Environment-friendly conveying and internal mixing equipment for high-performance rubber material for vehicle

A rubber material and high-performance technology, which is applied in the field of environmentally friendly conveying and mixing equipment for high-performance rubber materials for vehicles, can solve problems such as more demand and waste of resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

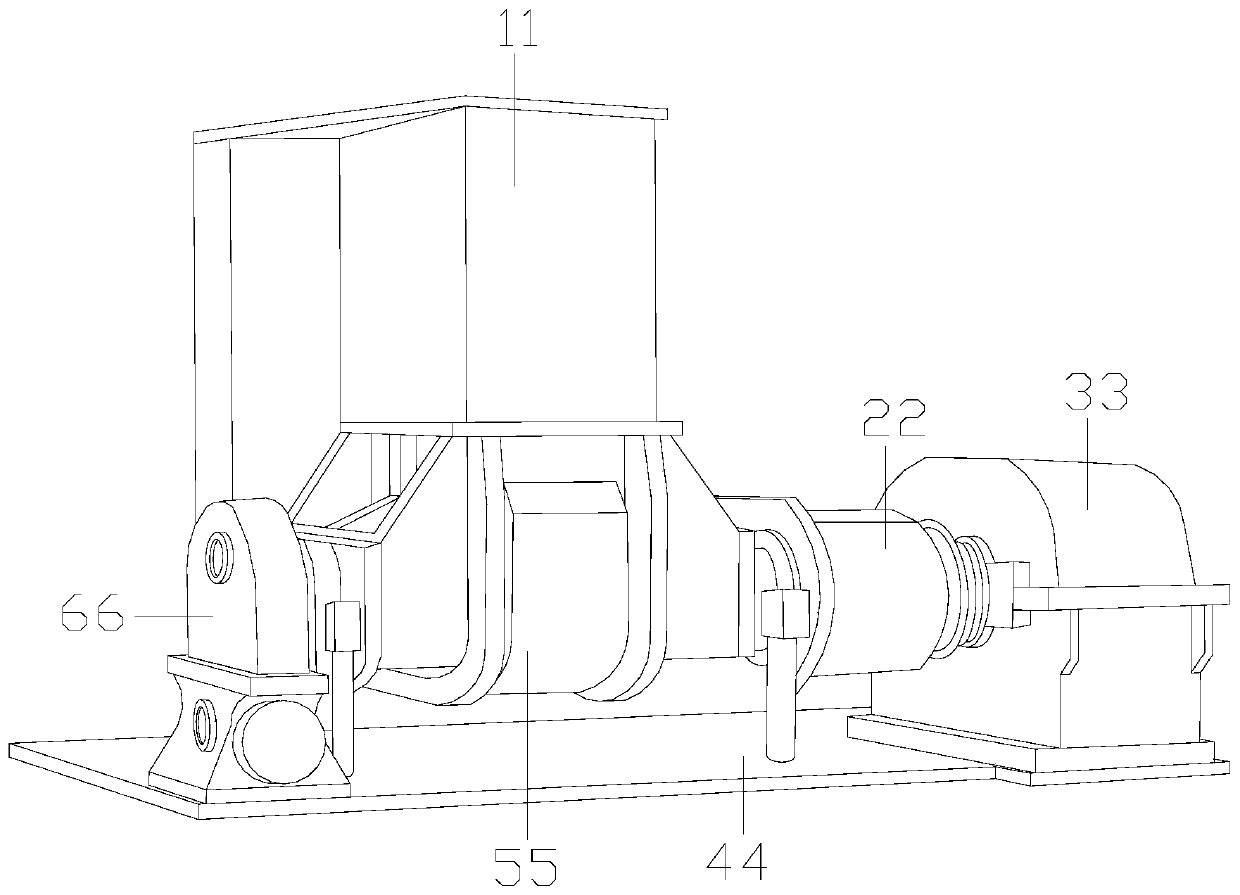

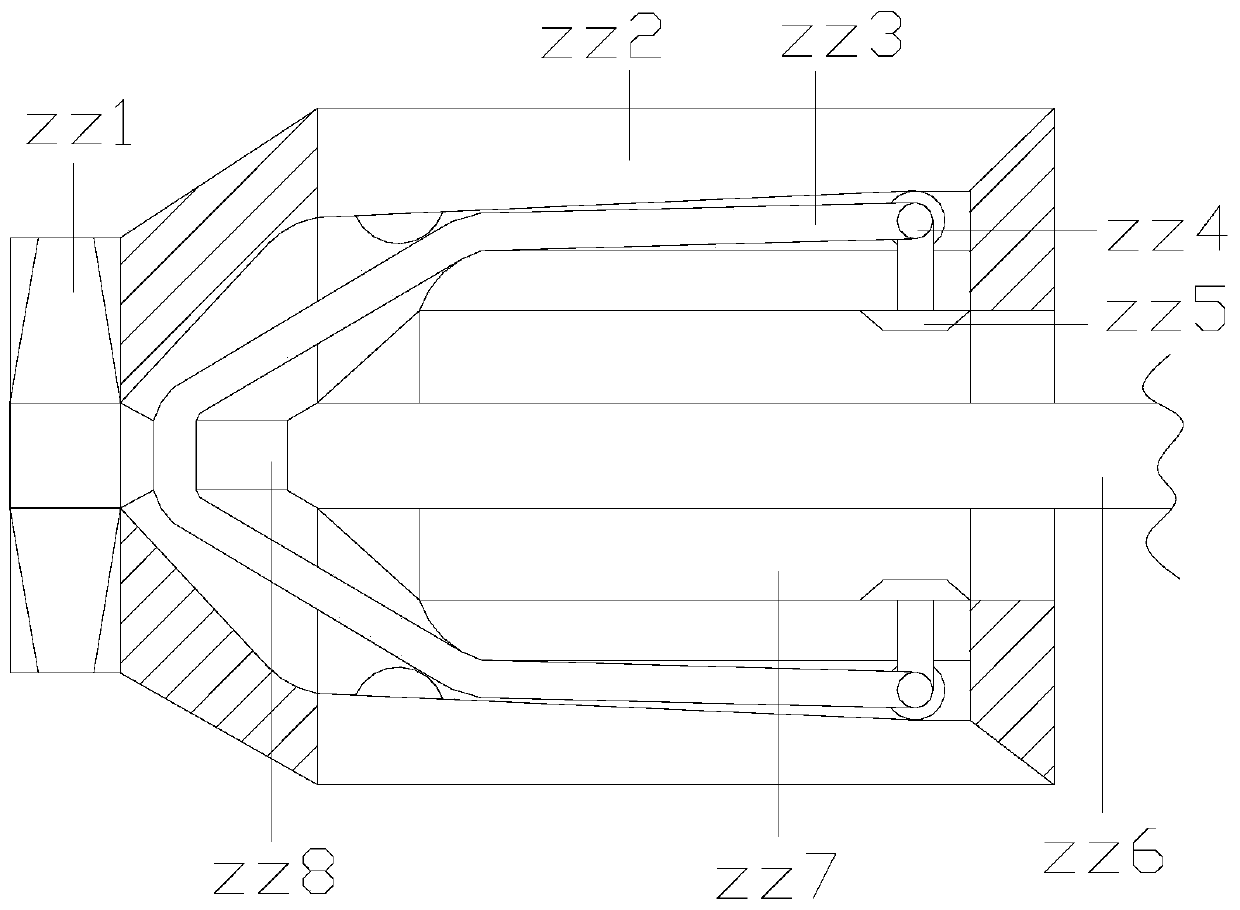

[0028] as attached figure 1 to attach Figure 7 Shown:

[0029] The present invention provides a high-performance rubber material environmental-friendly conveying and internal mixing equipment for vehicles, the structure of which includes an auxiliary mixing box 11, a feeding barrel 22, a control box 33, a bottom fixing plate 44, an internal mixer 55, and a bracket 66.

[0030] The auxiliary mixing box 11 is installed on the upper surface of the internal mixer 55, the feeding cylinder 22 is welded to the outer surface of the control box 33 and communicates with each other, and the end of the feeding cylinder 22 away from the control box 33 is connected to the internal mixer 55 Connection, the bottom end of the control box 33 is welded on the upper surface of the bottom solid plate 44, and the internal mixer 55 is connected with the bracket 66.

