Patents

Literature

72results about How to "Realize punching operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

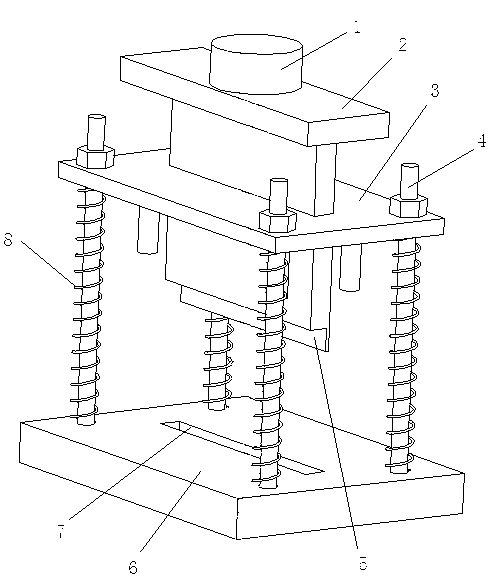

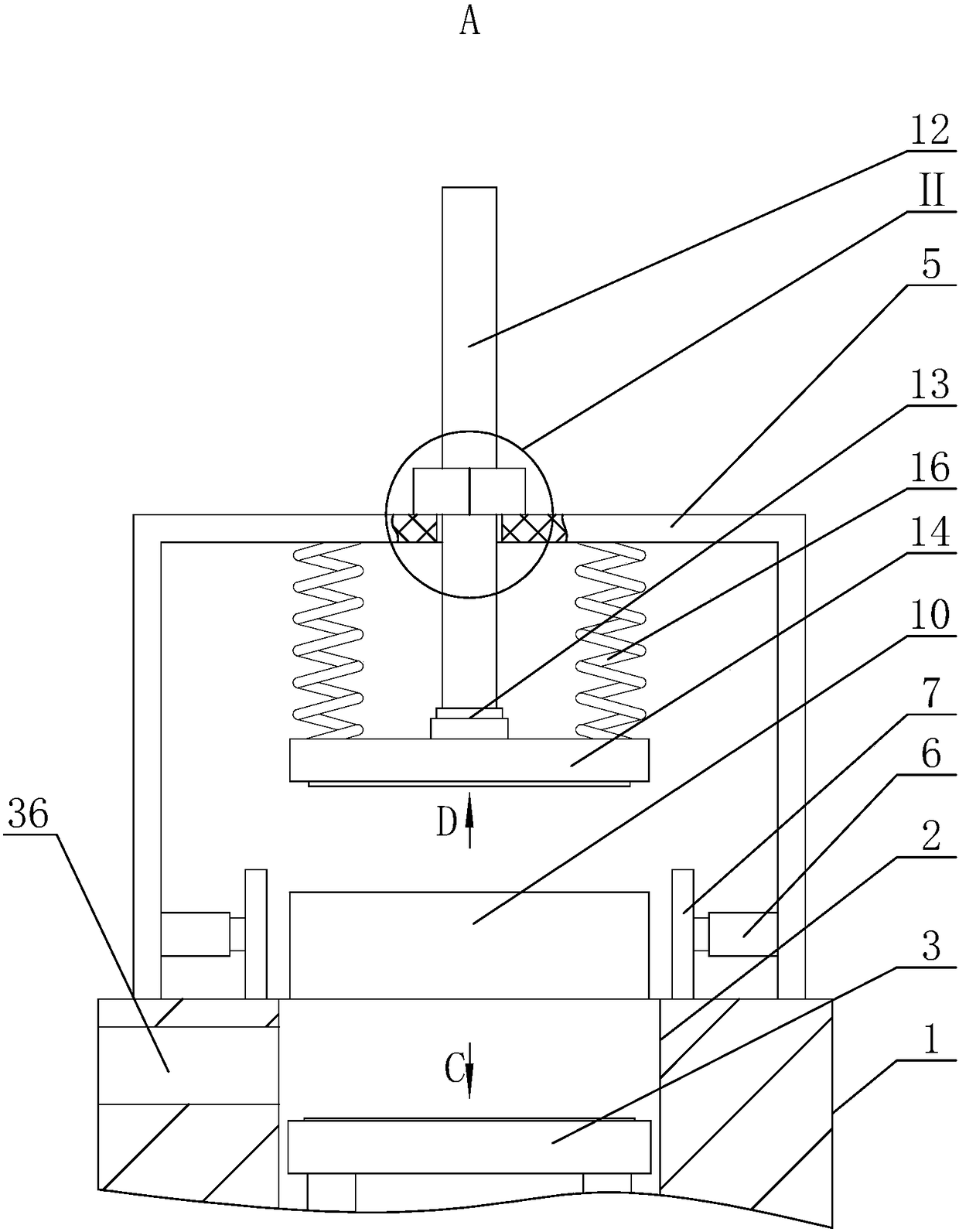

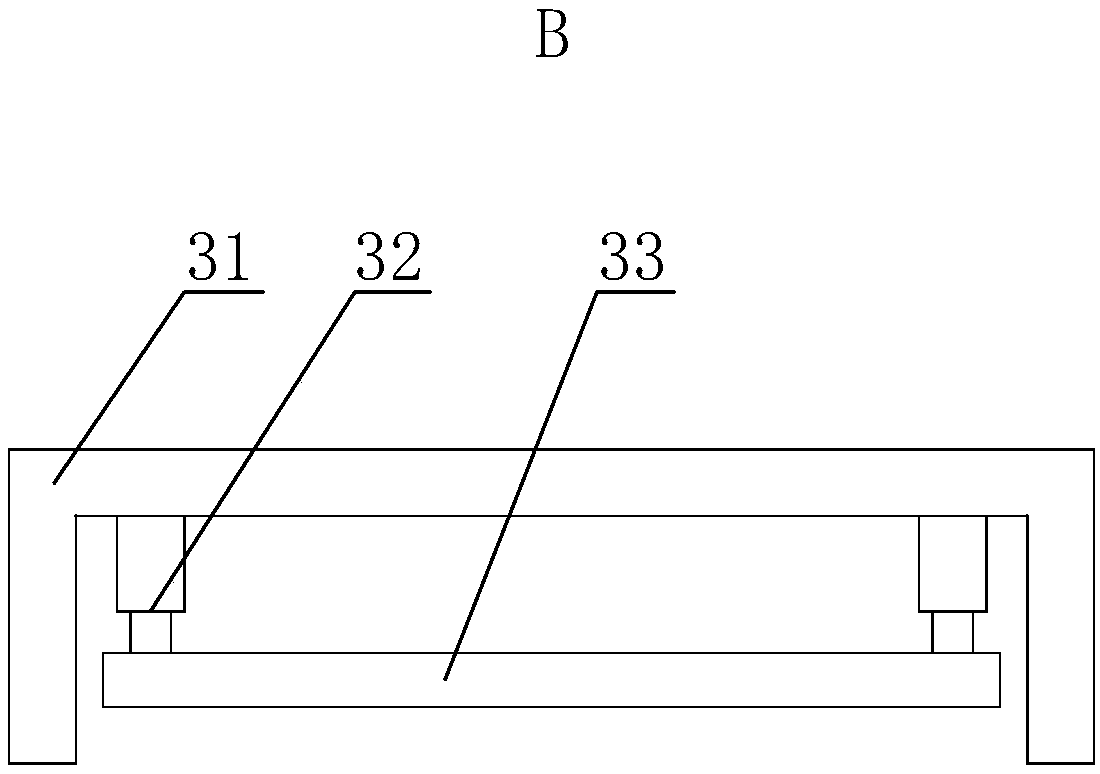

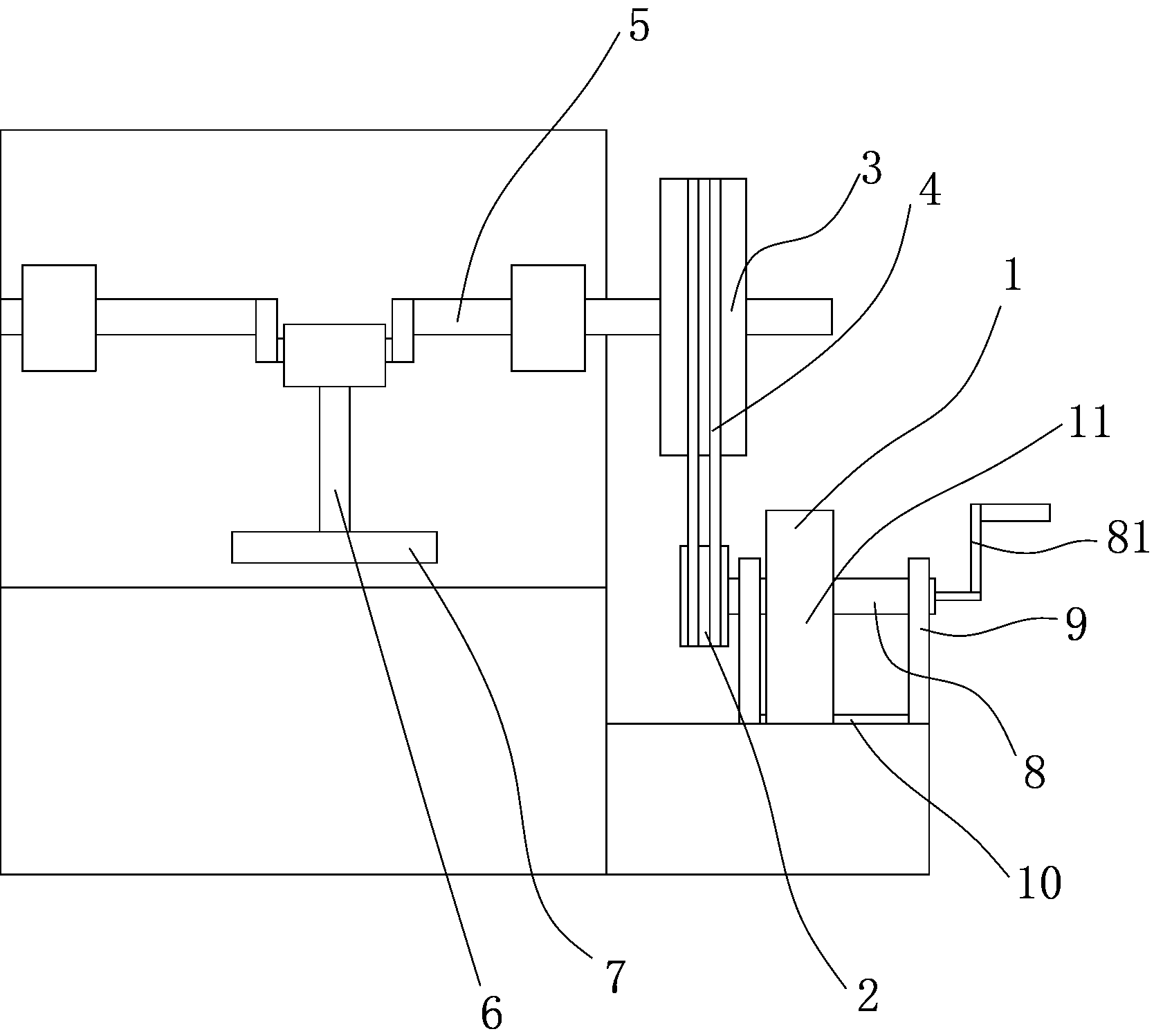

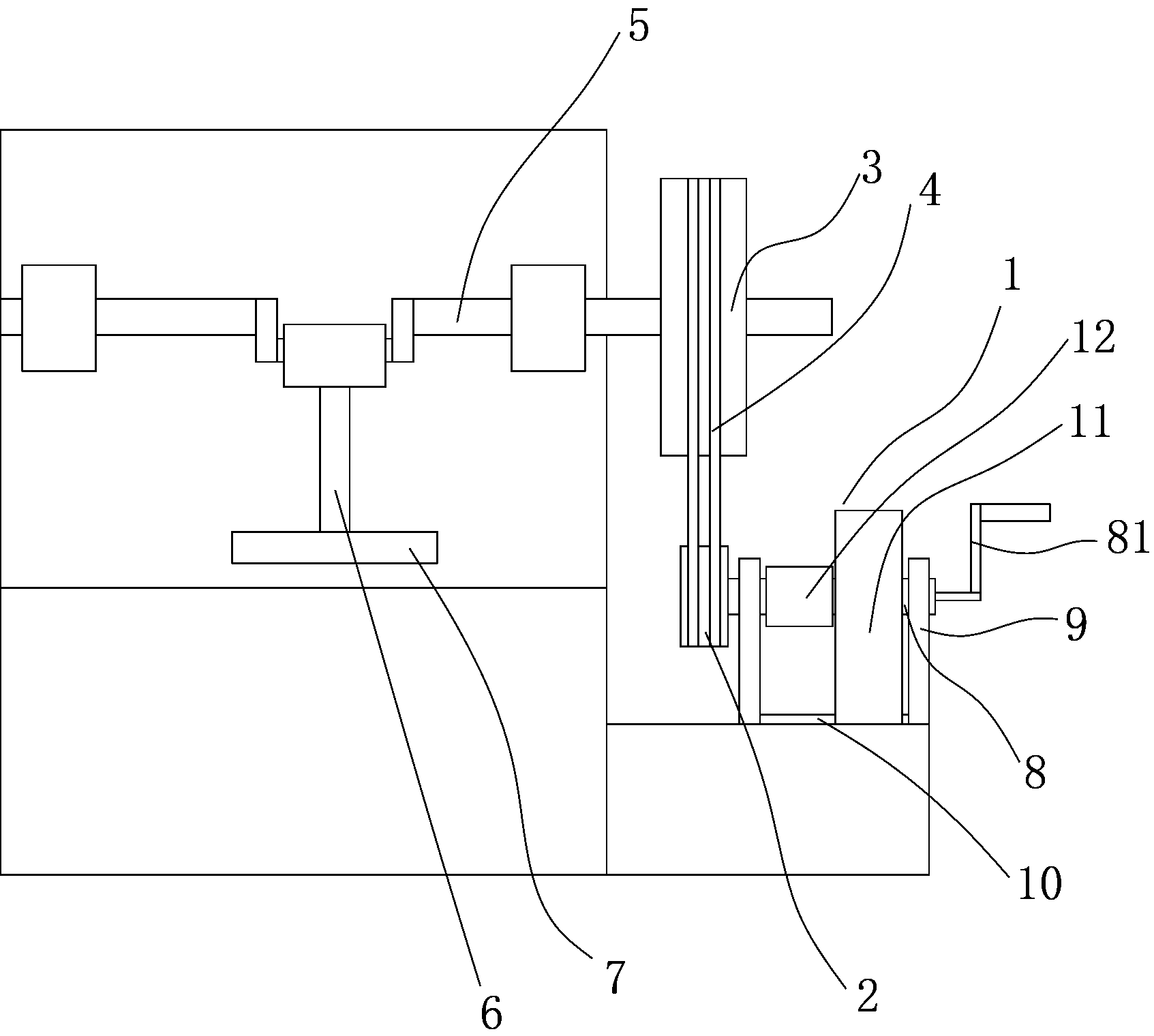

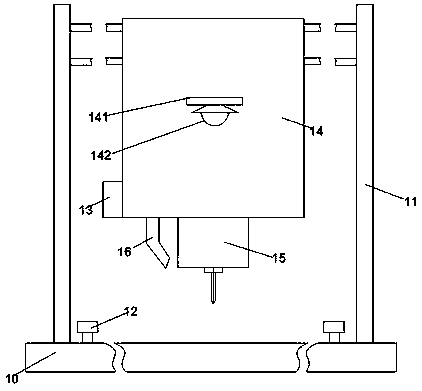

Sheet metal component punching mould

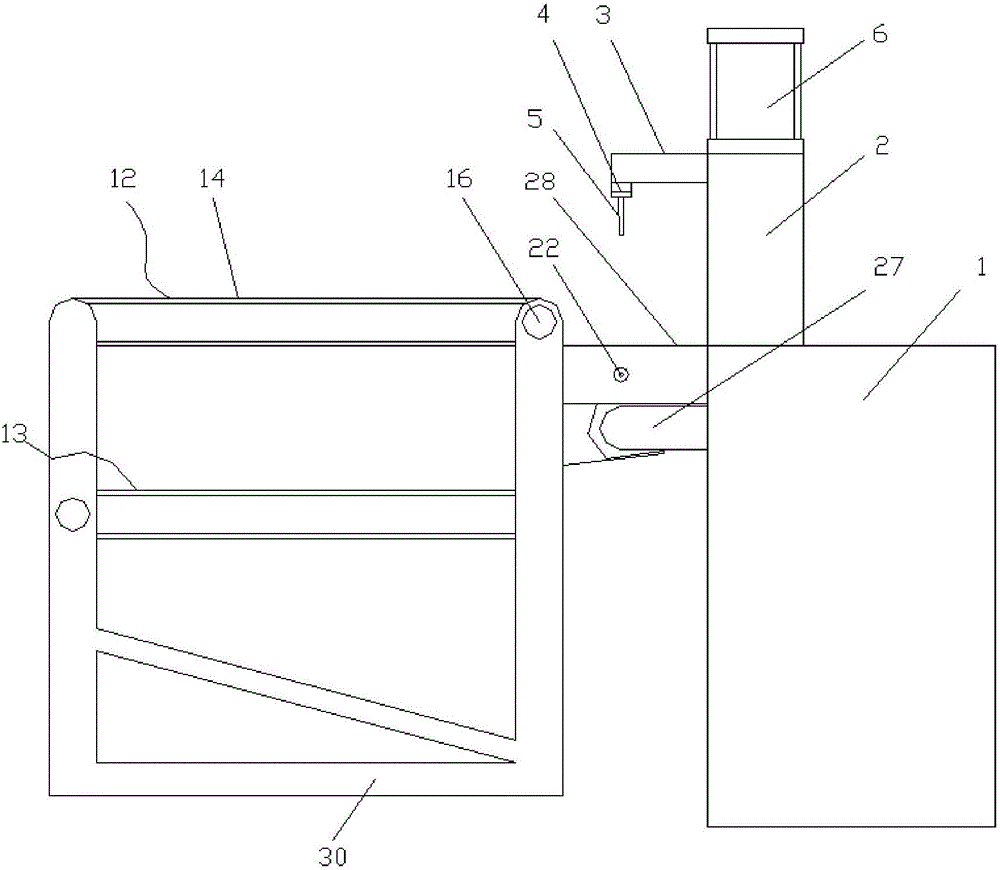

The invention relates to a sheet metal component punching mould belonging to the technical field of sheet metal component processing equipment. The sheet metal component punching mould comprises an upper mould plate and a lower mould plate, wherein the upper mould plate and the lower mould plate are longitudinally distributed; four guide pillars distributed in a square shape are arranged on the lower mould plate; the tops of the guide pillars penetrate through the upper mould plate and are fixed by using nuts; springs are sleeved on the guide pillars; a punching block is fixed on the upper mould plate; the top of the punching block is connected with an air cylinder, and the bottom of the punching block is provided with an L-shaped tool edge; the air cylinder and the L-shaped tool edge are respectively arranged at the upper side and the lower side of the upper mould plate; a square groove is arranged on the lower mould plate; and the L-shaped tool edge stretches into the square groove when the lower mould plate is descended. The sheet metal component punching mould has novel structural design; in the invention, the descending of the upper mould plate is controlled through the air cylinder, thereby realizing the punching operation of a sheet metal component; and the control of the descending direction of the upper mould plate is realized through the guide pillars and the springs, thereby enhancing the accuracy of punching processing.

Owner:WUHU HANGUANG STEREO PARKING EQUIP

Hardware punching iron filings adsorption equipment based on magnetic attraction principle

ActiveCN111673109APrevent splashFix damageFeeding apparatusBoring/drilling componentsComputer hardwarePunching

The invention relates to the technical field of hardware castings, and discloses hardware punching iron filings adsorption equipment based on the magnetic attraction principle. The hardware punching iron filings adsorption equipment comprises an equipment main body. A driving screw is arranged inside the equipment main body, and a movable rotating shaft is movably connected under the driving screw. The outer side of a bearing is movably connected with one end of a connecting rod. The other end of the connecting rod is movably connected with a sliding rod. A sliding block is arranged inside thesliding rod. The outer side of the sliding block is movably connected with a first magnetic rod and a second magnetic rod. The outer sides of the first magnetic rod and the second magnetic rod are movably connected with magnetic blocks. The inner sides of the magnetic blocks clamp an electromagnet. An abutment block is threadedly connected with the bottom end of the driving screw. According to the hardware punching iron filings adsorption equipment based on the magnetic attraction principle, through arranging a baffle on the outside of a punching bit, iron filings are avoided from being splashed, and the problem that staff is prone to being hurt due to the fact that traditional hardware punching equipment often has iron filings splashing is solved.

