Wheel anti-skid control method and system based on energy distribution model

A technology of energy distribution and wheels, applied in the direction of control drive, control device, electric energy management, etc., can solve the problems of sensitivity to changes in resistance and body weight, practicability of control methods, and dependence on vehicle parameters, etc., to achieve high adaptability and good anti-skid Control Effects, Effects of Smooth Control Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

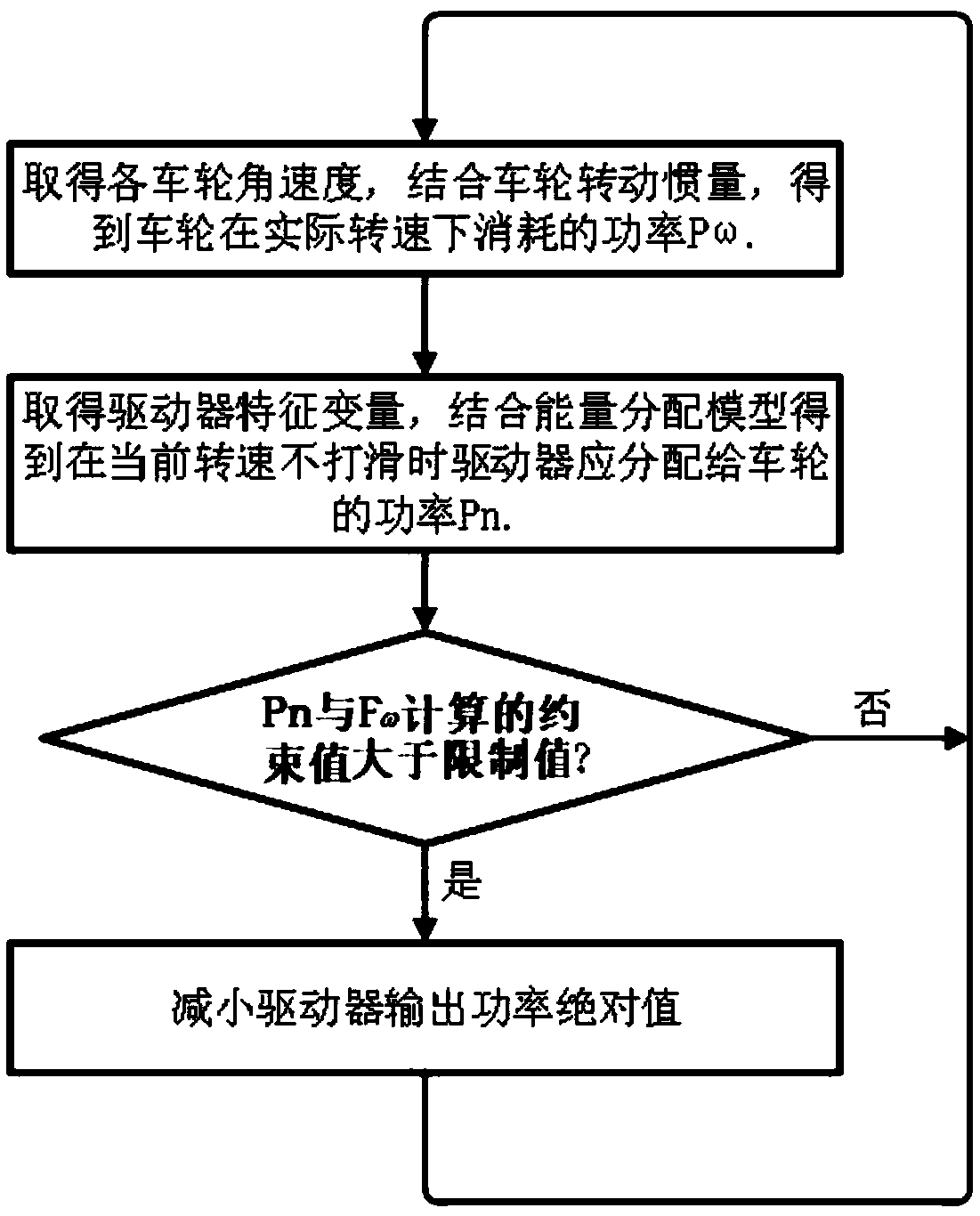

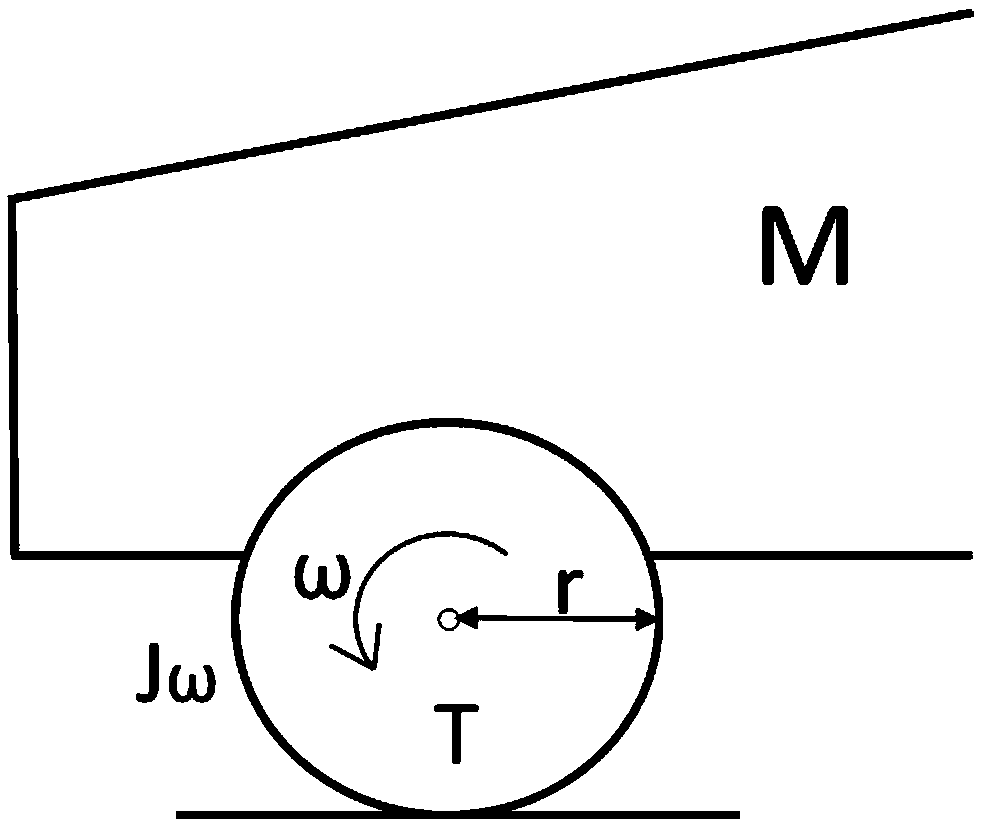

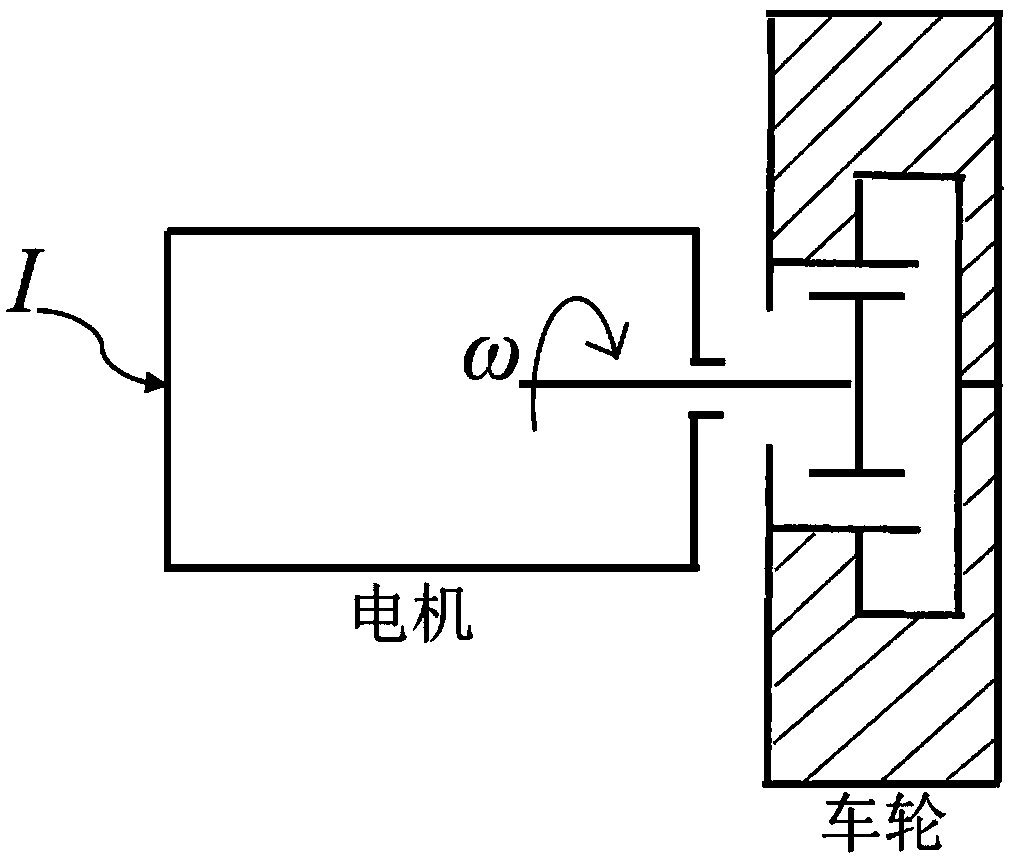

[0015] A wheel anti-slip control method based on the motor energy distribution model, which obtains the angular velocity ω of each wheel of the vehicle, and combines the moment of inertia J of the wheel ω , to get the mechanical power P consumed by the wheel at the actual wheel speed ω ; Obtain the motor current value I, and combine the motor energy distribution model to obtain the power P that the motor should distribute to the wheels when the current speed does not slip n ;By comparing the mechanical power P consumed by the wheels at the actual vehicle speed ω and the power P that should be distributed to the wheels when there is no slip at the actual wheel speed n , to adjust the motor output power size P d , and then control the torque output T of the driving wheel d , to achieve anti-skid wheels.

[0016] Based on this control strategy, use the motor current value that is relatively easy to measure to calculate the power that the motor should provide to the wheel when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com