A system and method for evaluating thermal performance of a vertical steam generator

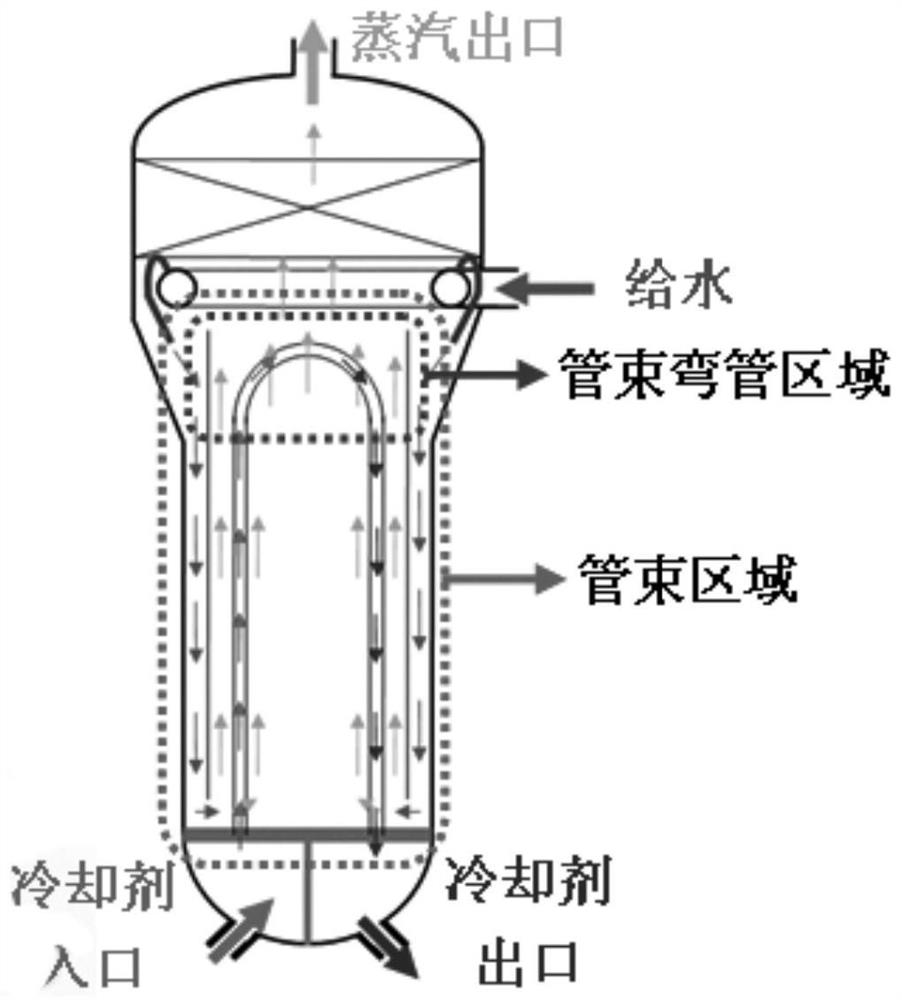

A steam generator and thermal performance technology, applied in the field of nuclear power plants, can solve the problems of large deviation of analysis results, incomplete analysis area, and inability to effectively cover the heat exchange of steam generators, etc., to achieve small structural deviation and complete and accurate analysis area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

