High-end aluminum processing technical equipment

A technical equipment, aluminum processing technology, applied in metal processing equipment, drilling/drilling equipment, metal processing machinery parts, etc., can solve problems such as single setting mode, inability to realize multiple sets of drilling operations, and reducing processing efficiency, etc. Achieve high degree of automation, improve punching efficiency and punching effect, and improve the effect of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

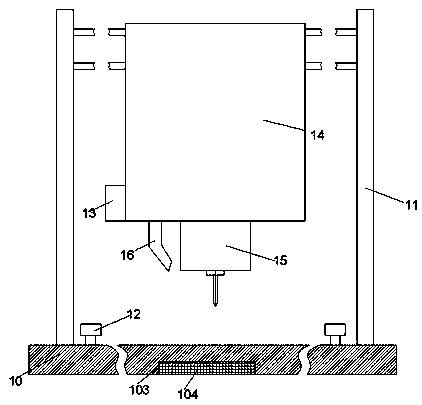

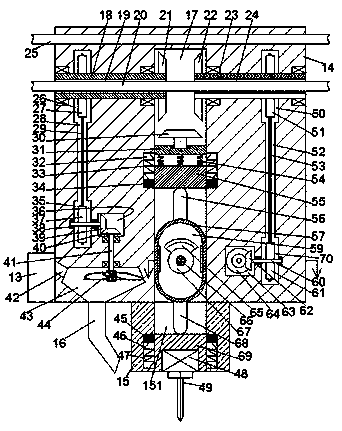

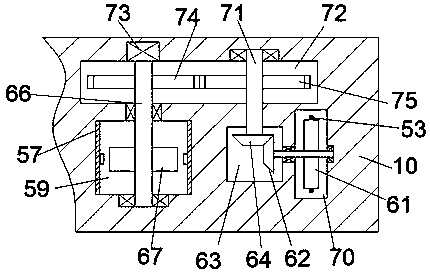

[0021] Such as Figure 1-3As shown, a high-end aluminum processing technical equipment of the present invention includes a base body 10, pillars 11 symmetrically arranged on the top end surface of the base body 10, and a sliding frame arranged between the left and right pillars 11 14. The bottom of the sliding frame 14 is fixed with a placement block 15, and the placement block 15 is provided with a sliding groove 151 with a notch downward, and a first sliding block is slidingly installed in the sliding groove 151 69, the first motor 48 is arranged in the bottom end surface of the first sliding block 69, and the bottom of the first motor 48 is connected with the drilling head 49, and the sliding frame 14 is provided with the sliding slot 151 communicates with and extends upwards the sliding cavity 17, the sliding seat 57 located above the first sliding block 69 is installed in the sliding cavity 17, and the sliding seat 57 is provided with front and rear penetrating The first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com