Owner:深圳市兴明源机械有限公司

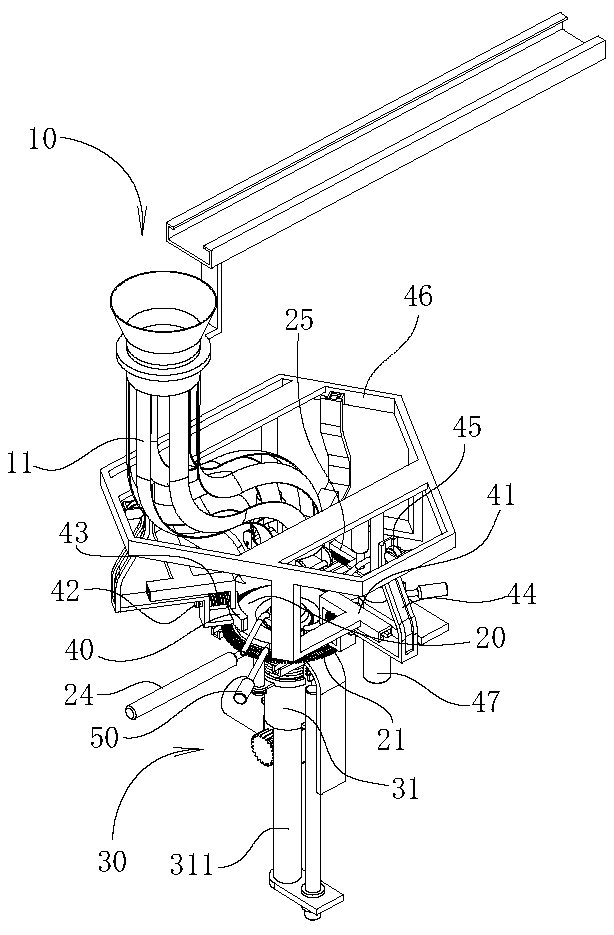

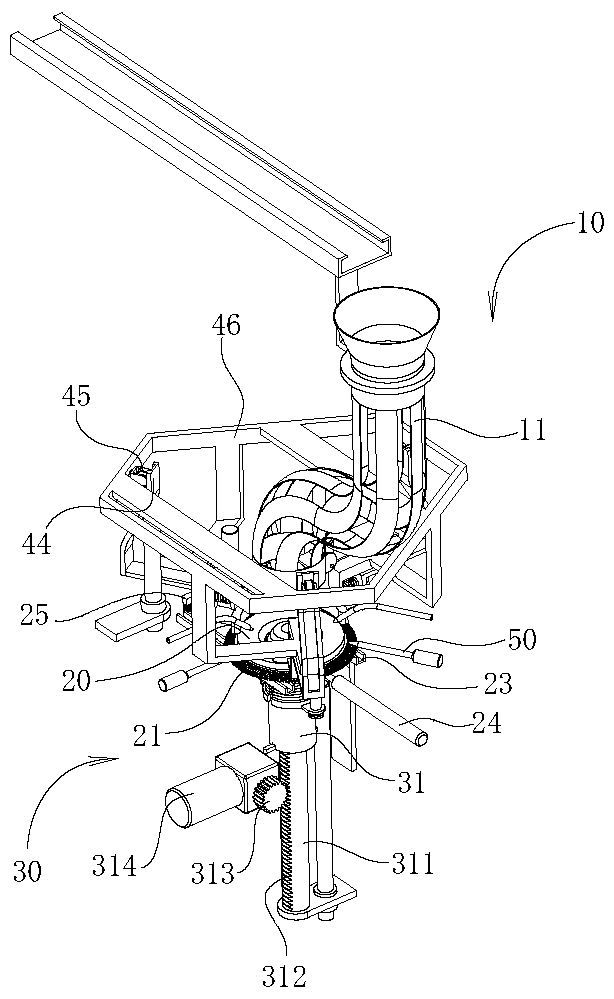

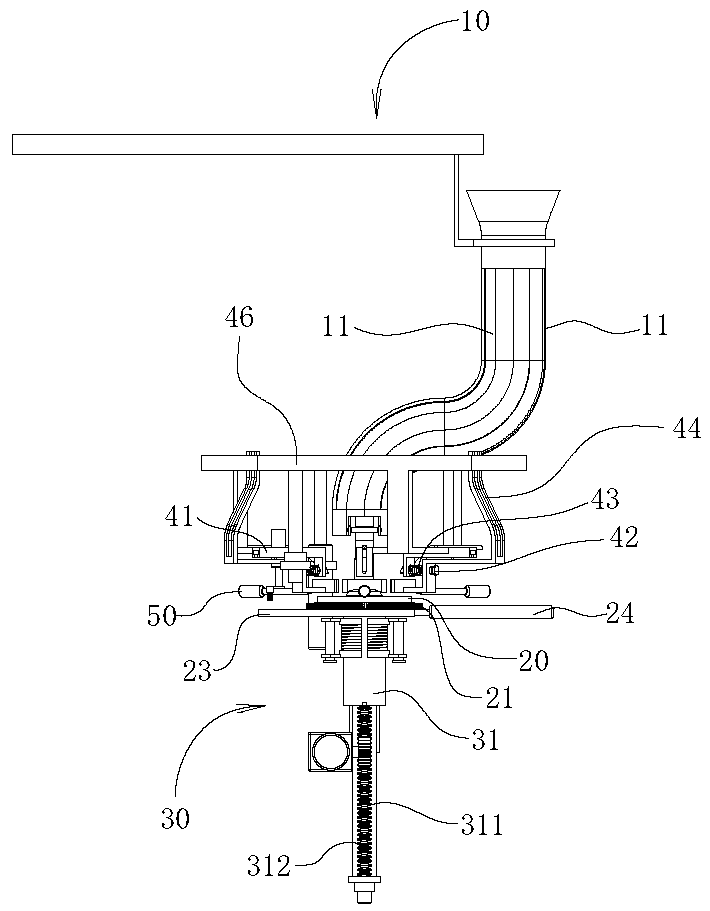

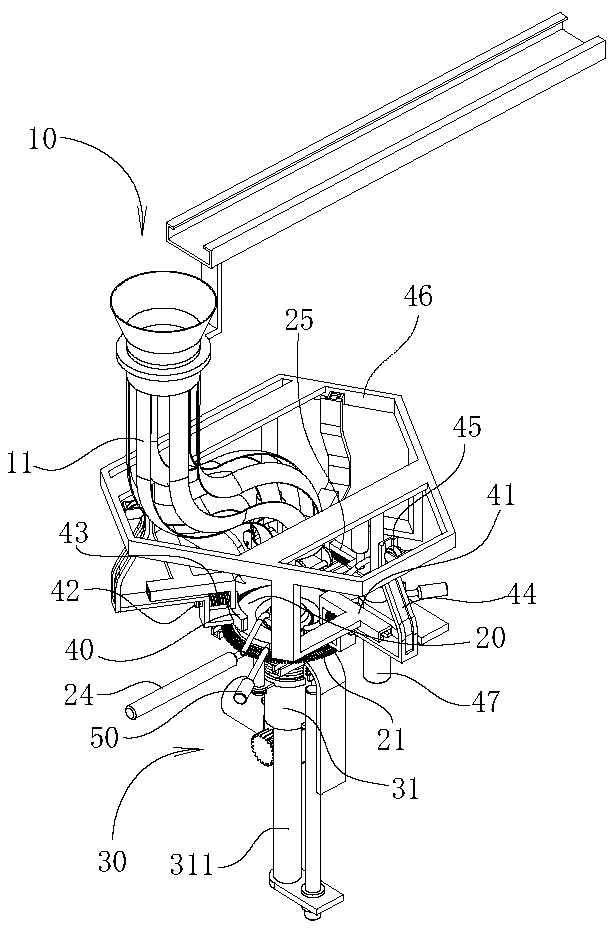

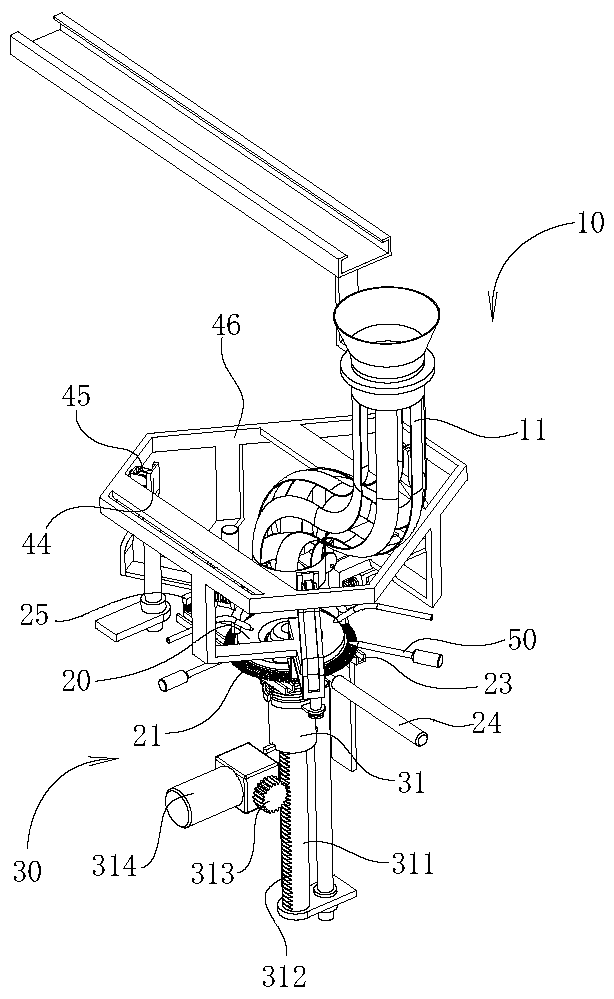

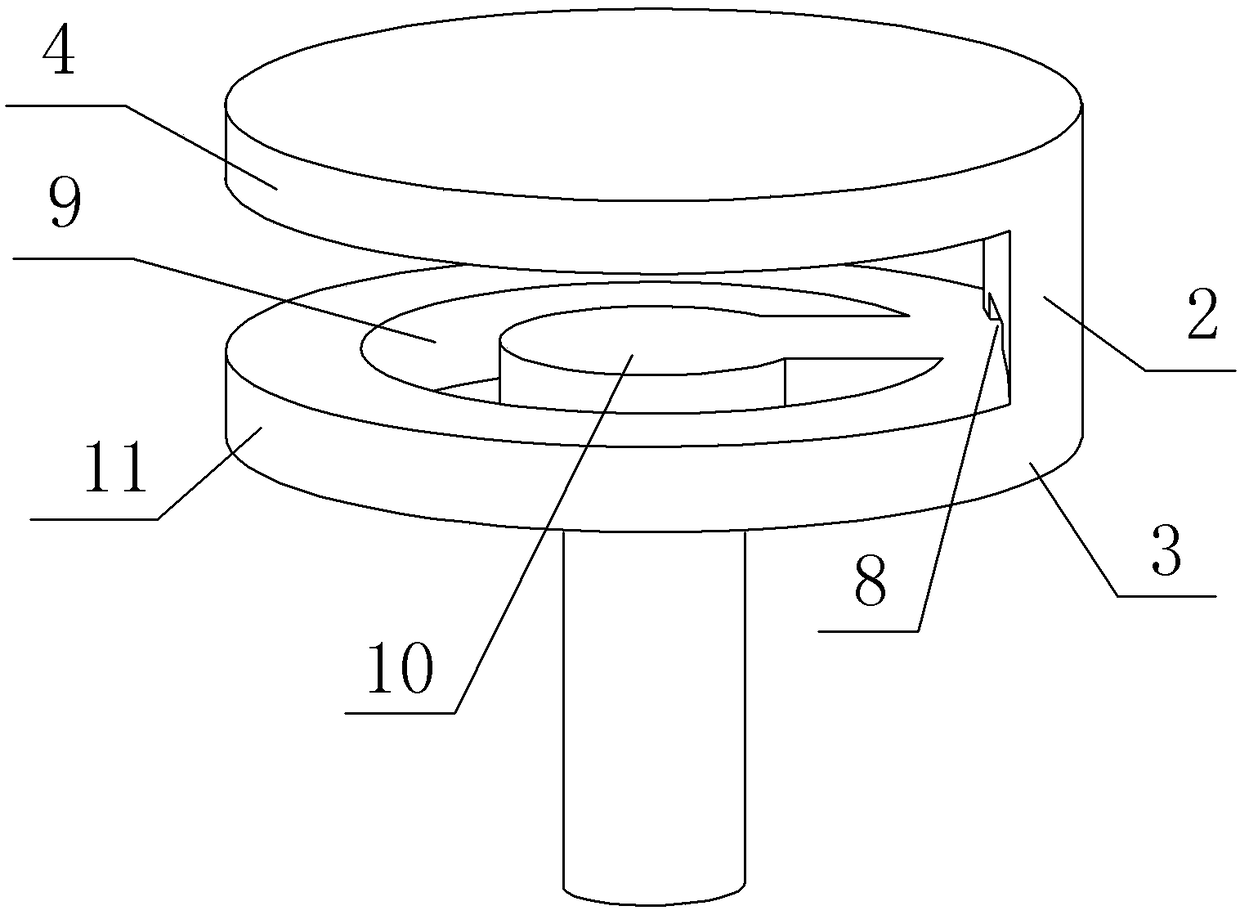

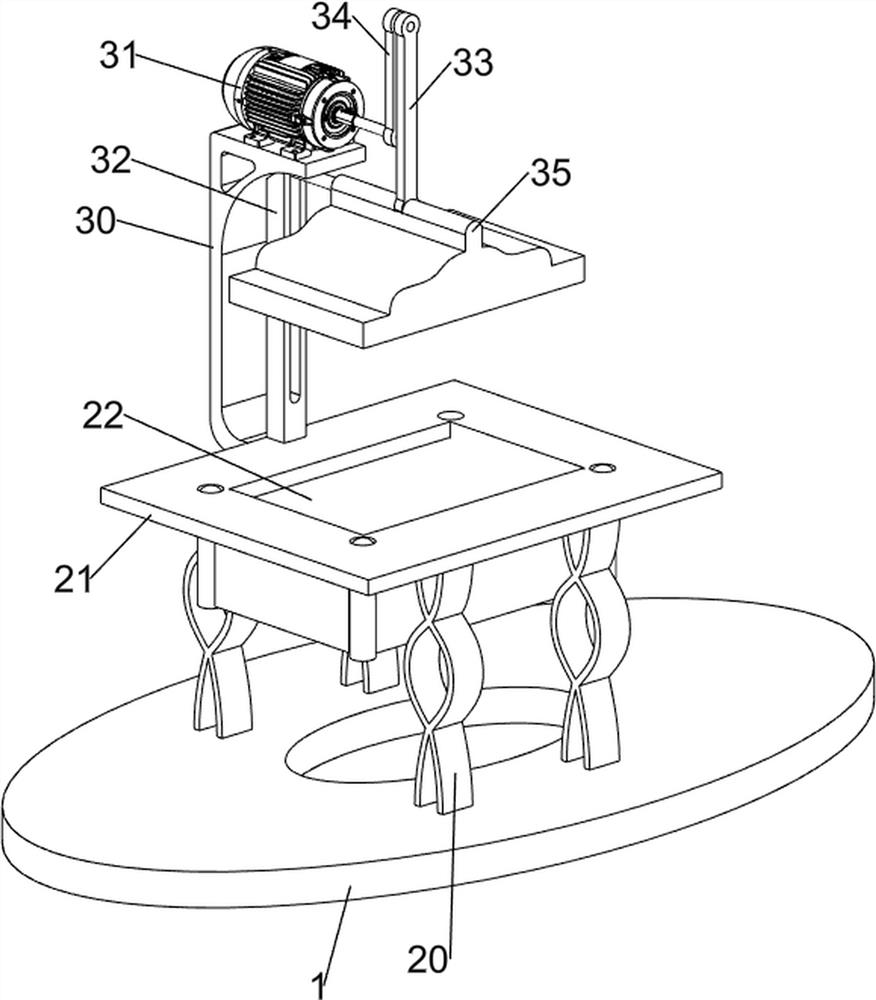

Intelligent punching device

The invention discloses an intelligent punching device, which comprises a framework, wherein a rotating mechanism, two or more than two cutting modules and a controller are arranged on the framework; the rotating mechanism is provided with a rotating tray; the two or more than two cutting modules are arranged on the rotating tray along the circumferential direction; each cutting module comprises a cutter blade, an ascending and descending motor and a pressure sensor; the ascending and descending motor is used for driving the cutter blade to ascend and descend; the pressure sensor is arranged between the cutter blade and the ascending and descending motor and is used for detecting the cutter blade pressure; the controller is used for receiving the pressure signal of the pressure sensor, and simultaneously controls the ascending and descending motor and the rotating mechanism according to the pressure signal. The intelligent punching device has the advantages that the structure is simple; the manufacturing cost of the device is low; the operation is convenient; the intelligent integration degree is high; on the premise of not destroying a target external structure, the hole manufacturing is automatically completed according to the design requirements; in addition, the hole size is adjustable.