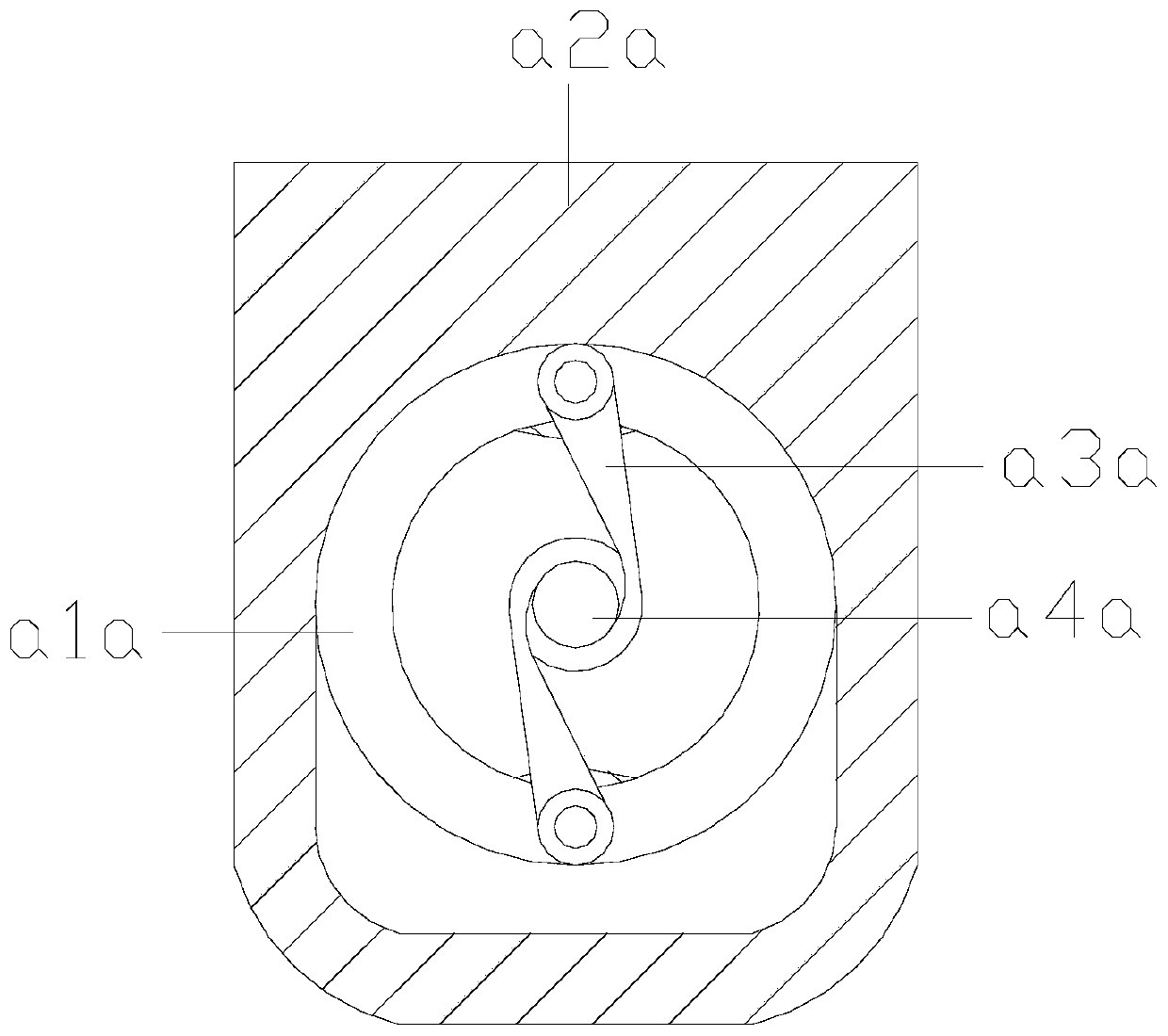

[0031] The internal mixer 55 includes an inner limiting ring a1a, an outer pocket shell a2a, a twisting strip a3a, and a solid core...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com