Continuous punch forming method of plates

A technology of stamping forming and sheet metal, applied in the field of stamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

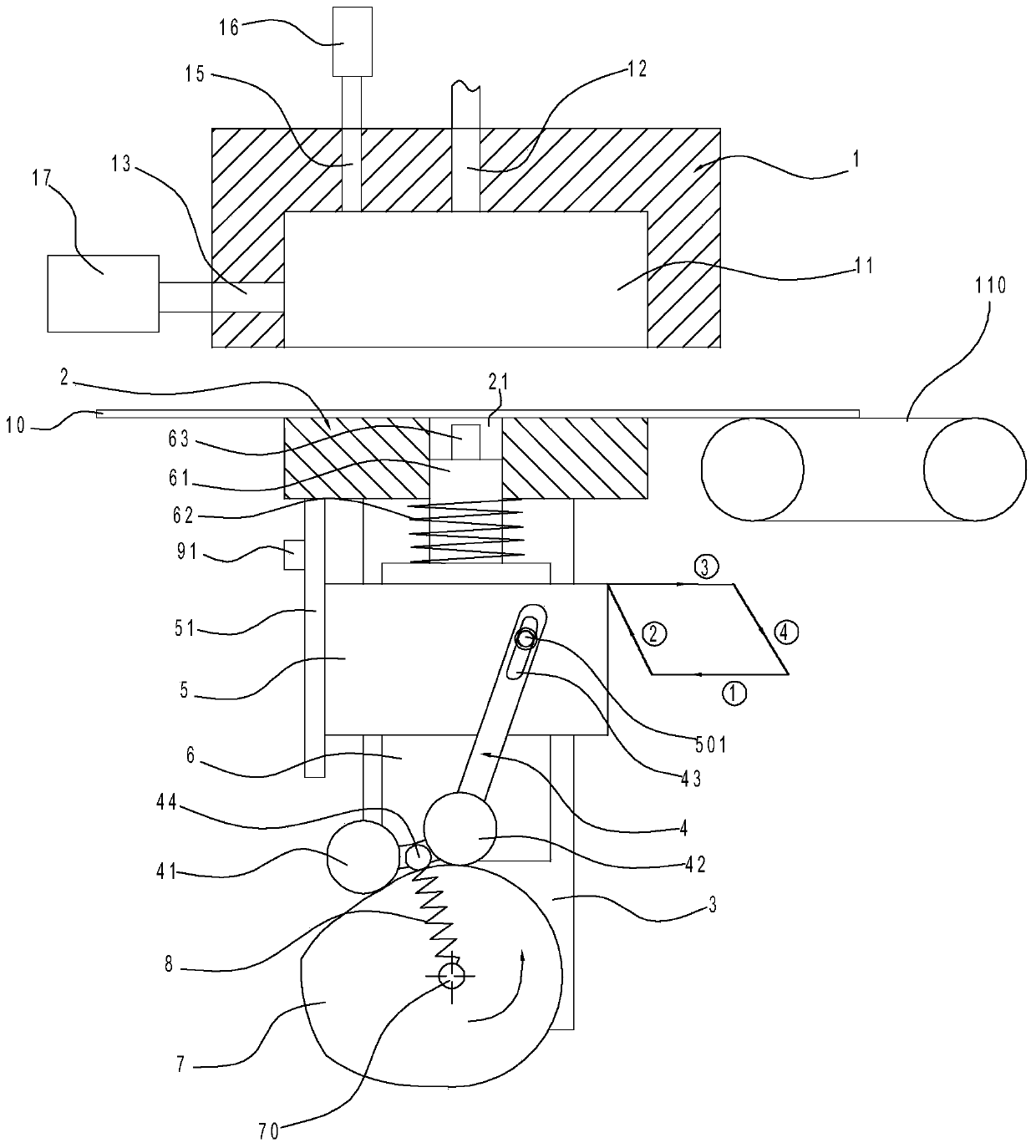

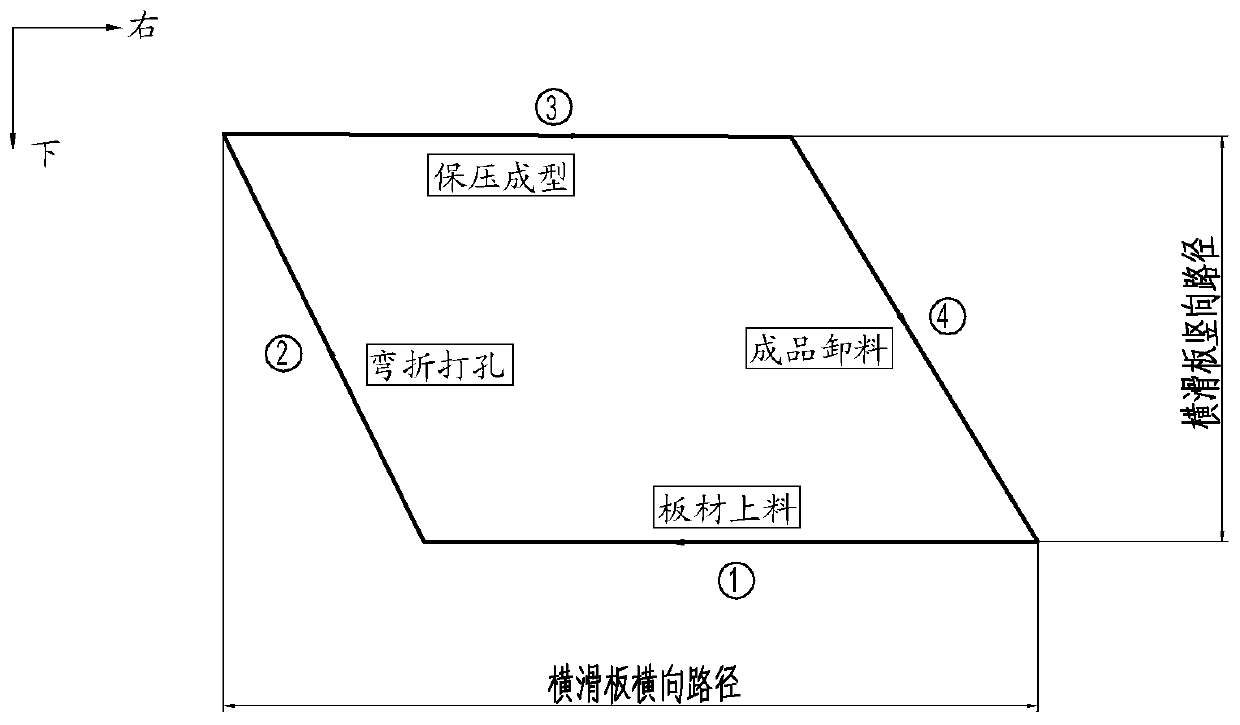

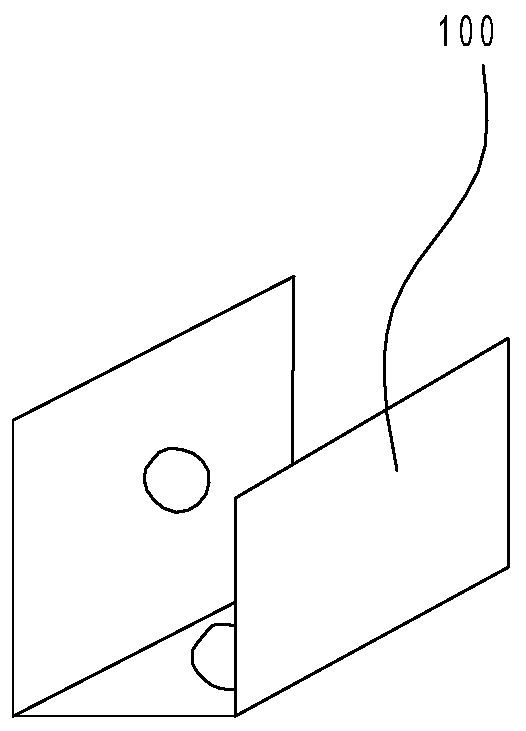

[0028] Firstly, a brief description will be given of the sheet material continuous stamping and forming device involved in the present invention. Such as Figures 1 to 11 As shown, the plate continuous stamping and forming device in this implementation includes an upper mold 1, a lower mold 2, a driving cam 7, a fixed plate 3, a horizontal slide 5, a vertical slide 6, a bending rod 4, a first roller 41, a second roller Post 42, compression spring 8, support rod 51, left punch 91, stamping spring 62, upper punch 63, suction pump 17 and blowing pump 16.

[0029] Among them, please combine figure 1 , 6 And 7, the upper die 1 of the present invention is fixedly arranged, and the lower die 2 is movable, and the upper die 1 is formed with a cavity 11 with a downward opening for U-shaped bending of the plate 10. In the cavity 11 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com