Owner:ZHEJIANG UNIV

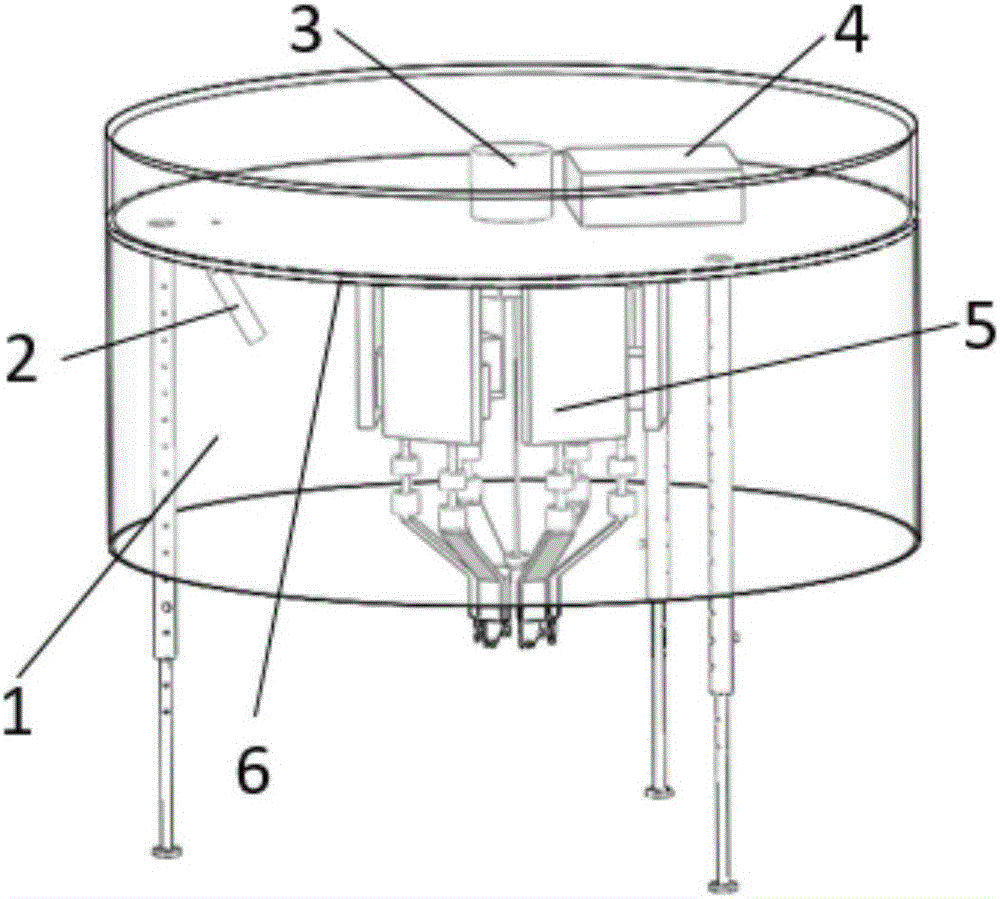

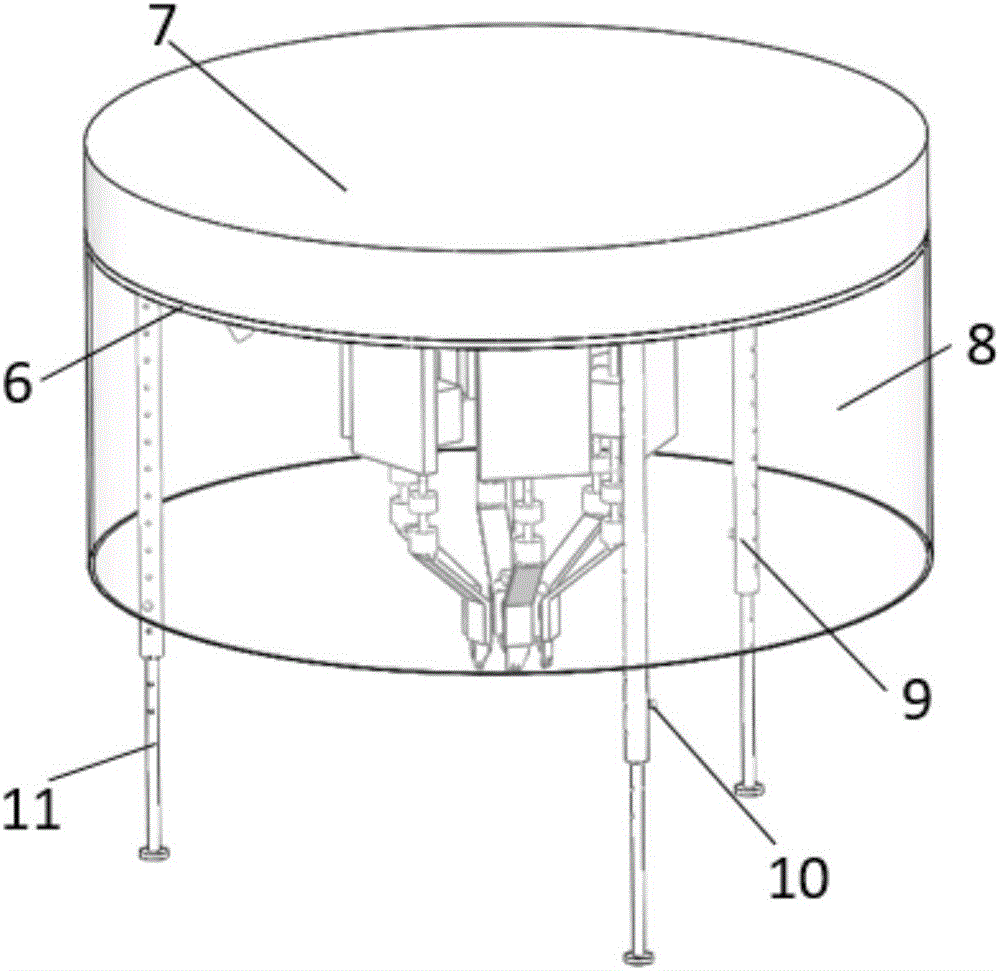

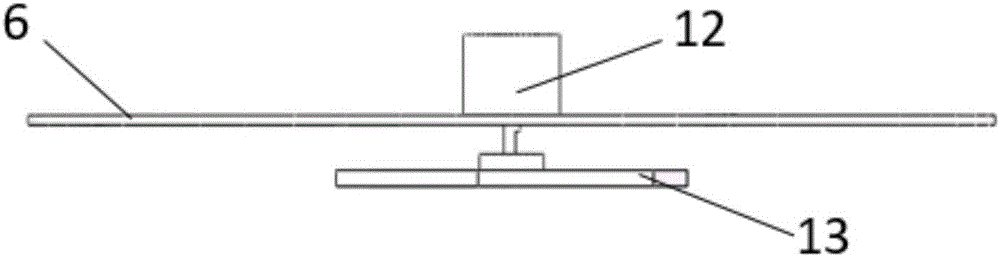

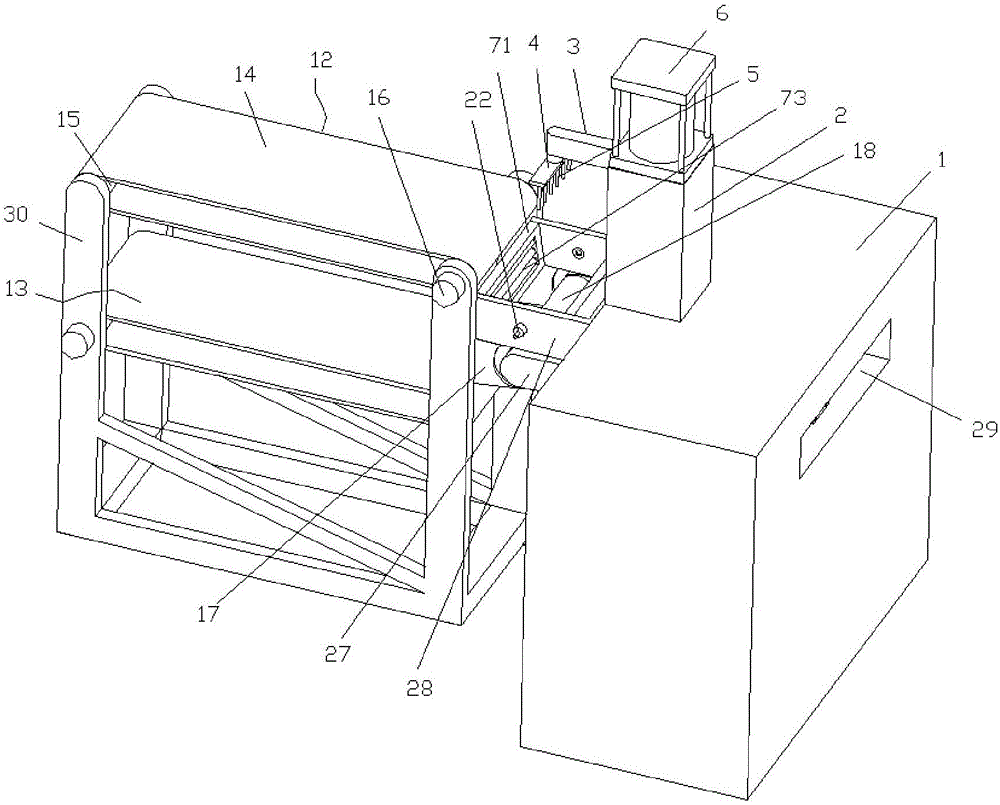

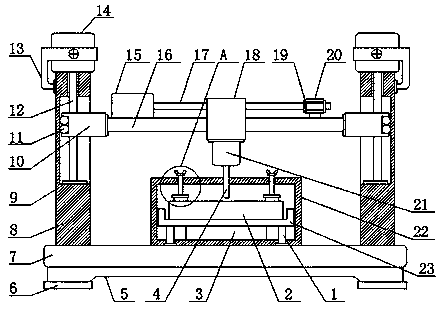

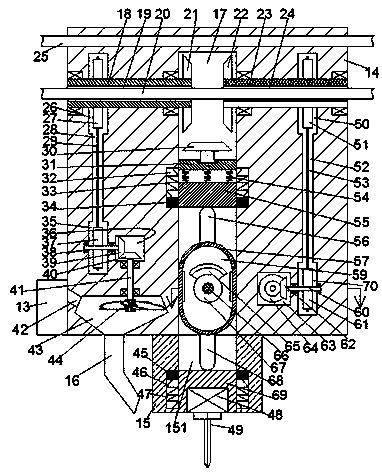

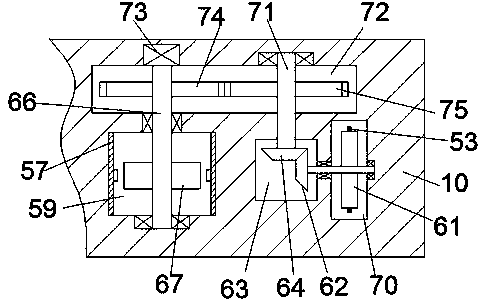

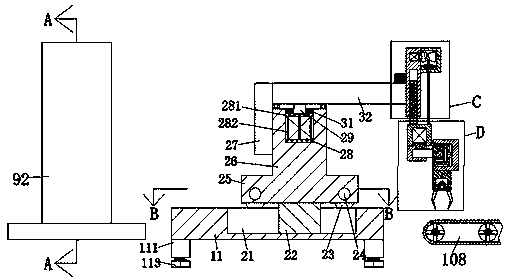

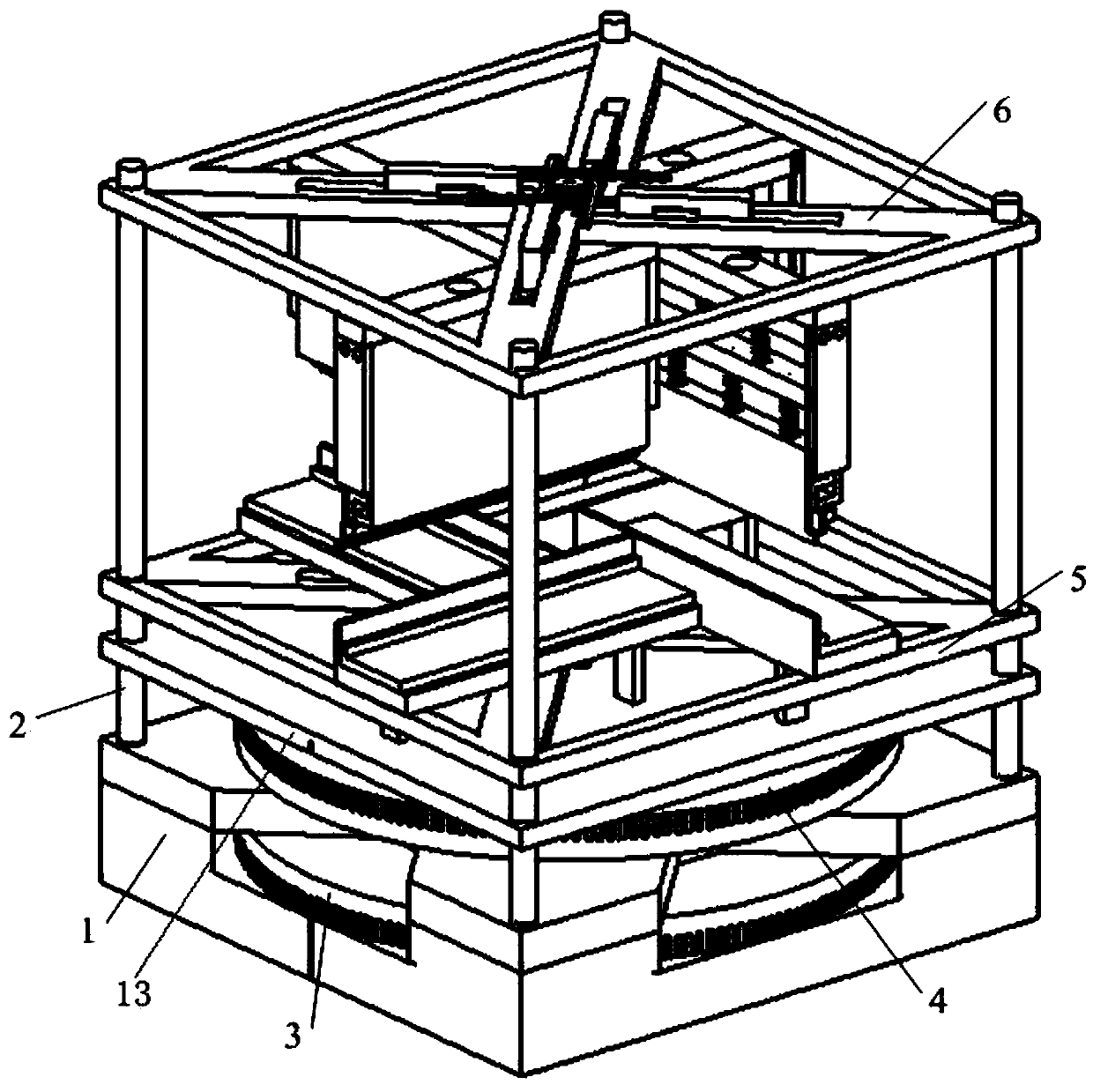

Bearing outer ring automatic punching machine

ActiveCN110842254AGuarantee processing qualityRealize outer wall clampingPositioning apparatusMetal working apparatusPunchingClassical mechanics

The invention relates to a bearing outer ring automatic punching machine. The bearing outer ring automatic punching machine comprises a bearing outer ring supply mechanism. A receiving plate is arranged below an outlet of the bearing outer ring supply mechanism, a bearing outer ring receiving mechanism is arranged at the middle position of the receiving plate, clamping jaws for clamping bearing outer rings are arranged at the position above the portion near the periphery of the receiving plate, the clamping jaws are equiangularly distributed in the circumferential direction and are synchronously close to or away from one another, punching drill bits are further arranged near the clamping jaws, a horizontally-pushing mechanism drives the receiving plate and is close to / away from a cleaningmechanism, bearing outer ring blanks are guided out through the supply mechanism to the receiving plate, the clamping jaws are started to be synchronously close to the center of the receiving plate,the outer walls of the bearing outer ring blanks are clamped, then the punching drill bits are started, the bearing outer ring blanks can be punched, the punched bearing outer ring blanks are pushed out through the horizontally-pushing mechanism, and the upper face of the receiving plate is cleaned through the cleaning mechanism, so that the cleanliness of the surface of a clamping mechanism is guaranteed, and the machining quality of the bearing outer rings is guaranteed.

