Precise positioning and punching equipment for fishing net silk frame

A precise positioning and punching technology, used in positioning devices, metal processing equipment, feeding devices, etc., can solve problems such as insufficient uniformity and aesthetics, and inability to accurately position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

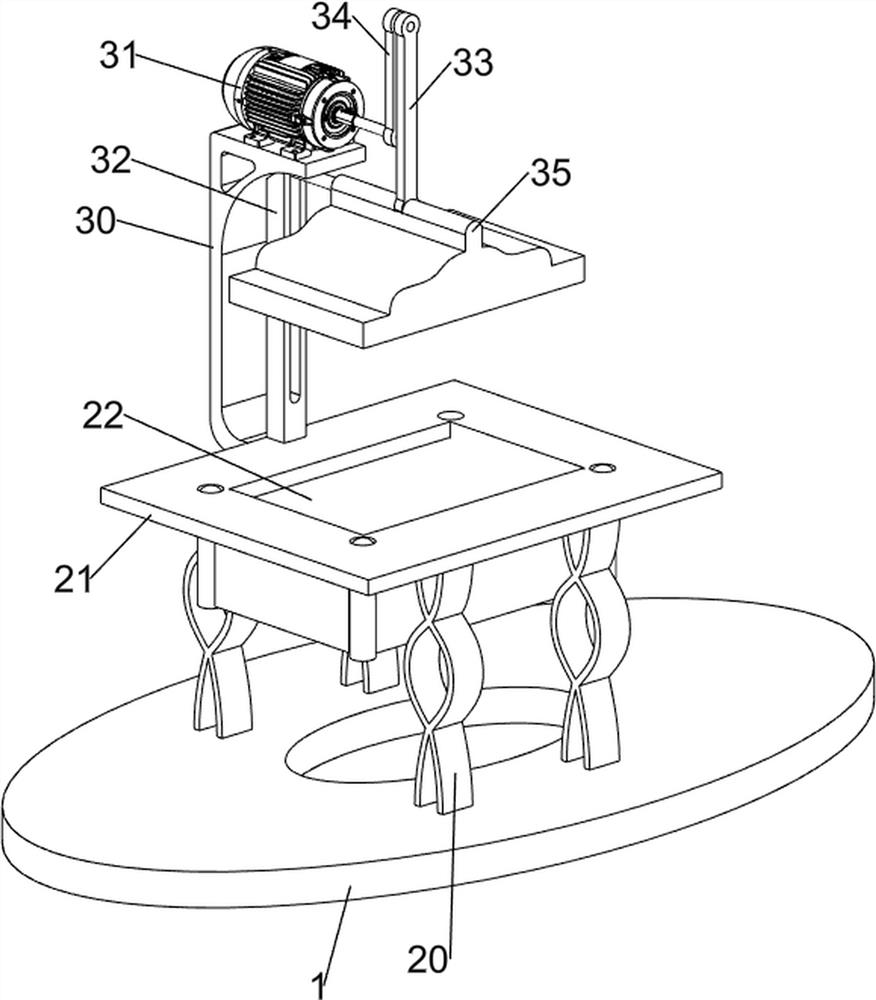

[0067] A punching equipment used for precise positioning of fishnet wire frames, such as figure 1 As shown, it includes a base 1 , a supporting mechanism 2 and a punching mechanism 3 , the upper side of the base 1 is connected with the supporting mechanism 2 , and the rear side of the supporting mechanism 2 is connected with the punching mechanism 3 .

[0068] When the device needs to be used, the user can place the raw material plate on the upper side of the support mechanism 2 to achieve the purpose of supporting the raw material plate and facilitating subsequent operations, start the punching mechanism 3, and the punching mechanism 3 rotates forward, and then makes The punching mechanism 3 moves downwards, and the punching mechanism 3 then moves upwards to achieve the purpose of stamping the raw material plate. After the operation is completed, the user can close the punching mechanism 3, remove the punched raw material plate, and use it again. , repeat the operation.

Embodiment 2

[0070] On the basis of Example 1, such as figure 2 As shown, the support mechanism 2 includes a support leg 20 and a placement platform 21, two support legs 20 are connected to the front and rear sides of the top of the base 1, and a placement platform 21 is connected between the tops of the support legs 20, and a recess is provided on the placement platform 21. Slot 22.

[0071] When the device needs to be used, the user can place the raw material board on the upper side of the placing table 21 to achieve the purpose of supporting the raw material board and facilitating the follow-up operation, and continue the follow-up operation. When using it again, repeat the operation.

[0072] Such as figure 2As shown, the punching mechanism 3 includes a support plate 30, a servo motor 31, a first slide rail 32, a first crank 33, a second crank 34 and a punching block 35, and the rear side of the placing table 21 is connected with a support plate 30 to support A servomotor 31 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com