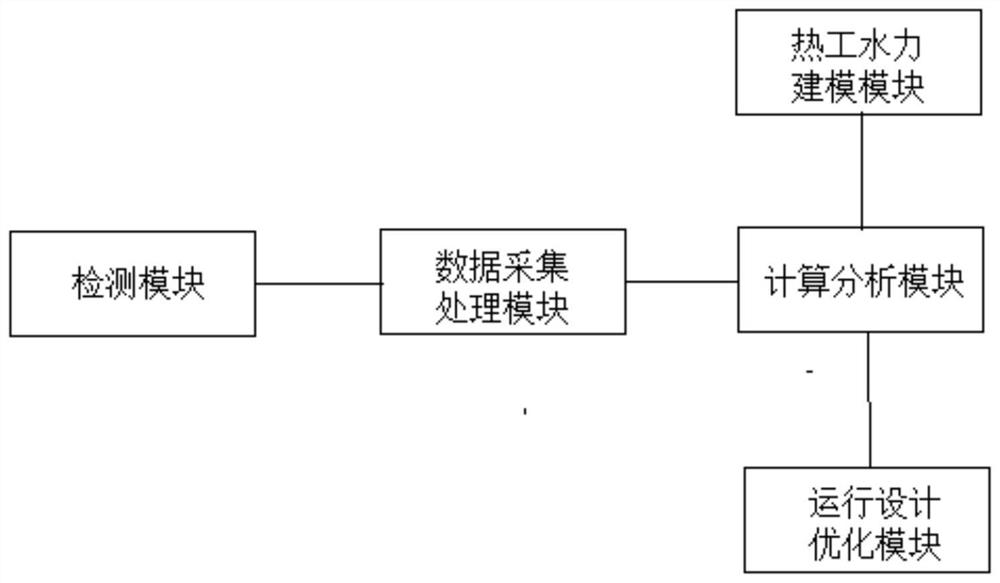

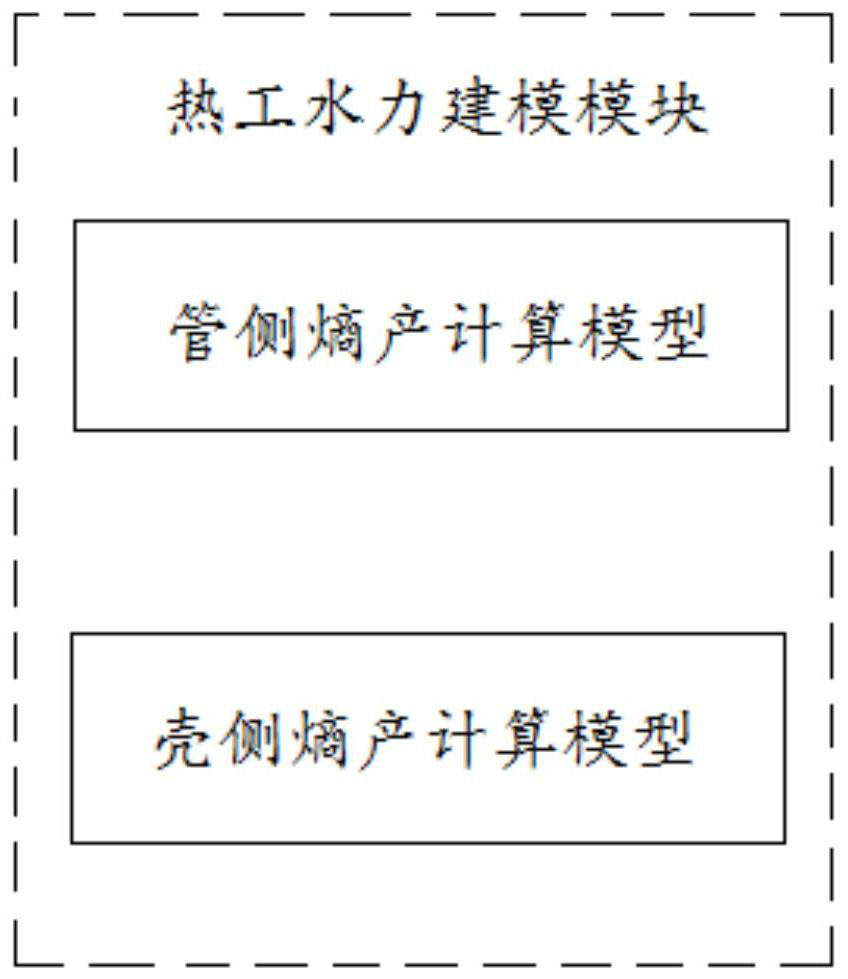

[0030] The embodiment of the present invention provides a system for evaluating the thermal performance of a vertical steam generator, see figure 2 , figure 2 It is a schematic structural diagram of the system module according to the first embodiment of the present invention. The evaluation system includes: a thermal-hydraulic modeling module, which is used to divide a plurality of different regions according to the structure of the steam generator tube side, the shell side and the single or dual phase characteristics of fluid flow In order to establish the corresponding entropy production calculation model; the detection module is set on the pipeline connected to the steam generator, and is used to detect the temperature signal and pressure signal corresponding to the tube side and the shell side during the operation of the steam generator; the data acquisition and processing module , connected to the detection module for data processing of the detected temperature and pres...

Embodiment 2

[0095] The implementation of the present invention provides a method for evaluating the thermal performance of a vertical steam generator, which is applicable to the thermal performance evaluation system for a vertical steam generator shown in Embodiment 1. See Figure 9 , the method includes the following steps:

[0096] S100. Divide a plurality of different regions according to the single or dual-phase characteristics of the steam generator tube side, shell side structure and fluid flow to establish respective corresponding entropy production calculation models;

[0097] S200, detecting the temperature signal and pressure signal corresponding to the tube side and the shell side during the operation of the steam generator;

[0098] S300, performing data processing on the detected temperature and pressure signals;

[0099] S400 , according to the processed temperature and pressure signals, and obtain the corresponding entropy production calculation model, respectively calcula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com