Oblique tunnel portal form manufacturing process

A manufacturing process and oblique cutting technology, which is applied in the direction of wellbore lining, tunnel lining, underground chamber, etc., can solve problems such as error in the design requirements of finished tunnel door formwork, and achieve the effect of small structural deviation and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

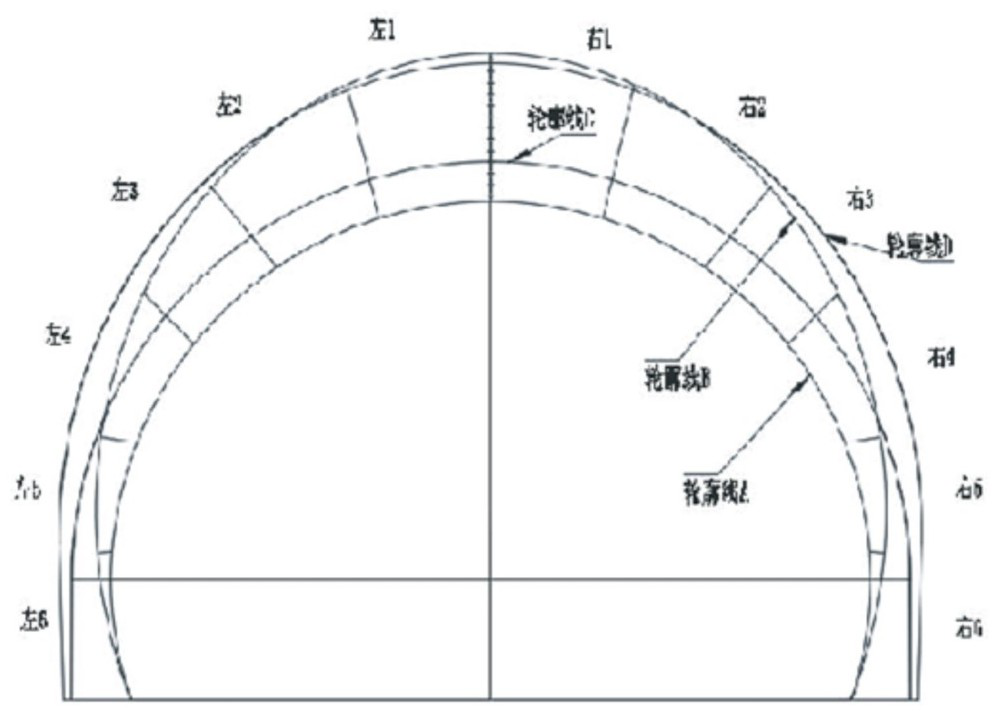

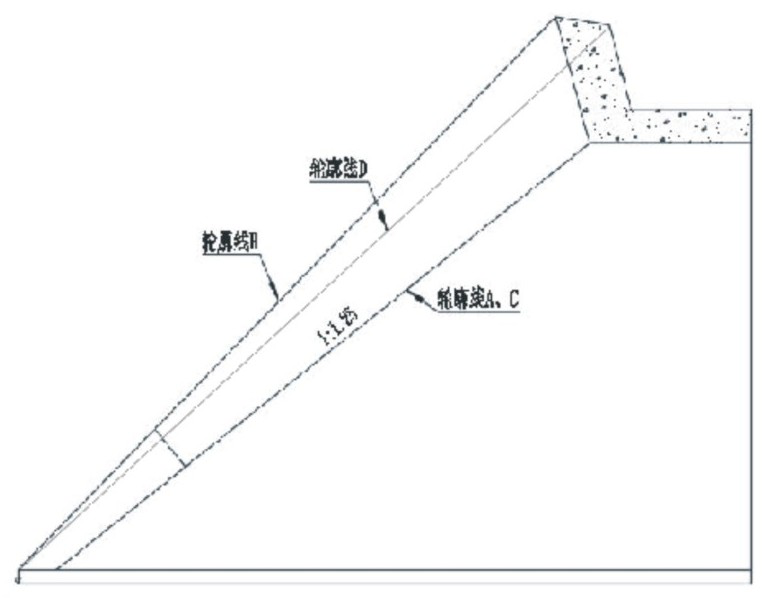

[0017] Embodiment one, combined with the attached Figure 1~4 , a kind of bevel-cut type portal formwork manufacturing process, the portal formwork includes inner formwork, outer formwork and upper cover plate, the manufacturing process of portal formwork specifically comprises the following steps:

[0018] (1) Since the door formwork is left-right symmetrical, the inner mold and the outer mold are composed of several single panels, therefore, the single-sided single-panel CNC blanking, the error is guaranteed to be within ±1mm;

[0019] (2) The single panel changes non-linearly during the CNC blanking and forming process, and the single panel needs to be coiled to control the forming;

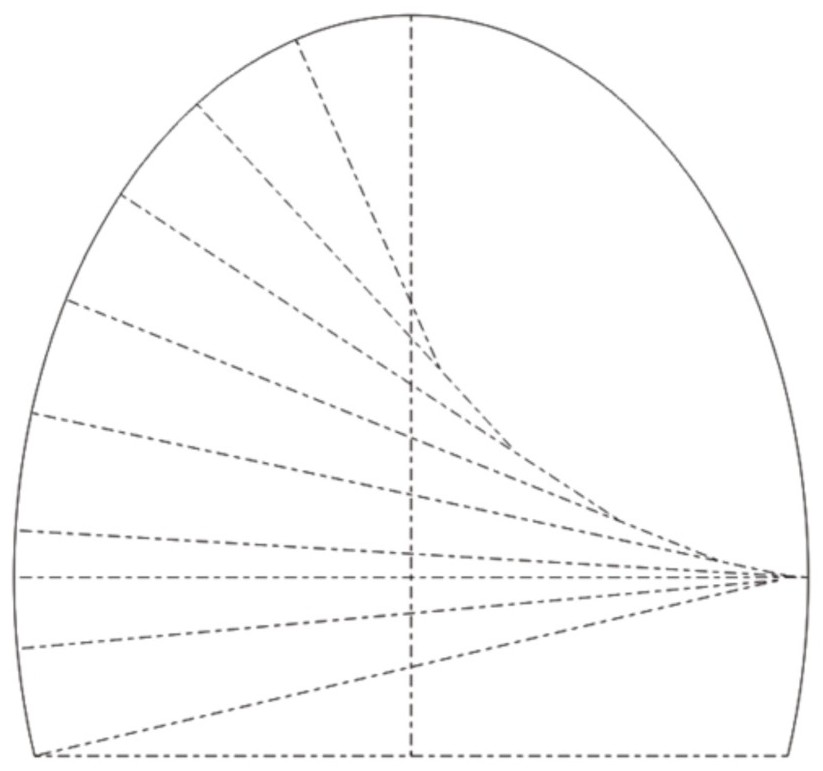

[0020] (3) The contours of the ground projection of the inner formwork and the outer formwork are elliptical. It is necessary to stake out and mark the ground in sections to obtain the upper and lower contour lines of the inner formwork and the outer formwork. There is a certain distance betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com