Owner:泾县谷声信息科技有限公司

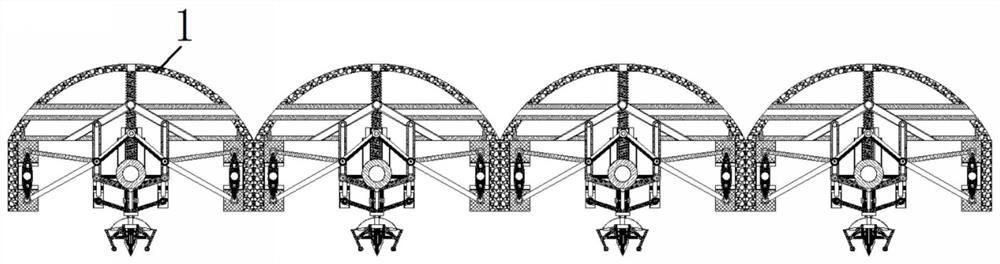

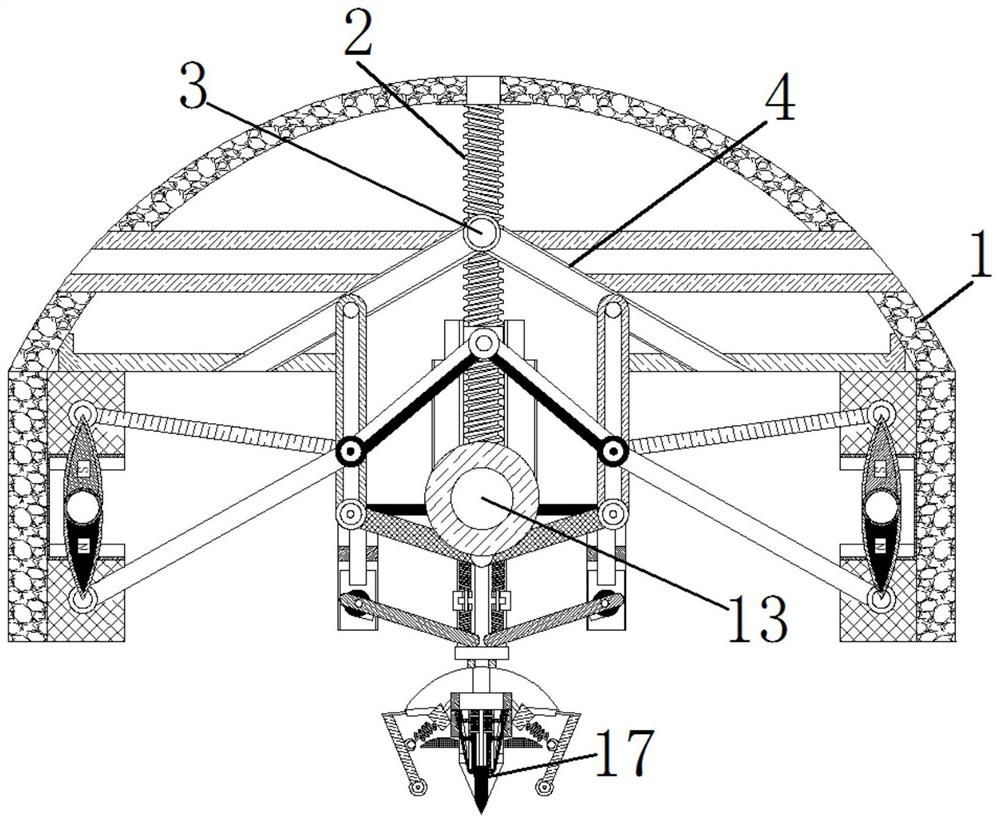

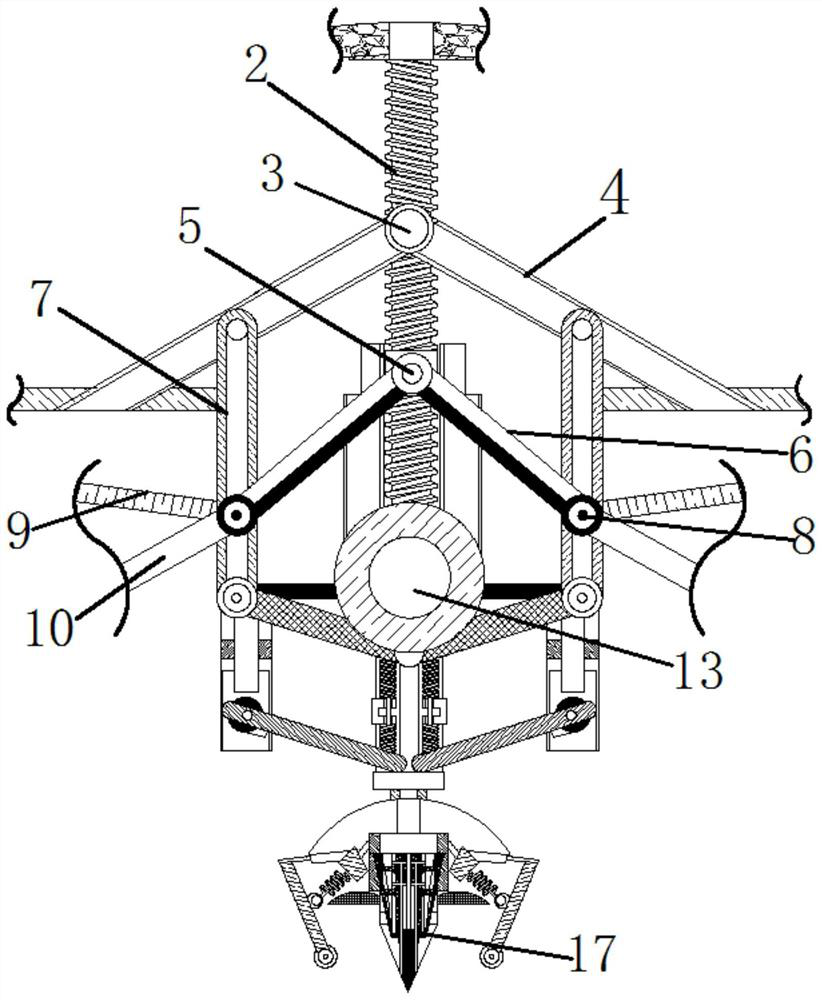

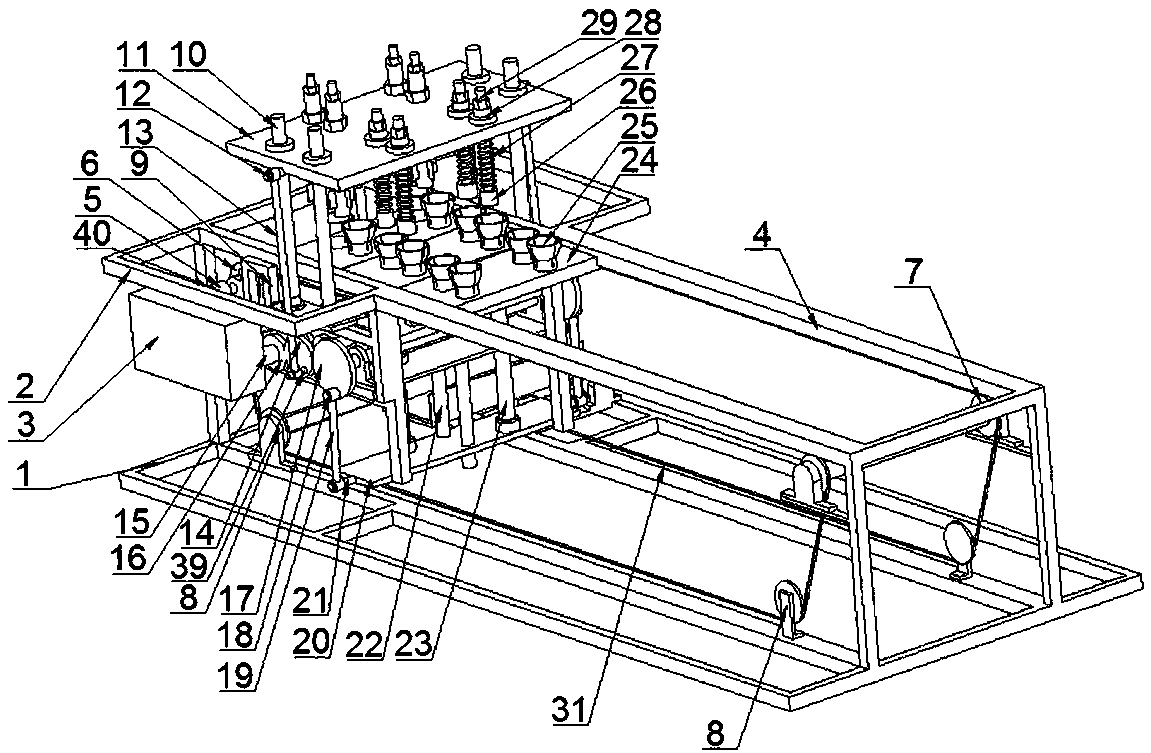

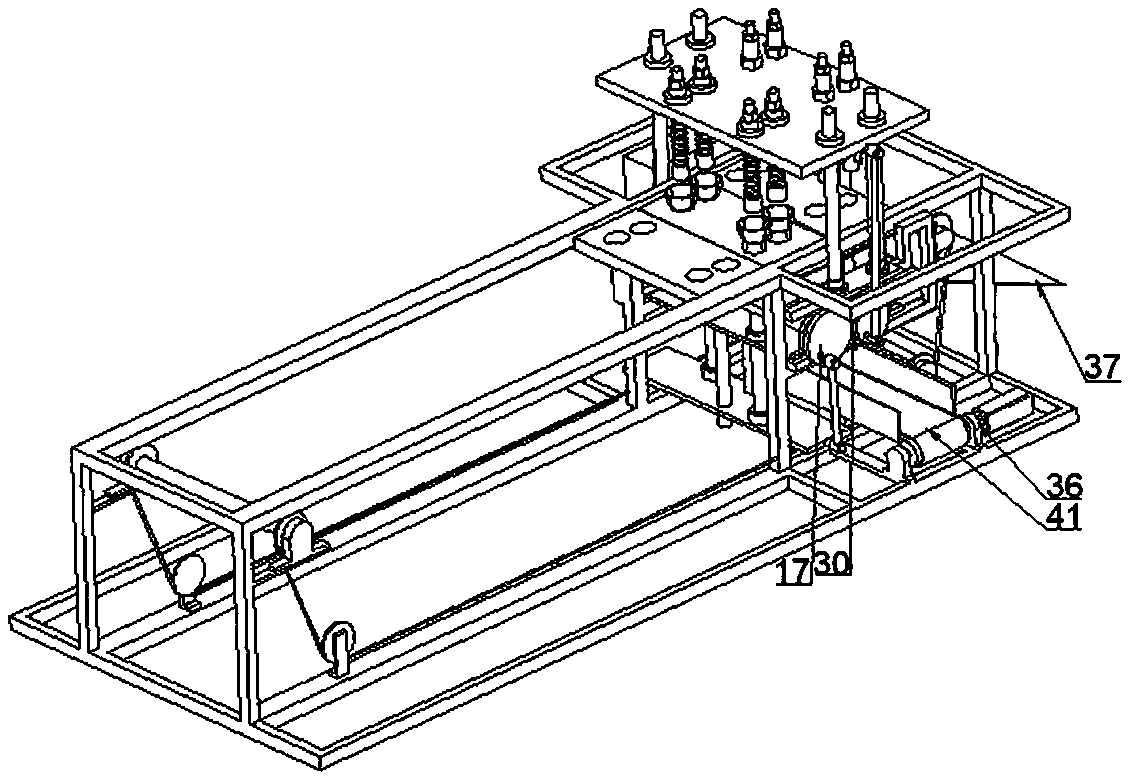

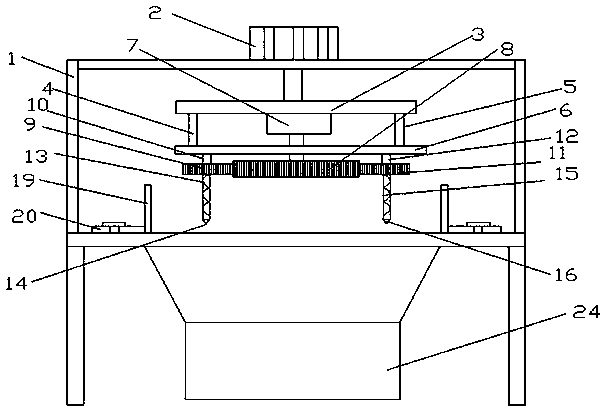

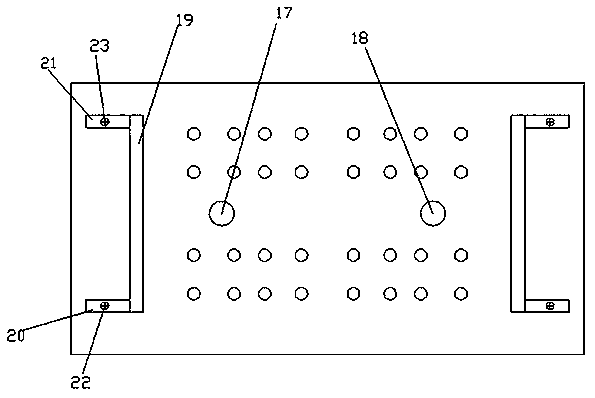

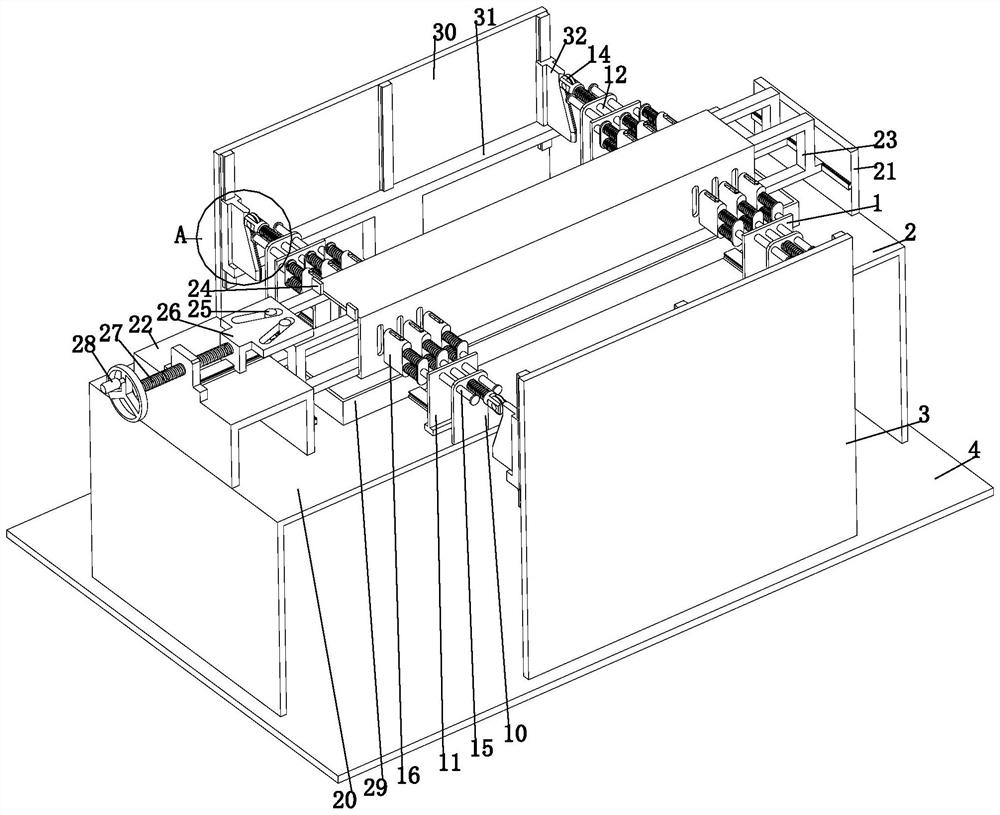

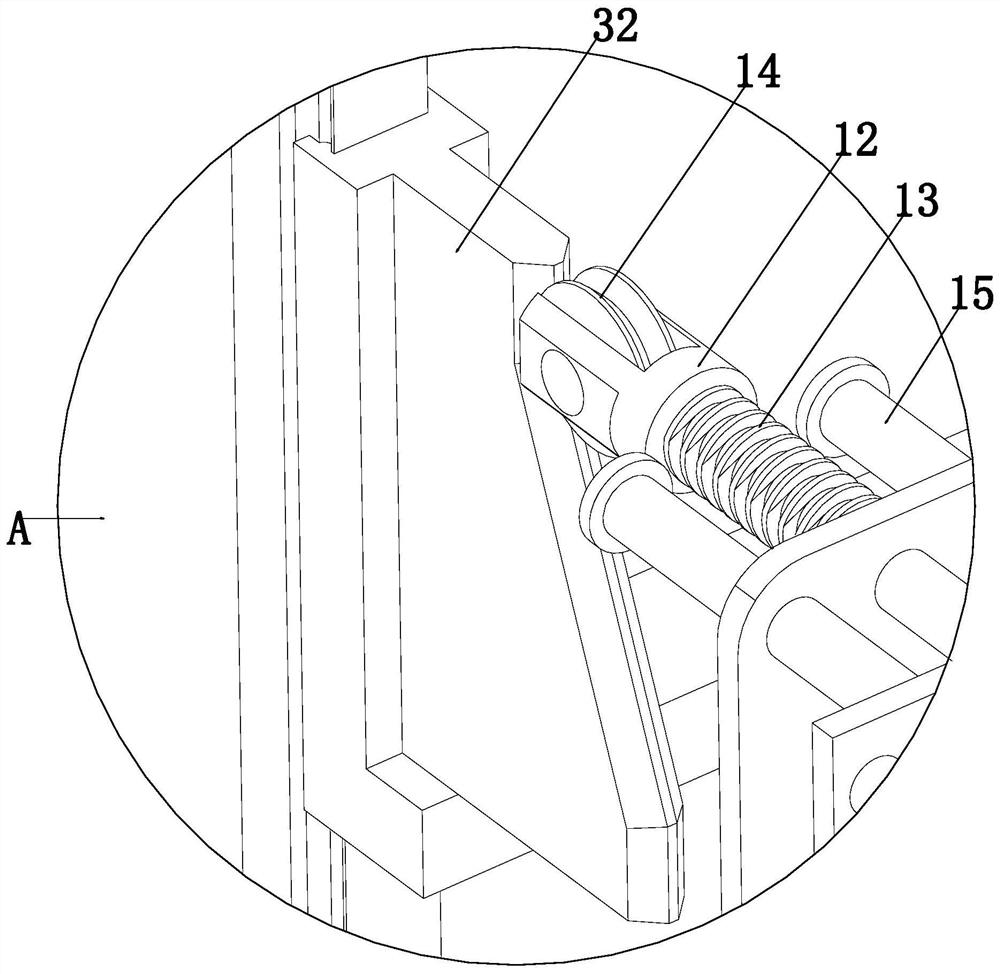

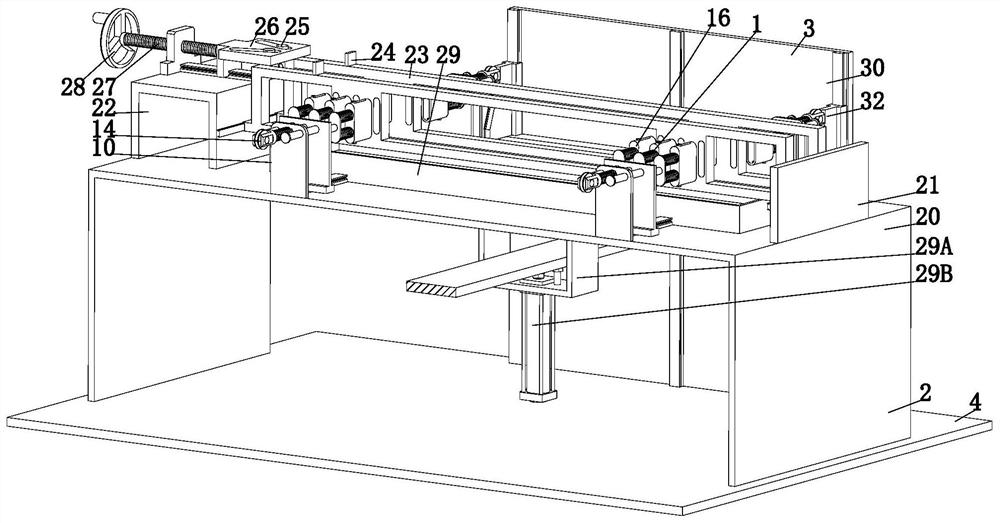

Full-automatic edible fungus culture stick perforating device

InactiveCN107432194ARealize punching operationRealize the operationCultivating equipmentsMushroom cultivationBiotechnologyAssembly line

The invention discloses a full-automatic edible fungus culture stick perforating device and relates to the technical field of fungus and mushroom culture apparatus. The full-automatic edible fungus culture stick perforating device comprises a body, a perforating assembly, a conveying assembly and an auxiliary rolling-over assembly. Edible fungus culture bags are perforated by the perforating assembly, and thus perforating efficiency is improved greatly as compared with that of the conventional manual perforating way. The conveying assembly is used for sending and discharging the culture bags, thereby realizing operation of an assembly line. The auxiliary rolling-over assembly is used for rolling over the culture bags in a perforating base to facilitate perforating on multiple surfaces of the culture bags so as to improve breathability of the culture bags. Besides, printing can be realized during rolling-over, and accordingly, the perforating device is multifunctional.

Owner:WUHU SUNYANG INFORMATION CONSULTATION

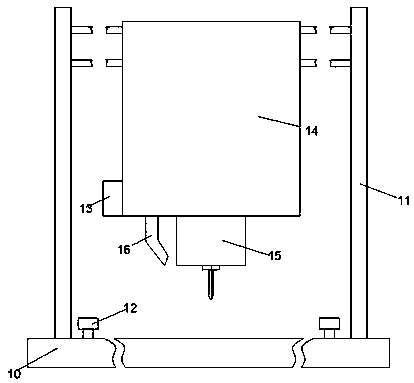

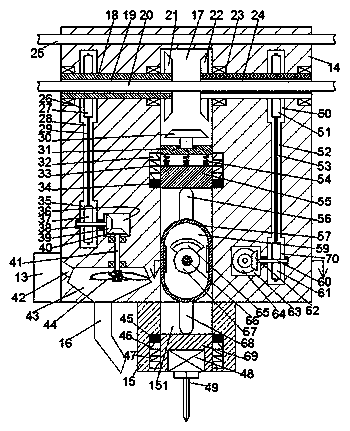

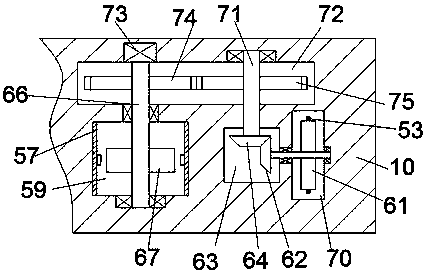

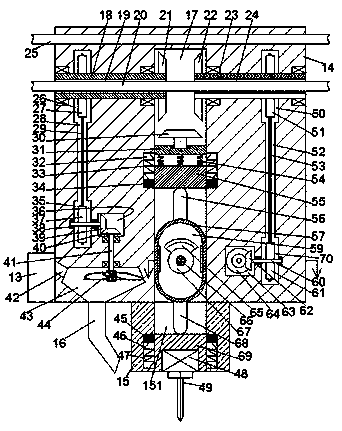

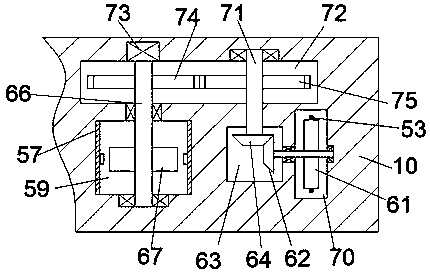

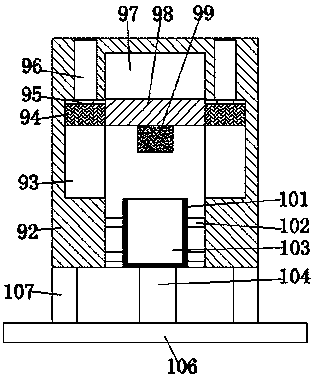

Dried blood spot puncher and punching method thereof

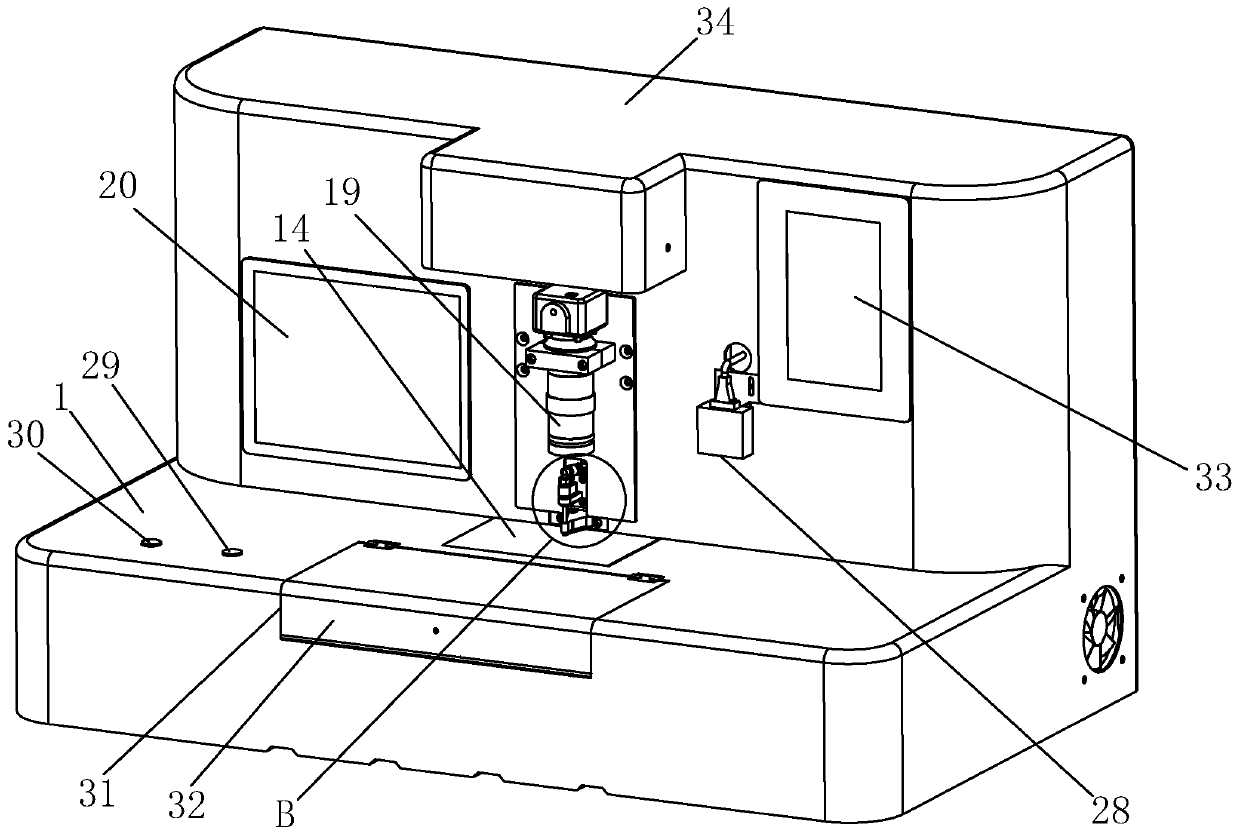

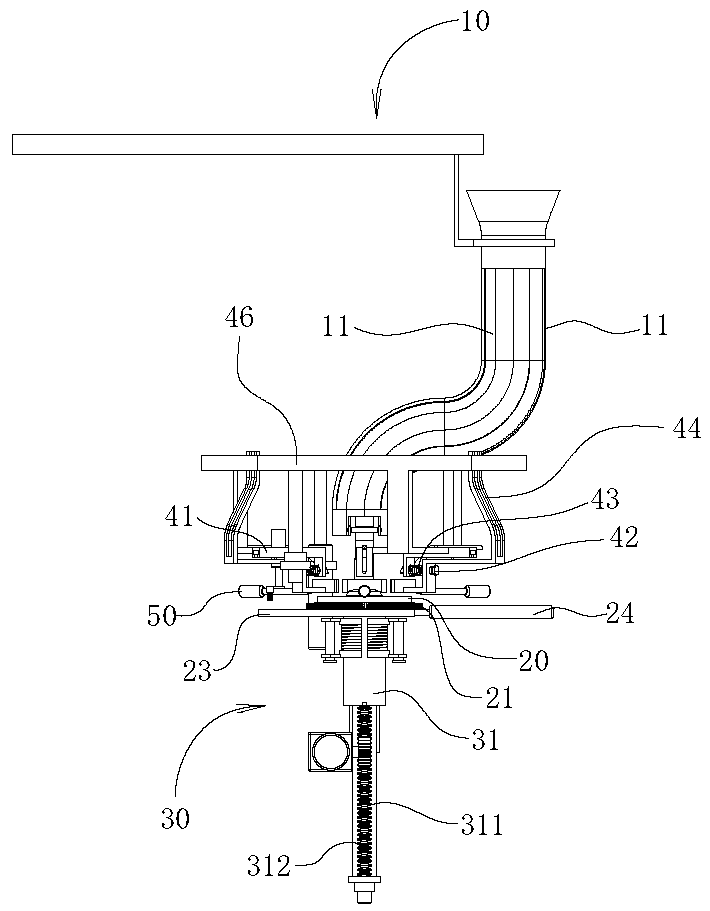

PendingCN111070306ARealize punching operationSuitable for useMetal working apparatusPunchingStructural engineering

The invention relates to the technical field of punchers, in particular to a dried blood spot puncher and a punching method thereof. The dried blood spot puncher comprises a workbench, wherein a driving assembly and a punching assembly are arranged on the workbench; a test tube tray is in driving connection to the driving assembly; the punching assembly comprises a punching punch, a punching upperdie and a punching lower knife which are sequentially distributed from top to bottom; a gap is reserved between the punching upper die and the punching lower knife and is used for placing a blood spot acquisition card; a first punched hole is formed in the punching upper die; a second punched hole is formed in the punching lower knife; a punching needle is fixed on the punching punch and is in sliding fit with the inner wall of the first punched hole; the bottom end of the punching needle is in shearing fit with the second punched hole; and an air hole is formed in the central axis of the punching needle. After the dried blood spot puncher is used for punching, blood sheets can be blown into test tubes, and the blood sheets falling into the test tubes cannot fly out of the test tubes dueto the influence of air flow; and the dried blood spot puncher has the advantage of being quiet during working, is efficient and energy-saving, and is suitable for being used in medical places.

Owner:江苏善久精密工业有限公司

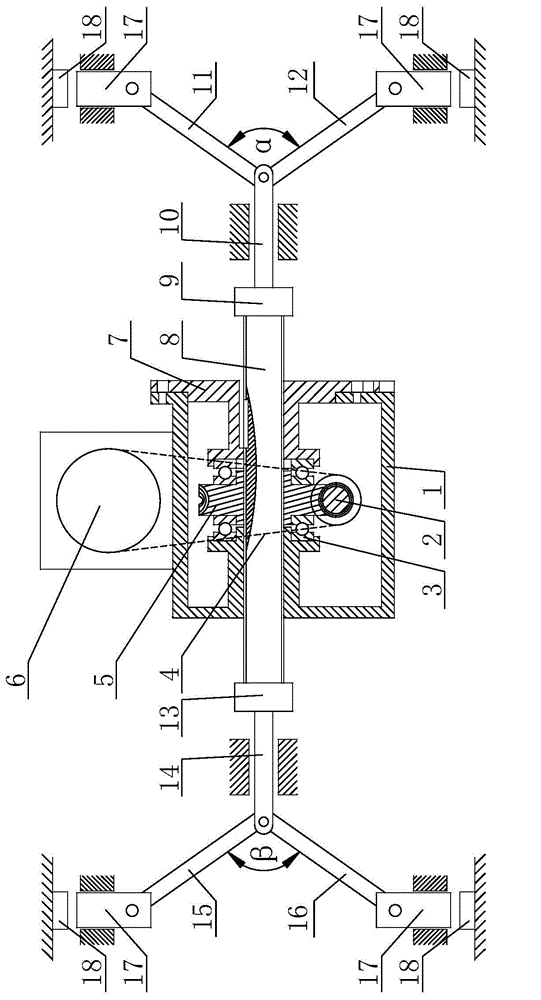

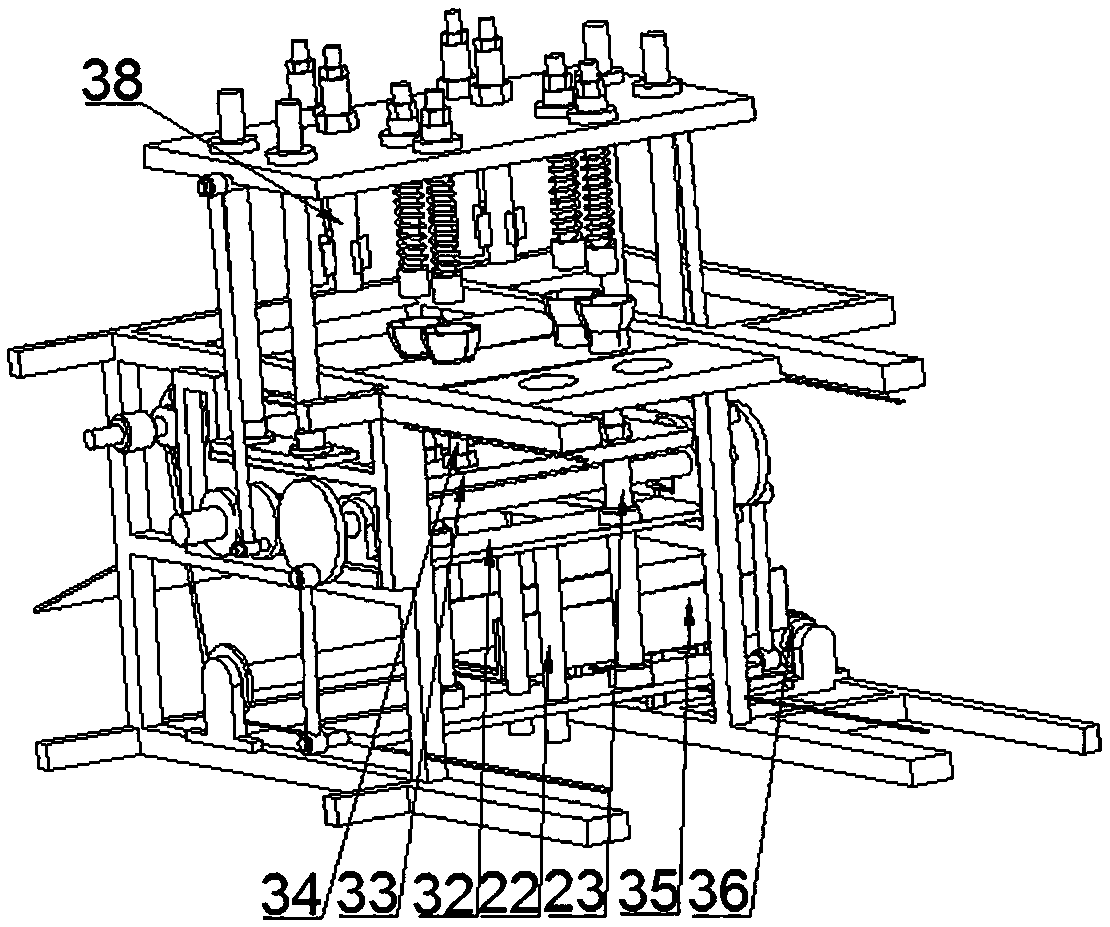

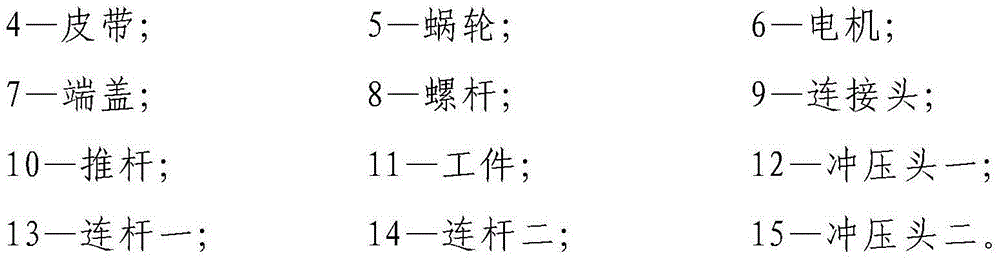

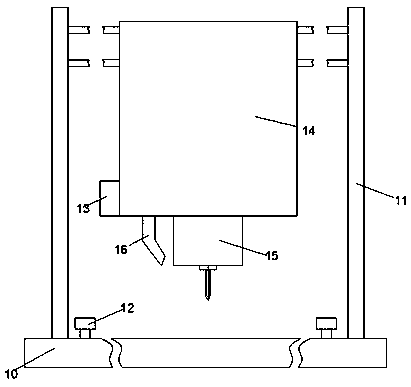

Worm and gear driving type four-station reciprocating stamping device

The invention discloses a worm and gear driving type four-station reciprocating stamping device. The worm and gear driving type four-station reciprocating stamping device comprises a shell, an end cover, a motor, a worm and a worm gear. The worm gear is rotationally installed between the shell and the end cover through a screw. The inner side of the worm gear is provided with a thread which is matched with the screw to constitute a thread pair. The worm is arranged on the shell and located on the outer side of the worm gear. The worm is connected with a power shaft of the motor through a belt. A first pushing rod is fixedly installed at one end of the screw, and the end of the first pushing rod is rotationally connected with a first connecting rod and a second connecting rod. A second pushing rod is fixedly installed at the other end of the screw, and the end of the second pushing rod is rotationally connected with a third connecting rod and a fourth connecting rod. Stamping heads for stamping workpieces are hinged to the ends of the first connecting rod, the second connecting rod, the third connecting rod and the fourth connecting rod correspondingly. The worm and gear driving type four-station reciprocating stamping device has the following characteristics of being reasonable in design, convenient to operate, high in automation degree and production efficiency, capable of saving time and labor and long in service life.

