Automatic fire extinguishing safety box

A technology of automatic fire extinguishing and safety box, which is applied in fire rescue and other fields, can solve problems such as inability to extinguish fire, achieve the effects of accelerating extinguishing, strengthening ventilation and heat dissipation, and reducing risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

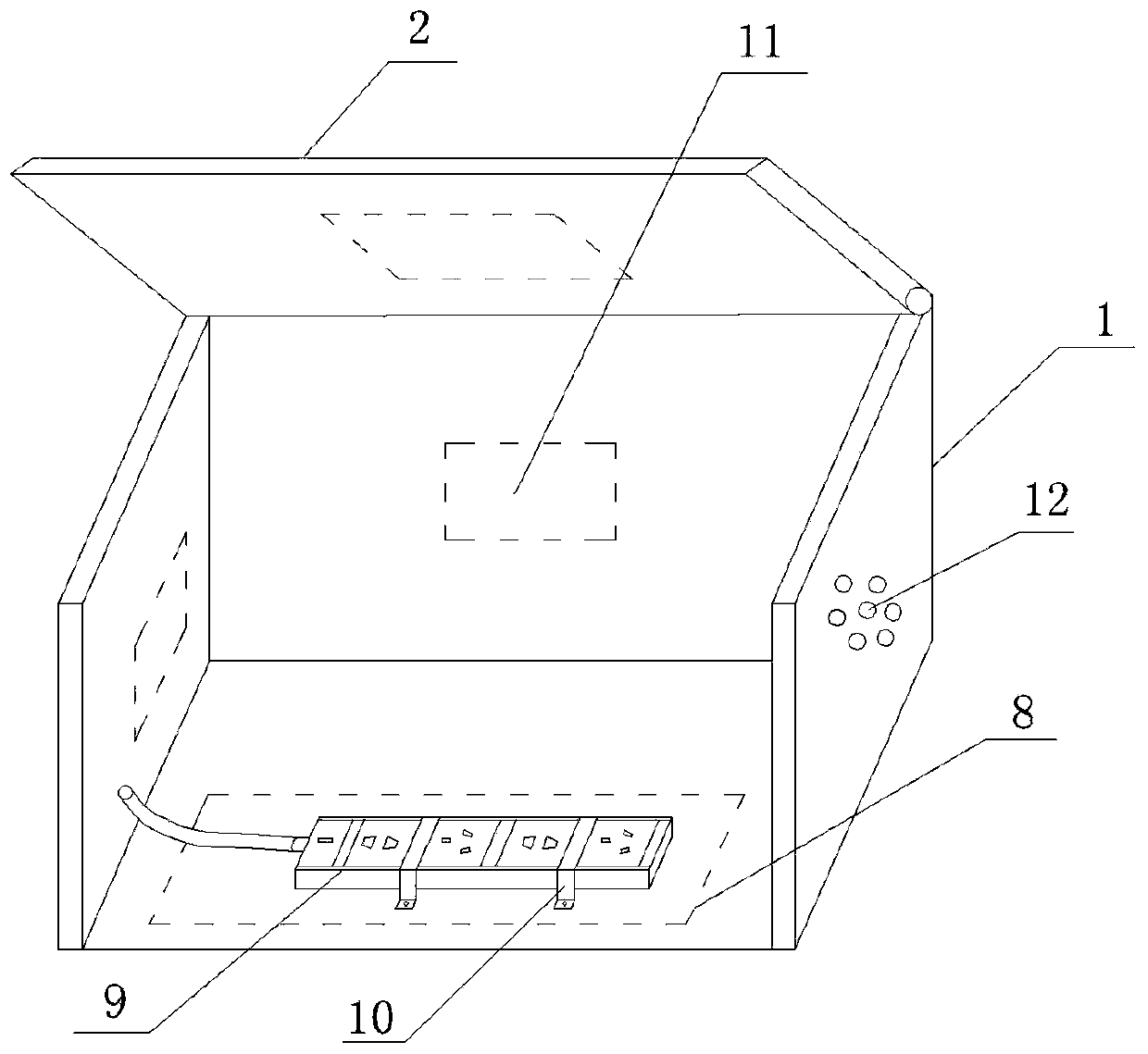

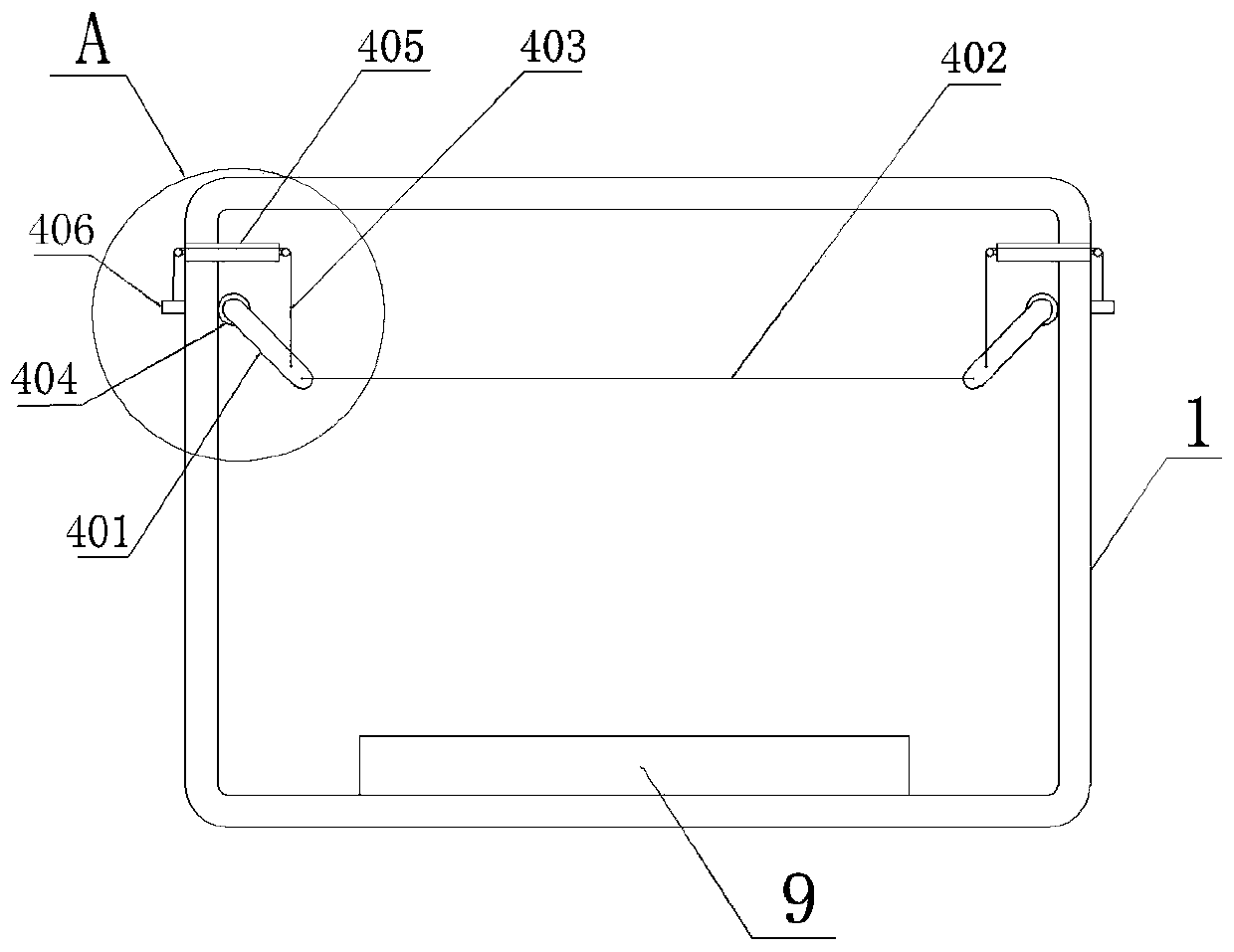

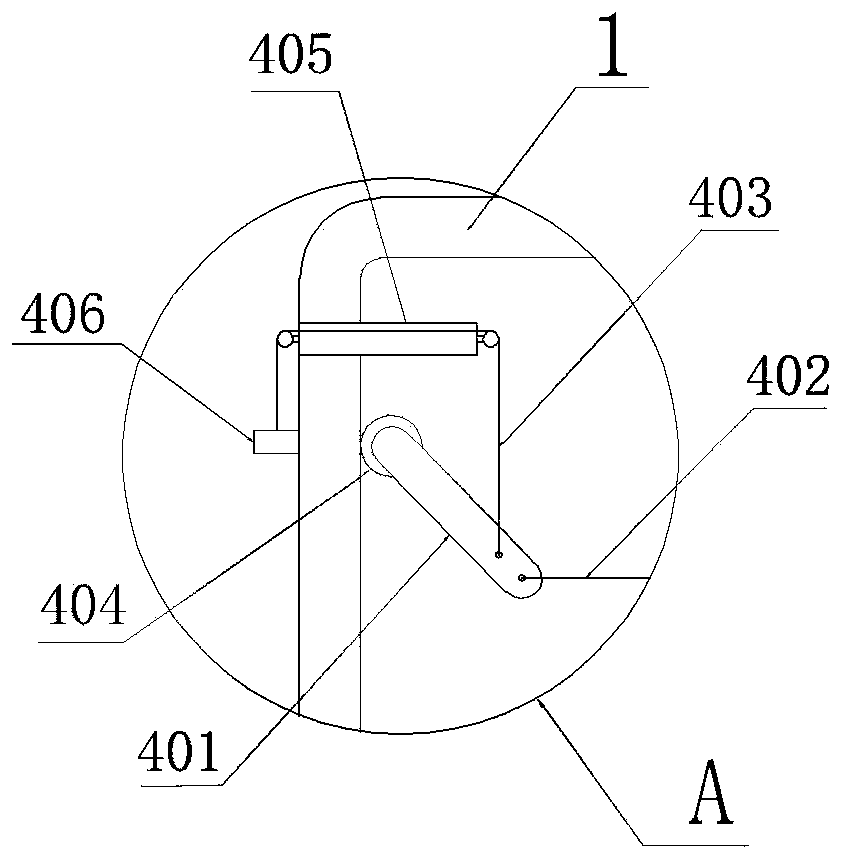

[0030] see figure 1 , in this embodiment, an automatic fire extinguishing safety box, including a box body 1 and a cover body 2, the box body 1 and the cover body 2 are movably connected through a hinge or a rotating shaft, and a socket position 8 is arranged inside the box body 1, and the socket position 8 is The socket 9 is installed through the fixing belt 10, the length of the fixing belt 10 can be adjusted, and it is used to adapt to most sockets on the market. The inner wall of the box body 1 or the bottom of the cover body 2 is provided with a fitting position 11, and the fitting position 11 is pasted with a fire extinguisher Material 7, the