Electromagnetic punching machine with punched hole detection device

A detection device and electromagnetic technology, applied in punching machines, manufacturing tools, metal processing, etc., can solve the problems of easy breakage of punches, failure of punching holes, complicated structure, etc., and achieve the effect of accelerating heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

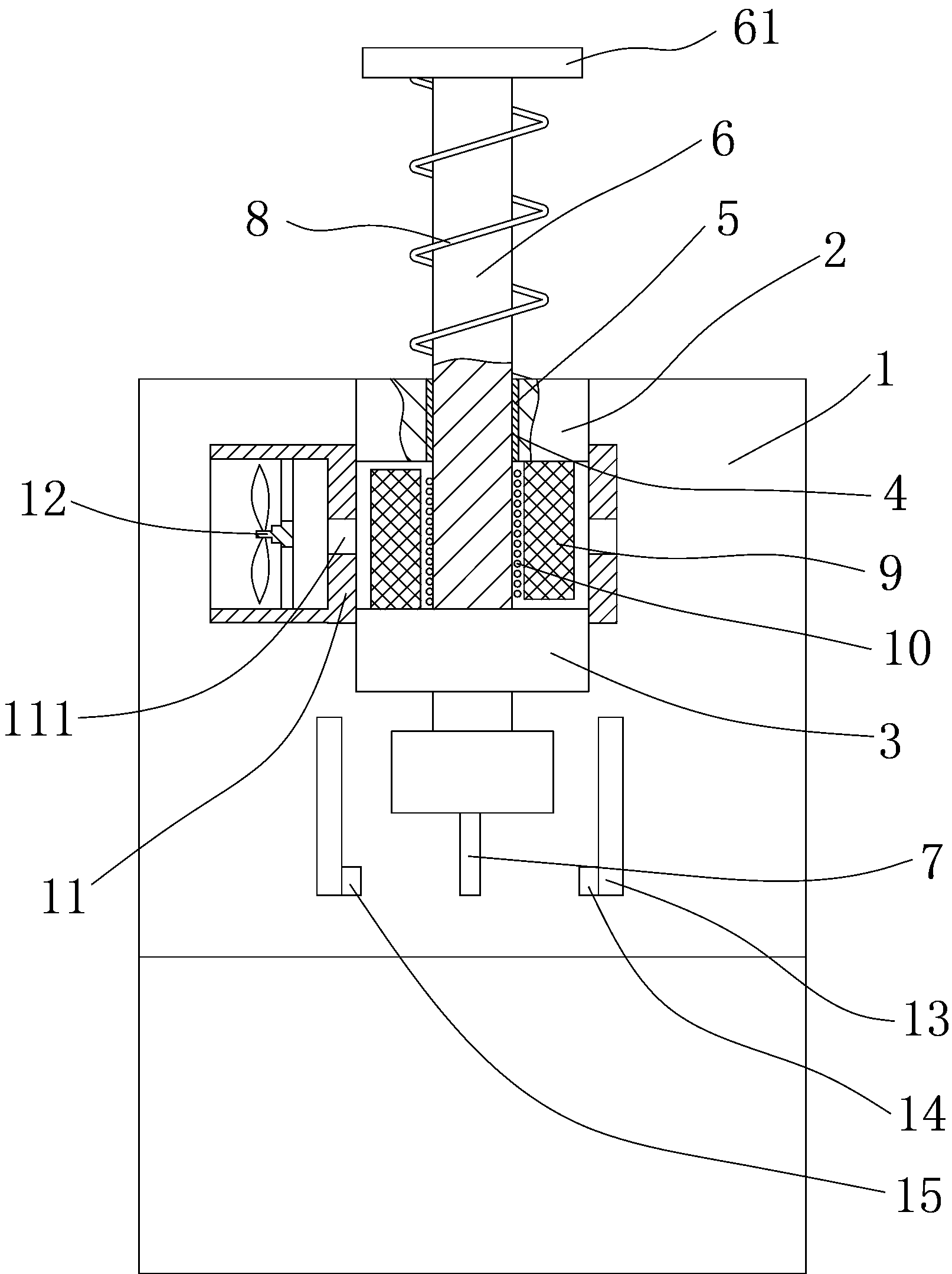

[0009] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see figure 1 , an electromagnetic punching machine with a punching detection device, including a machine tool body 1, an upper fixed block 2 and a lower fixed block 3 are arranged in the body 1, and the upper fixed block 2 and the lower fixed block 3 are both A through hole 4 is provided, and a slide rail 5 is arranged in the through hole 4, and a stamping rod 6 is slid on the slide rail 5, and an upper mold 7 is connected to the bottom of the stamping rod 6, and the upper end of the stamping rod 6 A flange 61 is provided, an elastic member 8 is arranged below the flange 61, the lower part of the elastic member 8 is against the upper fixing block 2, and a plurality of magnets 9 are arranged around the outside of the stamping rod 6, and the stamping rod 6 6. A wire 10 is wound around the middle, and a shell 11 is set on the outside of the magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com