Production process for oil seal

A production process and oil seal technology, which is applied in the direction of manufacturing tools, metal processing, grinding workpiece supports, etc., can solve the problems of reducing the processing efficiency of rubber rings, the inability to achieve grinding, and the deformation of rubber rings, so as to improve the grinding effect and reduce scratches. Injury, increase the effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Further detailed explanation through specific implementation mode below:

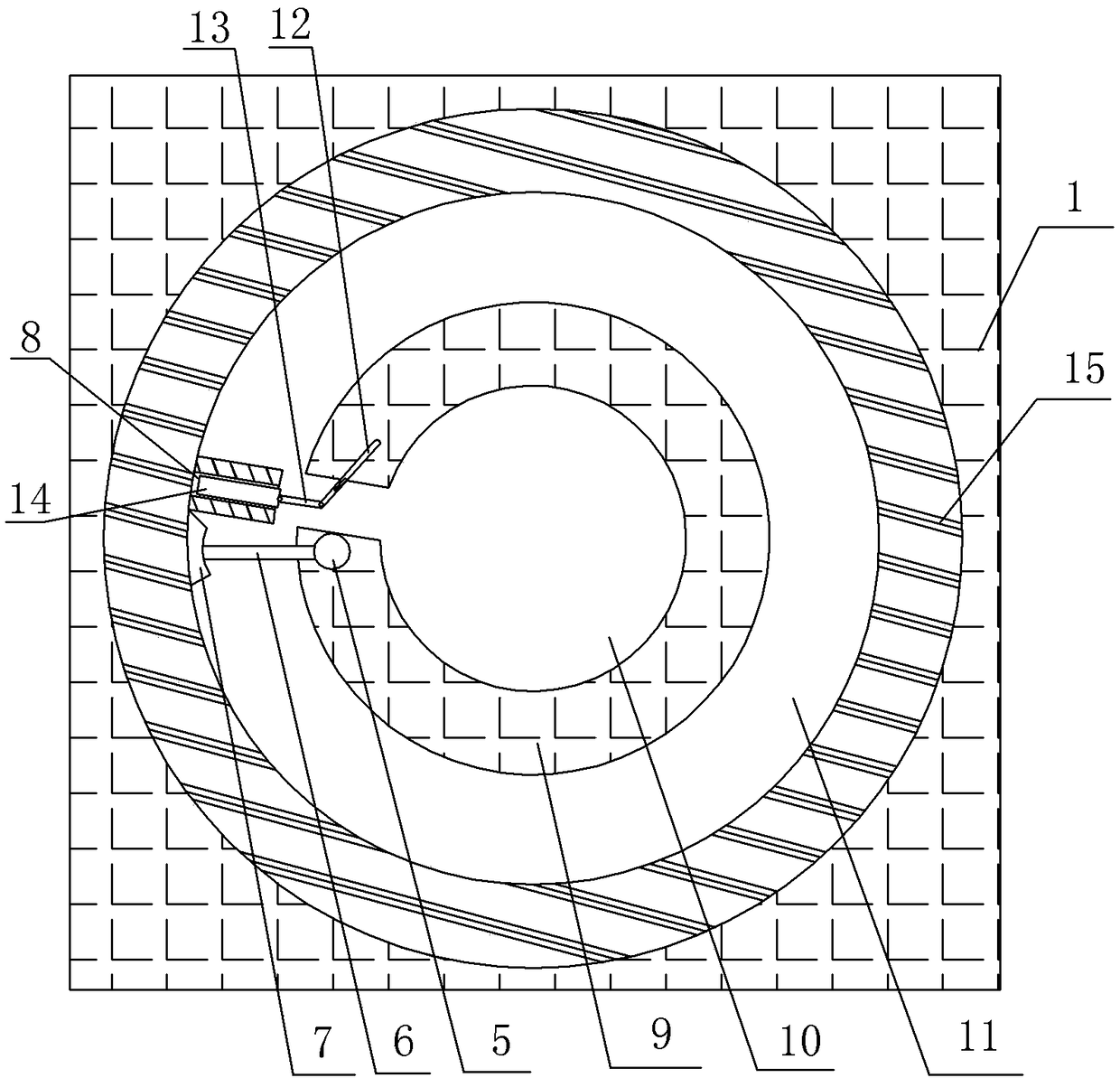

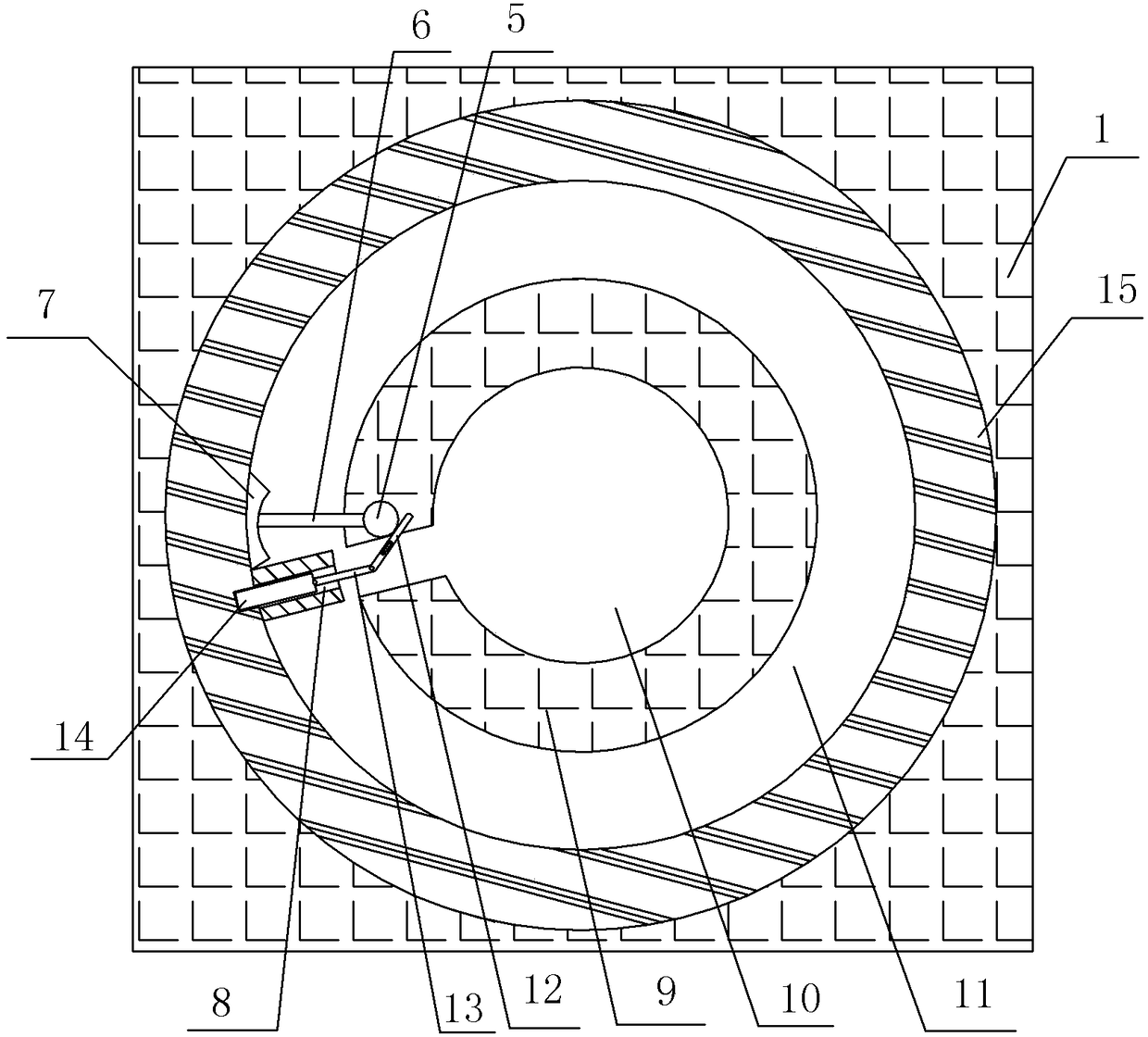

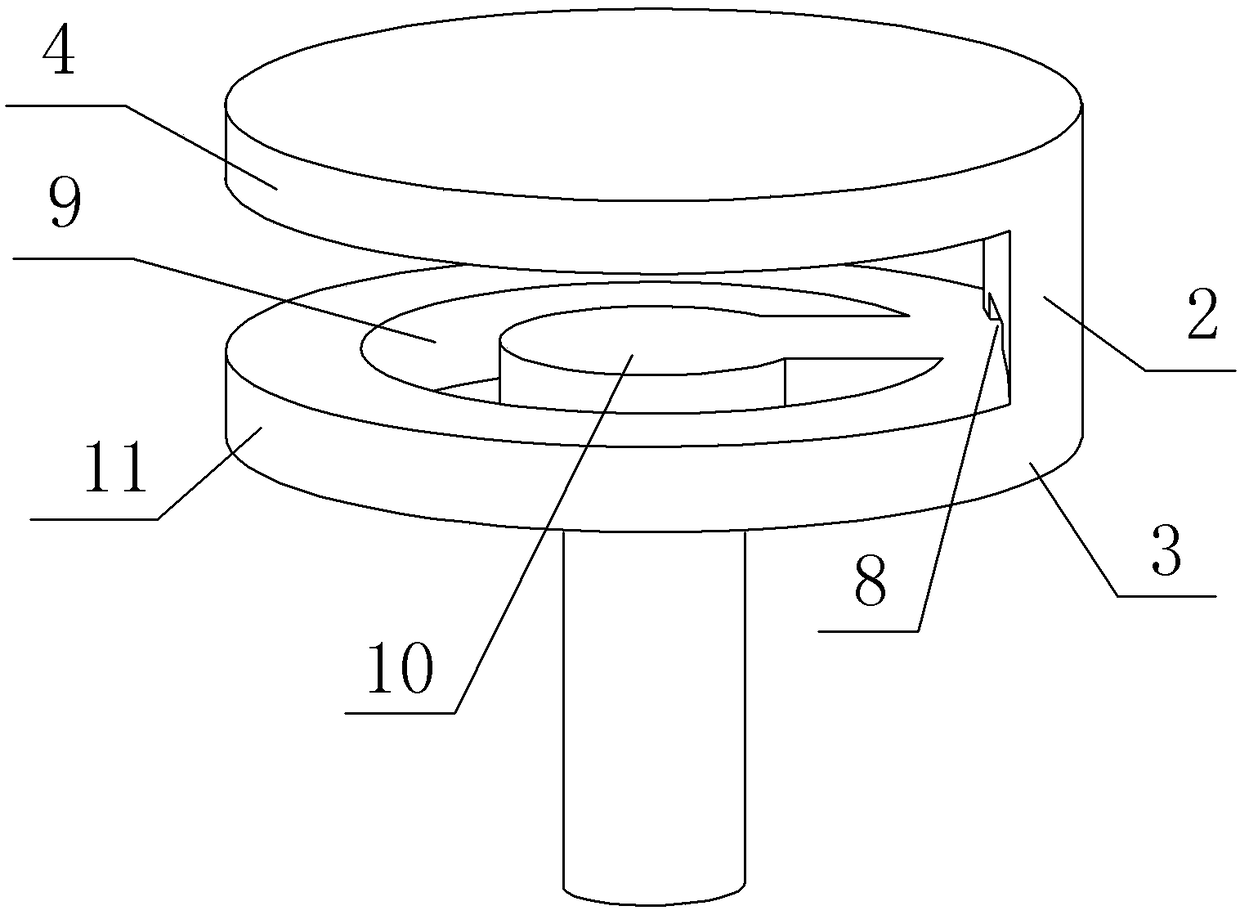

[0020] The reference signs in the drawings of the description include: grinding disc 1, connecting block 2, first expansion body 3, second expansion body 4, support rod 5, grinding rod 6, grinding body 7, channel 8, annular channel 9 , Support block 10, expansion block 11, rotating rod 12, adjusting rod 13, punching head 14, rubber ring 15.

[0021] The production process of the oil seal specifically includes the following steps:

[0022] Step 1: Prepare a polishing agent, which includes 2 parts of polymerization inhibitor, 6 parts of dispersant, 16 parts of abrasive, 5 parts of hexagonal boron nitride with a particle size of 3-5 μm, and the balance is deionized water, wherein the abrasive Including 8 parts each of boron carbide and silicon carbide, which are uniformly mixed and set aside;

[0023] Step 2: Prepare as figure 1 , 2 The oil seal grinding equipment shown in . . Grinding disc 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com