Owner:XIAN ZHONGZHI HUIZE PHOTOELECTRIC TECH

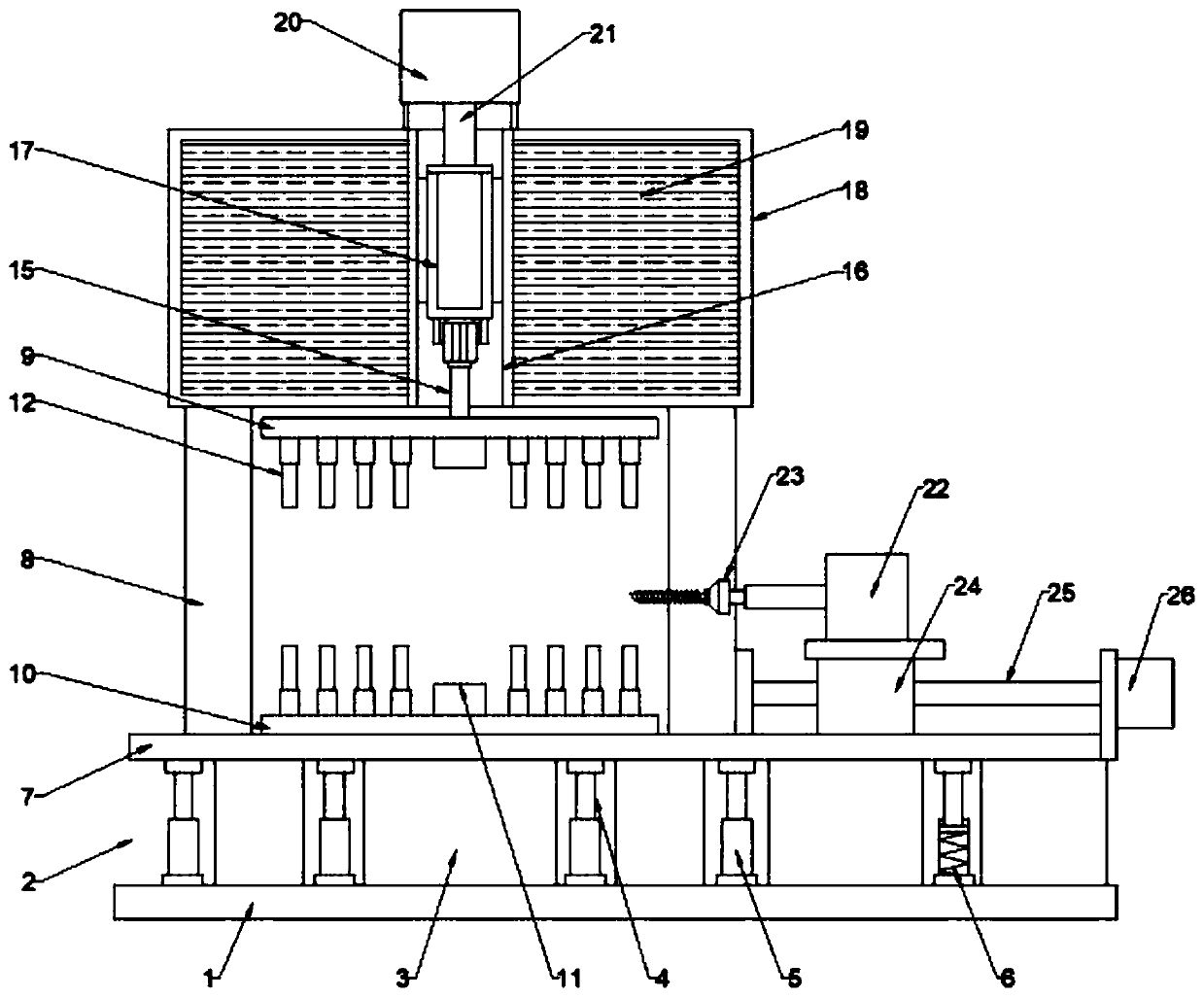

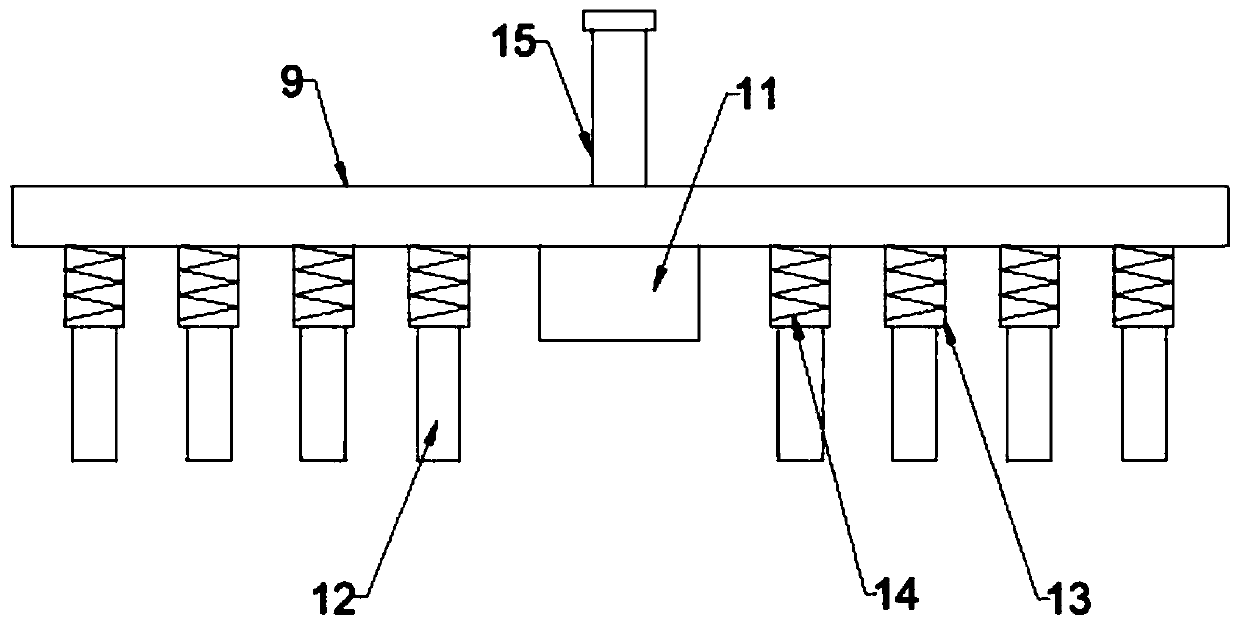

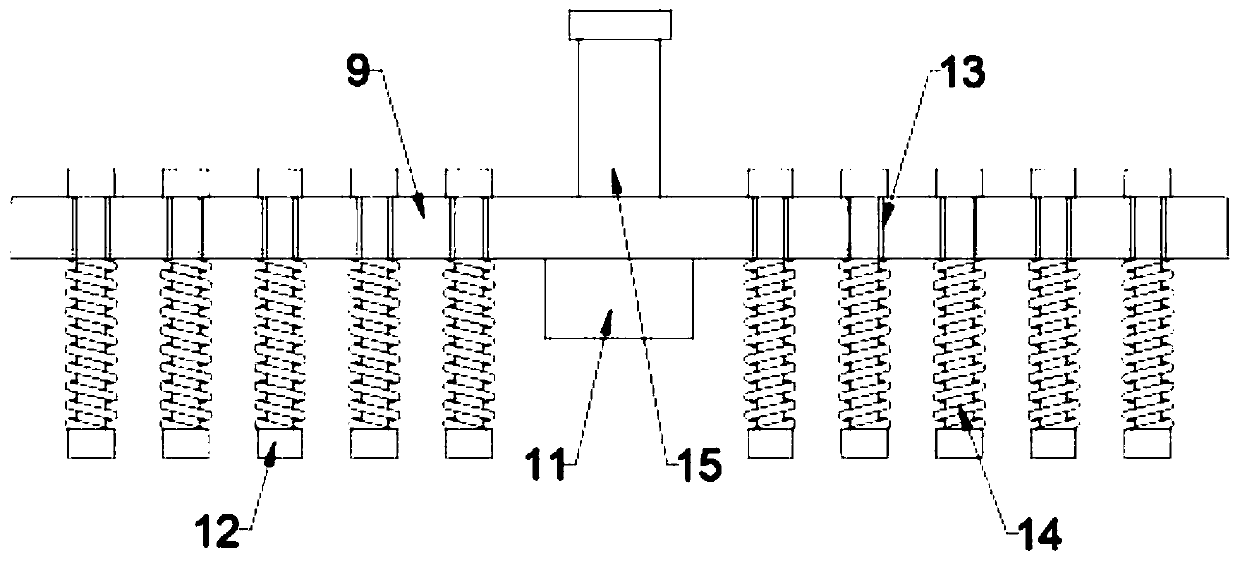

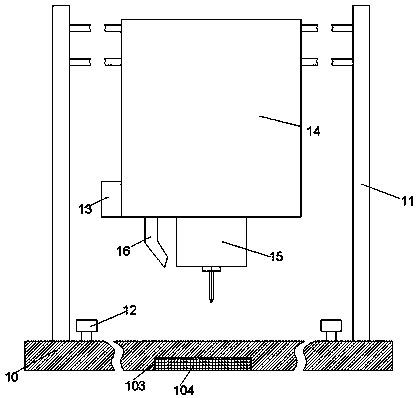

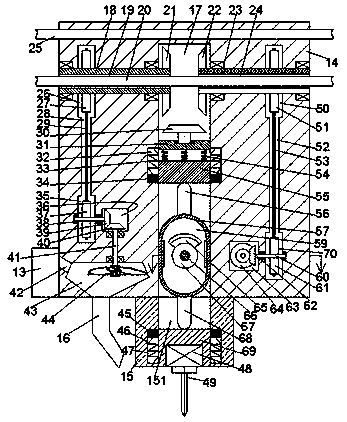

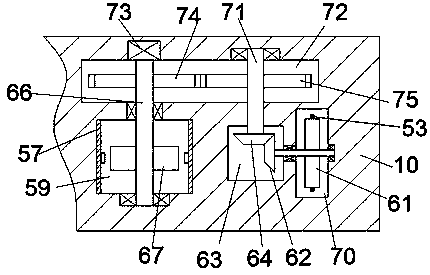

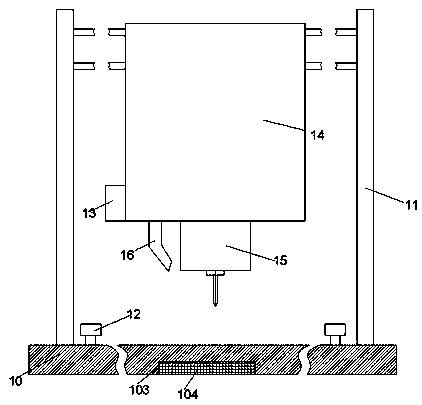

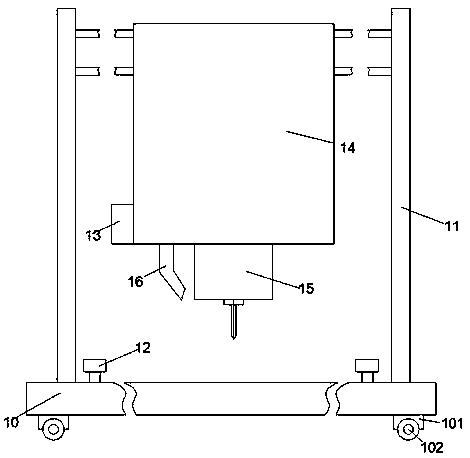

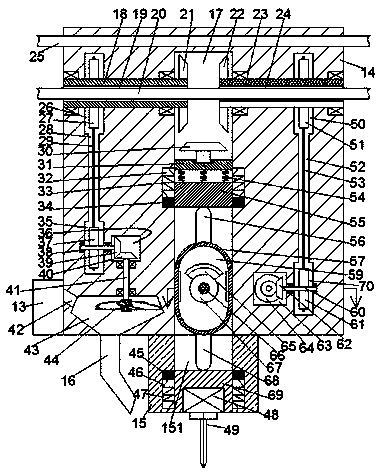

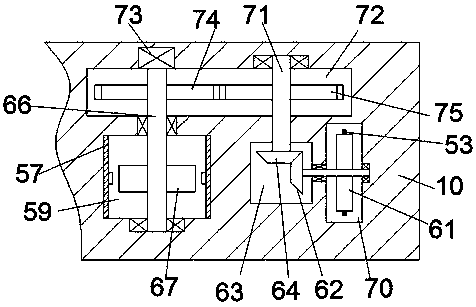

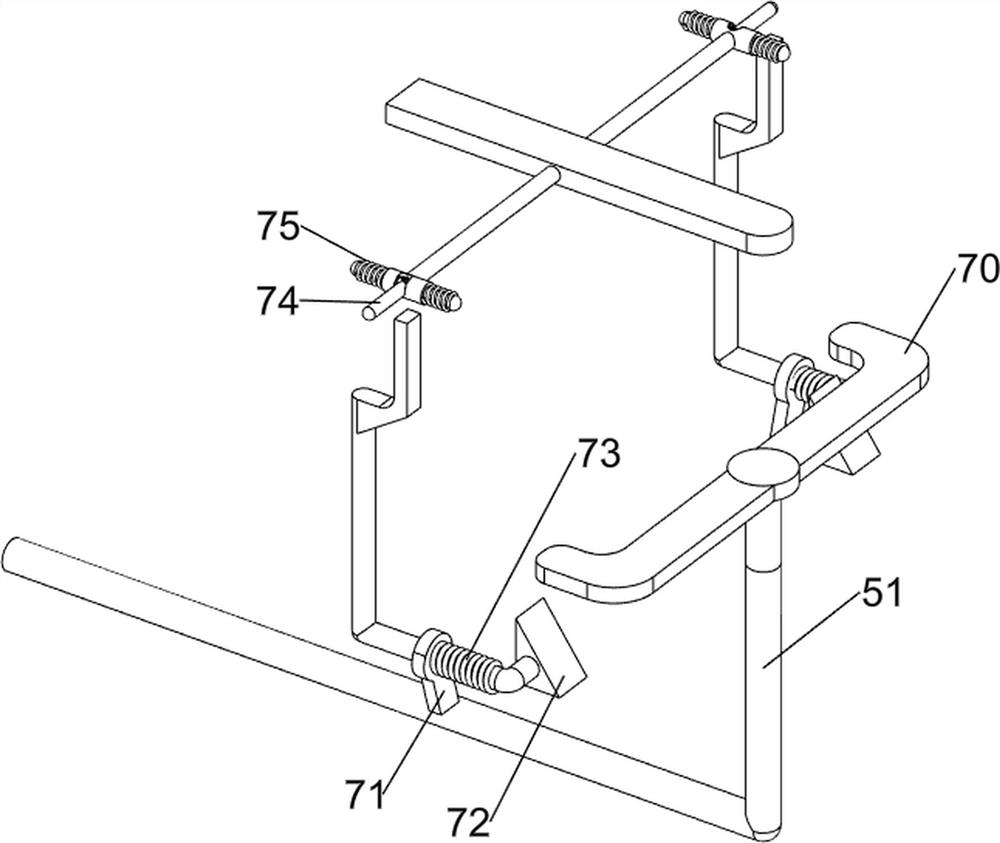

Vertical-positioning perforating device used for machining

InactiveCN111085700ARealize punching operationImprove drilling accuracyPositioning apparatusMaintainance and safety accessoriesPhysicsEngineering

The invention discloses a vertical-positioning perforating device used for machining and belongs to the technical field of mechanical part machining. The problem that clamping positioning is difficultwhen the outline dimension or performance of a workpiece is changed is solved. The technical scheme includes that the perforating device comprises a workbench, a supporting frame, an upper positioning plate, a lower positioning plate, a noise-reduction box and a perforating drill bit; a damping base is mounted at the bottom of the workbench; the supporting frame is mounted on the workbench; the top of the supporting frame is connected with the noise-reduction box; a sliding block is arranged in a vertical sliding groove in a sliding mode; the top of the sliding block is connected with a hydraulic block through a hydraulic rod; the bottom of the sliding block is connected with the upper positioning plate through a jacking pressure rod; the lower positioning plate is arranged under the upper positioning plate; and the hydraulic cylinder drives the sliding block to move, so that the upper positioning plate is driven to move, the upper positioning plate is matched with the lower positioning plate, the workpiece is clamped by means of clamping blocks and clamping rods, the perforating device is applicable to clamping and fixing of workpieces in different shapes, perforating operation on the workpiece is achieved through the perforating drill bit, operation is convenient and fast, and the perforating precision is high.

Owner:WEST ANHUI UNIV

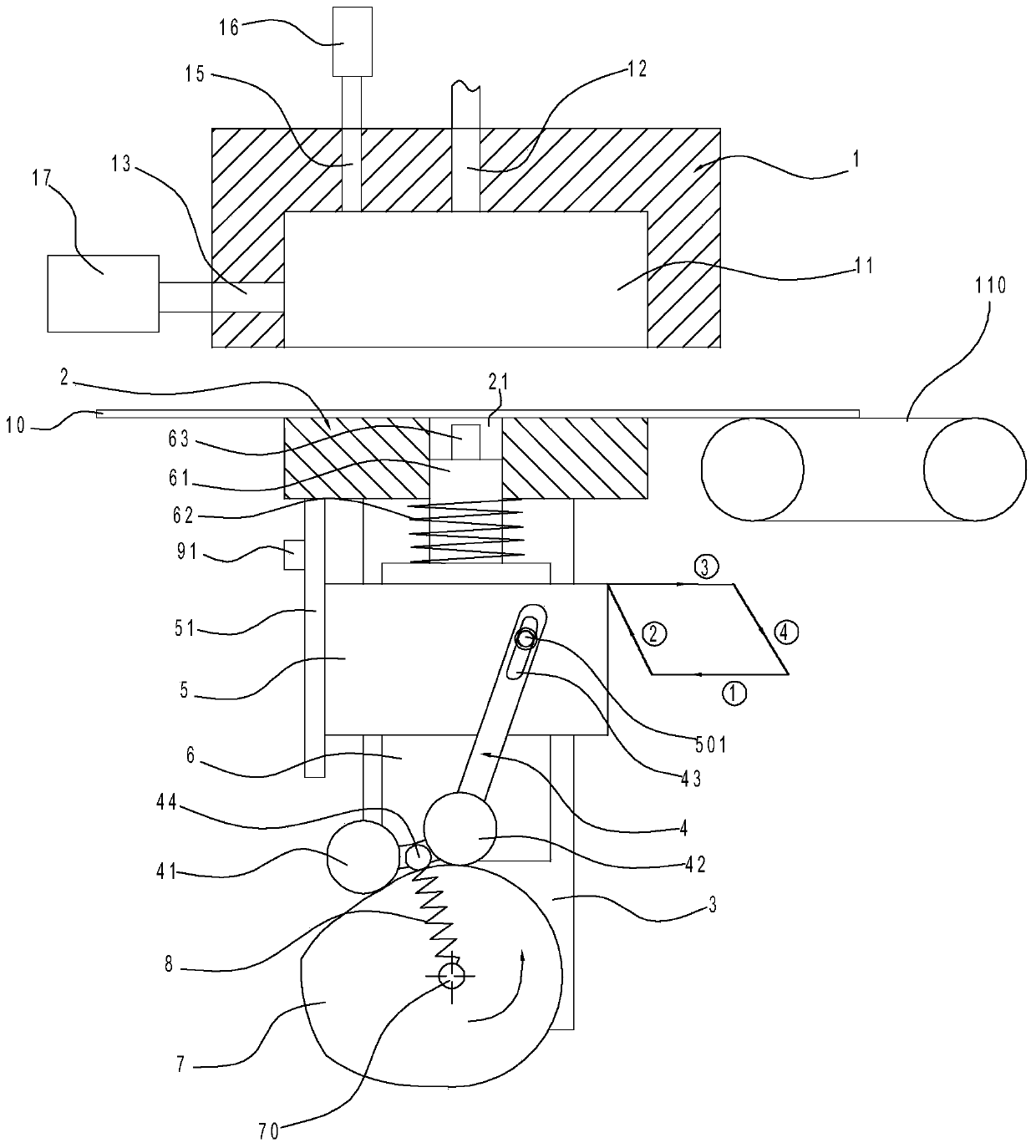

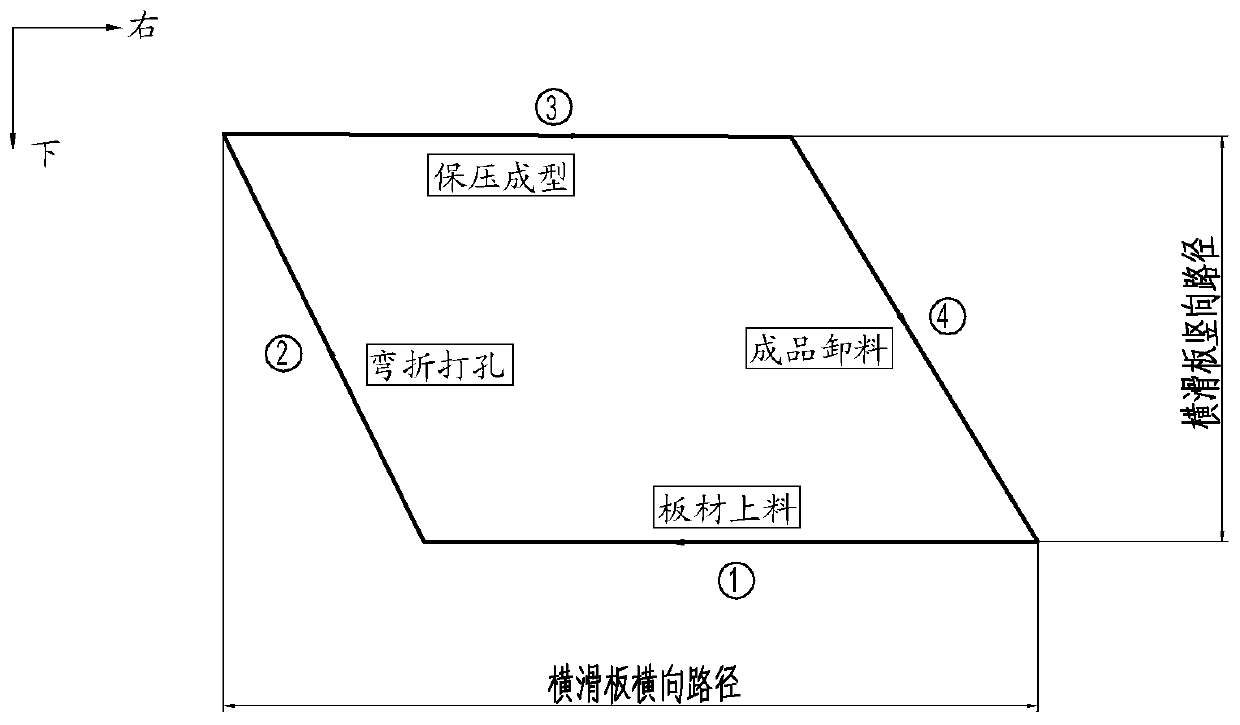

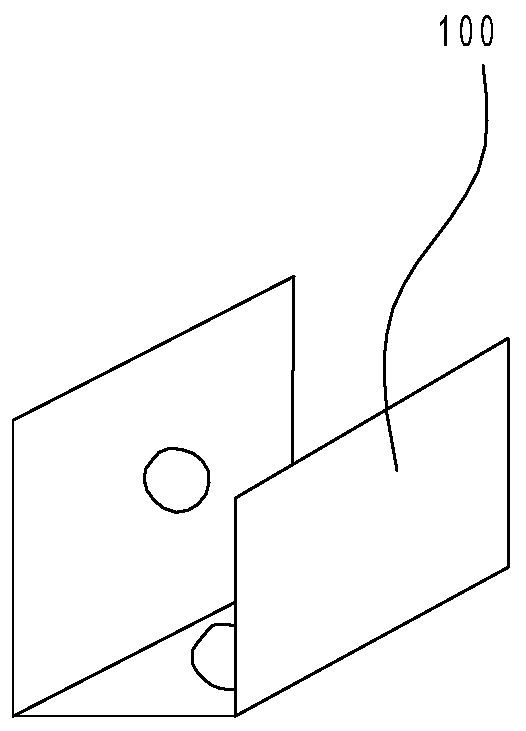

Continuous punch forming method of plates

ActiveCN110883212ARealize one-time bendingRealize punching operationOther manufacturing equipments/toolsStampingSlide plate

The invention discloses a continuous punch forming method of plates. The method is characterized by comprising the following steps of S1, feeding the plates one by one by a conveying table; S2, driving a near-arc section on a cam to make contact with two pin rollers, and feeding the plates to a position over a lower die; S3, bending and punching the plates, allowing a first transition section on the cam to gradually make contact with the two pin rollers, allowing a vertical sliding plate to gradually ascend, bending the plates along with the continuous ascending of the vertical sliding plate,allowing an upper punch to punch a bottom of a U-shaped connecting piece, meanwhile, allowing a transverse sliding plate to move leftwards, and allowing a left punch to punch a side wall of the U-shaped connecting piece; S4, conducting pressure maintaining forming; S5, unloading the U-shaped connecting piece, and S6, repeating steps S2 to S5 to achieve the automatic continuous stamping of the plates. The invention provides the continuous punch forming method of the plates, and the one-time bending and punching operations of the U-shaped connecting piece are achieved.

Owner:TAICANG TAOXIN INFORMATION TECH CO LTD

Financial voucher arrangement binding device

The invention discloses a financial voucher arrangement binding device. The financial voucher arrangement binding device comprises an operation platform; a groove is formed in the operation platform;a placing plate is arranged in the groove; the bottom of the placing plate is connected with a first electric push rod; the operation platform is provided with a financial voucher inlet; a bracket isarranged above the groove; the inner side of the bracket is connected with a second electric push rod; the second electric push rod is connected with an alignment plate; a vertical plate is arranged on the right side of the groove; the vertical plate is connected with one end of a third electric push rod; the other end of the third electric push rod is connected with a push plate; a baffle plate is arranged on the left side of the bracket; a through hole is formed in the top of the bracket; a screw rod is arranged in the through hole, and is connected with a pressing plate; the screw rod and anut are in threaded fit; a vertical rod is arranged on the left side of the operation platform, and is connected with a mounting plate; the mounting plate is connected with a fourth electric push rod; the fourth electric push rod is connected with a first motor; and the first motor is connected with an annular tool bit. The financial voucher arrangement binding device can automatically arrange and punch financial vouchers, effectively saves the time, improves the working efficiency, can effectively reduce the error rate, and guarantees integrity of the financial vouchers.

