Plate spring online bush press-fitting equipment

A bushing and leaf spring technology, which is applied in the field of leaf spring processing and assembly production equipment, can solve problems such as low processing efficiency and uneven press-fitting quality, and achieve the effects of improving production efficiency, reducing production costs, and avoiding product bumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

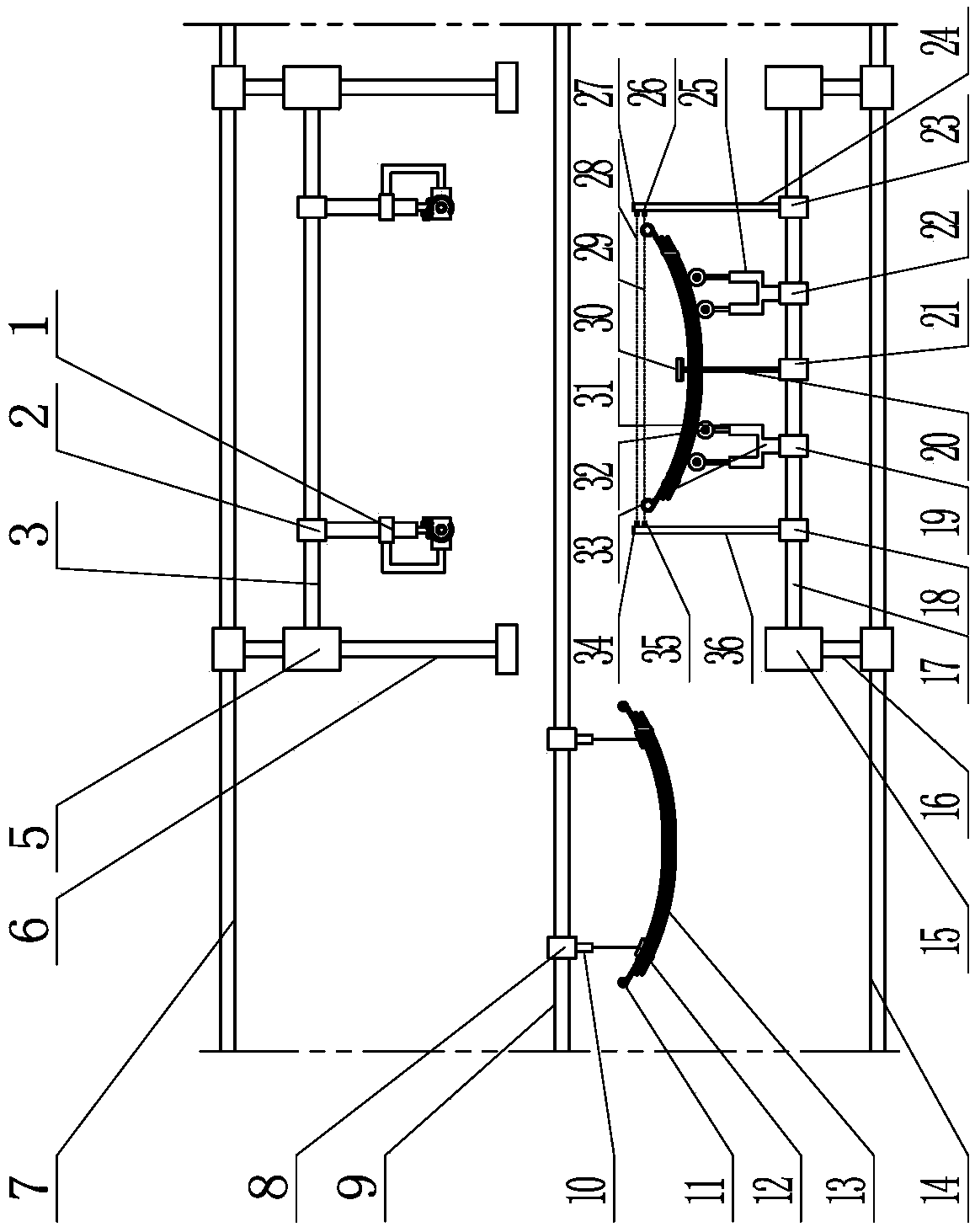

[0023] Such as figure 1 As shown, the leaf spring online bushing press-fitting equipment described in the present invention includes a transportation line and an assembly production line. The transportation line can clamp and transport the leaf spring and place the leaf spring on the assembly line. The ear holes at both ends of the bushing are press-fitted. After the press-fitting is completed, the transportation line can move the leaf spring out of the assembly line.