fire extinguishing material 7 can be automatic fire extinguishing stickers, automatic fire extinguishing small steel cylinders, superfine dry powder fire extinguishing bombs and the like. When a fire breaks out, the fire extinguishing material 7 will explode automatically when heated, and release the fire extinguishing agent therein...

Embodiment 2

[0036] see Image 6 , in this embodiment, the only difference between the automatic fire extinguishing safety box and the first embodiment is that: the box body 1 is provided with a storage component 6, and the storage component 6 is a suspension rod 601, and the suspension rod 601 is connected to the inner walls on both sides of the box body 1 Between, suspension rod 601 is positioned at socket position 8 just above, and suspension rod 601 below is hung with fire extinguishing material 7, and fire extinguishing material 7 can be automatic fire extinguishing paste, automatic fire extinguishing small steel bottle, superfine dry powder fire extinguishing bomb etc. When the socket position 8 burns due to the temperature rise, the flame will run upwards, so this design is beneficial for the fire extinguishing material 7 to sense the fire source, so as to ensure a better and faster fire extinguishing effect.

Embodiment 3

[0038] see Figure 7, in this embodiment, the difference between the automatic fire extinguishing safety box and the first embodiment is that the automatic fire extinguishing safety box includes a box body 1, a drawer 3 and a storage component 6, and the storage component 6 is a grid 602, and the drawer 3 and the grid 602 is arranged inside the box body 1, and the grid frame 602 is located above the drawer 3, the fire extinguishing material 7 can be placed on the grid frame 602, the inside of the drawer 3 is provided with a socket position 8, and the socket position 8 is fixedly connected with a socket 9 through a fixing band 10, Ventilation holes 12 are opened on the side wall of the box body 1 . When a fire breaks out, the fire extinguishing material 7 on the grid frame 602 will explode automatically when heated, and release the fire extinguishing agent therein to extinguish the fire source, which is safe, rapid and practical.

[0039] In summary, the present invention at l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com