Owner:符庭彬

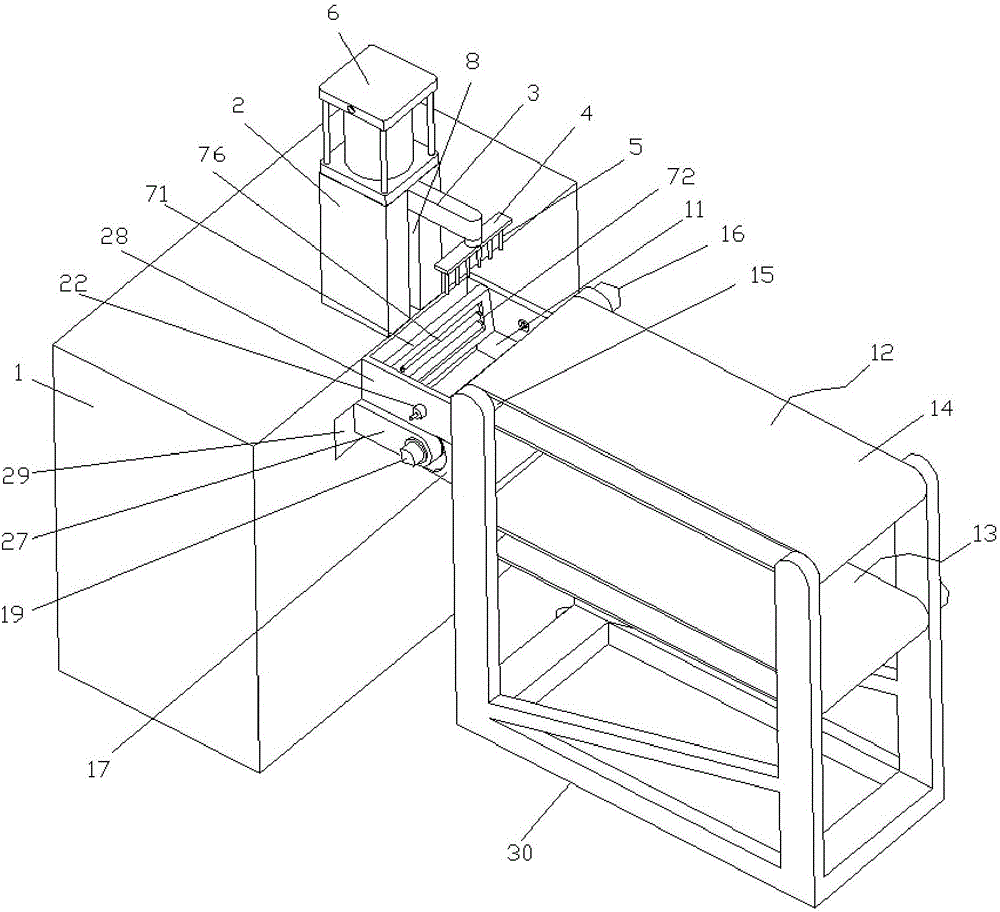

Automatic punching method for bearing outer ring

InactiveCN110842253AGuarantee processing qualityRealize outer wall clampingPositioning apparatusMetal working apparatusPunchingClassical mechanics

The invention relates to an automatic punching method for a bearing outer ring. A cut bearing outer ring blank is guided into a bearing outer ring feeding mechanism; a material receiving plate is arranged below a discharging opening of the bearing outer ring feeding mechanism, and a bearing outer ring material receiving mechanism is started to enable a material receiving head to rise, so that thematerial receiving head rises to be close to the lower portion of the discharging opening of the bearing outer ring feeding mechanism, and the bearing outer ring is guided into the material receivinghead; a clamping jaw is started to realize clamping operation on the bearing outer ring; and a punching drill bit is started to be close to the bearing outer ring, so that the punching operation on the bearing outer ring is achieved; the punching drill bit retreats and resets, and then the upper end of the material receiving head is far away from the material receiving plate; a flat pushing mechanism is started, so that the material receiving plate moves horizontally, the material receiving plate is pushed out horizontally, a brush plate of a cleaning mechanism gets close to the material receiving plate, and the bearing outer ring on the upper surface of the material receiving plate is pushed out; and the material receiving head rises and drives the material receiving plate to rise, so that a cleaning brush ring abuts against the inner side surface of the clamping jaw. According to the automatic punching method, the cleaning of the surface of the clamping mechanism can be effectively guaranteed so as to improve the machining precision of bearings.

Owner:XINCHANG WEIERTE BEARING

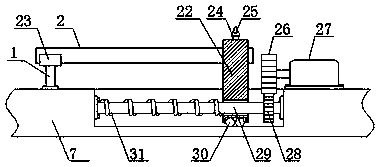

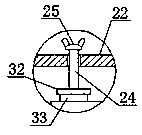

Perforating device

PendingCN108481424ARealize punching operationImprove drilling efficiencyMetal working apparatusDrive shaftReciprocating motion

The embodiment of the invention provides a perforating device. The perforating device comprises a frame, a first movable plate, a second movable plate and a transmission shaft; the frame comprises a frame plate, a driving mechanism is fixedly arranged on the first movable plate, a drill bit assembly is fixedly arranged on the second movable plate, the transmission shaft penetrates the frame plate,the first movable plate and the second movable plate, one end of the transmission shaft is connected with the driving mechanism, and the other end of the transmission shaft is connected with the drill bit assembly; and if the driving mechanism drives the transmission shaft to rotate, the first movable plate and the second movable plate do straight reciprocating motion in the axial direction of the transmission shaft, and the drill bit assembly does rotation motion. By means of the embodiment, the perforating efficiency on an object to be perforated can be improved, and the risk coefficient isreduced.

Owner:SHENZHEN DOZZON INNOVATION TECH CO LTD +1

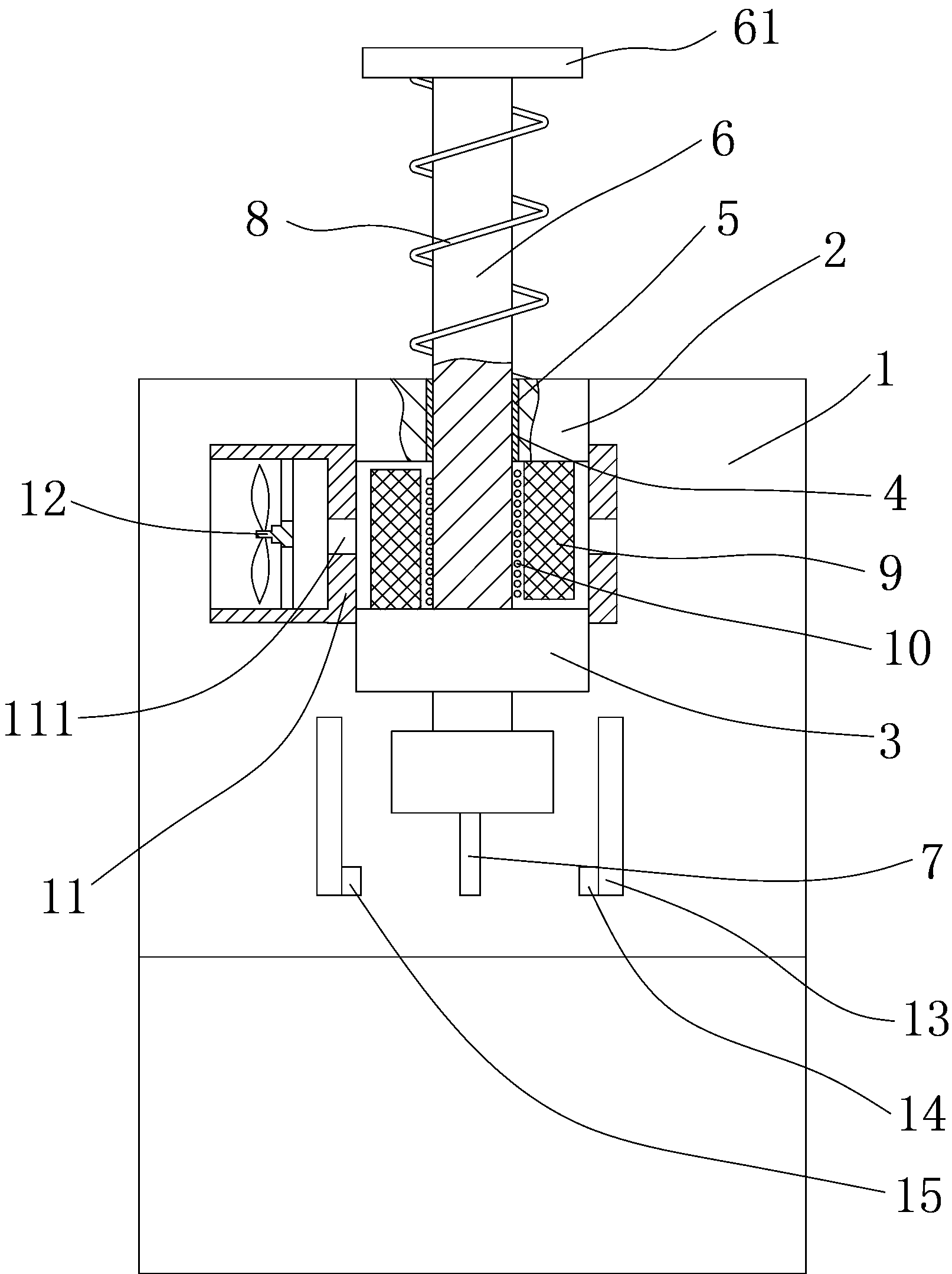

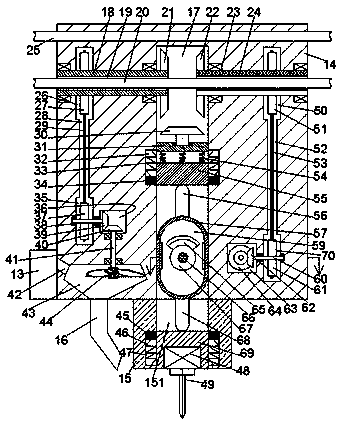

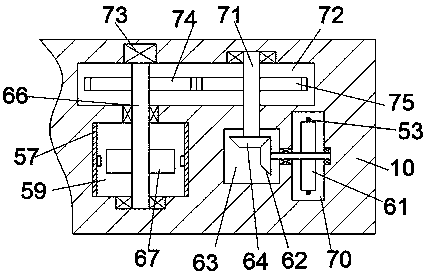

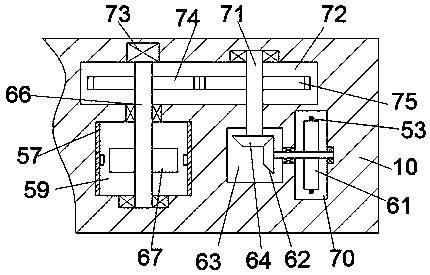

Electromagnetic punching machine with punched hole detection device

InactiveCN104260395ARealize punching operationImprove cooling effectPress ramMetal working apparatusPunch pressEngineering

The invention discloses an electromagnetic punching machine with a punched hole detection device. The electromagnetic punching machine comprises a machine body, an upper fixing block and a lower fixing block are arranged in the machine body, a through hole is formed in each of the upper fixing block and the lower fixing block, a sliding rail is arranged in each through hole, a punching rod is slidably arranged on the sliding rails, the bottom of the punching rod is connected with an upper die, a flange is arranged at the upper end of the punching rod, an elastic member is arranged below the flange, the lower side of the elastic member is abutted against the upper fixing block, a plurality of magnets are wound on the outer side of the punching rod, a lead is wound in the middle of the punching rod, a shell is arranged outside the magnets, ventilation ports are arranged on two sides of the shell, and a fan is arranged on one side of one ventilation port. When punching is needed, the lead is electrified to enable the punching rod to punch downwards to realize punching operation; after punching is completed, power is cut off, and the punching rod is rebounded to an initial position by the elastic member to realize punching operation; heat radiation of the lead is accelerated through air draft of the fan.

Owner:NINGBO GOANWIN MACHINERY TECH

Perforating device suitable for furniture board

InactiveCN108705613ARealize punching operationNo manual operation requiredStationary drilling machinesEngineeringMechanical engineering

The invention discloses a perforating device suitable for a furniture board and relates to the technical field of board processing devices. The perforating device comprises a base. The upper end of the base is symmetrically provided with two supporting columns. The opposite side walls of the two supporting columns are both provided with sliding grooves, and the sliding grooves are internally provided with movable blocks. The upper ends of the supporting columns are provided with first servo motors. The outer side walls of the supporting columns are fixedly connected with installation frames. The outer sides of the first servo motors are sleeved with the corresponding installation frames. The outer side walls of the installation frames are provided with locking screws which are used for fixing the first servo motors into the installation frames. The tail ends of output shafts of the first servo motors are fixedly connected with first rotating rods. The lower ends of the first rotating rods sequentially penetrate the corresponding supporting columns and the corresponding movable blocks and are in rotation connection with the side walls of the inner bottom ends of the sliding grooves.The perforating device suitable for the furniture board is suitable for perforating different positions of the furniture board, the labor force is saved, the working efficiency is improved, when theboard is perforated, fixation is stable, skewing is avoided when the board is perforated, and the perforating quality is improved.

Owner:孝感市凯馨智能家居设计有限公司

Electric punching machine

The invention discloses an electric punching machine comprising a motor. A rotating wheel is connected to the motor. The rotating wheel is in transmission with a flywheel through a belt. The flywheel is connected with a bent axle. A punch is arranged on the bent axle. An upper die is arranged on the punch. The motor comprises a stator and a rotor. The rotor is fixed on a rotating shaft. The rotating shaft is rotationally connected to a support frame. A sliding rail is arranged at the bottom of the stator. The sliding rail is parallel to the rotating shaft. A rocking handle is arranged at the end of the rotating shaft. During normal working of the punching machine, the rotor is electrified to rotate to drive the rotating shaft to rotate, the rotating shaft drives the rotating wheel to rotate, the rotating wheel drives the flywheel to rotate, and the flywheel drives the bent axle to rotate to realize punching. During power failure, the rotating shaft bears large electromagnetic resistance due to direct rotation, so that the stator is slid towards the other side of the sliding rail to a position where the rotor is slid out, and then, the rocking handle is rotated to realize punching.

Owner:北京曼特尔进出口贸易有限公司

Semiautomatic kernel removing and section cutting integrated machine

InactiveCN109732661ARealize punching operationFast and precise punchingFruit stoningMetal working apparatusPunchingDrive shaft

The invention discloses a semiautomatic kernel removing and section cutting integrated machine. According to the semiautomatic kernel removing and section cutting integrated machine, a drive motor isarranged in a drive frame, a horizontal drive shaft and a punching drive shaft, extending backwards, of the drive motor are used for driving an annularly-arranged drive chain so that fruit containingplates on the drive chain can be driven to rotate anticlockwise, and when the fruit containing plates move leftwards, the punching drive shaft and a section cutting eccentric wheel on the front side are in meshing transmission, and the section cutting eccentric wheel drives an upper sliding plate to move up and down. Downward pressing rods on the upper sliding plate are matched with kernel punching tools at the bottoms of the fruit containing plates for punching of the bottoms of fruit kernels, then, section cutting tools are used for punching away the fruit kernels of fruits in the fruit containing plates and cutting the fruits into sections, the punched fruit kernels are discharged to the outer portion through a fruit kernel discharging groove, and finished fruits without the fruit kernels are discharged leftwards through a finished fruit discharging groove to the left side of a frame body. The semiautomatic kernel removing and section cutting integrated machine is novel in structuredesign, and fruit kernel punching work and fruit flesh section cutting can be rapidly and accurately achieved.

Owner:沧州万顷机械设备有限公司

Goods-placing rack

InactiveCN108889972ARealize punching operationImprove drilling efficiencyLarge fixed membersBoring/drilling componentsEngineeringDrill

A shelf including mounting, A left-right symmetrical upright column arrange on that top end face of the frame base and a sliding frame arranged between the left-right two upright column, A mount blockis fixedly arranged at the bottom of the carriage, the mounting block is provided with a sliding groove with an opening downward, A first slider is smoothly installed in the sliding groove, A first motor is arranged in the bottom end face of the first slider, A drill head is dynamically connected to the bottom of the first motor, the sliding frame is provided with a sliding cavity which is communicated with the sliding groove and extends upward, The sliding cavity is smoothly installed with a sliding seat located above the first sliding block, the sliding seat is provided with a first steering cavity penetrating in front and back, a second steering cavity is arranged in the sliding frame at the rear side of the sliding cavity, and a first steering shaft extending in front and back is rotationally fitted between the second steering cavity and the sliding cavity.

Owner:广州泰若智能化科技有限公司

Advanced carton customization machine

InactiveCN108943839ASimple structureHigh degree of automationPaper-makingBox making operationsCartonEngineering

The invention discloses an advanced carton customization machine which comprises a base, supporting frames arranged on the end face of the top of the base in a left-and-right symmetrical manner and asliding support arranged between the left and right supporting frames. An installing block is fixedly arranged on the bottom of the sliding support and is internally provided with a sliding groove with a downward opening, a first sliding block is installed in the sliding groove in a sliding manner, a first motor is arranged in the end face of the bottom of the first sliding block, a hole drillinghead is in power connection with the bottom of the first motor, a sliding cavity communicating with the sliding groove and extending upwards is formed in the sliding support, a sliding base located above the first sliding block is installed in the sliding cavity in a sliding manner, a first rotating cavity penetrating front and back is arranged in the sliding base, a second rotating cavity extending left and right is arranged in the position, on the back side of the sliding cavity, of the sliding support, and a first rotating shaft extending front and back is installed between the second rotating cavity and the sliding cavity in a rotary fit manner.

Owner:GUANGZHOU LISHENG TRADING CO LTD

High-end aluminum processing technical equipment

InactiveCN109226810ASimple structureHigh degree of automationBoring/drilling componentsMaintainance and safety accessoriesDrillAluminium

The invention discloses high-end aluminum processing technical equipment. The equipment comprises a base body, support pillars symmetrically arranged on the top end face of the base body and a slidingshelf arranged between the left and right support pillars, a mounting block is fixedly arranged at the bottom of the sliding shelf, a sliding groove with a downward groove opening is formed in the mounting block, and a first sliding block is slidably mounted in the sliding groove; a first motor is arranged at the bottom end face of the first sliding block, the bottom of the first motor is in power connection with a drill, and a sliding cavity which is communicated with the sliding groove and extends upwards is formed in the sliding shelf; a sliding base which is located above the first sliding block is slidably mounted in the sliding cavity, a first rotary groove which is through front and back is formed in the sliding base, a second rotary groove extends left and right in the portion, atthe rear side of the sliding cavity, in the sliding shelf, and a first rotary pin shaft which extends front and back is rotatably and cooperatively mounted between the second rotary groove and the sliding cavity.

Owner:广州轻舟科技有限公司

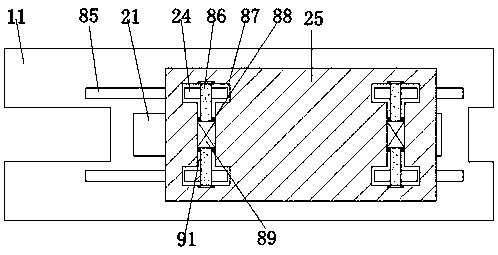

Drilling device of aluminum profile

PendingCN108941663ARealize punching operationRealize automatic symmetrical punching operationPositioning apparatusBoring/drilling componentsPiston rodPetroleum engineering

The invention provides a drilling device of an aluminum profile. The drilling device comprises a drilling frame, an air cylinder is arranged on the upper side of a top plate of the drilling frame, a piston rod of the air cylinder penetrates through a first through hole in the top plate of the drilling frame, and is connected with the upper surface of a first movable plate; the left end and the right end of the lower surface of the first movable plate are connected with the upper end of a first left support rod and the upper end of a first right support rod respectively, and the lower end of the first left support rod and the lower end of the first right support rod are both connected with the upper surface of a second movable plate. The drilling device of the aluminum profile has the beneficial effects that the aluminum profile to be machined is placed between a left positioning piece and a right positioning piece, then the cylinder is started, a left puncture nail piece and a right puncture nail piece are close to the aluminum profile plate, and then the motor is started, and namely the drilling operation of the aluminum profile can be realized; and the automatic symmetric drilling operation can be realized, and the working efficiency is improved.

Owner:湖州亨达铝业有限公司

Efficient carton customization machine

InactiveCN109177304ARealize punching operationImprove drilling efficiencyPaper-makingBox making operationsCartonEngineering

The invention discloses an efficient carton customization machine. The efficient carton customization machine comprises a base seat, supporting racks arranged to the top end face of the base seat in abilateral symmetry manner and a sliding rack arranged between the left supporting rack and the right supporting rack, wherein the bottom of the sliding rack is fixedly provided with an installation block, the installation block is internally provided with a sliding slot with the opening being downward, the sliding slot is internally and slidably provided with a first sliding block, the bottom endface of the first sliding block is internally provided with a first motor, the bottom of the first motor is in power connection with a drilling head, the sliding rack is internally provided with a sliding cavity which communicates with the sliding slot and extends upwards, the sliding cavity is internally and slidably provided with a sliding seat located above the first sliding block, the slidingseat is internally provided with a first rotating cavity running through front and back, the part, on the rear side of the sliding cavity, of the sliding rack is internally provided with a second rotating cavity in a left and right extending manner, and a first rotating shaft extending front and back is installed between the second rotating cavity and the sliding cavity in a rotating fit manner.

Owner:GUANGZHOU LISHENG TRADING CO LTD

Novel paper box customization machine

InactiveCN108839381ASimple structureHigh degree of automationPaper-makingBox making operationsCartonEngineering

The invention discloses a novel paper box customization machine. The novel paper box customization machine comprises a base, supporting frames arranged on the top end face of the base in a bilateral symmetry manner, and a sliding frame arranged between the left supporting frame and the right supporting frame. A mounting block is fixedly arranged at the bottom of the sliding frame, a sliding groovewith a downward opening is formed in the mounting block, a first sliding block is slidingly mounted in the sliding groove, a first motor is arranged in the bottom end face of the first sliding block,the bottom of the first motor is in power connection with a drilling head, a sliding cavity which communicates with the sliding groove and stretches upwards is formed in the sliding frame, a slidingseat located above the first sliding block is slidingly mounted in the sliding cavity, a first rotary cavity which is through front and back is formed in the sliding seat, a second rotary cavity is formed in the portion, on the rear side of the sliding cavity, in the sliding frame in a left-and-right stretching manner, and a first rotary shaft stretching front and back is mounted between the second rotary cavity and the sliding cavity in a rotating fit manner.

