Novel forging equipment

A new type of equipment and technology, applied in metal processing equipment, forging presses, forging presses, etc., can solve the problems of low work efficiency, high labor intensity, single setting mode, etc., and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

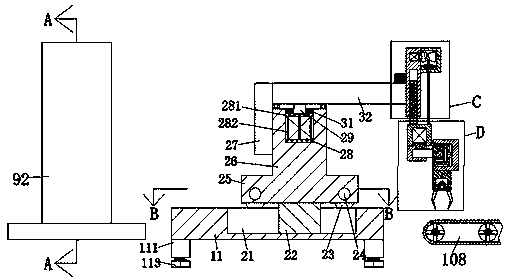

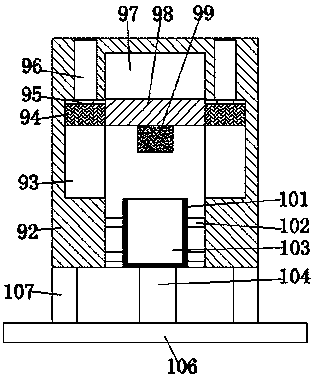

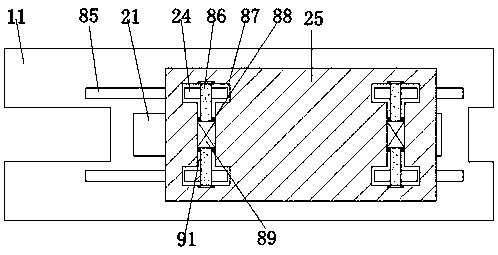

[0020] like Figure 1-Figure 8 As shown, a new type of forging equipment of the present invention includes a machine base 11, a conveying device arranged on the said machine base 11, and a stamping device arranged on the left side of the said machine base 11, and said machine base 11 has four The corner bottom is provided with a corner post 111 at the same time, and the inner bottom of the corner post 111 is provided with a threaded hole 112, and a threaded adjustment corner 113 is installed in the threaded hole 112, and the transmission device includes a sliding joint connected to the base 11 The first sliding block 25 on the upper end surface, a sliding connection device is provided between the first sliding block 25 and the base 11, and the middle position of the upper end surface of the first sliding block 25 is fixedly provided with The first fixed platform 26, the upper end surface of the first fixed platform 26 is fixed with the first electric rotating machine 28, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com