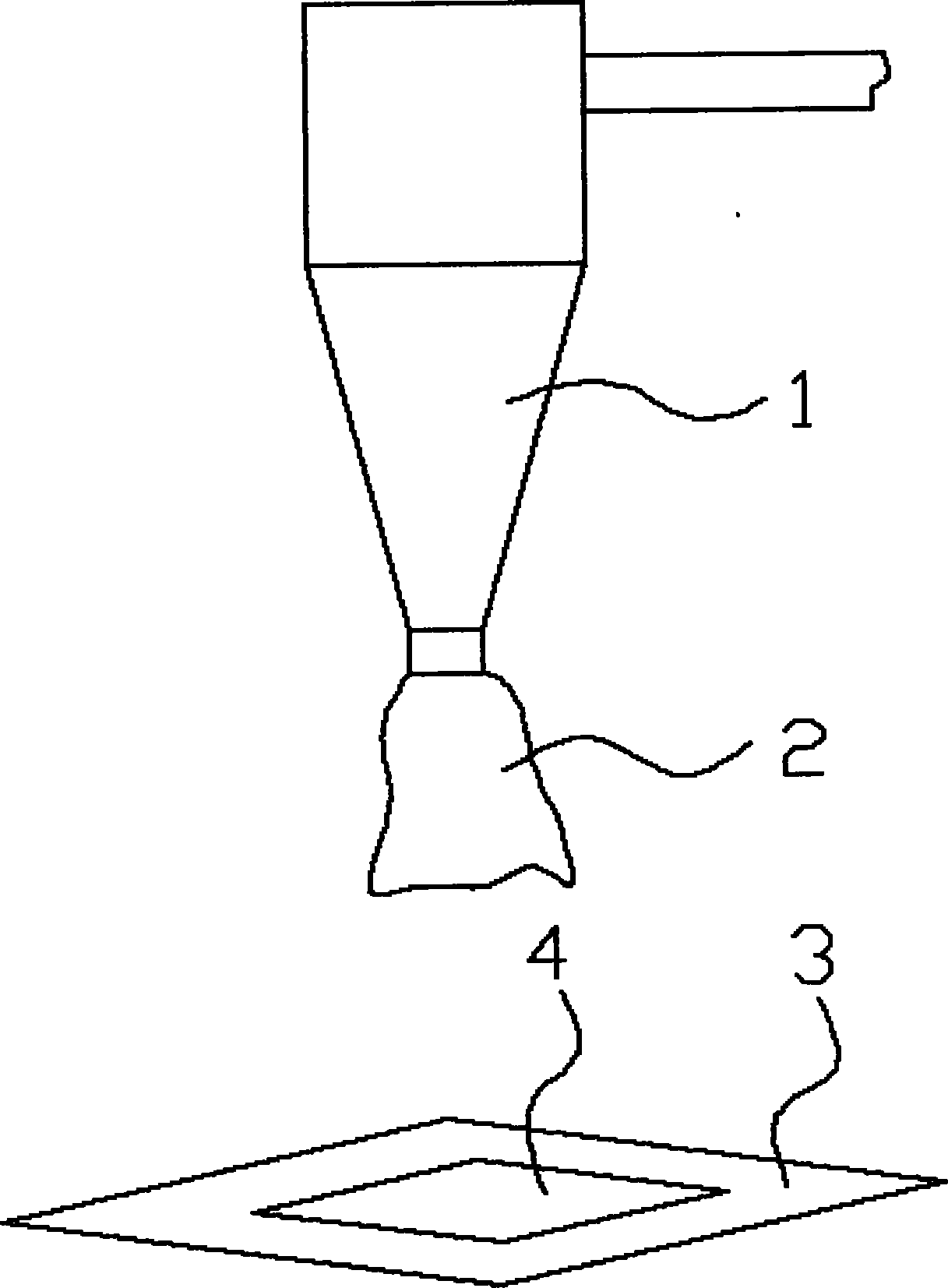

[0010] Such as figure 1 As shown, a crushing plastic quantitative filling and weighing device includes a discharge cover 1, the lower end of the discharge cover 1 is connected to the collection bag 2, and the bottom of the collection bag 2 is provided with a weighbridge 4, and the load-bearing plate of the weighbridge 4 is connected to the ground plane 3 flush.

[0011] The basic principles and main features of the present invention and the advantages of the present invention have been shown and described above. Those skilled in the industry should understand that the present invention is not limited by the above-mentioned embodiments, and what described in the above-mentioned embodiments and the description only illustrates the principles of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com