Owner:GUANGZHOU LISHENG TRADING CO LTD

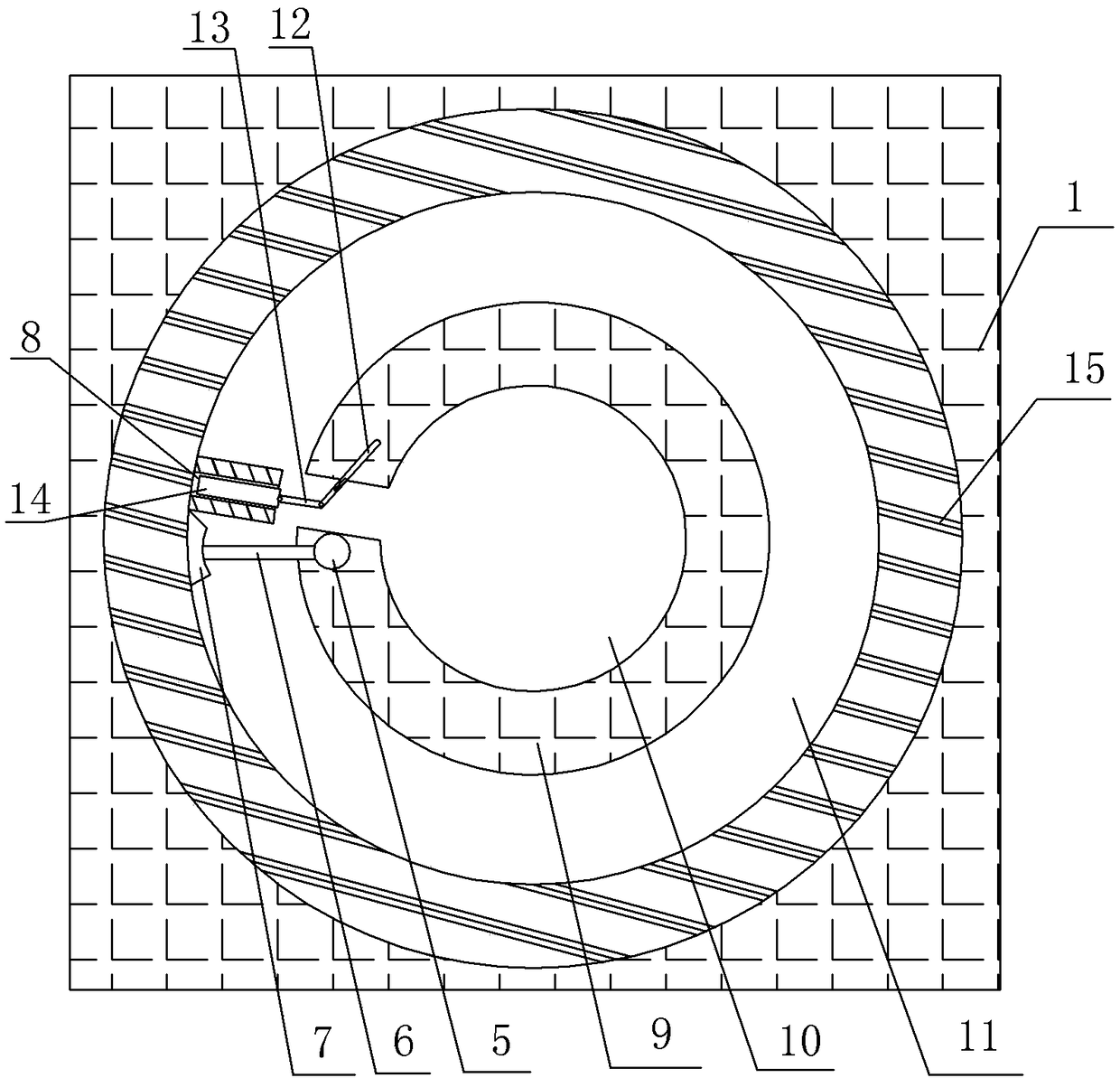

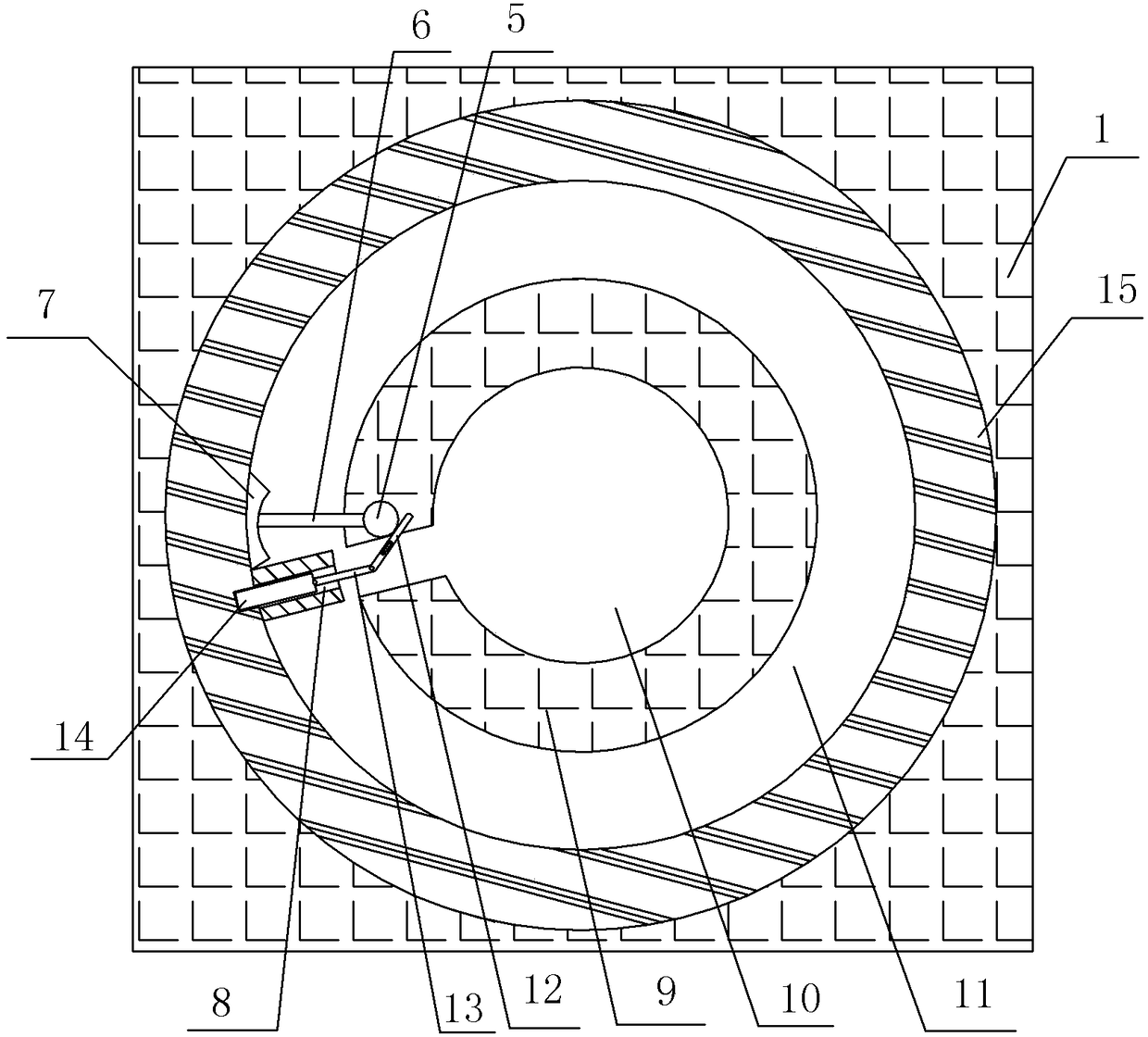

Production process for oil seal

ActiveCN108115470ARealize punching operationIncrease frictionMetal working apparatusGrinding work supportsRubber ringPetroleum engineering

The invention relates to the field of oil seals, in particular to a production process of an oil seal. The production process of the oil seal comprises the following steps: step 1, preparing a grinding agent for subsequent use; step 2, preparing grinding and piercing equipment; step 3, coating the inner wall and the outer wall of a rubber ring with the grinding agent; step 4, grinding; and step 5,piercing. By the technical scheme, the inner wall and the outer wall of the rubber ring can be ground, and meanwhile, the inner wall of the rubber ring is pierced.

Owner:邢台昌华橡胶密封件有限公司

Novel forging equipment

InactiveCN108405776ASimple structureEasy to operateForging/hammering/pressing machinesForging press detailsPunchingForging

The invention discloses novel forging equipment. The novel forging equipment comprises a machine base, a conveying device arranged on the machine base, and a punching device arranged on the left sideof the conveying device. The conveying device comprises a first sliding connecting block connected to the upper end face of the machine base in a sliding connecting fit manner, and a sliding connecting device is arranged between the first sliding connecting block and the machine base. A first fixing table is fixedly arranged at the middle position of the upper side end face of the first sliding connecting block. A first electric rotation machine is fixedly arranged in the upper side end face of the first fixing table. The upper side of the first fixing table is provided with an adapter arm, the adapter arm is connected with the first fixing table through a bearing in a rotation fit manner, a first adapter shaft is connected between the lower side end face of the adapter arm and the first electric rotation machine in a matched manner, and a first tight closing ring is arranged between the first adapter shaft and the upper side end face of the first fixing table.

Owner:刘永达

Pipe fitting drilling device

InactiveCN108788876ASimple structureHigh degree of automationFeeding apparatusBoring/drilling componentsDrill holeDrill bit

The invention discloses a pipe fitting drilling device. The pipe fitting drilling device comprise a machine base, supports which are laterally symmetrically arranged on the top end surface of the machine base and a sliding rack which is arranged between the two supports; an assembly block is fixedly arranged on the bottom part of the sliding rack; a sliding groove of which the end opening is downward is formed in the assembly block; a first sliding block is slidably arranged in the sliding groove; a first driver is arranged in the bottom end surface of the first sliding block; the bottom partof the first driver is in power connection with a drill bit; a sliding cavity which communicates with the sliding groove and extends upwards is formed in the sliding rack; a sliding base which is located above the first sliding block is slidably arranged in the sliding cavity; a first rotation cavity which is front-back through is formed in the sliding base; a second rotation cavity which extendsleftwards and rightwards is formed in a part, which is on the rear side of the sliding cavity, of the sliding rack; and a first rotary shaft which extends frontwards and backwards is arranged betweenthe second rotation cavity and the sliding cavity.

Owner:广州吉和电子商务有限公司

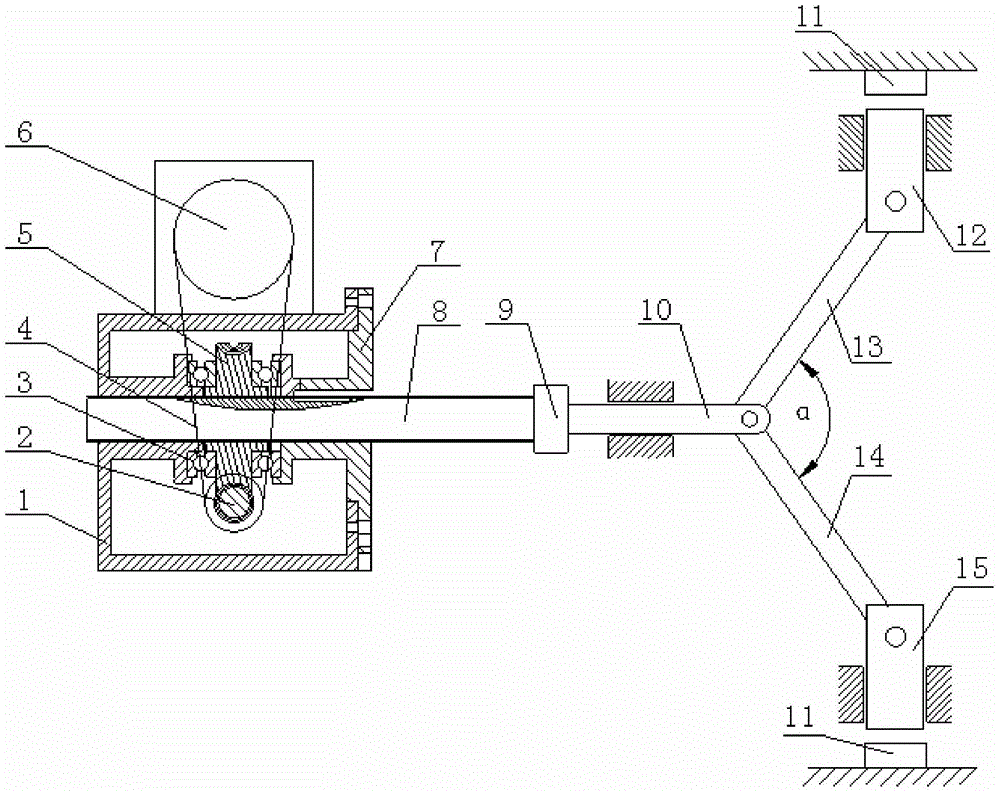

Worm wheel-worm driving dual-station stamping device

The invention discloses a worm wheel-worm driving dual-station stamping device. The device comprises a worm, a worm wheel, a casing and an end cover. The worm wheel is arranged between the casing and the end cover in a rotatable mode, and the worm is arranged on the outside of the worm wheel in the casing and is connected with the output end of the motor through a belt. A screw is arranged in the middle of the worm wheel, threads matched with the screw to form a thread pair are arranged inside the worm wheel, one end of the screw is in rotatable connection with one end of a push rod, the other end of the push rod is in rotatable connection with one end of a first connection rod and one end of a second connection rod, the other end of the first connection rod is in rotatable connection with a first stamping head, and the other end of the second connection rod is in rotatable connection with a second stamping head. The device has the advantages of being reasonable in design, convenient to operate, high in automatic degree, high in production efficiency, time saving and effort saving, long in service life, low in production cost and convenient to popularize and use.

Owner:XIAN ZHONGZHI HUIZE PHOTOELECTRIC TECH

Environment-friendly and ultra-wear-resistant water-based color plastic track material

InactiveCN108994952ASimple structureHigh degree of automationMetal working apparatusWater basedEnvironmental resistance