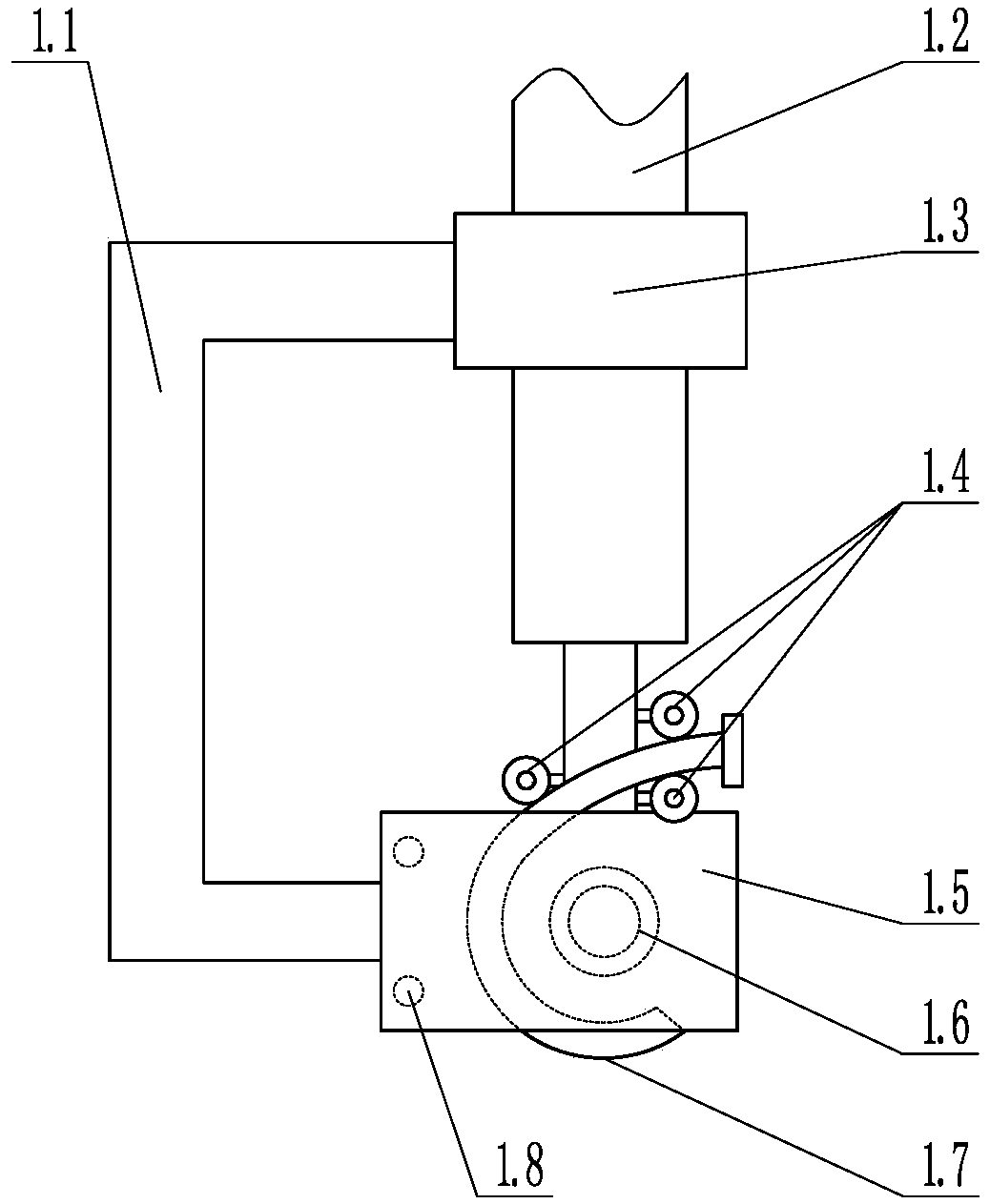

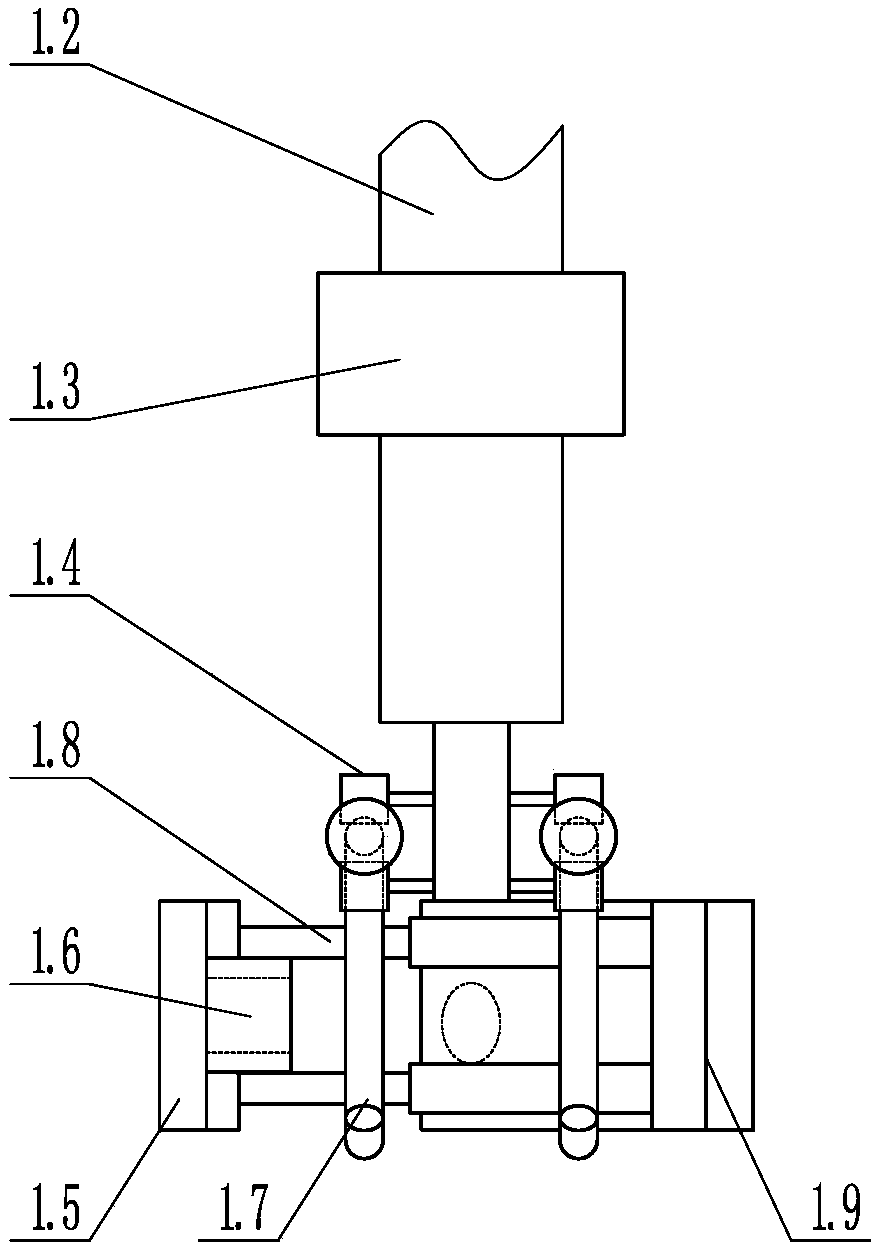

[0024] The transportation line includes a transportation rod, on which two or more transfer manipulators are set, and the transfer manipulator is installed on the rail running device through the manipulator lifting device, and the rail running device is set on the transportation rod, and the rail running device can Reciprocating movement along the transport bar.

[0025] The transfer manipulator is an electromagnetic chuck, which has magnetic force to attract and transfer the leaf spring when it is powered on,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com