Owner:FOSHAN CHENFAN ENVIRONMENTAL TECH CO LTD

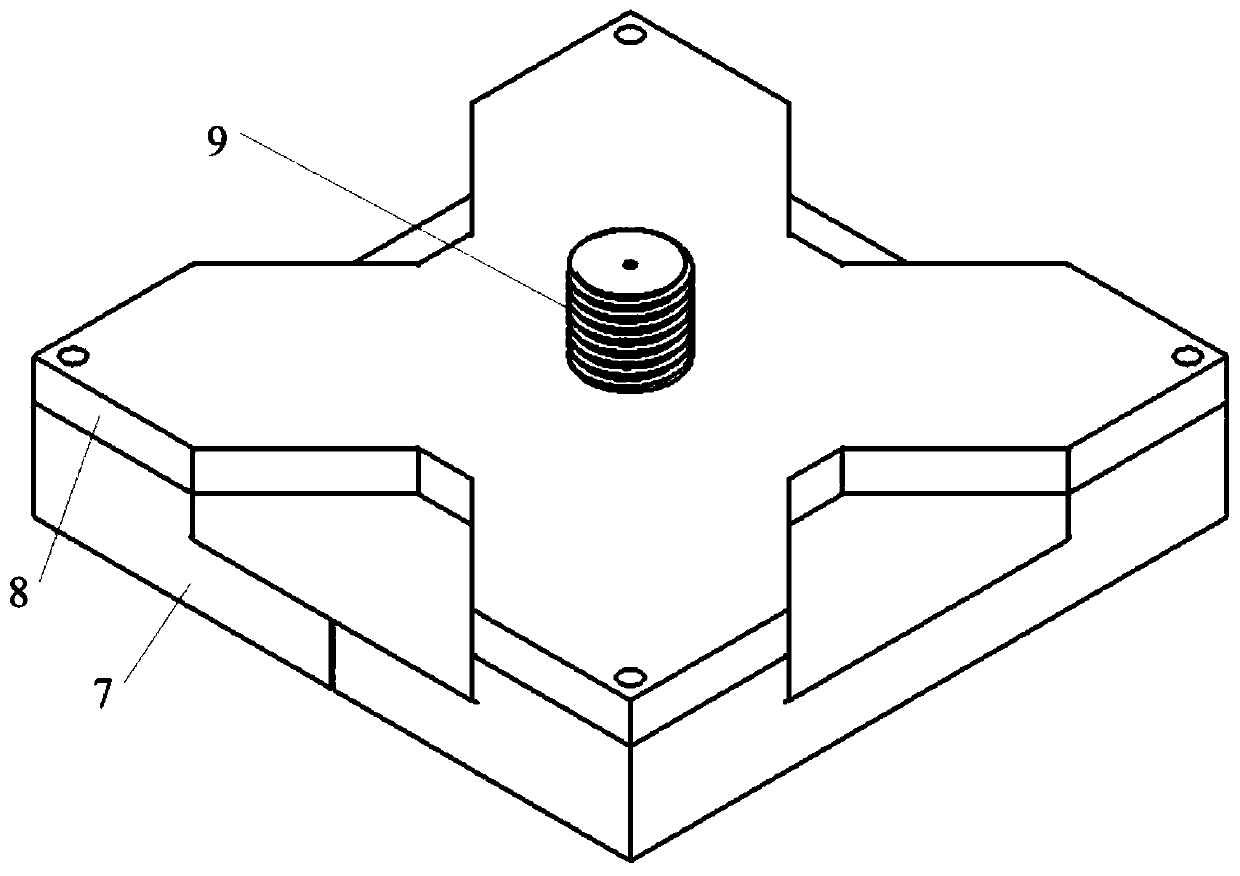

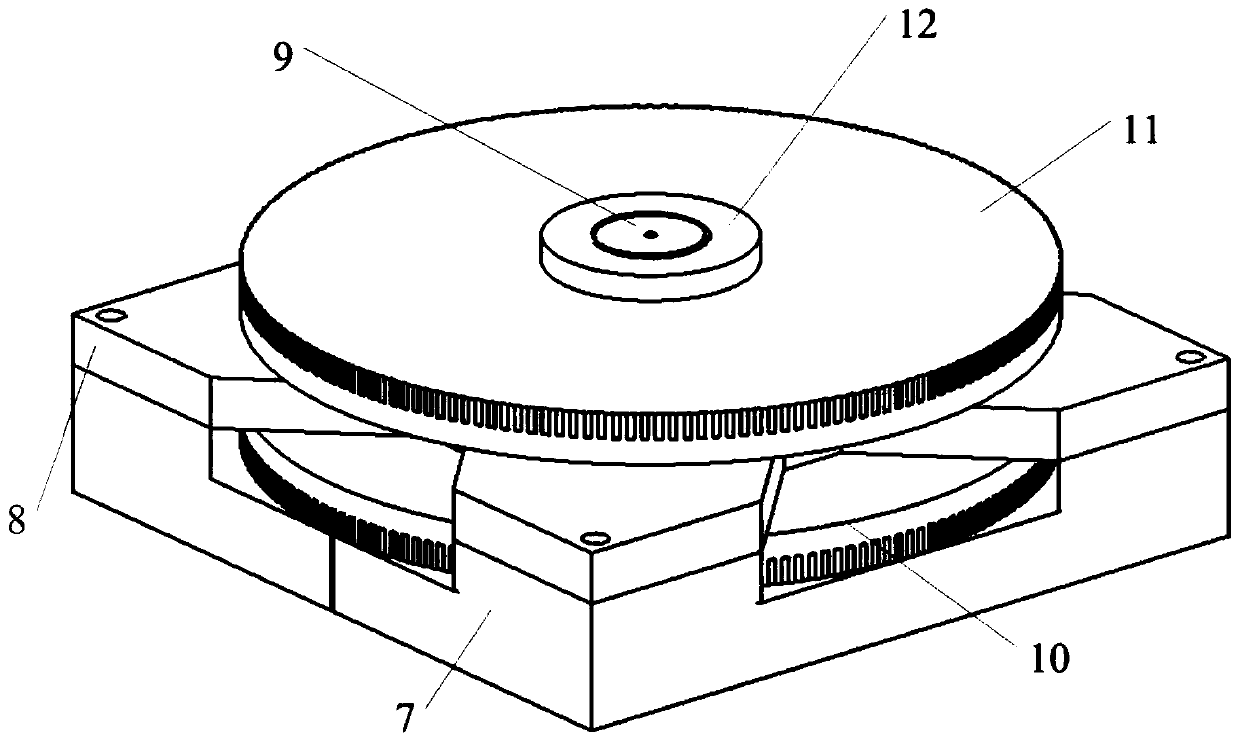

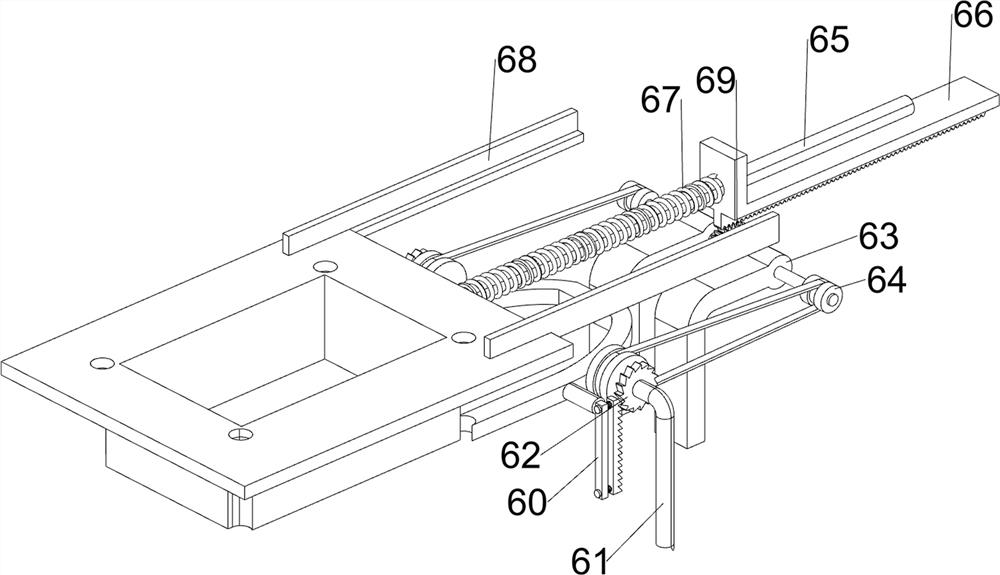

CQFP (Ceramic Quad Flat Package) lead four-side forming and cutting device

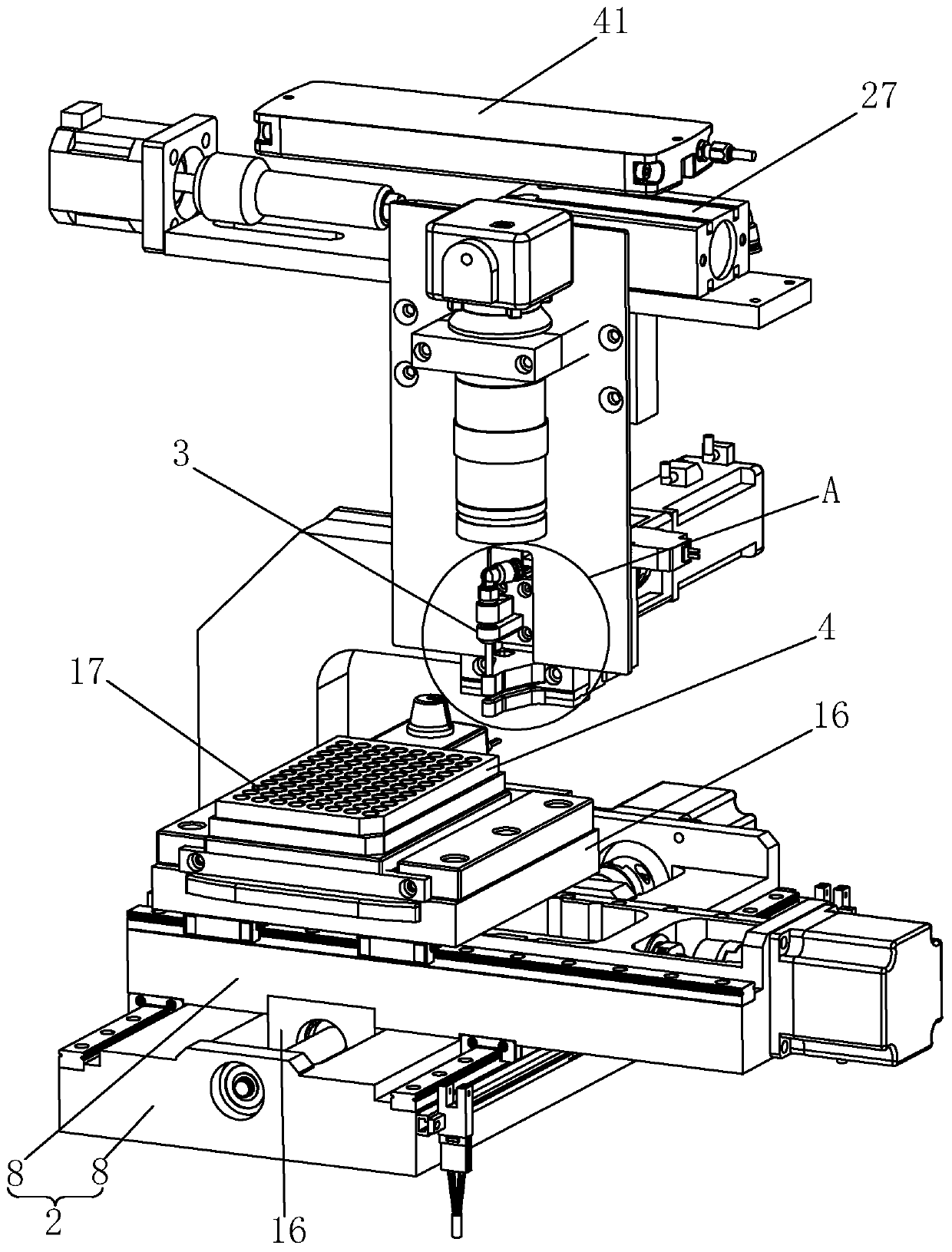

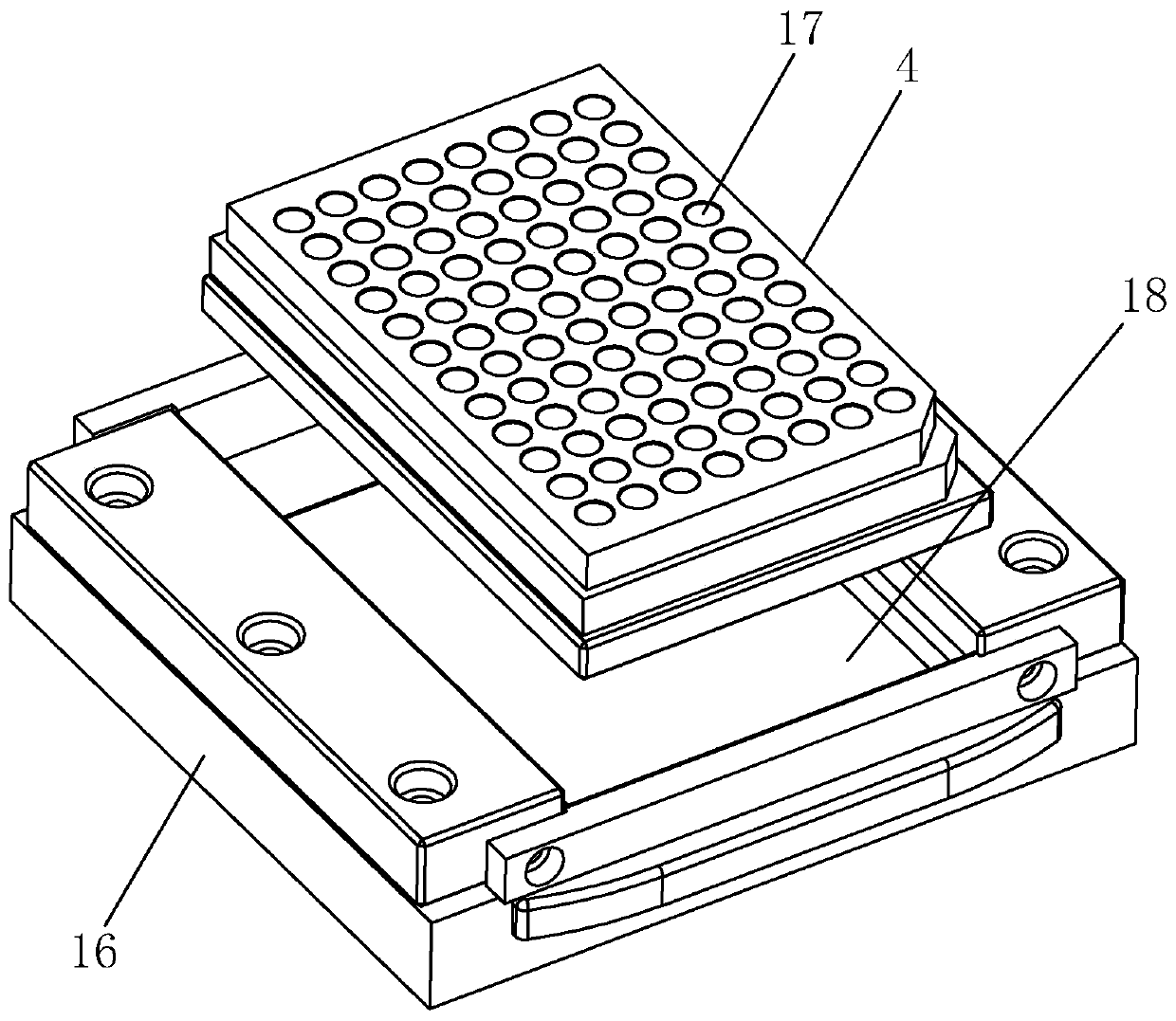

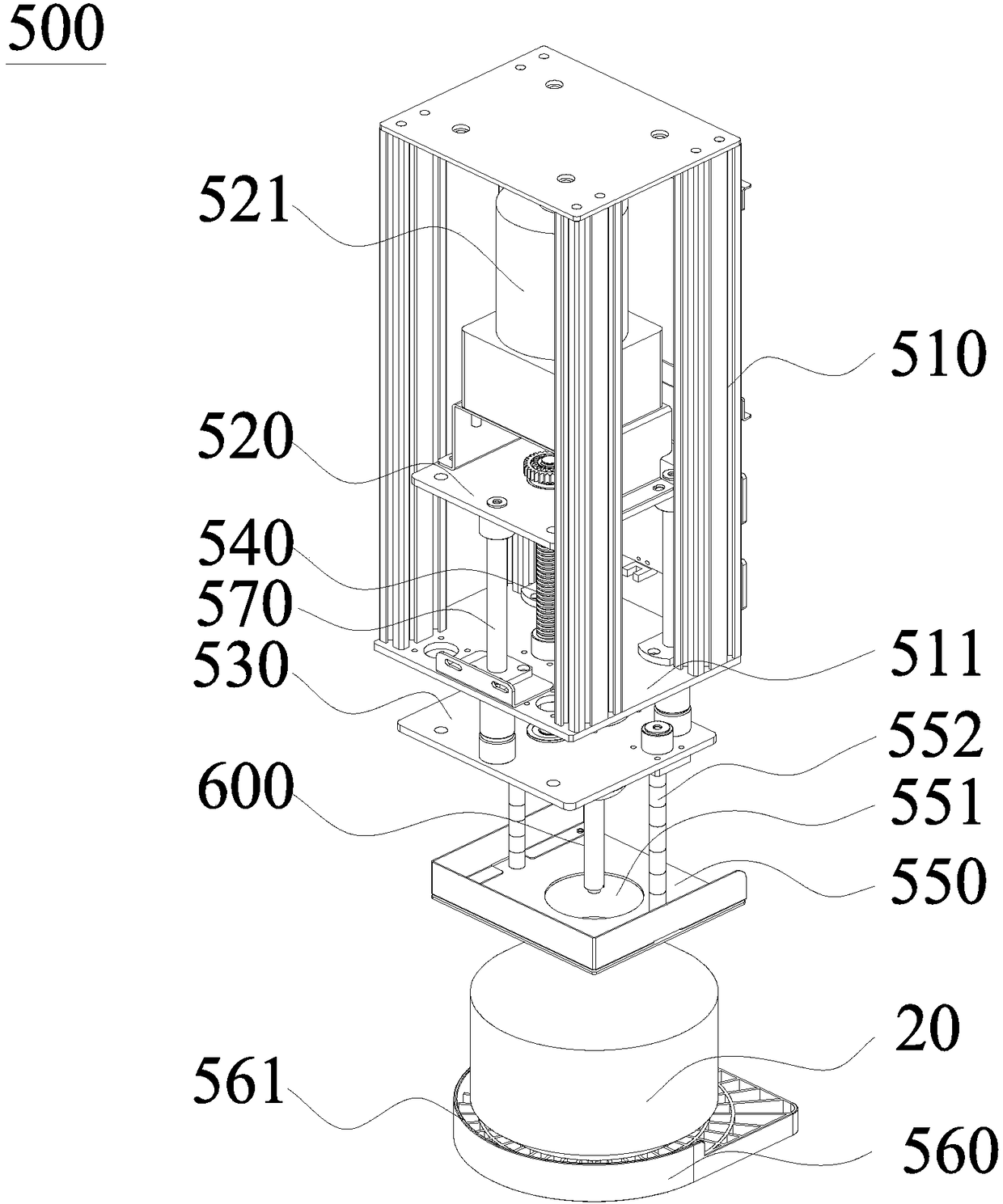

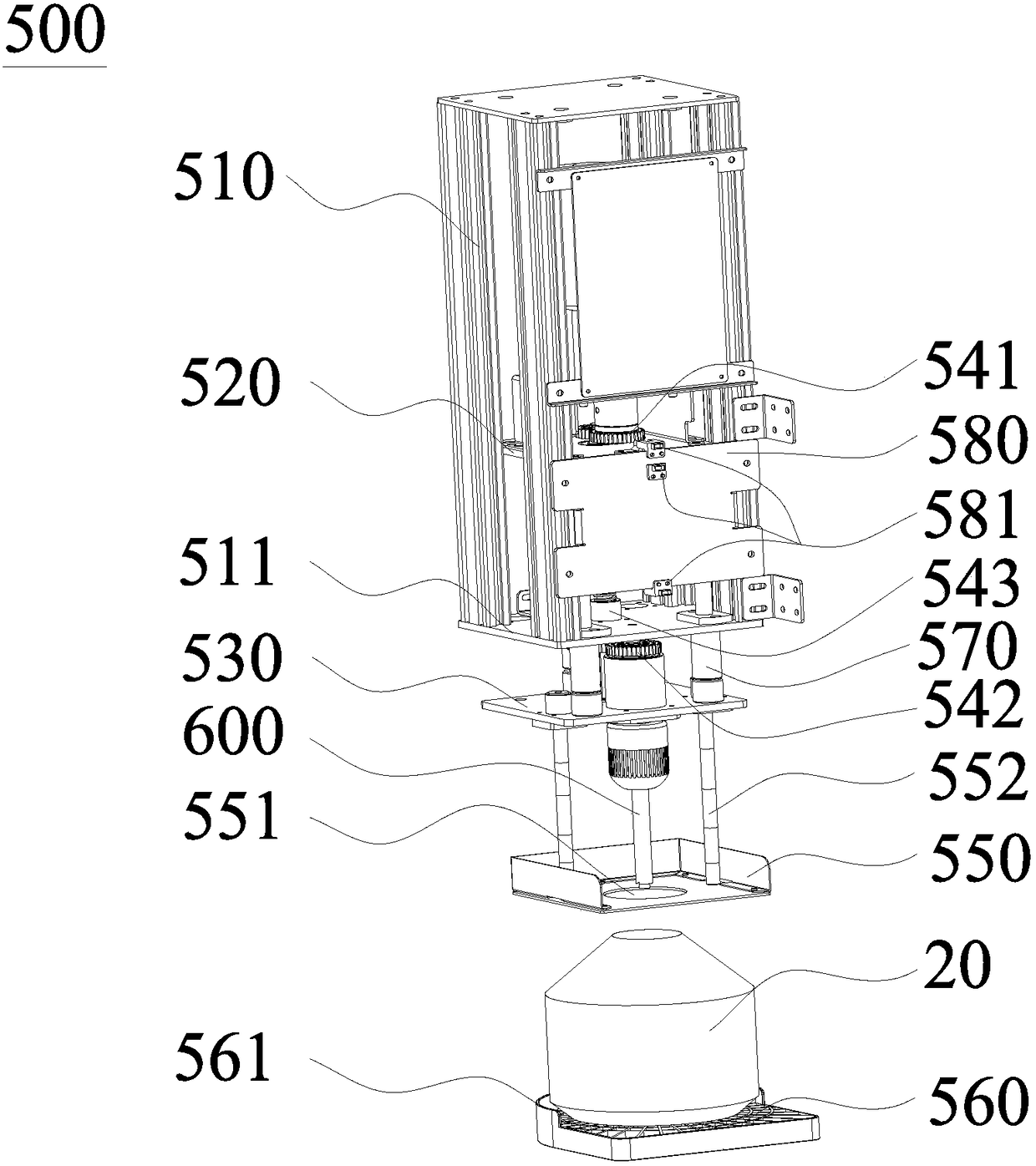

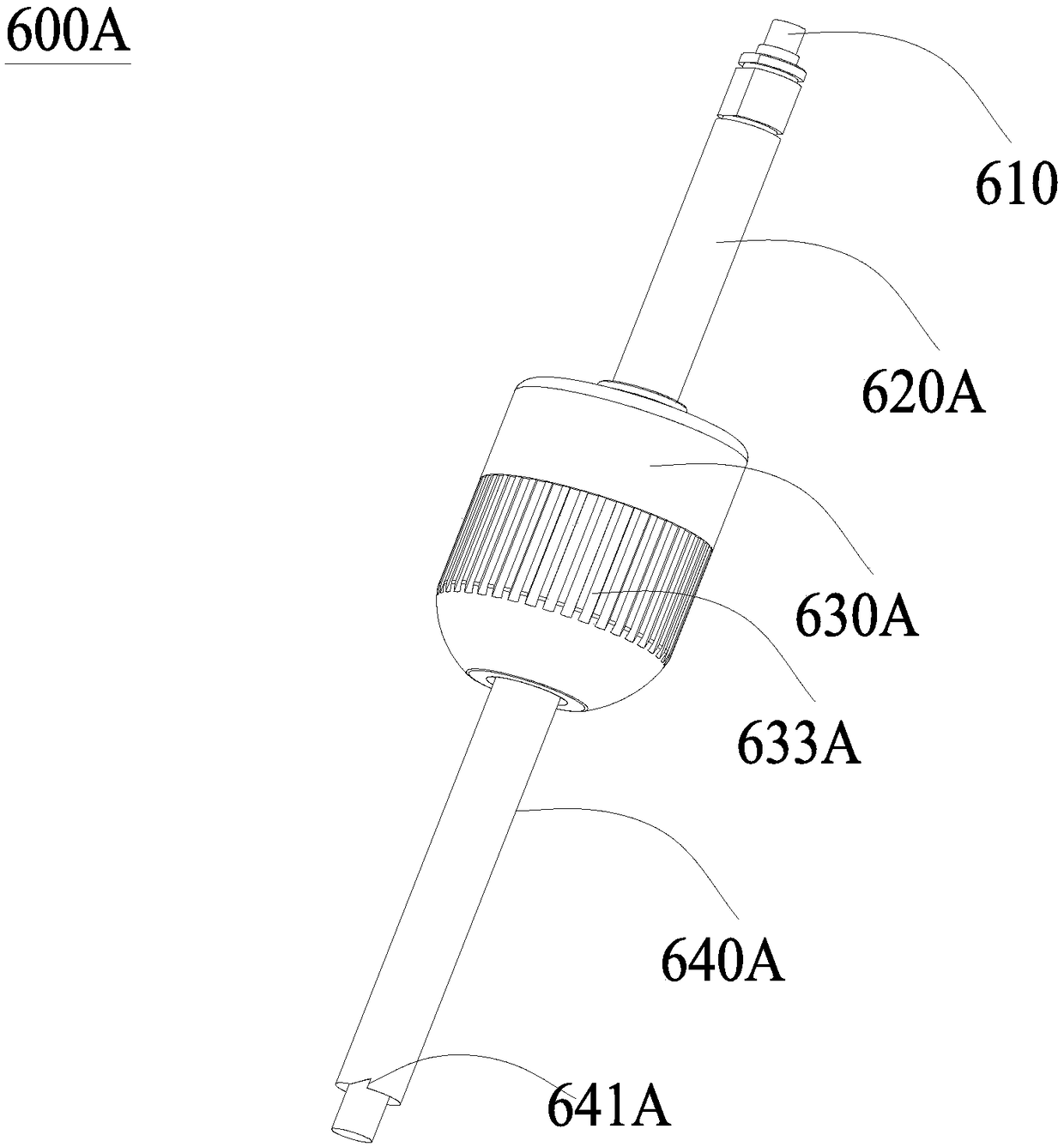

ActiveCN111496097ARealize punching operationEasy to take outShaping toolsSemiconductor/solid-state device manufacturingPunchingStructural engineering

The invention discloses a CQFP (Ceramic Quad Flat Package) lead four-side forming and cutting device, which comprises a base, a punching lower die device, a punching upper die device, a two-dimensional size regulation device, a station height regulation device and a control device, wherein the punching lower die device is used for punching the lower surface of a CQFP device lead; the punching upper die device is used for punching the upper surface of the CQFP device lead; the two-dimensional size regulation device is used for simultaneously regulating the two-dimensional sizes of the punchinglower die device and the punching upper die device; the punching upper die device is provided with a cutting foot mould used for shearing the unnecessary lead of the CQFP device; the two-dimensional size regulation device, the station height regulation device and the punching upper die device are all connected with the control device; and the control device is used for controlling the two-dimensional size regulation device and the station height regulation device to move, and is used for controlling the punching upper die device to vertically move to finish a lead punching formation operationand a cutting operation of the unnecessary lead. According to the device, the one-time forming and cutting of the four-side lead of the straight-lead CQFP can be realized, and formation efficiency andlead coplanarity are effectively guaranteed.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

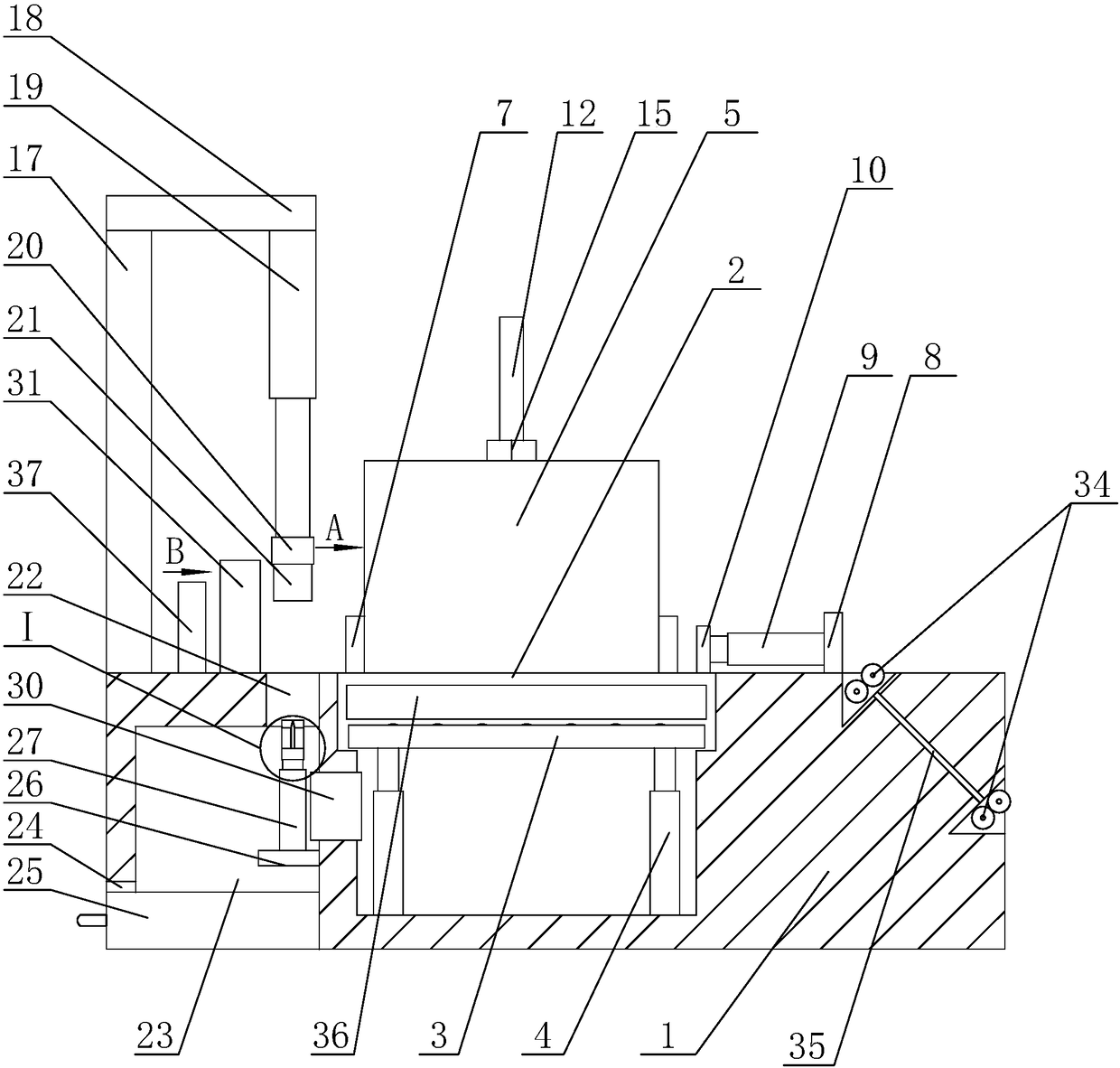

Blanking machining machine and method for aluminum alloy cable bridge manufacturing

PendingCN113083990AImprove punch qualityGuaranteed vertical flatnessPerforating toolsMetal-working feeding devicesPunchingStructural engineering

The invention provides a blanking machining machine and method for aluminum alloy cable bridge manufacturing. The machine comprises side punching mechanisms, a platform mechanism, a side force mechanism and a bottom plate, the platform mechanism is installed on the bottom plate, the side punching mechanisms are evenly arranged on the end surface of the platform mechanism in a sliding fit mode, each side punching mechanism is connected with the side force mechanism in a sliding fit mode, and the side force mechanism is installed on the bottom plate. The problems that in the prior art, installation holes connected with an aluminum alloy cable bridge are drilled by holding a drilling tool by a worker, the process is tedious, the efficiency is low, the aluminum alloy cable bridge cannot be rapidly assembled and connected, and the installation holes of the aluminum alloy cable bridge are not suitable for being drilled on a large scale are solved.

Owner:伍梦文

Precise positioning and punching equipment for fishing net silk frame

ActiveCN113070388ARealize punching operationAvoid getting stuckMetal-working feeding devicesPositioning devicesPunchingFishery

The invention relates to punching equipment, in particular to precise positioning and punching equipment for a fishing net silk frame. According to the precise positioning and punching equipment for the fishing net silk frame, precise positioning can be achieved, uniformity and attractiveness of punching are guaranteed, and the factory rate is increased. According to the technical scheme, the precise positioning and punching equipment for the fishing net wire frame comprises a supporting mechanism and a punching mechanism, wherein the top side of a base is connected with the supporting mechanism; and one side of the supporting mechanism is connected with the punching mechanism. Through cooperation of supporting legs and a placing table, the purposes of supporting a raw material plate and facilitating follow-up operation are achieved.

Owner:刘俊

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com